Abstract

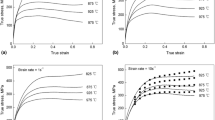

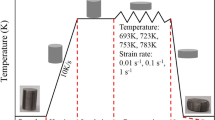

Hot compression tests were conducted to determine the processing window for deformation of solutionized Inconel 718 over a range of high temperature and strain rate. Hot working map based on the dynamic material model was developed to establish the hot-processing regime. Maximum hot deformation efficiency within the processing regime is marked by the dynamic recrystallization, whereas an instability regime exhibits the highly deformed grains with shear bands. Further, selected deformed specimens were aged at 750 °C for 8 hours. Using electron back scattered diffraction and microhardness analyses, different microstructural properties such as grain size, twin fraction, grain average misorientation, and hardness were correlated. For deformed specimens, it was found that hardness is a function of misorientation and grain size. However, after aging treatment, hardness for all the specimens was found to lie in the range of 400 to 425 HV. Further, through transmission electron microscopy analysis, it was confirmed that deformed specimens are devoid of any precipitates while the deformed specimens followed by aging showed γ″ precipitates. Thus, the lack of correlation between the hardness and the grain size in the aged specimen was due to evolution of precipitates.

Similar content being viewed by others

References

E.A. Loria: JOM, 1992, vol. 44, pp. 33–36.

T.M. Pollock and S. Tin: J. Propuls. Power, 2006, vol. 22, pp. 361–74.

R.C. Reed: The Superalloys Fundamentals and Applications, 1 Edn., Cambridge University Press, New York, 2006.

M.C. Chaturvedi and Y. Han: Met. Sci., 1983, vol. 17, pp. 145–49.

R. Cozar and A. Pineau: Metall. Trans., 1973, vol. 4, pp. 47–59.

S. Azadian, L.-Y. Wei, and R. Warren: Mater. Charact., 2004, vol. 53, pp. 7–16.

H. Yuan and W.C. Liu: Mater. Sci. Eng. A, 2005, vol. 408, pp. 281–89.

A. Agnoli, M. Bernacki, R. Logé, J.-M. Franchet, J. Laigo, and N. Bozzolo: Metall. Mater. Trans. A, 2015, vol. 46, pp. 4405–21.

M. Azarbarmas, M. Aghaie-Khafri, J.M. Cabrera, and J. Calvo: Mater. Sci. Eng. A, 2016, vol. 678, pp. 137–52.

M. Sundararaman, P. Mukhopadhyay, and S. Banerjee: Acta Metall., 1988, vol. 36, pp. 847–64.

Y.V.R.K. Prasad and N. Ravichandran: Bull. Mater. Sci., 1991, vol. 14, pp. 1241–48.

S. Guo, D. Li, H. Pen, Q. Guo, and J. Hu: J. Nucl. Mater., 2011, vol. 410, pp. 52–58.

X.M. Chen, Y.C. Lin, D.X. Wen, J.L. Zhang, and M. He: Mater. Des., 2014, vol. 57, pp. 568–77.

Q.M. Guo, D.F. Li, and S.L. Guo: Mater. Manuf. Process., 2012, vol. 27, pp. 990–95.

A. Nowotnik: Superalloys 2008 (Eleventh International Symposium), TMS, 2008, pp. 709–17.

M.C. Somani, K. Muraleedharan, N.C. Birla, V. Singh, and Y.V.R.K. Prasad: Metall. Mater. Trans. A, 1994, vol. 25, pp. 1693–702.

P.J. Wray: J. Appl. Phys., 1969, vol. 40, pp. 4018–29.

R. Raj: Metall. Trans. A, 1981, vol. 12, pp. 1089–97.

Y.V.R.K. Prasad, H.L. Gegel, S.M. Doraivelu, J.C. Malas, J.T. Morgan, K.A. Lark, and D.R. Barker: Metall. Trans. A, 1984, vol. 15, pp. 1883–92.

S.V.S. NarayanaMurty, M.S. Sarma, and B.N. Rao: Metall. Mater. Trans. A, 1997, vol. 28, pp. 1581–82.

J.C. Malas and V. Seetharaman: JOM, 1992, vol. 44, pp. 8–13.

S.L. Semiatin and G.D. Lahoti: Metall. Trans. A, 1981, vol. 12, pp. 1705–17.

F. Montheillet, J.J. Jonas, and K.W. Neale: Metall. Mater. Trans. A, 1996, vol. 27, pp. 232–35.

X. Ma, W. Zeng, K. Wang, Y. Lai, and Y. Zhou: Mater. Sci. Eng. A, 2012, vol. 550, pp. 131–37.

Y.V.R.K. Prasad, K. P. Rao, and S.Sasidhar: Hot Working Guide: A Compendium of Processing Maps, 2nd ed., ASM International, 2015.

F. Sui, L. Xu, L. Chen, and X. Liu: J. Mater. Process. Technol., 2011, vol. 211, pp. 433–40.

S. Medeiros, Y.V.R. Prasad, W. Frazier, and R. Srinivasan: Mater. Sci. Eng. A, 2000, vol. 293, pp. 198–207.

N. Srinivasan and Y.V.R.K. Prasad: Metall. Mater. Trans. A, 1994, vol. 25, pp. 2275–84.

D. Wen, Y.C. Lin, H.-B. Li, X. Chen, J. Deng, and L. Li: Mater. Sci. Eng. A, 2014, vol. 591, pp. 183–92.

H. Zhang, K. Zhang, Z. Lu, C. Zhao, and X. Yang: Mater. Sci. Eng. A, 2014, vol. 604, pp. 1–8.

Y.C. Lin, X.-M. Chen, D. Wen, and M. Chen: Comput. Mater. Sci., 2014, vol. 83, pp. 282–89.

