Abstract

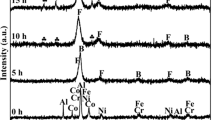

Nanocrystalline AlxCoCrFeNi (x = 0, 0.3, 0.6, 1 mol) high-entropy alloys were synthesized by mechanical alloying (MA) and consolidated by spark plasma sintering (SPS). Single-phase face-centered cubic (FCC) structure was achieved with x = 0 and 0.3. Dual-phase body-centered cubic (BCC)/B2 + FCC structure was obtained in x = 0.6 and 1. Complete solid solution was achieved with a significantly reduced duration of MA (10 h) followed by a brief SPS leading to crystallite size of < 10 nm for MA powders and < 60 nm post-SPS. Incremental changes in Al content translate into increase of BCC + B2 phase fraction and alter the co-existing FCC phase composition consequently. Ni dominates FCC phase of CoCrFeNi and Al0.3CoCrFeNi, whereas Fe dominates FCC phase of Al0.6CoCrFeNi and AlCoCrFeNi. Carbon and Oxygen addition during milling process resulted in nanoscale dispersion of Cr7C3 carbide and Cr2O3 /Al2O3 post-SPS. The hardness of AlCoCrFeNi (730HV0.3) was the highest among all MA-SPS alloys.

Graphical abstract

Similar content being viewed by others

Availability of data and material

The raw/processed data required to reproduce these findings cannot be shared at this time as the data also forms part of an ongoing study.

Code availability

Not applicable.

References

B. Murty, J.-W. Yeh, S. Ranganathan, High-Entropy Alloys (Butterworth-Heinemann, Oxford, 2014)

J. Pang, H. Zhang, L. Zhang, Z. Zhu, H. Fu, H. Li, A. Wang, Z. Li, H. Zhang, Ductile Ti1.5ZrNbAl0.3 refractory high entropy alloy with high specific strength. Mater. Lett. (2021). https://doi.org/10.1016/j.matlet.2021.129428

C. Lee, Y. Chou, G. Kim, M.C. Gao, K. An, J. Brechtl, C. Zhang, W. Chen, J.D. Poplawsky, G. Song, Y. Ren, Y.C. Chou, P.K. Liaw, Lattice-distortion-enhanced yield strength in a refractory high-entropy alloy. Adv Mater 32(49), e2004029 (2020)

W.-R. Wang, W.-L. Wang, S.-C. Wang, Y.-C. Tsai, C.-H. Lai, J.-W. Yeh, Effects of Al addition on the microstructure and mechanical property of AlxCoCrFeNi high-entropy alloys. Intermetallics 26, 44–51 (2012)

T. Yang, S. Xia, S. Liu, C. Wang, S. Liu, Y. Zhang, J. Xue, S. Yan, Y. Wang, Effects of AL addition on microstructure and mechanical properties of AlxCoCrFeNi High-entropy alloy. Mater. Sci. Eng. A 648, 15–22 (2015)

A. Zhang, J. Han, J. Meng, B. Su, P. Li, Rapid preparation of AlCoCrFeNi high entropy alloy by spark plasma sintering from elemental powder mixture. Mater. Lett. 181, 82–85 (2016)

B.S. Murty, S. Ranganathan, Novel materials synthesis by mechanical alloying/milling. Int. Mater. Rev. 43(3), 101–141 (1998)

S. Varalakshmi, M. Kamaraj, B.S. Murty, Synthesis and characterization of nanocrystalline AlFeTiCrZnCu high entropy solid solution by mechanical alloying. J. Alloys Compd. 460(1), 253–257 (2008)

W. Ji, Z. Fu, W. Wang, H. Wang, J. Zhang, Y. Wang, F. Zhang, Mechanical alloying synthesis and spark plasma sintering consolidation of CoCrFeNiAl high-entropy alloy. J. Alloys Compd. 589, 61–66 (2014)

Z. Fu, W. Chen, H. Wen, Z. Chen, E.J. Lavernia, Effects of Co and sintering method on microstructure and mechanical behavior of a high-entropy Al0.6NiFeCrCo alloy prepared by powder metallurgy. J. Alloys Compd. 646, 175–182 (2015)

C. Zhao, J. Li, Y. Liu, W.Y. Wang, H. Kou, E. Beaugnon, J. Wang, Tailoring mechanical and magnetic properties of AlCoCrFeNi high-entropy alloy via phase transformation. J. Mater. Sci. Technol. 73, 83–90 (2021)

