Abstract

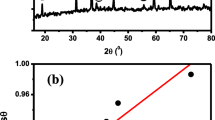

The effect of particle size on the density and resistivity of ITO green bodies and targets was systematically investigated. The experimental results show that the relative density of ITO green bodies decreases with the increase of ITO particle size. When the particle size is 10.7 nm, the relative density of ITO green bodies rises to the maximum value of 56.6%. The resistivity declines exponentially with the increase of particle size, which satisfies the exponential equation of R = exp(−41.823 × d). When the particle size is 41.6 nm, the resistivity reaches the minimum value of 0.8 Ω·cm. The relative density of ITO target decreases with the increase of particle size. Fine particles can increase the driving force of densification in initial stage. Electron mobility, caused by grain boundary scattering, will increase due to the increase of particle size or the decrease of grain boundary potential. When the particle size is 10.7 nm, the target with compact grain stacking and low porosity shows a maximum relative density of 99.25%, and the resistivity reaches the minimum value of 0.34×10−3 Ω·cm.

Similar content being viewed by others

References

Wang HW, Xu XJ, Zhang JR, et al. A Cost-effective Co-precipitation Method for Synthesizing Indium Tin Oxide Nanoparticles without Chlorine Contamination[J]. J. Mater Sci. Technol., 2010, 26(11): 1 037–1 040

Beji N, Souli M, Ajili M, et al. Effect of Iron Doping on Structural, Optical and Electrical Properties of Sprayed In2O3 Thin Films[J]. Superlattice. Microst., 2015, 81: 114–128

Zhong ZY, Lu Z, Long L, et al. Preparation and Property of Titanium-gallium Co-doped Zinc Oxide Semiconductor Thin Film[J]. New Chemical Materials, 2016, 44(8): 62–65

Lee HM, Kim SS, Kim HK. Artificially MoO3 Graded ITO Anodes for Acidic Buffer Layer Free Organic Photovoltaics[J]. Appl. Surf. Sci., 2016, 364: 340–348

Sunde TOL, Einarsrud MA, Grande T. Solid State Sintering of Nano-crystalline Indium Tin Oxide[J]. J. Eur. Ceram. Soc., 2013, 33(3): 565–574

Friend RH, Gymer RW, Holmes AB, et al. Electroluminescence in Conjugated Polymers[J]. Nature, 1999, 397(6715): 121–128

Kim M, Kim J, Cho J, et al. A Study of the Characteristics of Indium Tin Oxide after Chlorine Electro-chemical Treatment[J]. Mater. Res. Bull., 2016, 82: 115–121

Baldo MA, Thompson ME, Forrest SR. High-efficiency Fluorescent Organic Light-emitting Devices using a Phosphorescent Sensitizer[J]. Nature, 2000, 403(6771): 750–753

Müller CD, Falcou A, Reckefuss N, et al. Multi-colour Organic Light-emitting Displays by Solution Processing[J]. Nature, 2003, 421(6925): 829–833

Sun Y, Giebink NC, Kanno H, et al. Management of Singlet and Triplet Excitons for Efficient White Organic Light-emitting Devices[J]. Nature, 2006, 440(7086): 908–912

Alam MZ, De LI, Boyd RW. Large Optical Nonlinearity of Indium Tin Oxide in Its Epsilon-near-zero Region[J]. Science, 2016, 352(6287): 795–797

Huang M, Hameiri Z, Aberle AG, et al. Influence of Discharge Power and Annealing Temperature on the Properties of Indium Tin Oxide Thin Films Prepared by Pulsed-DC Magnetron Sputtering[J]. Vacuum, 2015, 121: 187–193

Meng QY, Li SQ, Kang YX, et al. Electrical and Optical Properties of Nano Aluminum Film/Particle Structure[J]. J. Wuhan Univ. Technol., 2017, 32(5): 989–993

Wang Y, Liu JX, Liu C. Effect of Nanosized ITO Powders on Preparation of ITO Targets by Sintering Method[J]. Rare Metal Mat. Eng., 2011, 40(12): 2 179–2 183

Zhu GS, Xu HR. Study on the Preparation of ITO Ceramic Target with High Density[J]. Journal of Yunnan University (Natural Sciences Edition), 2007, 29(6): 601–606

Sasaki T, Endo Y, Nakaya M, et al. One-step Solvothermal Synthesis of Cubic-shaped ITO Nanoparticles Precisely Controlled in Size and Shape and Their Electrical Resistivity[J]. J. Mater. Chem., 2010, 20(37): 49–53

Liang F, Liu JX. Sintering, Microstructure and Electricity Properties of ITO Targets with Bi2O3-Nb2O5 Addition[J]. Ceram. Int., 2017, 43(8): 5 856–5 861

Mei FS, Qin K, Yuan TC, et al. Effects of Oxygen Flow Velocity on the Sintering Properties of ITO Targets[J]. J. Mater. Sci.-Mater. El., 2017, 28(3): 14 711–14 719

Mei FS, Yuan TC, Li RD, et al. Improving the Densification of Indium Tin Oxide Targets via Secondary Cold Isostatic Pressing and Oxygen Exchange Treatments[J]. Scripta Mater., 2018, 155: 109–113

Sathiaraj TS. Effect of Annealing on the Structural, Optical and Electrical Properties of ITO Films by RF Sputtering under Low Vacuum Level[J]. Microelectron. J., 2008, 39(12): 1 444–1 451

Coble RL. Sintering Crystalline Solids. I. Intermediate and Final State Diffusion Models[J]. J. Appl Phys., 1961, 32(5): 787–792

Seabaugh MM, Kerscht IH, Messing GL. Texture Development by Templated Grain Growth in Liquid-phase-sintered α-alumina[J]. J. Am. Ceram. Soc., 1997, 80(5): 1 181–1 188

Lee JH, Kim YH, Sang JA, et al. Grain-size Effect on the Electrical Properties of Nanocrystalline Indium Tin Oxide Thin Films[J]. Mater. Sci. Eng. B-Adv., 2015, 199: 37–41

Author information

Authors and Affiliations

Corresponding author

Additional information

Funded by the Beijing Municipal Natural Science Foundation (No. 2192041)

Rights and permissions

About this article

Cite this article

Zhai, X., Peng, X., Ma, Y. et al. Effect of Particle Size on Target Sintering Behavior of Cubic ITO Nanopowders. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 35, 1098–1103 (2020). https://doi.org/10.1007/s11595-020-2360-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-020-2360-z