X.-M. Chen, Y.C. Lin, M. Chen, H. Li, D. Wen, J. Zhang, and M. He: Mater. Des., 2015, vol. 77, pp. 41–49.

H.Y. Zhang, S.H. Zhang, M. Cheng, and Z.X. Li: Mater. Charact., 2010, vol. 61, pp. 49–53.

A. Thomas, M. El-Wahabi, J.M. Cabrera, and J.M. Prado: J. Mater. Process. Technol., 2006, vol. 177, pp. 469–72.

G.A. Rao, M. Kumar, M. Srinivas, and D.S. Sarma: Mater. Sci. Eng. A, 2003, vol. 355, pp. 114–25.

A. Chamanfar, L. Sarrat, M. Jahazi, M. Asadi, A. Weck, and A.K. Koul: Mater. Des., 2013, vol. 52, pp. 791–800.

F. Theska, A. Stanojevic, B. Oberwinkler, S.P. Ringer, and S. Primig: Acta Mater., 2018, vol. 156, pp. 116–24.

N. Bozzolo, N. Souaï, and R.E. Logé: Acta Mater., 2012, vol. 60, pp. 5056–66.

T. Al-Samman and G. Gottstein: Mater. Sci. Eng. A, 2008, vol. 490, pp. 411–20.

Y. Wang, W.Z. Shao, L. Zhen, and B.Y. Zhang: Mater. Sci. Eng. A, 2011, vol. 528, pp. 3218–27.

H. Jiang, J. Dong, M. Zhang, L. Zheng, and Z. Yao: J. Alloys Compd., 2015, vol. 647, pp. 338–50.

C.A. Dandre, S.M. Roberts, R.W. Evans, and R.C. Reed: Mater. Sci. Technol., 2000, vol. 16, pp. 14–25.

S.I. Wright, M.M. Nowell, S.P. Lindeman, P.P. Camus, M. De Graef, and M.A. Jackson: Ultramicroscopy, 2015, vol. 159, pp. 81–94.

M. Zouari, N. Bozzolo, and R.E. Loge: Mater. Sci. Eng. A, 2016, vol. 655, pp. 408–24.

R. Gujrati, C. Gupta, J.S. Jha, S. Mishra, and A. Alankar: Mater. Sci. Eng. A, 2019, vol. 744, pp. 638–51.

T. Sakai, A. Belyakov, R. Kaibyshev, H. Miura, and J.J. Jonas: Prog. Mater. Sci., 2014, vol. 60, pp. 130–207.

G. He, F. Liu, L. Huang, Z. Huang, and L. Jiang: J. Alloys Compd., 2017, vol. 701, pp. 909–19.

J.J. Jonas, C.M. Sellars, and W.J.M. Tegart: Metall. Rev., 1969, vol. 14, pp. 1–24.

S. Mishra, K. Narasimhan, and I. Samajdar: Mater. Sci. Technol., 2007, vol. 23, pp. 1118–26.

S. Mandal, S.K. Mishra, A. Kumar, I. Samajdar, P.V. Sivaprasad, T. Jayakumar, and B. Raj: Philos. Mag., 2008, vol. 88, pp. 883–97.

H. Ziegler: vol. 4, Wiley, New York, 1963, pp. 93–113.

Y.V.R.K. Prasad and T. Seshacharyulu: Mater. Sci. Eng. A, 1998, vol. 243, pp. 82–88.

M. Calcagnotto, D. Ponge, E. Demir, and D. Raabe: Mater. Sci. Eng. A, 2010, vol. 527, pp. 2738–46.

J. Humphreys and G.S. Rohrer: Recrystallization and Related Annealing Phenomena, Third Edit., Elsevier, 2017.

Y.C. Lin, M. Chen, and J. Zhong: Mech. Res. Commun., 2008, vol. 35, pp. 142–50.

E.I. Poliak and J.J. Jonas: ISIJ Int., 2003, vol. 43, pp. 684–91.

S. Mandal, A.K. Bhaduri, and V. Subramanya Sarma: Metall. Mater. Trans. A, 2011, vol. 42, pp. 1062–72.

F. Chen, J. Liu, H. Ou, B. Lu, Z. Cui, and H. Long: Mater. Sci. Eng. A, 2015, vol. 642, pp. 279–87.

D.J. Abson and J.J. Jonas: Met. Sci. J., 1970, vol. 4, pp. 24–28.

D. Wen, Y.C. Lin, J. Chen, X. Chen, J. Zhang, Y. Liang, and L. Li: J. Alloys Compd., 2015, vol. 618, pp. 372–79.

M. Miller: Micron, 2001, vol. 32, pp. 757–64.

J. Oblak, D.. Duvall, and D.. Paulonis: Mater. Sci. Eng., 1974, vol. 13, pp. 51–56.

I.J. Moore, M.G. Burke, N.T. Nuhfer, and E.J. Palmiere: J. Mater. Sci., 2017, vol. 52, pp. 8665–80.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted March 25, 2019.

Rights and permissions

About this article

Cite this article

Gupta, C., Jha, J.S., Jayabalan, B. et al. Correlating Hot Deformation Parameters with Microstructure Evolution During Thermomechanical Processing of Inconel 718 Alloy. Metall Mater Trans A 50, 4714–4731 (2019). https://doi.org/10.1007/s11661-019-05380-0

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-019-05380-0