Abstract

In this study, kefir-containing healthy snacks were produced by using 3D food printing technique. Although kefir has many important health benefits, its consumption is quite low. It was thought that kefir-containing snacks in attractive shapes produced with a 3D food printer could increase the kefir consumption. For this purpose, disintegrated kefir gels prepared with starch, gelatin and alginate were used as inks. First, the minimum gelation concentration (C*) of each gelator was determined. Then, disintegrated gels with concentrations of C*, C*+1%, and C*+2% were prepared with each gelator and the effect of gelator concentration on printing quality was investigated for each gelator. Printing quality was associated with storage modulus, loss factor and flow behavior, and the minimum gelator concentration required for a suitable formulation for 3D printing (highest printability and dimensional stability) was determined as 5%, 6% and 3% for starch, gelatin and alginate, respectively. Lactobacillus spp. and Lactococcus spp. contents of the starch-based sample were found to be significantly lower than those of fresh kefir and gelatin and alginate-based samples. Sensory properties and consumer appreciation were lower for the gelatin-based sample. Due to the high printing quality (98% printability and 99% dimensional stability), high probiotic content (7.81 and 8.13 log cfu/ml Lactobacillus spp. and Lactococcus spp. content, respectively) and high consumer appreciation (4.71 out of 5 for general acceptance), alginate-based sample (containing 3% alginate) was chosen as the best sample. In conclusion, new, chewable, alive, alternative kefir products were successfully developed for consumers seeking new ways of kefir consumption.

Similar content being viewed by others

Introduction

The 3D printing technique is a developing technology in which a 3D structure is produced by the deposition of materials layer by layer. In the food industry, 3D printing is used to create 3D food objects in attractive shapes with texture, content, and sensory characteristics suitable for personal preferences and needs [1]. Considering all, 3D printers are thought to be a developing production technique with a high potential in the preparation of customized food products. It was stated that using 3D food printers in food manufacturing can solve various problems like preparing suitably textured foods for people with swallowing difficulties, preparing high nutrition snacks for children, and utilization of alternative food sources such as ground mealworms [2,3,4].

Foods to be processed with extrusion-based 3D printers must have a shear-thinning flow and a significant shear stress and elastic modulus values. Shear-thinning makes easier to print and sufficient shear stress and elastic modulus values ensure that better retention of structure/shape after printing [5, 6]. When developing formulations for processing in extrusion-based 3D printers, the formulations of products were modified or various thickeners were used for samples that are naturally unsuitable for printing (like fruit juices) [7, 8]. Further, some studies utilized microgel formulations as inks for bioprinting [9]. It was stated that microgels have shear-thinning flow behavior and sufficient shear stress [9]. One of the methods used in microgel production is the breaking-down method, in which the macrogels are broken down into small pieces [10]. This method is similar to the method used in this study to produce disintegrated gels, and therefore it was thought that disintegrated gels might be suitable for processing in 3D food printers.

Kefir is a traditional fermented dairy drink produced with starter cultures or kefir grains. Basic nutrients in kefir are similar to those of milk, and moreover the fermentation process improve the nutritional/health value. In addition, it is rich in probiotic microorganisms, especially lactic acid bacteria. Kefir has various health benefits like anti-carcinogenic, anti-inflammatory, cholesterol-lowering, anti-hypertensive, anti-microbial, anti-oxidative, anti-diabetic, anti-allergenic and immunological effects [11, 12]. In a study, it was observed that approximately 70% of the people did not consume kefir, and approximately 30% of them did not consume kefir due to its sensory properties [13]. In another study, it was determined that approximately 85% of the people did not consume kefir [14].

In this study, kefir-containing healthy snacks were produced with 3D food printing technique by using disintegrated kefir gels prepared with starch, gelatin, and alginate. This healthy traditional drink has been used for the first time to be processed in a 3D food printer. Effect of gelator concentration on the rheological properties and 3D printing quality was investigated. Also sensory, textural, and microbial properties and compositions of the 3D printed kefir objects were determined. Although kefir has many important health benefits, its consumption is quite low as mentioned above. Therefore, offering kefir in a different product form like 3D printed chewable object with attractive shapes might satisfy the needs of some consumers, or at least, would provide a new way of kefir consumption. The objectives were to study the preparation parameters of 3D printed kefir gels, and comprehensive evaluation of the properties of the 3D printed objects based on kefir to offer new food alternatives.

Materials and Methods

Materials

Fresh kefir (standard liquid commercial product, stored at 4 °C) was purchased from Altınkılıç Food and Milk Industry Trade Inc. (Çanakkale, Turkiye) and stored in the fridge (4 °C) throughout the study. Corn starch (food grade), sodium alginate (food grade) and bovine gelatin powder (220 Bloom, food grade) used in gel production were obtained from Alfasol (Istanbul, Turkiye). All chemicals and solvents used in the analyses were of analytical or chromatographic grade and purchased from Sigma (St. Louis, MO, USA) and Merck Co. (Darmstadt, Germany).

