Abstract

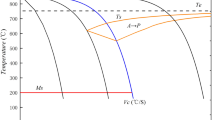

To obtain a better understanding the thermal stress of a rail, the thermal simulator was used to measure the expansion curves of different stresses loaded during the continuous cooling process of U75V rail. The transformation plasticity model was established. The experimental results show that stress can accelerate the transformation process of pearlite. While the same cooling rate is accelerated with the increase of stress, the transformation process of pearlite is accelerated, and the proportion of plastic strain transformation in total strain increases. At the same stress, the process of transformation of pearlite decreases with the increase in cooling rate, and the proportion of transformation plastic strain in total strain decreases. When considering the transformation plasticity, the axial residual stress is more consistent with the actual working condition, the accuracy of the transformation plasticity model is higher; during the continuous cooling process, and the loading stress has a significant influence on the structure. When the stress increases, the orientation of the pearlite lamellae becomes disordered, the pearlite lamellae are bent, the lamellae spacing is no longer uniform, and the hardness is improved.

Similar content being viewed by others

References

Masoumi M, De Lima NB, Tressia G, et al. Microstructure and Crystallographic Orientation Evolutions below the Superficial White Layer of a Used Pearlitic Rail[J]. J. Mater. Res. Technol., 2019, 8(6): 6 275–6 288

Kuziak R, Pidvysots’kyy V, Pernach M, et al. Selection of the Best Phase Transformation Model for Optimization of Manufacturing Processes of Pearlitic Steel Rails[J]. Arch.Civ. Mech. Eng., 2019, 19(2): 535–546

Inoue T. Macro-, Meso-, and Nanoscopic Metallo Thermo Mechanics[J]. J. Phys., 2004, 120: 3–20

Li GF, Liu J, Jiang GZ, et al. Numerical Simulation of Flow, Temperature and Phase Fields in U71Mn Rail-head Quenching Process[J]. Comput. Model New Technol., 2014, 18(1): 61–70

Sidhoum Z, Ferhoum R, Almansba M, et al. Experimental and Numerical Study of the Mechanical Behavior and Kinetics of the Martensitic Transformation in 304L TRIP Steel: Applied to Folding[J]. Int. J. Adv. Manuf. Tech., 2018, 97(5): 2 757–2 765

Denis S, Gautier E, Simon A, et al. Stress-phase Transformation Interactions-basic Principles, Modeling and Calculation of Internal Stress[J]. Mater. Sci. Tech-Lond., 1985, 1(10): 805–814

Denis S. Considering Stress-phase Transformation Interactions in the Calculation of Heat Treatment Residual Stresses[J]. J. Phys., 1996, 6(1): 159–174

Denis S. Sjostrom S. Simon A. Coupled Temperature, Stress, Phase Transformation Calculation Model Numerical Illustration of the Internal Stress Evolution during Cooling of a Eutectoid Carbon Steel Cylinder[J]. Mater. Trans., 1987, 18(7): 1 203–1 212

Denis S, Archambault P, Aubry C, et al. Modelling of Phase Transformation Kinetics in Steels and Coupling with Heat Treatment Residual Stress Predictions[J]. J. Phys., 1999, 9: 323–332

Lee SJ, Lee YK. Finite Element Simulation of Quench Distortion in a Low-alloy Steel Incorporating Transformation Kinetics[J]. Acta Mater., 2008, 56(7): 1 482–1 490

Leblond JB, Devaux J, Devaux JC. Mathematical Modelling of Transformation Plasticity in Steels I: Case of Ideal-plastic Phases[J]. Int J. Plasticity, 1989, 5(6): 551–572

Leblond JB. Mathematical Modelling of Transformation Plasticity in Steels II: Coupling with Strain Hardening Phenomena[J]. Int. J. Plasticity, 1989, 5(6): 573–591

Liu Y, Qin SW, Hao QG, et al. Finite Element Simulation and Experimental Verification of Internal Stress of Quenched AISI 4140 Cylinders[J]. Metall. Mater. Trans. A, 2017, 48: 1 402–1 413

De Oliveira WP, Savi MA, Pacheco PMCL. Finite Element Method Applied to the Quenching of Steel Cylinders using a Multiphase Constitutive Model[J]. Arch. Appl. Mech., 2013, 83(7): 1 013–1 037

