Abstract

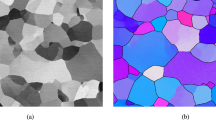

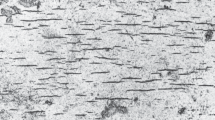

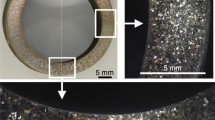

Alloy 617, a high-temperature creep-resistant, nickel-based alloy, is being considered for the primary heat exchanger for the Next Generation Nuclear Plant (NGNP), which will operate at temperatures exceeding 760 °C and a helium pressure of approximately 7 MPa. Observations of the crept microstructure using optical microscopy indicate creep stress does not significantly influence the creep void fraction at a given creep strain over the relatively narrow set of creep conditions studied. Void formation was found to occur only after significant creep in the tertiary regime (>5 pct total creep strain) had occurred. Also, orientation imaging microscopy (OIM) was used to characterize the grain boundaries in the vicinity of creep voids that develop during high-temperature creep tests (900 °C to 1000 °C at creep stresses ranging from 20 to 40 MPa) terminated at creep strains ranging from 5 to 40 pct. Preliminary analysis of the OIM data indicates voids tend to form on grain boundaries parallel, perpendicular, or 45 deg to the tensile axis, while few voids are found at intermediate inclinations to the tensile axis. Random grain boundaries intersect most voids, while coincident site lattice (CSL)–related grain boundaries did not appear to be consistently associated with void development. Similar results were found in oxygen-free, high-conductivity (OFHC) copper, severely deformed using equal channel angular extrusion, and creep tested at 450 °C and 14 MPa.

Similar content being viewed by others

Notes

INCONEL is a trademark of Special Metals Corporation, Huntington, WV.

PHILIPS is a trademark of Philips Electronic Instruments, Mahwah, NJ.

References

Q. Wu, H. Song, R. Swindeman, J. Shingledecker, and V. Vasudevan: Metall. Mater. Trans. A, 2008, vol. 39A, pp. 2569–85.

S. Kihara, A. Ohtomo, and Y. Saiga: Metall. Mater. Trans. A, 1980, vol. 11A, pp. 1019–31.

Q. Wu, H. Song, R.W. Swindeman, J.P. Shingledecker, and V.K. Vasudevan: Metall. Mater. Trans. A, 2008, vol. 39A, pp. 2569–85.

K.M. Ralls, T.H. Courtney, and J. Wulff: Introduction to Materials Science and Engineering, John Wiley and Sons, New York, NY, 1976, p. 489.

S. Yang, U. Krupp, H. Christ, and V.B. Trindade: Adv. Eng. Mater., 2005, vol. 7, pp. 723–26.

S. Schlegel, S. Hopkins, E. Young, J. Cole, T. Lillo, and M. Frary: Metall. Mater. Trans. A, 2009, vol. 40A, DOI: 10.1007/s11661-009-0027-7.

E. Gariboldi, M. Cabibbo, S. Spigarelli, and D. Ripamonti: Int. J. Pressure Vessels Piping, 2008, vol. 85, pp. 63–71.

R.H. Cook: Nucl. Technol., 1984, vol. 66, pp. 283–88.

R. Swindeman and M.J. Swindeman: Int. J. Pressure Vessels Piping, 2008, vol. 85, pp. 72–79.

V. Randle: Acta Mater., 1997, vol. 46, pp. 1459–80.

E.M. Lehockey and G. Palumbo: Mater. Sci. Eng., 1997, vol. A237, pp. 168–72.

V. Thaveeprungsriporn and G. Was: Metall. Mater. Trans. A, 1997, vol. 28A, pp. 2101–12.

T. Watanabe: Res. Mechanica, 1984, vol. 11, pp. 47–84.

H. Kokawa, T. Watanabe, and S. Karashima: Phil. Mag. A, 1981, vol. 44, pp. 1239–54.

H.U. Hong, B.S. Rho, and S.W. Nam: Mater. Sci. Eng., vol. A318, 2001, pp. 285–92.

B. Alexandreanu, B. Sencer, V. Thaveeprungsriporn, and G. Was: Acta Mater., 2003, vol. 51, pp. 3831–48.

V. Segal: Mater. Sci Eng. A, vol. 197, pp. 157–64.

B. Wilshire and C.J. Palmer: Scripta Mater., 2002, vol. 46, pp. 483–88.

K.R. McNee, G.W. Greenwood, and H. Jones: Scripta Mater., 2000, vol. 44, pp. 351–57.

J.P. Hirth and J. Lothe: Theory of Dislocations, 2nd ed., John Wiley and Sons, New York, NY, 1982, p. 839.

F. Diologent and P. Caron: Mater. Sci. Eng. A, 2004, vol. 385, pp. 245–57.

F. Pettinari, J. Douin, G. Saada, P. Caron, A. Coujou, and N. Clement: Mater. Sci. Eng. A, 2002, vol. 325, pp. 511–19.

M.F. Ashby: Acta Metall., 1972, vol. 20, pp. 887–97.

G.E. Dieter: Mechanical Metallurgy, 3rd ed., McGraw-Hill Book Company, New York, NY, 1986, pp. 449–51.

H.E. Evans: Mechanisms of Creep Fracture, Elsevier Applied Science Publishers, New York, NY, 1984, pp. 25–62.

R.H. Priest and E.G. Ellsion: Mater. Sci. Eng., 1981, vol. 49, pp. 7–17.

ASME Boiler and Pressure Vessel Code, Section III—Rules for Construction of Nuclear Facility Components, Division 1, Subsection NH—Class 1 Components in Elevated Temperature Service, The American Society of Mechanical Engineers, New York, NY.

V. Randle: The Measurement of Grain Boundary Geometry, Institute of Physics Publishing, Philadelphia, PA, 1993, pp. 2–5.

R.E. Reed-Hill: Physical Metallurgy Principles, 2nd ed., PWS Publishers, Boston, MA, 1973, pp. 390–97.

V. Randle: Scripta Mater., 2006, vol. 54, pp. 1011–15.

C. Kim, A.D. Rollet, and G.S. Rohrer: Scripta Mater., 2006, vol. 54, pp. 1005–09.

Acknowledgments

This work was supported by the United States Department of Energy, Office of Nuclear Energy, under the DOE Idaho Operations Office, Contract No. DE-AC07-05ID14517.

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is based on a presentation given in the symposium “Materials for the Nuclear Renaissance,” which occurred during the TMS Annual Meeting, February 15–19, 2009, in San Francisco, CA, under the auspices of Corrosion and Environmental Effects and the Nuclear Materials Committees of ASM-TMS.

Rights and permissions

About this article

Cite this article

Lillo, T., Cole, J., Frary, M. et al. Influence of Grain Boundary Character on Creep Void Formation in Alloy 617. Metall Mater Trans A 40, 2803–2811 (2009). https://doi.org/10.1007/s11661-009-0051-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-009-0051-7