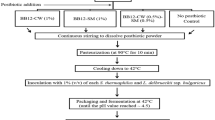

Production of Kefir Gels

Corn starch, sodium alginate and bovine gelatin were used separately in the production of kefir gels and the minimum gelation concentrations (C*) were determined for each gelator. The concentrations were decided as a result of preliminary trials and 4 levels were tested for each gelator. Corn starch gels were produced according to a previous study with minor modifications [15]. For this purpose, starch was added to kefir at concentrations of 4, 5, 6, 7% (w/v). After that, kefir-starch mixture was mixed at 85 °C for 10 min. Then, the mixture was kept for 24 h at 4 °C. Sodium alginate gels were prepared by the “internal gelification” method based on a previous study with minor modifications [16]. For this purpose, an amount of calcium ion (equivalent to half the molar content of alginate monomer) was added to kefir and dissolved by mixing for 5 min at 25 °C. After that, sodium alginate was added to kefir at concentrations of 1, 2, 3, 4% (w/v). Then, kefir-alginate mixture was mixed for 5 min at 25 °C. Then, the mixture was kept for 24 h at 4 °C. To prepare gelatin gels, gelatin powder was added to kefir at concentrations of 3, 4, 5, 6% (w/v). After that, kefir-gelatin mixture was mixed at 35 °C for 15 min. Then the mixture was kept for 24 h at 4 °C.

Determination of Minimum Gelation Concentration

Minimum gelation concentrations (C*) were determined separately for each gelator and disintegrated kefir gels were produced considering these concentrations. The minimum gelation concentrations (C*) were determined visually according to a previous study [17]. In visual evaluation, the tubes were turned upside down and the samples without flow and solid appearance were accepted as gel.

Rheological properties of kefir gels were also determined. In oscillatory rheological analyses of the kefir gels, storage modulus (G’), loss modulus (G’’) and loss factor (tan δ) values were evaluated. Rheological analyses were accomplished by using a DHR 2 rheometer (TA Instruments, USA) equipped with cross-hatched parallel plate geometry (40 mm diameter and 1000 μm gap). Parameters used in the analyses were selected based on the method used in a previous study [17]. First, amplitude sweep (strain = 0.1–100%) tests were applied at 25 °C and 1 Hz frequency to determine the linear viscoelastic region (LVR) for each gel sample. After that, frequency sweep (0.1 to 100 Hz) tests were applied for each gel sample at 25 °C and the LVR strains. For each sample, storage modulus (G’), loss modulus (G’’) and loss factor (tan δ) values were measured.

Production of Disintegrated Kefir Gels

After the determination of minimum gelation concentration (C*), three concentration levels, including the minimum gelation concentration, were selected for each gelator (C*, C*+1%, C*+2%), and these concentrations were used to produce the disintegrated kefir gels. For production of disintegrated kefir gels, gels were produced as mentioned above with the selected concentrations, and each gel was mixed with distilled water (1:1, weight: volume). Then, each gel in the water was broken down into small pieces with a blender (22,000 rpm, 1 min) (Russell Hobbs, RRH Small Electric Appliances Limited Company, Istanbul, Turkey). Finally, these disintegrated gels were separated from the aqueous phase by centrifugation (6800g, 20 min, 25 °C) (Sigma 2-16 K, Postfach, Germany).

Rheological Analyses of the Disintegrated Kefir Gels

Rheological analyses of the disintegrated kefir gels were performed by using a DHR 2 rheometer (TA Instruments, USA) equipped with cross-hatched parallel plate geometry (40 mm diameter and 1000 μm gap). Amplitude sweep (0.1–100% strain, 1 Hz frequency, 25 °C analysis temperature) and frequency sweep (0.1–100 Hz frequency, LVR strain, 25 °C analysis temperature) tests were applied based on the method used in a previous study [17]. For each sample, storage modulus (G’), loss modulus (G’’) and loss factor (tan δ) values were determined.

Viscosity and shear stress measurements were also accomplished according to a previous study [8]. Analyses were applied at the shear rate ranging from 1 to 100 s− 1 at 25 °C.

3D Printing Process

An extrusion-based 3D printer (Wiiboox Sweetin, China) with CURA 15.02 software (Ultimaker B.V., Netherlands) was used to process the disintegrated kefir gels. 3D objects were produced in the form of cylinder (diameter: 30 mm, height: 30 mm). Printing parameters were as follows; 25 °C printing temperature, 40 mm/s printing speed, 100% filling rate, 100% flow rate, 0.84 mm filament diameter, 2 mm bottom/top thickness. Printing parameters used in this study were selected by considering preliminary trials and previous studies [3, 18].

Determination of Suitability of Disintegrated Kefir Gels for Processing in a 3D Printer

The suitability of disintegrated kefir gels for processing in a 3D printer was assessed by conformity of the printed objects to the target geometry and dimensional stability (the printed objects’ stability over time). Methods in a previous study were used in these analyses [8]. For determination of printability (conformity to target geometry), height of the printed object was measured with a digital caliper immediately after the printing process and compared with the height determined with the software. For determination of dimensional stability, deformation rates of 3D objects were examined. For this purpose, height of the printed object was measured with a digital caliper immediately after the printing process. After that, printed object was kept at 25 °C for 1 h and height of the object was measured again. Finally, the change in the height was calculated. Printability and dimensional stability values were calculated by using the following Eqs. (1) and (2), respectively.

According to the results of these analyses, the minimum gelator concentration required for a suitable formulation for 3D printing process (highest printability and dimensional stability) was determined for each gelator separately and these concentrations were used for the subsequent parts of the study.

Determination of Physicochemical Properties of the 3D Printed Objects and Kefir

Moisture, fat, protein, and ash contents of the 3D printed objects and liquid kefir were determined according to methods of AOAC 925.23, AOAC 2000.18, AOAC 991.20 and AOAC 945.46, respectively [19]. Color values were measured using a Minolta colorimeter CR 400 (Minolta Camera Co., Osaka, Japan). The pH and viscosity values of liquid kefir were measured with a pH meter (Sartorius, Germany) and a rotational viscometer (Brookfield viscometer DV ΙΙ + Pro, Brookfield Engineering, USA), respectively.