Carlone P, Palazzo GS, Pasquino R. Finite Element Analysis of the Steel Quenching Process: Temperature Field and Solid-solid Phase Change[J]. Comput. Math. Appl., 2010, 59(1): 585–594

Bok HH, Choi JW, Suh DW, et al. Stress Development and Shape Change during Press-hardening Process using Phase-transformation-based Finite Element Analysis[J]. Int. J. Plasticity, 2015, 73: 142–170

Li YJ, Pan JS, Hu MJ, et al. Martensitic Phase Transformation Plastic-ity and Its Application in Numerical Simulation of Quenching[J]. J. Shanghai Jiaotong Univer., 2001, 35(3): 352–361

Li C, Li MV, Li SH, et al. Effect of Stresses on Martensite Transformation Kinetics and Transformation Plasticity of S34MnV Steel[J]. Mater. Res. Express, 2019, 6(7)

Chen L, Chang G, Wei R, et al. Stress Influence on Pearlite Transition Phase Transformation Plasticity of U75V Heavy Rail Steel[J]. Int. J. Plasticity, 2014, 21(5): 105–120

El Majaty Y, Leblond JB, Kondo D. A Novel Treatment of Greenwood-Johnson’s Mechanism of Transformation Plasticity-case of Spherical Growth of Nuclei of Daughter-phase[J]. J. Mech. Phys. Solids, 2018, 121: 175–197

Otsuka T, Brenner R, Bacroix B. FFT-based Modelling of Transformation Plasticity in Polycrystalline Materials during Diffusive Phase Transformation[J]. Int. J. Eng. Sci., 2018, 127: 92–113

Kaiser D, De Graaff B, Jung AM, et al. A Dilatometric Study on the Influence of Compressive Stresses on the Tempering of Martensitic AISI 4140 Steel-evidence of Transformation Induced Plasticity during Cementite Precipitation[J]. Mat. Sci. Eng. A-Struct., 2017, 705: 114–121

Li B, Zhu GM, Kang YL, et al. Determination and Study of Physical Parameters of U75V Rail Rolling Simulation[J]. Hot Work Technol., 2014, 43(17): 24–28

Song H, Gao M X, Jia H, et al. Study on the Phase Change Deformation of U75V Heavy Rail during the Cooling Process[J]. Int. J. Plasticity, 2011, 18(3): 95–100

Liu XY, Yang C, Yang XR. Dynamic Mechanical Behavior and Adiabatic Shear Bands of Ultrafine Grained Pure Zirconium[J]. J. Wuhan Univ. Technol., 2020, 35(1): 200–207

Pan L, He W, Gu BP. Effect of Crystallographic Orientation on Quenching Stress during Martensitic Phase Transformation of Carbon Steel Plate[J]. J. Wuhan Univ. Technol., 2017, 32(5): 1 213–1 219

Bohlke T, Neumann R, Rieger F. Two-scale Modeling of Grain Size and Phase Transformation Effects[J]. Steel Res. Int., 2014, 85(6): 1 018–1 034

Yeddu HK, Borgenstam A, Agren J. Stress-assisted Martensitic Transformations in Steels: A 3-d Phase-field Study[J]. Acta Mater., 2013, 61(7): 2 595–2 606

Acknowledgements

The authors gratefully acknowledge Science and Technology Innovation Guidance Project of Inner Mongolia Autonomous Region “Research and Application of Key Technology of the third Generation High Strength Heavy Load Wear Resistant Heat Treatment Rail”.

Author information

Authors and Affiliations

Corresponding author

Additional information

Funded by the Inner Mongolia Science and Technology Major Project(No. ZDZX2018024), the Natural Science Foundation of Inner Mongolia(No. 2019LH05016), the Research Program of Science and Technology at Universities of Inner Mongolia Autonomous Region of China(No. NJZY20089), and the Innovation Fund of Inner Mongolia University of Science and Technology(No. 2019QDL-B06)

Rights and permissions

About this article

Cite this article

Cen, Y., Chen, L., Chang, G. et al. Transformation Characteristics and Microstructure of Rail under Low Stress during Continuous Cooling. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 36, 269–279 (2021). https://doi.org/10.1007/s11595-021-2406-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-021-2406-x