Abstract

Single-step solvothermal method is used to prepare Cu/CuSe as an electrocatalyst for methanol electro-oxidation reaction (MOR). 1,3-butan-diol is selected as a reaction medium, whose viscosity and complex formation with Cu(II) ions dictate the catalyst morphology. The catalyst has a macroporous structure, which is composed of nanoballs with a high purity, crystallinity, and uniform morphology. The electrocatalyst is excellent for MOR, as it delivers current density of 37.28 mA/mg at potential of 0.6 V (vs Ag/AgCl) in the electrolyte of 1 M KOH and 0.75 M methanol at a 50 mV/s scan rate under conditions of cyclic voltammetry. The catalyst also shows good stability for 3600 s with negligible charge transfer resistance and high electrochemical active surface area (ECSA) value of 0.100 mF/cm2.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Technology advancement has triggered fast depletion of fossil fuels, which resulted in energy crisis and environmental pollution. These issues attract researcher’s attention, to develop renewable energy sources such as direct methanol fuel cells (DMFCs) [1, 2]. DMFCs produce energy from MOR, which exhibits superior activity, rich source (methanol), and high energy density [3, 4]. Additionally, MOR can reduce carbon emission as well as methanol content in industrial technical waste [5, 6]. Platinum is an excellent catalyst for MOR but the high price, low abundance, and CO poisoning hinder its application [7, 8].

In this regards, transition metal–based electrocatalysts, such as copper selenides are consider to be promising material for MOR, due to high activity, multiple crystal phases, and multiple oxidation states of Cu in selenides [9]. Copper strongly facilitates alcohol oxidation, in particular in an alkaline medium [10]. Combining copper with selenium, e.g., copper selenides with the unique metallic properties [1], may further improve the applications in the direction of electrocatalysis. The available work about copper selenides is related to PtCu/Cu2-xSe nanowires, which deliver a total current density of 5.29 A/mg for methanol oxidation, which is 5.3-fold higher than commercially available Pt/C [9].

With this motivation, a single phase Cu/CuSe was synthesed via simple, one-step solvothermal reaction for MOR application. The catalyst morphology consists of small nanoballs which aggregate to develop macroporous morphology with excellent performances toward MOR. The electrocatalyst delivers current density of 37.28 mA/mg at potential of 0.6 V (vs Ag/AgCl) in the electrolyte of 1 M KOH and 0.75 M methanol at a 50 mV/s scan rate under conditions of cyclic voltammetry. The catalyst also shows good stability for 3600 s with negligible charge transfer resistance and high electrochemical active surface area (ECSA) value of 0.100 mF/cm2.

Materials and methods

One-step simple solvothermal method was used for synthesis of Cu/CuSe. Typically 1.2 mmol of Cu(NO3)2·2H20 and 0.8 mmol of Na2SeO3 were mixed simultaneously in 30 mL of 1,3-butane-diol and stirred to form a homogeneous mixture. The mixture was transferred into 50 mL stainless steel Teflon autoclave and heated at 180 °C for 16 h. Then, the sample was cooled down to room temperature to collect sample after centrifuging. The sample was washed with water and ethanol to remove impurities and finally dried and stored in ambient conditions to be used for further application.

Electrochemical application

A three-electrode system connected with µAutolab potentiostat was used for electrochemical applications. Pt rod, Ag/AgCl (3 M KCl), and glassy carbon electrode (GCE) were used as auxiliary, reference, and working electrode, respectively. Five milligrams of the sample was added to a mixture of 750 µL of water and 250 µL of ethanol and ultrasonicated for 20 min until full homogenization. The as-prepared suspension (2 µL) was drop-casted on a freshly cleaned GCE surface and drying at room temperature; subsequently, 2 µL of Nafion was dropped on the modified GCE surface and dried. The final modified GCE was used for electrochemical application in an alkaline solution (1 M KOH) with different concentrations of methanol (0.25–1 M) at different scan rates (25–100 mV/s) via cyclic voltammetry (CV). Electrochemical impedance spectroscopy (EIS) was studied at open circuit potential, at frequency range of 0.1–105 Hz with AC amplitude of 5 mV. Chronoamperometry was conducted at potential of 0.6 V vs Ag/AgCl for continuous 3600 s. The electrochemical active surface area (ECSA) was calculated from CVs collected in the non-faradic region at scan rates of 20 to 100 mV/s.

Characterization

The electrocatalyst is characterized with STEM (HR-SEM, Nova NanoSEM 450, FEI, Hillsboro, OR, USA, equipped with STEM II detector) to determine its morphology via scanning electron microscopy (SEM) and transmission electron microscopy (TEM). The presence of metal and the purity of sample were determined by energy dispersive spectroscopy (EDS, EDAX/AMETEK, Materials Analysis Division, Model Octane Super, Mahwah, NJ, USA). The purity and phase composition of the sample were determined with XRD (Aeris 1.2.0 (PAN analytical) diffractometer with Cu radiation and PIXcel 1D detector).

