Abstract

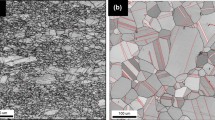

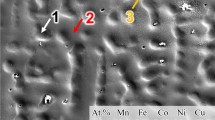

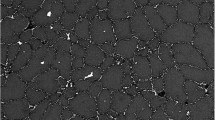

The hot tensile deformation properties and microstructure evolution of high purity C71500 cupronickel alloy at 1 023–1 273 K and 0.000 1–0.1 s−1 strain rates were studied by uniaxial hot tensile deformation method. Based on the experimental data, the flow behavior, microstructure and fracture characteristics of the alloy were analyzed after considering the influence of different deformation parameters. The relationship between microstructure and high temperature (T⩾1 023 K) plasticity is discussed, and the fracture mechanism is revealed. The relationship between strain rate sensitivity coefficient and stress index and plastic deformation is discussed. The constitutive equation of the alloy is established by Johnson-Cook model. Based on the dynamic material model, the energy dissipation model is established, and Prasad’s instability criterion based on Ziegler’s expected rheological theory is used to predict the unstable region in the processing map. Processing map in hot tensile is analyzed to provide theoretical basis for different processing technology.

Similar content being viewed by others

References

CINCERA S, BRESCIANI E. De-nickelification of 70/30 Cupronickel Tubing in a Cooling Heat Exchanger[J]. Journal of Failure Analysis & Prevention, 2012, 12(3): 300–304

DROLENGA L J P, IJSSELING F P, KOLSTER B H. The Influence of Alloy Composition and Microstructure on the Corrosion Behaviour of Cu-Ni Alloys in Seawater[J]. Materials & Corrosion, 2015, 34(4): 167–178

TORRES BAUTISTA B E, WIKIEŁ A J, DATSENKO I, et al. Influence of Extracellular Polymeric Substances (EPS) from Pseudomonas NCIMB 2021 on the Corrosion Behaviour of 70Cu-30Ni Alloy in Sea-water[J]. Journal of Electroanalytical Chemistry, 2015, 737: 184–197

WEI M, YANG B, LIU Y, et al. Research Progress and Prospect on Erosion-Corrosion of Cu-Ni Alloy Pipe in Seawater[J]. Journal of Chinese Society for Corrosion & Protection, 2016, 36(6): 513–521

ZHANG D N, SHANGGUAN Q Q, XIE C J, et al. A Modified Johnson-Cook Model of Dynamic Tensile Behaviors for 7075-T6 Aluminum Alloy[J]. Journal of Alloys & Compounds, 2015, 619: 186–194

LIN Y C, CHEN X M, LIU G. A Modified Johnson-Cook Model for Tensile Behaviors of Typical High-Strength Alloy Steel[J]. Materials Science & Engineering A, 2010, 527(26): 6980–6986

CAO F, FEI X, XUE G. Hot Tensile Deformation Behavior and Microstructural Evolution of a Mg-9.3Li-1.79Al-1.61Zn Alloy[J]. Materials & Design, 2016, 92: 44–57

EFTEKHARI M, FATA A, FARAJI G, et al. Hot Tensile Deformation Behavior of Mg-Zn-Al Magnesium Alloy Tubes Processed by Severe Plastic Deformation[J]. Journal of Alloys & Compounds, 2018, 742: 442–453

AO D W, CHU X R, LIN S X, et al. Hot Tensile Behaviors and Microstructure Evolution of Ti-6Al-4V Titanium Alloy under Electropulsing[J]. Acta Metallurgica Sinica(English Letters), 2018, 31(12): 1287–1296

REIS A G A, REIS D A P, ABDALLA A N J, et al. Hot Tensile Behavior and Fracture Characteristics of a Plasma Nitrided Maraging 300 Steel[J]. Materials Science Forum, 2017, 899: 436–441

HUANG Y, LIU C, XIAO Z. Hot Tensile Deformation and Fracture Behaviours of Hastelloy C-276 Alloy[J]. Materials Science & Technology, 2017, 34: 1–8

