Abstract

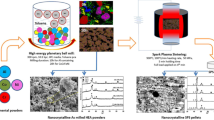

The microstructure and aging behavior of a nanocrystalline Al-Cu-Mg-Fe-Ni-Sc alloy was studied. The nanocrystalline powders were produced by milling at liquid nitrogen temperature and then consolidated using spark plasma sintering (SPS). The microstructure after SPS consisted of a bimodal aluminum grain structure (coarse-grained and fine-grained regions), along with Al9FeNi and Al2CuMg particles dispersed throughout. The microstructure observed in the as-consolidated sample is rationalized on the basis of high current densities that are generated during sintering. Solution treatment and aging of the SPS Al-Cu-Mg-Fe-Ni-Sc sample resulted in softening instead of hardening. This observation can be explained by the reduced amount of Cu, Mg, and Si in solid solution available to form S′ Al2CuMg due to the precipitation of Al7FeCu2 and Si-rich particles, and by the fact that rodlike S′ Al2CuMg particles could only precipitate out in the coarse-grained regions, greatly decreasing their influence on the hardness. This lack of precipitation in the fine-grained region is argued to represent a new physical observation and is rationalized on the basis of physical and thermodynamic effects. The nanocrystalline SPS Al-Cu-Mg-Fe-Ni-Sc sample was also extremely thermally stable, retaining a fine-grained structure even after solution treatment at 530°C for 5 h. The observed thermal stability is rationalized on the basis of solute drag and Zener pinning caused by the impurities introduced during the cryomilling process.

Similar content being viewed by others

References

N.A. Belov, A.A. Akesnov, and D.G. Eskin: Iron in Aluminum Alloys, Taylor & Francis, New York, NY, 2002, pp. 1–99.

I.J. Polmear: Mater. Trans., JIM, 1996, vol. 37, pp. 12–31.

V. Gerold: Scripta Metall., 1988, vol. 22, pp. 927–32.

P.G. Shewmon: Transformations in Metals, McGraw-Hill, New York, NY, 1969, p. 315.

I.J. Polmear and M.J. Couper: Metall. Trans. A, 1988, vol. 19A, pp. 1027–35.

A. Roósz and H.E. Exner: Acta Metall. Mater., 1990, vol. 38, pp. 2009–16.

I.N.A. Oguocha and S. Yannacopoulos: Mater. Sci. Eng., 1997, vol. A231, pp. 25–33.

J. Majimel, G. Molénat, M.J. Casanove, D. Schuster, A. Denquin, and G. Lapasset: Scripta Mater., 2002, vol. 46, pp. 113–19.

L.S. Toropova, D.G. Eskin, M.L. Kharakterova, and T.V. Dobatkina: Advanced Aluminum Alloys Containing Scandium, Gordon and Breach, Amsterdam, 1998, p. 21.

D.N. Seidman, E.A. Marquis, and D.C. Dunand: Acta Mater., 2002, vol. 50, pp. 4021–35.

G.M. Novotny and A.J. Ardell: Mater. Sci. Eng., 2001, vol. A318, pp. 144–54.

E.A. Marquis and D.N. Seidman: Acta Mater., 2001, vol. 49, pp. 1909–19.

C.C. Koch: Ann. Rev. Mater. Sci., 2003, vol. 5, pp. 91–99.

E. Gaffet, N. Malhouroux, and M. Abdellaoui: J. Alloys Compounds, 1993, vol. 194, pp. 339–60.

C. Suryanarayana: Int. Mater. Rev., 1995, vol. 40, pp. 41–64.

D.B. Witkin and E.J. Lavernia: Progr. Mater. Sci., 2006, vol. 51, pp. 1–60.

C.C. Koch: Nanostruct. Mater., 1993, vol. 2, pp. 109–29.

B.J.M. Aikin, T.H. Courtney, and D.R. Mauri: Mater. Sci. Eng., 1991, vol. A147, pp. 229–37.

F. Zhou, R. Luck, K. Lu, E.J. Lavernia, and M. Ruhle: Phil. Mag. A, 2002, vol. 82, pp. 1003–15.

C. Suryanarayana: Progr. Mater. Sci., 2001, vol. 46, pp. 1–184.

J. Eckert, J.C. Holzer, C.E. Kill, III, and W.L. Johnson: J. Mater. Res., 1992, vol. 7, pp. 1751–61.

D. Oleszak and P.H. Shingu: J. Appl. Phys., 1996, vol. 79, pp. 2975–80.

C.C. Koch: Nanostr. Mater., 1997, vol. 9, pp. 13–22.

F.A. Mohamed and Y. Xun: Mater. Sci. Eng., 2003, vol. A354, pp. 133–39.

M.J. Luton, C.S. Jayanth, M.M. Disko, S. Matras, and J. Vallone: Mater. Res. Soc. Symp. Proc., 1989, vol. 132, pp. 79–86.

B. Huang, J. Vallone, and M.J. Luton: Nanostr. Mater., 1995, vol. 5, pp. 631–42.

R.J. Perez, B. Huang, and E.J. Lavernia: Nanostr. Mater., 1996, vol. 7, pp. 565–72.

J.C. Rawers, R.D. Govier, and G. Korth: Mater. Sci. Forum, 1995, vols. 179–181, pp. 363–68.