Result and discussion

Formation mechanism

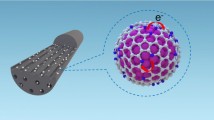

The material is synthesized in 1,3-butane-diol solvent, which is critically important for the final morphology of the material, as it forms copper complexes with Cu2+ ions, added in the form of Cu(NO3)2. In the course of the reaction with selenite ions, the slow release of copper ions from the organic complexes leads to formation of a large number of nucleation centers, resulting in nanosized CuSe deposit. At the same time, relatively high viscosity of the organic medium slows down the kinetics of the reaction, which also contribute to more nucleation centers, resulting in a ball-like morphology of the synthetized material [11]. Some of the Cu set in the vicinity of crystal or in between the ball morphology of the sample to give Cu/CuSe composite. It is most likely that nanoballs are initially formed, which bind to each other in the course of the reaction yielding finally a macroporous morphology.

Morphology and composition

The SEM images (Fig. 1a, b) confirmed that the material is composed of nanosized spherical particles. The nanoballs are bound together to develop macroporous morphology of the materials. The binding of nanoballs yields rough/irregular surface of the material which is responsible for maximizing active spots for electrocatalytic reaction. SEM data also confirmed that material is uniformly developed. TEM study (Fig. 1c, d) supported SEM data and revealed that the material is composed of nanoballs with different sizes; presumably, initially formed nanoballs aggregate, leading to irregular macroporous morphology. Energy dispersive X-ray (EDX) data (Fig. 2a) revealed that the synthesized material is mainly composed of Cu and Se, which confirmed the purity of the sample. The porosity of the material increases the surface area, providing a short distance for electrolyte to interact with active materials, which is critical for intensive MOR activity.

The XRD graph shown in Fig. 2b consists of sharp peaks at 35.5°, 42°, 49.2°, and 80.8° ascribed fringe values of (013), (014), (100), and (019) corresponding to COD # 04–014-1982 of the hexagonal crystal of CuSe. The peaks present at 43.3°, 51.2°, and 73° are corresponded to fringe value of (111), (200), and (220) of cubic copper crystal according to COD # 01–088-3992. The XRD data confirmed that the electrocatalyst is highly pure, crystalline, and composed of copper and copper selenide.

MOR application

MOR application of Cu/CuSe is studied in an alkaline solution (1 M KOH) with different concentrations (0–1 M) of methanol, at scan rates from 25 to 100 mV/s in CV (Fig. 3a). The cyclic voltammetry was first applied in 1 M KOH solution without methanol with repetitive potential cycling until obtaining a stable voltammetric response, at scan rate of 50 mV/s. The CV shows a small anodic current tail in the supporting electrolyte (1 M KOH) with an onset potential of 0.65 V (vs Ag/AgCl). As methanol was added in the electrolyte solution (0.25 M), the current increased dramatically and the onset potential of the anodic current diminished to 0.45 V (vs Ag/AgCl), which is 200 mV lower than in the absence of methanol. Such a decrease in the onset potential and increase of the current density are attributed to MOR. As concentration of methanol increases, the onset potential decrease slightly, but the current enhances greatly. At methanol concentration of 0.75 M, the system shows the best performance, as the further increase to 1 M methanol does not produce significant current change. It confirmed that the 1 M KOH and 0.75 M methanol are suitable combination for best MOR application, as it provide the highest current density of 37.28 mA/mg at potential of 0.60 V (vs Ag/AgCl) and low Tafel slope of 128.1 mV/dec, as shown in Fig. 3a and b, respectively. The current density was normalized by ECSA as shown in Fig. S1. The current density increased after normalization, which confirmed that MOR is not only related to ECSA but it is also related to the materials conductivity, synergism/interaction of Cu and CuSe, which enhanced its intrinsic activity for MOR [7, 12].

Detail current density and the Tafel slope with respect to methanol concentrations are shown in Table 1. The system is also studied at a varying scan rate over the interval 25–100 mV/s. As the scan rate enhances, the onset potential decreases concomitantly; in addition, the current density increases due to diffusional transfer effect of the methanol toward the electrode surface (Fig. 3c). Thus, the scan rate of 50 mV/s is considered as an optimal value, taking into account the electrocatalytic rate of the electrode reaction of methanol.

Stability is a vital feature of any catalyst for its practical application. Cu/CuSe shows a very good stability for 3600 s in the course of chronoamperometric experiment at potential of 0.60 V in 1 M KOH, containing 0.75 M methanol (Fig. 3d). The electrochemical active surface area (ECSA) is calculated from the double-layered capacitance (Cdl) obtained from CV (− 0.20 to − 0.10 V, non-faradaic potential range) at scan rates varying from 20 to 100 mV/s [13]. The current density Ja−c (a = anodic, c = cathodic at potential of − 0.15 V vs Ag/AgCl) is plotted against scan rate and gets linear slope. Half of the slope is equal to ESCA, which is equal to 0.100 mF/cm2 for Cu/CuSe as shown in Fig. 4a. The EIS is collected in 1 M KOH containing 0.75 M methanol over the frequency interval 0.1–105 Hz, with the AC amplitude of 5 mV, at open circuit potential. EIS (Fig. 4b) shows almost negligible semi-circle at high frequency which confirmed negligible charge transfer (Rct). The graph (Fig. 4c) also shows almost horizontal line at low frequency which confirmed its good capacitance due to large surface. The related bode plot is shown in Fig. S2 [13].