Texture Analyses of the 3D Printed Objects

Texture profiles were determined by using TA-HD Plus Texture Analyzer (Stable Micro Systems Ltd., UK) equipped with TTC Spreadability Rig (Stable Micro Systems Ltd., UK). The measurement parameters were as follows; compression test mode, 3 mm/s test speed, 10 mm/s post-test speed, distance as target mode and 23 mm distance.

Microbial Analyses of the 3D Printed Objects and Kefir

10 g of sample were mixed with 90 mL physiological saline (0.85% NaCl, Sigma, USA) solution. Then, homogenization was carried out for 1 min in the Stomacher and appropriate dilutions of the suspension were prepared using physiological saline solution. Lactobacillus spp. and Lactococcus spp. counts were performed according to the study of Uskudar Guclu et al. (2021) with minor modifications [20]. Lactobacillus spp. count was performed according to the pour plate method with De Man-Rogosa-Sharpe agar (MRS agar) (HiMedia, India) and the incubation was carried out under anaerobic conditions in an anaerobic cabin (Electrotek 400TG, UK) (80% N2, 10% CO2, 10% H2) at 30 °C for 72 h [20]. Lactococcus spp. count was performed according to the pour plate method with M-17 Agar (Merck, Germany) and the incubation was accomplished under anaerobic conditions at 37 °C for 48 h [20]. The yeast content was determined according to the pour plate method with Dichloran Rose Bengal Chloramphenicol Agar (DRBC Agar) (Merck, Germany) and the incubation was carried out at 25 °C for 5 days [21]. The microbiological analyses were completed on fresh samples, and after the 6th and 12th days of storage. In a preliminary study, microbial spoilage was observed in the samples after the 12th day. Therefore, the periods of analyses were selected accordingly.

Sensory Descriptive Analyses of the 3D Printed Objects

Sensory descriptive analysis was applied with Quantitative Descriptive Analysis (QDA) technique [22]. There were six female and four male volunteer panelists aged between 24 and 53. These panelists were trained at least 15 h in different days and sessions. There were 5 sessions and each session lasted about 3 h in separate 5 days. A signed consent form indicating that the samples were food-grade and safe was provided to panelists. Under the management of the panel leader, eleven different descriptive terms were developed for the samples. Descriptive terms and their references used in these analyses are provided in Table 1. Samples were coded with three-digit random numbers and served at room temperature to the panelists at different evaluation sessions. A 10 cm line scale from 0 at minimum intensity to 10 at maximum intensity was used to quantify the sensory characteristics. Water, unsalted cracker, dry coffee, and expectoration cups were provided to panelists besides samples. All tests were accomplished under daylight at room temperature. 3D printed kefir objects were produced two times and analysis was done in duplicate for each of the production replicates.

Consumer Tests of the 3D Printed Objects

Hedonic test (degree of liking) was applied to determine the degree of consumer acceptance [22]. For this purpose, the same consent form was provided, and the samples were coded and served at room temperature to volunteer consumers. Samples were evaluated by 100 volunteer consumers (80 female, 20 male, aged between 19 and 53) by using 5-point hedonic scale (1 = Dislike extremely, 5 = Like extremely). Samples were evaluated in terms of “appearance”, “smell/aroma”, “taste/flavor”, “mouthfeel” and “general acceptance”. The term “appearance” was evaluated in terms of shape integrity. The terms “smell/aroma” and “taste/flavor” were evaluated according to consumer acceptance considering the characteristic taste and aroma of kefir. The term “mouthfeel” was evaluated based on characteristics such as hardness, stickiness, chewiness, etc. The term “general acceptance” was evaluated considering all these attributes. Water, unsalted cracker, and expectoration cups were provided to consumers besides samples.

Statistical Analysis

3D printed kefir objects were produced two times as two replicates, and every listed analysis was done at least in duplicate or triplicate for each of the production replicates. The collected data were analyzed with ANOVA and treatment groups were compared with Tukey’s test, and the sensory data were analyzed by the nonparametric Kruskal–Wallis test. Minitab Ver. 21.4.2 (Minitab, LLC., USA) and SPSS (SPSS Inc., USA) package software programs were used for the statistical analyses [23, 24]. The level of confidence was at least 95% in this study.

Results and Discussion

Minimum Gelation Concentrations

Since the 3D printing was conducted at 25 °C, the minimum gelation concentration (C*) of each gelator was determined at that temperature by visual evaluation. Rheological measurements were also accomplished at that temperature.

For visual evaluation, tubes that turned upside down are shown in Fig. 1. An unsolid appearance with flow was observed for the samples at 4%, 3%, and 1% concentrations for starch, gelatin, and alginate, respectively. Hence, the minimum gelation concentrations (C*) for corn starch, bovine gelatin and sodium alginate in the gelation of kefir were determined as 5%, 4% and 2%, respectively.