F. Zhou, J. Lee, S. Dallek, and E.J. Lavernia: J. Mater. Res., 2001, vol. 16, pp. 3451–58.

F. Zhou, R. Rodriguez, and E.J. Lavernia: Mater. Sci. Forum, 2002, vol. 386–388, pp. 409–14.

R.Z. Valiev, R.K. Islamgaliev, and I.V. Alexandrov: Progr. Mater. Sci., 2000, vol. 45, pp. 103–89.

X.K. Sun, H.T. Cong, M. Sun, and M.C. Yang: Metall. Trans. A, 2000, vol. 31A, pp. 1017–24.

V.L. Tellkamp, A. Melmed, and E.J. Lavernia: Metall. Mater. Trans. A, 2001, vol. 32A, pp. 2335–43.

R.W. Hayes, R. Rodriguez, and E.J. Lavernia: Acta Mater., 2001, vol. 49, pp. 4055–68.

M. Omori: Mater. Sci. Eng., 2000, vol. A287, pp. 183–88.

M. Tokita: Mater. Sci. Forum, 1999, vols. 308–311, pp. 83–89.

J.R. Groza: Metals Handbook, vol. 7, Field Activated Sintering, Powder Metallurgy, ASM, Metals Park, OH, 1998, p. 583.

J. Schneider, M. Garcia, and J.R. Groza: J. Mater. Res., 2001, vol. 16, pp. 286–92.

W. Chen, U. Anselmi-Tamburini, J.E. Garay, J.R. Groza, and Z.A. Munir: Mater. Sci. Eng., 2005, vol. A394, pp. 132–38.

X. Li and B. Bhushan: Mater. Characterization, 2002, vol. 48, pp. 11–36.

E.J. Lavernia and Y. Wu: Spray Atomization and Deposition, John Wiley & Sons, Chichester, United Kingdom, 1996, p. 10.

R. Trivedi, F. Jin, and I.E. Anderson: Acta Mater., 2003, vol. 51, pp. 289–300.

J.S. Benjamin and T.E. Volin: Metall. Trans., 1974, vol. 5, pp. 1929–34.

F. Zhou, X.Z. Liao, Y.T. Zhu, S. Dallek, and E.J. Lavernia: Acta Mater., 2003, vol. 51, pp. 2777–91.

A. Zúñiga: University of California, Davis, unpublished research, 2005.

H.J. Fetch: Nanostr. Mater., 1995, vol. 6, pp. 33–42.

T.G. Nieh and J. Wadsworth: Scripta Metall. Mater., 1991, vol. 25, pp. 955–58.

F.A. Mohamed: Acta Mater., 2003, vol. 51, pp. 4107–19.

P.J. Apps, J.R. Bowen, and P.B. Prangnell: Acta Mater., 2003, vol. 51, pp. 2811–22.

M. Kato, T. Fujii, and S. Onaka: Mater. Sci. Eng., 2001, vol. A317, pp. 108–14.

V. Yamakov, D. Wolf, S.R. Phillpot, and H. Gleiter: Acta Mater., 2002, vol. 50, pp. 5005–20.

X.Z. Liao, F. Zhou, E.J. Lavernia, S.G. Srinivasan, M.I. Baskes, D.W. He, and Y.T Zhu: Appl. Phys. Lett., 2003, vol. 83, pp. 632–34.

A. Frøseth, H. Van Swygenhoven, and P.M. Derlet: Acta Mater., 2004, vol. 52, pp. 2259–68.

H. Conrad: Mater. Sci. Eng., 2000, vol. A287, pp. 227–37.

D.J. Chakrabarti and D.E. Laugh lin: Progr. Mater. Sci., 2004, vol. 49, pp. 389–410.

A.K. Gupta, A.K. Jena, and M.C. Chaturvedi: Mater. Sci. Technol., 1987, vol. 3, pp. 1012–18.

B. Huang, R.J. Perez, and E.J. Lavernia: Mater. Sci. Eng., 1988, vol. A255, pp. 124–32.

R.Z. Valiev, C. Song, S.X. McFadden, A.K. Mukherjee, and R.S. Mishra: Phil. Mag. A, 2001, vol. 81, pp. 25–36.

J.D. Boyd and R.B. Nicholson: Acta Metall., 1971, vol. 19, pp. 1379–91.

P. Merle and F. Fouquet: Acta Metall., 1981, vol. 29, pp. 1919–27.

W. Tirry and D. Schryvers: Acta Mater., 2005, vol. 53, pp. 1041–49.

S.P. Ringer, T. Sakurai, and I.J. Polmear: Acta Mater., 1997, vol. 45, pp. 3731–44.

A. Garg, Y.C. Chang, and J.M. Howe: Scripta Metall. Mater., 1990, vol. 24, pp. 677–80.

S. Abis, P. Mengucci, and G. Riontino: Phil. Mag. A, 1994, vol. 70, pp. 851–68.

K. Raviprasad, C.R. Hutchinson, T. Sakurai, and S.P. Ringer: Acta Mater., 2003, vol. 51, pp. 5037–50.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Zúñiga, A., Ajdelsztajn, L. & Lavernia, E.J. Spark plasma sintering of a nanocrystalline Al-Cu-Mg-Fe-Ni-Sc alloy. Metall Mater Trans A 37, 1343–1352 (2006). https://doi.org/10.1007/s11661-006-1086-7

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11661-006-1086-7