Conclusion

The electrocatalyst is prepared via simple solvothermal method. The catalyst exhibits macroporous morphology which is composed of nanoballs. This unique morphology of the sample is consequence of the usage of 1,3-butane-diol as a reaction medium. The electrocatalyst shows good performance for methanol oxidation. The best performance is obtained in 1 M KOH and 0.75 M methanol at scan rate of 50 mV/s. Electrocatalyst shows current density of 37.28 mA/mg, with low charge transfer resistance, and a long-term stability of 3600 s at potential of 0.6 V (vs Ag/AgCl). The catalyst exhibits ECSA value of 0.100 mF/cm2.

Data availability

Data will be available on request.

References

Shi Y, Li H, Ao D, Chang Y, Xu A, Jia M, Jia J (2021) 3D nickel diselenide architecture on nitrogen-doped carbon as a highly efficient electrode for the electrooxidation of methanol and urea. J Alloy Compd 885:160919

Jia J, Zhao L, Chang Y, Jia M, Wen Z (2020) Understanding the growth of NiSe nanoparticles on reduced graphene oxide as efficient electrocatalysts for methanol oxidation reaction. Ceram Int 46:10023–10028

Zhao F, Ye J, Yuan Q, Yang X, Zhou Z (2020) Realizing a CO-free pathway and enhanced durability in highly dispersed Cu-doped PtBi nanoalloys towards methanol full electrooxidation. J Mater Chem A 8:11564–11572

Luo Q, Peng M, Sun X, Asiri AM (2015) In situ growth of nickel selenide nanowire arrays on nickel foil for methanol electro-oxidation in alkaline media. RSC Adv 5:87051–87054

Liu H, Qin J, Zhao S, Gao Z, Fu Q, Song Y (2019) Two-dimensional circular platinum nanodendrites toward efficient oxygen reduction reaction and methanol oxidation reaction. Electrochem Commun 98:53–57

Xie J, Zhang Q, Gu L, Xu S, Wang P, Liu J, Ding Y, Yao YF, Nan C, Zhao M, You Y, Zou Z (2016) Ruthenium–platinum core–shell nanocatalysts with substantially enhanced activity and durability towards methanol oxidation. Nano Energy 21:247–257

Feng Z, Wang E, Huang S, Liu J (2020) A bifunctional nanoporous Ni–Co–Se electrocatalyst with a superaerophobic surface for water and hydrazine oxidation. Nanoscale 12:4426–4434

Yu Y, Wang X-L, Zhang H-K, Cao Z-Q, Wu H-Y, Jia B-R, Yang J-J, Qu X-H, Qin M-L (2022) Facile synthesis of transition metal carbide nanoparticles embedded in mesoporous carbon nanosheets for hydrogen evolution reaction. Rare Met 41:2237–2242

Peng H, Ren J, Wang Y, Xiong Y, Wang Q, Li Q, Zhao X, Zhan L, Zheng L, Tang Y, Lei Y (2021) One-stone, two birds: alloying effect and surface defects induced by Pt on Cu2−xSe nanowires to boost C-C bond cleavage for electrocatalytic ethanol oxidation. Nano Energy 88:106307

Hsieh M-W, Whang T-J (2013) Electrodeposition of PdCu alloy and its application in methanol electro-oxidation. Appl Surf Sci 270:252–259

Hussain I, Lamiel C, Sahoo S, Ahmad M, Chen X, Javed MS, Qin N, Gu S, Li Y, Nawaz T, Ansari MZ, Zhang K (2022) Factors affecting the growth formation of nanostructures and their impact on electrode materials: a systematic review. Mater Today Phys 27:100844

Feng Z, Shi T, Liu W, Zhang W, Zhang H (2022) Highly active bifunctional electrocatalyst: nanoporous (Ni, Co)0.85Se anchored on rGO for water and hydrazine oxidation. Int J Energy Res 46:15938–15947

Hussain S, Ullah N, Zhang Y, Shaheen A, Javed MS, Lin L, Shah SB, Liu G, Qiao G (2019) One-step synthesis of unique catalyst Ni9S8@ C for excellent MOR performances. Int J Hydrogen Energy 44:24525–24533

Funding

Authors acknowledge with gratitude the support from the National Science Centre of Poland through the Opus Lap grant no. 2020/39/I/ST4/01854.

Author information

Authors and Affiliations

Contributions

N. U.: supervision, conceptualization, writing—original draft, and investigation; D. G.: supervision, writing—review and editing, and resources; K. K.: review and editing; M. M.: investigation; K. R. S.: investigation; J. G.: investigation; V. M.: formal analysis, writing—review and editing and supervision.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Ullah, N., Guziejewski, D., Koszelska, K. et al. Formation mechanism of macroporous Cu/CuSe and its application as electrocatalyst for methanol oxidation reaction. Ionics 29, 4835–4840 (2023). https://doi.org/10.1007/s11581-023-05182-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11581-023-05182-w