Abstract

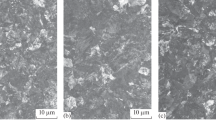

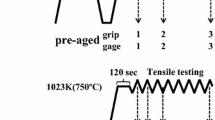

The microstructure development of a high-carbon steel (0.67 pct C) for railway wheels as they are affected by rolling contact with rail tracks and by cyclic frictional heat from braking is studied in the vicinity of the contact surface by scanning electron microscopy (SEM) and electron backscattered diffraction. An ultrafine microstructure consisting of ferrite grains with a size of less than 1 μm and spheroidized cementite particles is formed in the region up to 100 μm below the contact surface. The generation of low-angle sub-boundaries associated with the rearrangement of accumulated dislocations involved in continuous recrystallization of ferrite microstructure contributes to the microstructure refinement at temperatures lower than A1 temperature (1000 K). Fine spheroidized cementite particles with uniform distribution obstruct the migration of high-angle grain boundaries, by which the dislocation density is maintained sufficiently high for the formation of sub-boundaries. The formation of a texture, corresponding to the surface texture typically formed in low-carbon steels by hot rolling without lubrication at ferritic temperatures, is observed in the ultrarefined microstructure region. The results drawn from this study strongly indicate the occurrence of “in-situ microstructure control” under service conditions.

Similar content being viewed by others

References

E. Kabo and A. Ekberg: Wear, 2002, vol. 253, pp. 26–34.

A. Ekberg and E. Kabo: Wear, 2005, vol. 258, pp. 1288–1300.

K. Handa, Y. Kimura, and Y. Mishima: Proc. Materials Science and Technology (MS&T) 2008, Pittsburgh, PA, Oct. 5–9, 2008, The Printing House, Inc., Stoughton, WI, pp. 2001–09.

Japanese Standards Association: JIS E 5401-1, JSA, Tokyo, Japan, 1998.

International Union of Railways: UIC CODE 541-3, 5th ed., UIC, Paris, France, 2004.

S.P. Timoshenko and J.N. Goodier: Theory of Elasticity, McGraw-Hill Book Co., New York, NY, 1970, p. 414.

D.M. Turley: Mater. Sci. Eng. A, 1975, vol. 19, pp. 79–86.

S.B. Newcomb and W.M. Stobbs: Mater. Sci. Eng. A, 1984, vol. 66, pp. 195–204.

W. Lojkowski, M. Djahanbakhash, G. Bürkle, S. Gierlotka, W. Zielinski, and H.-J. Fecht: Mater. Sci. Eng. A, 2001, vol. 303, pp. 197–208.

L. Wang, A. Pyzalla, W. Stadlbauer, and E.A. Werner: Mater. Sci. Eng. A, 2003, vol. 359, pp. 31–43.

H.W. Zhang, S. Ohsaki, S. Mitao, M. Ohnuma, and K. Hono: Mater. Sci. Eng. A, 2006, vol. 421, pp. 191–99.

S.M. Zakharov and I.G. Goryacheva: Wear, 2005, vol. 258, pp. 1142–47.

J.G. Li, M. Umemoto, Y. Todaka, and K. Tsuchiya: Acta Mater., 2007, vol. 55, pp. 1397–1406.

J.G. Li, M. Umemoto, Y. Todaka, and K. Tsuchiya: Mater. Sci. Eng. A, 2006, vols. 435–436, pp. 383–88.

V.N. Gridnev and V.G. Gavrilyuk: Phys. Met., 1982, vol. 4, pp. 531–51.

J. Languillaume, G. Kapelski, and B. Baudelet: Acta Mater., 1997, vol. 45, pp. 1201–12.

V.G. Gavriljuk: Mater. Sci. Eng. A, 2003, vol. 345, pp. 81–89.

Y. Ivanisenko, W. Lojkowski, R.Z. Valiev, and H.-J. Fecht: Acta Mater., 2003, vol. 51, pp. 5555–70.

X. Sauvage and Y. Ivanisenko: J. Mater. Sci., 2007, vol. 42, pp. 1615–21.

R. Song, D. Ponge, D. Raabe, and R. Kaspar: Acta Mater., 2005, vol. 53, pp. 845–58.

A. Ohmori, S. Torizuka, K. Nagai, N. Koseki, and Y. Kogo: Mater. Trans. JIM, 2004, vol. 45, pp. 2224–31.

S.V.S.N. Murty, S. Torizuka, and K. Nagai: Mater. Sci. Eng. A, 2005, vol. 410, pp. 319–23.

L. Storojeva, D. Ponge, R. Kaspar, and D. Raabe: Acta Mater., 2004, vol. 52, pp. 2209–20.

R. Song, D. Ponge, D. Raabe, J.G. Speer, and D.K. Matlock: Mater. Sci. Eng. A, 2006, vol. 441, pp. 1–17.

T. Sakai, Y. Saito, and K. Kato: Trans. ISIJ, 1988, vol. 28, pp. 1036–42.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted February 27, 2009.

Rights and permissions

About this article

Cite this article

Handa, K., Kimura, Y. & Mishima, Y. Ferrite and Spheroidized Cementite Ultrafine Microstructure Formation in an Fe-0.67 Pct C Steel for Railway Wheels under Simulated Service Conditions. Metall Mater Trans A 40, 2901–2908 (2009). https://doi.org/10.1007/s11661-009-0015-y

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-009-0015-y