The rheological properties (storage modulus (G’), loss modulus (G’’) and loss factor (tan δ)) of the starch, gelatin and alginate-based kefir gels are presented in Figs. 2 and 3, and Fig. 4, respectively. The solid-like behavior is characterized by the storage modulus (G’) and loss modulus (G’’) is the liquid-like response. Loss factor (tan δ = G’’/G’) indicates the material dominant behavior. Higher tan δ value indicates more fluid-like behavior and lower tan δ value indicates more solid-like behavior [25]. For all gelators, significant increases were observed in the storage modulus values with increasing the gelator concentrations. Additionally, for all gelators, tan δ values relatively decreased as gelator concentrations increased. In previous studies, the relationship between gel strength and gelator concentration was associated with greater water absorption by starch granules for starch gels, formation of the greater number of junction zones for gelatin gels, and the degree of interaction between calcium ions and sodium alginate monomers for alginate gels [26,27,28]. When the storage modulus and loss factor values were considered, liquid-like behavior were more dominant at 4%, 3%, and 1% concentrations for corn starch, bovine gelatin and sodium alginate, respectively. It can be said that rheological analysis results supported to visual evaluation.

To the best of our knowledge, there is no study about kefir gels produced with starch, gelatin or alginate for direct comparison. In a study, starch suspensions ranging from 2 to 20% (w/v) were prepared with distilled water and it was observed that gel was formed even at the concentration of 2% for maize starch [29]. In another study, dairy ingredients were added at 5% and 10% concentrations and their effects on the starch gel were investigated. It was observed that dairy ingredients reduced the gel hardness and peak viscosity in starch gels [30]. As a result, dairy ingredients generally weaken the starch gel structure, therefore, it was thought that higher starch concentration was needed in the production of starch-based kefir gel. In a study, rheological properties of gelatin gels were investigated, and it was observed that as the gelatin concentration increased, the melting point of the gel increased. Gels with melting point of 29–33 °C, 27–32 °C and 25–27 °C were obtained with 5.0%, 2.5% and 1.0% gelatin, respectively [27]. In our study, in the visual evaluation applied at 25 °C, gel formation was not observed with 3% gelatin. In another study, the gel strength of bovine gelatin gel (6.67% gelatin) was examined at pH 3 to 10, and it was found that gel strength decreased as pH decreased [31]. Relatively higher gelatin concentration was needed for kefir gel production in our study, probably due to differences in physicochemical properties of the systems such as composition, pH, etc. In a study, the optimal composition of alginate hydrogel was determined as 2.7% alginate and 0.9% CaCl2 [32]. In another study, well gelatinous samples were obtained with alginate in distilled water at the concentration of 1.5 and 2% [33]. Results of this study concur with the literature in terms of alginate-based kefir gels.

As stated above, three concentration levels, including the minimum gelation concentration, were selected for each gelator (C*, C*+1%, C*+2%). For this purpose, corn starch at concentrations of 5%, 6%, and 7%, bovine gelatin at concentrations of 4%, 5%, and 6%, and sodium alginate at concentrations of 2%, 3%, and 4% were used for the production of disintegrated kefir gels.

Rheological Properties of the Disintegrated Kefir Gels

Flow behavior properties (apparent viscosity versus shear rate) of the starch, gelatin and alginate-based disintegrated kefir gels are shown in Figs. 5 and 6, and Fig. 7, respectively. It was observed that the apparent viscosity values of all samples decreased with the increase in shear rate and consequently all samples had a shear-thinning flow behavior. The shear-thinning flow behavior was associated with the breakdown of structural units between the elements due to the hydrodynamic forces produced during shear stress [8]. At higher shear rates, the apparent viscosity values were lower at the concentration of 4% for gelatin and 2% for alginate, while there was no statistically significant difference between concentrations for starch.

Storage modulus (G’), loss modulus (G’’) and loss factor (tan δ) values of the starch, gelatin and alginate-based disintegrated kefir gels are presented in Figs. 5 and 6, and Fig. 7, respectively. There was no statistically significant difference between concentrations in starch-based samples in terms of loss factor values, on the other hand, loss factor values relatively decreased with an increase in the gelator concentrations for gelatin and alginate-based samples. The storage modulus values increased with an increase in the gelator concentrations for all samples.

To the best of our knowledge, there is no study about disintegrated kefir gels produced with starch, gelatin or alginate for direct comparison. In a study, effect of starch concentration (5%, 7.5%, and 10%) on the rheological properties of grape molasses was investigated. It was observed that starch gels showed shear-thinning flow behavior and as the starch concentration increased, the storage modulus value increased, and the gel structure became stronger [26]. In another study, gelatin gels with and without milk proteins containing 1.0%, 2.5%, and 5.0% gelatin were prepared, and it was stated that higher storage modulus values and stronger gels were obtained with higher gelatin concentration [27]. In a study, alginate gels (0.5%, 1%, 1.5% and 2.0%) were characterized with shear-thinning flow behavior and it was observed that as alginate concentration increased, stronger gels were obtained [33]. As a result, it can be said that starch, gelatin and alginate-based gels have a shear-thinning flow behavior and the gel strength is directly related to the gelator concentration, and in conclusion, the results in this study concur with literature in this respect.

Printing Quality of Disintegrated Kefir Gels with a 3D Printer

Printed objects and printability and dimensional stability values of the 3D printed kefir objects are shown in Figs. 8 and 9, respectively. It is known that rheological properties are the main factor affecting the 3D printing quality. Shear-thinning flow behavior makes easier to print and sufficient shear stress and elastic modulus values ensure better retention of shape after printing [5, 6]. For this reason, printing quality was associated with the rheological properties of the disintegrated kefir gels.

As mentioned above, all samples had shear-thinning flow behavior and thus, continuous extrusion was achieved during the printing process for all samples, and the printing process was easily carried out.