CAI J, ZHANG X, WANG K, et al. Physics-Based Constitutive Model to Predict Dynamic Recovery Behavior of BFe10-1-2 Cupronickel Alloy during Hot Working[J]. High Temperature Materials & Processes, 2016, 35: 1–9

JUN C, KUAISHE W, WEN W. Characterization of High Temperature Deformation Behavior of BFe10-1-2 Cupronickel Alloy Using Constitutive Equation and Processing Map[J]. Rare Metal Materials & Engineering, 2016, 45(10): 2549–2554

SHI C, MAO W, CHEN X G. Evolution of Activation Energy During Hot Deformation of AA7150 Aluminum Alloy[J]. Materials Science & Engineering: A, 2013, 571: 83–91

DENG J, LIN Y C, LI S-S, et al. Hot Tensile Deformation and Fracture Behaviors of AZ31 Magnesium Alloy[J]. Materials & Design, 2013, 49: 209–219

LIN Y C, DENG J, JIANG Y-Q, et al. Effects of Initial δ Phase on Hot Tensile Deformation Behaviors and Fracture Characteristics of a Typical Ni-Based Superalloy[J]. Materials & Design, 2014, 55: 949–957

ZHOU M, LIN Y C, DENG J, et al. Hot Tensile Deformation Behaviors and Constitutive Model of An Al-Zn-Mg-Cu Alloy[J]. Materials & Design, 2014, 59: 141–150

GAO X, WU H-B, LIU M, et al. Dynamic Recovery and Recrystallization Behaviors of C71500 Copper-Nickel Alloy Under Hot Deformation[J]. Journal of Materials Engineering & Performance, 2020, 29(11): 7678–7692

GEGEL H L, MALAS J C, GUNASEKERA J S, et al. Computer-aided Design of Extrusion Dies by Metal-flow Simulation[M]. AGARD Process Modeling Appl. to Metal Forming and Thermomech, 1984

PRASAD Y V R K, GEGEL H L, DORAIVELU S M, et al. Modeling of Dynamic Material Behavior in Hot Deformation: Forging of Ti-6242 [J]. Metall Trans A, 1984, 15(10): 1883–1892

GAO X, WU H, LIU M, et al. Processing Map of C71500 Copper-nickel Alloy and Application in Production Practice[J]. Journal of Wuhan University of Technology-Mater. Sci. Ed., 2020, 35(6): 1–12

CHEN B, ZHOU W M, LI S, et al. Hot Compression Deformation Behavior and Processing Maps of Mg-Gd-Y-Zr Alloy[J]. Journal of Materials Engineering & Performance, 2013, 22(9): 2458–2466

PRAGER W. On Ideal Locking Materials[J]. Transactions of The Society of Rheology, 1957, 1(1): 169–175

LIN Y C, DING Y, CHEN M-S, et al. A New Phenomenological Constitutive Model for Hot Tensile Deformation Behaviors of a Typical Al-Cu-Mg Alloy[J]. Materials & Design, 2013, 52: 118–127

WEN Z, GAO X, CHENG J, et al. Processing Map and Hot Deformation Behavior of Mo-Nb Single Crystals[J]. Rare Metal Materials & Engineering, 2018, 47(2): 485–490

ZHONG T, RAO K P, PRASAD Y V R K, et al. Processing Maps, Microstructure Evolution and Deformation Mechanisms of Extruded AZ31-DMD During Hot Uniaxial Compression[J]. Materials Science & Engineering A, 2013, 559: 773–781

RAO K P, ZHONG T, PRASAD Y V R K, et al. Hot Working Mechanisms in DMD-Processed Versus Cast AZ31-1 wt% Ca Alloy[J]. Materials Science & Engineering A, 2015, 644(8): 184–193

Author information

Authors and Affiliations

Corresponding author

Additional information

Funded by Ministry of Industry and Information Technology of the People’s Republic of China (No. TC170A2KN-8) and the National Natural Science Foundation of China (No. 51801149)

Rights and permissions

About this article

Cite this article

Gao, X., Wu, H., Liu, M. et al. Fracture Behavior and Processing Deformation of C71500 Cupronickel Alloy during Hot Tensile Deformation. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 36, 407–415 (2021). https://doi.org/10.1007/s11595-021-2424-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-021-2424-8