C. Zhao, J. Li, Y. Liu, X. Ma, Y. Jin, W.Y. Wang, H. Kou, J. Wang, Optimizing mechanical and magnetic properties of AlCoCrFeNi high-entropy alloy via FCC to BCC phase transformation. J. Mater. Sci. Technol. 86, 117–126 (2021)

A. Parakh, M. Vaidya, N. Kumar, R. Chetty, B.S. Murty, Effect of crystal structure and grain size on corrosion properties of AlCoCrFeNi high entropy alloy. J. Alloys Compd. (2021). https://doi.org/10.1016/j.jallcom.2020.158056

Y. Zhang, T.T. Zuo, Z. Tang, M.C. Gao, K.A. Dahmen, P.K. Liaw, Z.P. Lu, Microstructures and properties of high-entropy alloys. Prog. Mater. Sci. 61, 1–93 (2014)

S. Mohanty, T.N. Maity, S. Mukhopadhyay, S. Sarkar, N.P. Gurao, S. Bhowmick, K. Biswas, Powder metallurgical processing of equiatomic AlCoCrFeNi high entropy alloy: microstructure and mechanical properties. Mater. Sci. Eng., A 679, 299–313 (2017)

V. Shivam, J. Basu, V.K. Pandey, Y. Shadangi, N.K. Mukhopadhyay, Alloying behaviour, thermal stability and phase evolution in quinary AlCoCrFeNi high entropy alloy. Adv. Powder Technol. 29(9), 2221–2230 (2018)

V. Shivam, Y. Shadangi, J. Basu, N.K. Mukhopadhyay, Evolution of phases, hardness and magnetic properties of AlCoCrFeNi high entropy alloy processed by mechanical alloying. J. Alloys Compd. 832, 154826 (2020)

Z. Chen, W. Chen, B. Wu, X. Cao, L. Liu, Z. Fu, Effects of Co and Ti on microstructure and mechanical behavior of Al0.75FeNiCrCo high entropy alloy prepared by mechanical alloying and spark plasma sintering. Mater. Sci. Eng. A 648, 217–224 (2015)

R. Jayasree, R.B. Mane, R. Vijay, D. Chakravarty, Effect of process control agents on mechanically alloyed Al0.3CoCrFeNi. Mater. Lett. (2021). https://doi.org/10.1016/j.matlet.2021.129618

S. Praveen, J. Basu, S. Kashyap, R.S. Kottada, Exceptional resistance to grain growth in nanocrystalline CoCrFeNi high entropy alloy at high homologous temperatures. J. Alloys Compd. 662, 361–367 (2016)

I. Moravcik, A. Kubicek, L. Moravcikova-Gouvea, O. Adam, V. Kana, V. Pouchly, A. Zadera, I. Dlouhy, The origins of high-entropy alloy contamination induced by mechanical alloying and sintering. Metals 10, 9 (2020)

M. Vaidya, A. Karati, K. Guruvidyathri, M. Nagini, K.G. Pradeep, B.S. Murty, Suppression of σ-phase in nanocrystalline CoCrFeMnNiV high entropy alloy by unsolicited contamination during mechanical alloying and spark plasma sintering. Mater. Chem. Phys. 255, 123558 (2020)

Y.-L. Chen, Y.-H. Hu, C.-A. Hsieh, J.-W. Yeh, S.-K. Chen, Competition between elements during mechanical alloying in an octonary multi-principal-element alloy system. J. Alloys Compd. 481(1), 768–775 (2009)

R. John, A. Karati, M.M. Garlapati, M. Vaidya, R. Bhattacharya, D. Fabijanic, B.S. Murty, Influence of mechanically activated annealing on phase evolution in Al0.3CoCrFeNi high-entropy alloy. J. Mater. Sci. 54(23), 14588–14598 (2019)

M.M. Garlapati, M. Vaidya, A. Karati, S. Mishra, R. Bhattacharya, B.S. Murty, Influence of Al content on thermal stability of nanocrystalline AlxCoCrFeNi high entropy alloys at low and intermediate temperatures. Adv. Powder Technol. 31(5), 1985–1993 (2020)

M. Vaidya, A. Prasad, A. Parakh, B.S. Murty, Influence of sequence of elemental addition on phase evolution in nanocrystalline AlCoCrFeNi: novel approach to alloy synthesis using mechanical alloying. Mater. Des. 126, 37–46 (2017)