Printability was significantly affected by gelator concentration for gelatin and alginate-based samples. The printability values were calculated to be about 90% at the concentrations of 4% and 2% for gelatin and alginate, respectively. Disintegrated kefir gels with 4% gelatin and 2% alginate had relatively lower apparent viscosity values and higher loss factor values, and therefore these samples were considered to show more liquid-like behavior. It was thought that due to this relatively high fluidity, the layers could not resist the pressure and started to collapse during the printing process, and the storage modulus values were not high enough to resist this deformation. Maximum stability was achieved at 6% concentration for gelatin and 3% and 4% concentrations for alginate. It was thought that the storage modulus values of alginate-based sample at 2% concentration and gelatin-based samples at 4% and 5% concentrations were not sufficient to resist deformation over time.

For starch-based samples, the printability and dimensional stability were not affected by the gelator concentration. In starch-based samples, there was no significant difference between gelator concentrations in terms of apparent viscosity values at higher shear rates and loss factor values, and so, there was no difference in terms of fluidity among the samples. Consequently, their storage modulus values were sufficient to prevent deformation and the samples showed high printability and dimensional stability.

There is no directly comparable study on the processing of disintegrated kefir gels, containing starch, gelatin and alginate, in a 3D food printer. In a study about gelatin gels processing in a 3D food printer, gelatin was used at concentrations of 14, 16 and 18%. It was determined that as the gelatin concentration increased, the printed 3D structure became more stable. It was also observed that at lower concentrations (< 12%), the previous layers were not hard enough to support the structure and therefore the target geometry could not be achieved [34]. In our study, a 3D object with high printability and stability was obtained with 6% gelatin. In another study about 3D printing properties of sodium alginate-based gels, sodium alginate was used at concentrations of 2, 4, 6, 8, 10, and 12%. It was observed that at lower alginate concentrations (2, 4, 6%), the deposited layers could not resist and collapsed due to low mechanical strength [35]. In our study, 3D objects with high printability and stability were obtained with 3% and 4% alginate. In a study about 3D printing of starch-based lemon juice gel, starch was used at concentrations of 10, 12.5, 15, 17.5, 20%. It was observed that lower starch content (10, 12.5%) led to lower viscosity and larger loss factor values, and as a result, these samples, which had more liquid-like behavior and high fluidity, could not resist deformation and maintain their shape [36]. In contrast, in our study, a 3D object with high printability and stability was obtained even with 5% starch.

It was observed that the results in our study did not concur with the literature for both starch, gelatin, and alginate-based samples. It was thought that such a result could be achieved due to the differences in raw materials (kefir versus water), and the use of the disintegrated gels in this study. Gel disintegration was quite helpful to remove excess water before printing. Nonetheless, studies about 3D food printing demonstrated that printing quality was mostly related to the rheological properties and gelator concentrations, as shown in this study.

Consequently, the minimum gelator concentration required for a suitable formulation for 3D printing (highest printability and dimensional stability) was determined as 5%, 6% and 3% for starch, gelatin and alginate, respectively. The main characteristics of kefir (taste, composition, etc.) were desired to be preserved as much as possible, therefore, it was considered that gelator should be added at the lowest possible concentration. For this purpose, disintegrated kefir gels were produced at the concentrations stated above with each gelator and processed separately to produce 3D objects. In the following parts of the study, main characteristics of these 3D printed kefir objects were determined.

Physicochemical Properties of the 3D Printed Objects and Kefir

Basic composition, viscosity, pH, and color values of the kefir used in the study are presented in Table 2. In a study, kefir samples were produced with two different kefir grains and two different lyophilized starter cultures, and physicochemical properties of these samples were determined. Viscosity and pH values of the kefir samples were determined as 75.80-148.18 cP and 4.33–4.70, respectively. Protein, fat, dry matter and ash contents were measured as 3.64–4.22%, 2.68–2.88%, 10.54–10.93% and 0.68–0.71%, respectively. As a result, it was observed that the type of grains and cultures affected the physicochemical properties of kefir [37]. In another study, six different commercial kefir samples were obtained from local market and their physicochemical properties were investigated. pH values and dry matter, protein and fat contents of the samples were determined as 3.86–4.06, 9.49–11.97%, 2.30–3.44% and 2.50-3.00%, respectively. L, a*, and b* color values of the samples were measured as 84.21–86.68, -2.40- -2.87, and 4.80–6.03, respectively. It was stated that differences between samples in terms of physicochemical properties may be due to the compositional variations of raw materials and kefir cultures used in their production [38]. Although the results in this study generally concur with the literature, there are some slight differences. As mentioned in the studies, physicochemical properties of kefir are not uniform and these properties are affected by compositional variations of raw materials and the type of grains and cultures used [37, 38].

Color values and basic compositions of the 3D objects are shown in Table 2. Some minor differences in color values were observed with different gelators. The dry matter contents of the 3D objects were significantly higher than the kefir probably because of the addition of gelators and the separation of some of the water present in the kefir during the centrifugation process in the production of disintegrated gels. The protein content of the gelatin-based sample was significantly higher, as expected. Significant differences were also observed in the ash contents of the samples. Due to the high mineral content of sodium alginate, its addition as a gelator significantly increased the ash content of the printed object. In general, composition of the liquid kefir was not changed in negative way during 3D printed object preparation, and 3D printed kefir objects could be considered as nutritionally rich snacks due to retained nutrition content and probiotic activity. In a study, 3D printed snacks were produced by using wheat flour dough substituted with different amounts of yellow mealworm powder (10% and 20%) [4]. Protein, lipid and ash contents of wheat flour were found as 11.7%, 1.1%, and 0.7% and with the addition of yellow mealworm powder these values increased up to 20.4%, 5.6%, and 1.3%, respectively. In another study, 3D printed gluten-free cereal snack were produced with incorporation of Spirulina or Chlorella vulgaris [39]. Protein, total fatty acids and ash contents of samples with Chlorella (5%) and Spirulina (5%) were found as 7.86% and 9.87%, 7.65% and 8.23%, and 2.06% and 2.15%, respectively. It can be said that the protein, fat, and ash contents of the snacks produced in our study were relatively lower than the samples in these studies. This was an expected result due to the use of additives with high nutritional content in these studies.

Texture Profiles of the 3D Printed Kefir Objects

Texture is one of the most important sensorial properties that affect consumers’ preferences. Instrumental Texture Profile Analysis (TPA) was used for determination of texture profiles and the results are presented in Table 3. The firmness, also referred to as hardness, is the positive peak force of the penetration and the work of shear is the area under this positive peak. Stickiness is the negative peak force of the withdrawal and the area under this negative peak is defined as the work of adhesion. These two terms are related to how a food sticks to the inside of the mouth during chewing [40, 41].

The highest values in all textural properties were measured in the alginate-based sample and it was followed by starch and gelatin-based samples, respectively. It is well known that the rheological properties are closely related to the textural properties. Similarly, the highest storage modulus and viscosity values were measured for the alginate-based sample and it was followed by starch and gelatin-based samples, respectively. In addition, the sensory analysis results also supported to the texture profiles of the samples. As seen in Fig. 10a, hardness and stickiness values were determined to be significantly higher in the alginate-based sample.

Microbiological Characteristics of the 3D Printed Kefir Objects

Lactobacillus spp., Lactococcus spp. and yeast contents of Kefir (control) and 3D printed kefir objects were analyzed on fresh sample as well as 6 and 12 days stored samples, and the findings were presented in Table 4.

There was no statistically significant difference between gelatin and alginate-based products and kefir in terms of microorganism contents. Therefore, these products can also be considered probiotic. Lactobacillus spp. and Lactococcus spp. contents of the starch-based sample were significantly lower than those of fresh kefir and gelatin and alginate-based samples. As stated above, the production of alginate gel was carried out at room temperature (25 °C), while the temperatures were increased to 35 and 85 °C in the preparation of gelatin and starch gels, respectively. It was thought that the decrease in the counts of Lactobacillus spp. and Lactococcus spp. was due to the high temperature used in the production of the starch gel. As a result, the probiotic content in the starch-based sample was low, therefore the use of starch can be avoided in the production of kefir-containing snacks or lower temperatures can be used in gel production to preserve the probiotic content. Since nutritious value of kefir is based on its alive microbiota.

In a study, Lactobacillus spp. contents of the kefir samples were measured as 4.45–8.42 log cfu/mL [37]. In another study, Lactobacillus spp., Lactococcus spp. and yeast contents of kefir samples were determined as 9.21–9.28 log cfu/mL, 9.23–9.29 log cfu/mL and 4.71–5.53 log cfu/mL, respectively [42]. In general, it can be said that results in the study concur with the literature.

Sensory Descriptions and Consumer Preferences of the 3D Printed Kefir Objects

The results of the sensory descriptive analysis are presented in Fig. 10a. Eleven different descriptive terms (1 appearance, 4 mouth sense and 6 aroma/taste) were developed for 3D printed kefir objects. There was no significant difference in terms of ‘shape integrity’, which was an expected result because products showed high conformity to the target geometry at the selected concentrations. Significant differences were observed in terms of ‘hardness’, ‘chewiness’, ‘stickiness’, ‘sandy mouthfeel’, ‘fermented taste/aroma’, and ‘kefir flavor’. Hardness and stickiness values were found to be significantly higher in the alginate-based sample, similar to the results of the texture profile analysis. The chewiness value of the gelatin-based sample was also found to be relatively low probably because of the lower hardness value. In addition, the characteristic taste/aroma of kefir was perceived less in the gelatin-based sample. Gelatin might have masked or encapsulated the aroma. In a study, ten different sensory descriptors were developed for kefir samples. Among these terms, sour, sweet, creamy, fermented, and dairy were also determined for the 3D printed kefir objects in this study [37].

Results of the consumer hedonic tests are presented in Fig. 10b. There was no significant difference in terms of appearance, as expected. However, consumer preferences were significantly affected in terms of smell/aroma, taste/flavor, mouthfeel and general acceptance. Differences between samples in terms of mouthfeel might be due to the differences in the hardness and stickiness values which were measured in texture profile and sensory descriptive analyses. According to the sensory descriptive analysis, the characteristic taste/aroma of kefir was perceived at a lower intensity in the gelatin-based sample and for this reason, it was thought that the gelatin-based sample was not liked by consumers. As a result, it can be said that in starch and alginate-based samples, the characteristic sensory properties of kefir were preserved, and these healthy snacks were accepted by consumers.

As a result, due to the high printing quality (98% printability and 99% dimensional stability), high probiotic content (7.81 and 8.13 log cfu/ml Lactobacillus spp. and Lactococcus spp. content, respectively) and high consumer appreciation (4.71 out of 5 for general acceptance), alginate-based sample (containing 3% alginate) was chosen as the best sample. At the end of the study, the printability of 3D objects in attractive shapes was tested using alginate-based formulation (3% alginate), and the printed objects are presented in the Fig. 11.