A. Fourmont, S. Le Gallet, O. Politano, C. Desgranges, F. Baras, Effects of planetary ball milling on AlCoCrFeNi high entropy alloys prepared by Spark Plasma Sintering: experiments and molecular dynamics study. J. Alloys Compd. 820, 153448 (2020)

E. Colombini, R. Rosa, L. Trombi, M. Zadra, A. Casagrande, P. Veronesi, High entropy alloys obtained by field assisted powder metallurgy route: SPS and microwave heating. Mater. Chem. Phys. 210, 78–86 (2018)

R.B. Mane, B.B. Panigrahi, Comparative study on sintering kinetics of as-milled and annealed CoCrFeNi high entropy alloy powders. Mater. Chem. Phys. 210, 49–56 (2018)

R.B. Mane, B.B. Panigrahi, Sintering mechanisms of mechanically alloyed CoCrFeNi high-entropy alloy powders. J. Mater. Res. 33(19), 3321–3329 (2018)

S. Rohila, R.B. Mane, G. Ummethala, B.B. Panigrahi, Nearly full-density pressureless sintering of AlCoCrFeNi-based high-entropy alloy powders. J. Mater. Res. 34(5), 777–786 (2019)

W.-R. Wang, W.-L. Wang, J.-W. Yeh, Phases, microstructure and mechanical properties of AlxCoCrFeNi high-entropy alloys at elevated temperatures. J. Alloys Compd. 589, 143–152 (2014)

P. Wang, H. Cai, S. Zhou, L. Xu, Processing, microstructure and properties of Ni1.5CoCuFeCr0.5−xVx high entropy alloys with carbon introduced from process control agent. J. Alloys Compd. 695, 462–475 (2017)

R. Sokkalingam, M. Tarraste, K.B. Surreddi, V. Mikli, V. Muthupandi, K. Sivaprasad, K.G. Prashanth, Powder metallurgy of Al0.1CoCrFeNi high-entropy alloy. J. Mater. Res. 35(21), 2835–2847 (2020)

O. Molnarova, J. Duchon, E. de Prado, S. Csaki, F. Prusa, P. Malek, Bimodal microstructure in an AlZrTi alloy prepared by mechanical milling and spark plasma sintering. Materials 13, 17 (2020)

Y.-F. Kao, T.-J. Chen, S.-K. Chen, J.-W. Yeh, Microstructure and mechanical property of as-cast, -homogenized, and -deformed AlxCoCrFeNi (0≤x≤2) high-entropy alloys. J. Alloys Compd. 488(1), 57–64 (2009)

M. Annasamy, N. Haghdadi, A. Taylor, P. Hodgson, D. Fabijanic, Static recrystallization and grain growth behaviour of Al0.3CoCrFeNi high entropy alloy. Mater. Sci. Eng. A 754, 282–294 (2019)

J. Hou, M. Zhang, S. Ma, P.K. Liaw, Y. Zhang, J. Qiao, Strengthening in Al0.25CoCrFeNi high-entropy alloys by cold rolling. Mater. Sci. Eng. A 707, 593–601 (2017)

S. Yang, X. Yan, K. Yang, Z. Fu, Effect of the addition of nano-Al2O3 on the microstructure and mechanical properties of twinned Al0.4FeCrCoNi1.2Ti0.3 alloys. Vacuum 131, 69–72 (2016)

S. Hovard, K.D. Preston, Profile fitting of powder diffraction patterns. Minerology 20(4), 217–275 (1989)

Acknowledgments

The support of the Deakin Advanced Characterization Facility and Sophisticated Analytical Instrument Facility IIT Madras is gratefully acknowledged. We are thankful to Dr. Lavanya Raman of IIT Madras for her guidance in XRD analysis and Dr. Qi Chao of Deakin University for his support in TEM sample preparation.

Funding

Not applicable.

Author information

Authors and Affiliations

Contributions

Not applicable.

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Bhattacharya, R., Annasamy, M., Cizek, P. et al. Evolution of phase constitution with mechanical alloying and spark plasma sintering of nanocrystalline AlxCoCrFeNi (x = 0, 0.3, 0.6, 1 mol) high-entropy alloys. Journal of Materials Research 37, 959–975 (2022). https://doi.org/10.1557/s43578-021-00483-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43578-021-00483-0