Conclusion

In this study, kefir-containing healthy snacks were produced with a 3D food printer by using disintegrated kefir gels, which were prepared with starch, gelatin and alginate. Printing quality was associated with the rheological properties of the samples and samples with proper storage modulus and loss factor values showed higher printability and dimensional stability. Probiotic content of the starch-based sample was found to be significantly lower than that of fresh kefir and gelatin and alginate-based samples probably because of the high temperature used in the gel preparation. Lower temperatures can be used in gel production to preserve the probiotic content. Sensory analysis showed that mouth sense and taste/aroma were affected by the gelator type and gelatin-based sample was not appreciated by consumers. Due to the high printing quality (98% printability and 99% dimensional stability), high probiotic content (7.81 and 8.13 log cfu/ml Lactobacillus spp. and Lactococcus spp. content, respectively) and high consumer appreciation (4.71 out of 5 for general acceptance), alginate-based sample (containing 3% alginate) was chosen as the best sample. In conclusion, this study aimed to increase the kefir consumption, which is rich in nutritional content and probiotic microorganisms, with kefir-containing snacks in attractive shapes produced with a 3D food printer. 3D printed kefir objects could offer consumers chewable, condensed, alive, easily consumable new alternatives to get the health benefits of kefir drink. Thus, this study contributes to the development of 3D printers in the food sector and to gain new perspectives on the use of 3D food printers.

Data Availability

Data will be made available on request.

References

F.C. Godoi, S. Prakash, B.R. Bhandari, J. Food Eng. 179, 44 (2016). https://doi.org/10.1016/j.jfoodeng.2016.01.025

A.Z. Kouzani, S. Adams, D.J. Whyte, R. Oliver, B. Hemsley, S. Palmer, S. Balandin, DesTech Conf. Proc. Int. Conf. Des. Tech. (2017) https://doi.org/10.18502/keg.v2i2.591

A. Derossi, R. Caporizzi, D. Azzollini, C. Severini, J. Food Eng. 220, 65 (2018). https://doi.org/10.1016/j.jfoodeng.2017.05.015

C. Severini, D. Azzollini, M. Albenzio, A. Derossi, Food Res. Int. 106, 666 (2018). https://doi.org/10.1016/j.foodres.2018.01.034

M.R. Sommer, L. Alison, C. Minas, E. Tervoort, P.A. Rühs, A.R. Studart, Soft Matter. 13, 1794 (2017). https://doi.org/10.1039/C6SM02682F

L. Liu, Y. Meng, B. Bhandari, X. Dai, K. Chen, Y. Zhu, S. Prakash, Food Bioproc. Tech. 12, 267 (2019) https://doi.org/10.1007/s11947-018-2209-z

J. Lipton, D. Arnold, F. Nigl, N. Lopez, D. Cohen, N. Noren, H. Lipson, Int. Sol. Freeform Fabric. Symp. (2010) https://doi.org/10.26153/tsw/15245

R.S.M. Azam, M. Zhang, B. Bhandari, C. Yang, Food Biophys. 13, 250 (2018). https://doi.org/10.1007/s11483-018-9531-x

K. Song, A.M. Compaan, W. Chai, Y. Huang, ACS Appl. Mater. Interfaces. 12, 22453 (2020). https://doi.org/10.1021/acsami.0c01497

T. Ishii, K. Matsumiya, M. Aoshima, Y. Matsumura, NPJ Sci. Food. 2, 15 (2018). https://doi.org/10.1038/s41538-018-0023-7

H. Kesenkaş, O. Gürsoy, H. Özbaş, in Fermented Foods in Health and Disease Prevention, ed. by J. Frias, C. Martinez-Villaluenga, E. PeñasAcademic Press, UK, (2017), p. 339. https://doi.org/10.1016/B978-0-12-802309-9.00014-5

A.M. Gut, T. Vasiljevic, T. Yeager, O.N. Donkor, Int. Dairy. J. 118, 105021 (2021). https://doi.org/10.1016/j.idairyj.2021.105021

S. Yelce, M. Gül, MKU Tar Bil Derg. 25, 316 (2020). https://doi.org/10.37908/mkutbd.656795

S. Bilici, E. Köksal, Ö. Küçükerdönmez, N. Şanlıer, Healthmed. 6, 997 (2012)

Q. Xing, C. Hou, Z. Zhang, K. Han, Q. Yan, J. Luo, Starch. 69, 1600287 (2017). https://doi.org/10.1002/star.201600287

S. Fu, A. Thacker, D.M. Sperger, R.L. Boni, I.S. Buckner, S. Velankar, E.J. Munson, L.H. Block, AAPS PharmSciTech. 12, 453 (2011). https://doi.org/10.1208/s12249-011-9587-0

E. Yilmaz, E. Keskin Uslu, C. Öz, JAOCS 98, 643 (2021) https://doi.org/10.1002/aocs.12490

A. Derossi, M. Paolilo, R. Caporizzi, C. Severini, J. Food Eng. 275, 109865 (2020). https://doi.org/10.1016/j.jfoodeng.2019.109865

AOAC, Official Methods of Analysis of AOAC International, 22nd edn. (Oxford University Press, UK, 2023)

A. Uskudar Guclu, E. Yesil, A. Altay Kocak, M. Saka, H.C. Mırza, B. Dınc, A. Basustaoglu, Jordan J. Biol. Sci. 14, 799 (2021). https://doi.org/10.54319/jjbs/140421

G. Özcan Ateş, N.N. Demirel Zorba, J. Microbiol, Biotechnol. Food Sci. 9, 899 (2020). https://doi.org/10.15414/jmbfs.2020.9.5.899-906

M.C. Meilgaard, G.V. Civille, B.T. Carr, Sensory Evaluation Techniques, 5th edn. (CRC, USA, 2016)

Minitab, Statistical Software (Minitab, Inc., USA, 2023)

SPSS, SPSS Professional Statistics (SPSS Inc., USA, 2022)

H.A. Barnes, A Handbook of Elementary Rheology (Institute of Non-Newtonian Fluid Mechanics, University of Wales, UK, 2000)

M. Goksel, M. Dogan, O.S. Toker, S. Ozgen, K. Sarioglu, R.A. Oral, Food Bioproc. Tech. 6, 259 (2013) https://doi.org/10.1007/s11947-011-0705-5

Z. Pang, H. Deeth, P. Sopade, R. Sharma, N. Bansal, Food Hydrocoll. 35, 484 (2014). https://doi.org/10.1016/j.foodhyd.2013.07.007

C. Jeong, S. Kim, C. Lee, S. Cho, S.-B. Kim, Foods. 9, 180 (2020). https://doi.org/10.3390/foods9020180

N.S.M. Yazid, N. Abdullah, N. Muhammad, I.O.P. Conf, Ser. Earth Environ. Sci. (2018). https://doi.org/10.1088/1755-1315/269/1/012031

L. Kumar, M. Brennan, H. Zheng, C. Brennan, Food Chem. 245, 518 (2018). https://doi.org/10.1016/j.foodchem.2017.10.125

R.N. Raja Mohd Hafidz, C.M. Yaakob, I. Amin, A. Noorfaizan, Int. Food Res. J. 18, 813 (2011)

I.M.S. Gajic, I.M. Savic, Z. Svircev, Polymers. 15, 2592 (2023). https://doi.org/10.3390/polym15122592

I. Gladukh, M. Podorozhna, EUREKA: Health Sci. 2, 82 (2021). https://doi.org/10.21303/2504-5679.2021.001732

J. In, H. Jeong, S. Song, S.C. Min, Foods. 10, 2272 (2021). https://doi.org/10.3390/foods10102272

C. Feng, M. Zhang, B. Bhandari, Y. Wang, B. Wang, J. Food Process. Eng. 44 (2021). https://doi.org/10.1111/jfpe.13583. e13583

F. Yang, M. Zhang, B. Bhandari, Y. Liu, LWT-Food Sci. Technol. 87, 67 (2018). https://doi.org/10.1016/j.lwt.2017.08.054

İ, B. Şen Dağ, Y. Aydeniz Güneşer, J. Karagül Yüceer, Adv. Res. Nat. Appl. Sci. 7, 343 (2021). https://doi.org/10.28979/jarnas.907107

O. Gursoy, K. Kocatürk, H.Ö. Güler, H.N. Dal, Y. Yakalı, Yilmaz, Akademik Gıda. 18, 375 (2020). https://doi.org/10.24323/akademik-gida.850881

P. Letras, S. Oliveira, J. Varela, M.C. Nunes, A. Raymundo, Algal Res. 68, 102863 (2022). https://doi.org/10.1016/j.algal.2022.102863

M.S. Rahman, Z.H. Al-Attabi, N. Al-Habsi, M. Al-Khusaibi, in Techniques to Measure Food Safety and Quality, ed. by M.S. Khan, M.S. RahmanSpringer Nature, Switzerland, (2021), p 427. https://doi.org/10.1007/978-3-030-68636-9

C. Schadle, S. Mittermaier, S. Sanahuja, Foods. 11, 806 (2022). https://doi.org/10.3390/foods11060806

T. Kök-Taş, A.C. Seydim, B. Özer, Z.B. Guzel-Seydim, J. Dairy. Sci. 96, 780 (2013). https://doi.org/10.3168/jds.2012-5753

Acknowledgements

This article was originated from Selçuk OK’s Ph.D. thesis.

Funding

This research did not receive any specific grant from funding agencies in the public commercial, or not-for-profit sectors.

Open access funding provided by the Scientific and Technological Research Council of Türkiye (TÜBİTAK).

Author information

Authors and Affiliations

Contributions

Selçuk Ok: Conceptualization, Data curation, Formal analysis, Investigation, Methodology, Software, Validation, Visualization, Writing - original draft, Writing - review & editing. Emin Yilmaz: Conceptualization, Data curation, Investigation, Methodology, Project Administration, Resources, Supervision, Validation, Writing - original draft, Writing - review & editing. Nükhet Nilüfer Demirel Zorba: Data curation, Formal analysis, Methodology, Resources, Validation, Writing - original draft, Writing - review & editing.

Corresponding author

Ethics declarations

Informed Consent

In this study, sensory descriptive analyses and consumer tests were accomplished with trained panelists and volunteer consumers. Participants were selected from volunteers and the requirements and risks of the study were fully explained. Additionally, a signed consent form, indicating that the samples were food-grade and safe, was provided to panelists and consumers.

Competing Interests

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Ok, S., Yilmaz, E. & Demirel Zorba, N.N. Preparation and Characterization of 3D Printed Objects Based on Different Kefir Gels. Food Biophysics (2024). https://doi.org/10.1007/s11483-024-09839-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11483-024-09839-5