Abstract

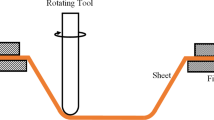

Improving and controlling surface quality has always been a challenge for incremental sheet forming (ISF), whereas the generation mechanism of waviness surface is still unknown, which impedes the widely application of ISF in the industrial field. In this paper, the formation mechanism and the prediction of waviness are both investigated through experiments, numerical simulation, and theoretical analysis. Based on a verified finite element model, the waviness topography is predicted numerically for the first time, and its generation is attributed to the residual bending deformation through deformation history analysis. For more efficient engineering application, a theoretical model for waviness height is proposed based on the generation mechanism, using a modified strain function considering deformation modes. This work is favorable for the perfection of formation mechanism and control of surface quality in ISF.

Similar content being viewed by others

Abbreviations

- BS:

-

Bending and stretching strain model

- FE:

-

Finite element

- FM:

-

Full model

- ISF:

-

Incremental sheet forming

- MBS:

-

Modified bending and stretching strain model

- PM:

-

Partial model

- TPISF:

-

Two-point incremental sheet forming

- F, G, H, Q, M, and N :

-

Material coefficients of Hill48 yield function

- F A, F B, F C :

-

Tangential forces per unit width in Regions A, B, and C, respectively

- F dcf :

-

Tension force in friction experiment

- F f :

-

Frictional force in friction experiment

- F n :

-

Compressive force in friction experiment

- H w :

-

Waviness height

- K :

-

Material coefficient of Ludwik constitutive function

- l :

-

Forming depth

- L :

-

Width size of partial FE model

- n :

-

Material hardening index of Ludwik constitutive function

- r :

-

Distance to the spherical centre

- R :

-

Tool radius

- R z :

-

Surface roughness of maximum peak to valley height

- sz :

-

Step size

- t 0 :

-

Initial sheet thickness

- V :

-

Feed rate in friction experiment

- α :

-

Forming angle

- α f :

-

Actual contacting angle

- α t :

-

Actual forming angle after incremental forming

- β :

-

Residual forming angle

- σ 0 :

-

Yield stress

- σ tan, σ cir, σ thi :

-

Normal stresses in tangential, circumferential, and thickness directions, respectively

- σ Atan , σ Athi :

-

Tangential stress and thickness stress at Region A, respectively

- σ Btan , σ Bthi :

-

Tangential stress and thickness stress at Region B, respectively

- σ Bthi,r=R :

-

Contact stress along the thickness direction at Region B

- σ xx, σ yy, σ zz :

-

Normal stresses along the X (rolling direction), Y (transverse direction), and Z (thickness direction) directions, respectively

- \({\bar \sigma}\) :

-

Equivalent stress

- φ :

-

Current forming angle

- dϕ :

-

Increment of tangential length

- dθ :

-

Increment of circumference width

- ε B,BS, ε S,BS :

-

Bending strain and stretching strain in a bending and stretching strain model, respectively

- ε B,MBS, ε S,MBS :

-

Bending strain and stretching strain in MBS, respectively

- ε PMmax , ε FMmax :

-

Max principal strain of partial and full model at specific forming depth of l, respectively

- ε p :

-

Predeformation strain

- ε tan, ε cir, ε thi :

-

Normal strains in the tangential, circumference, and thickness directions, respectively

- ε tan,BS :

-

Tangential strain evolution in BS

- ε tan,MBS :

-

Tangential strain evolution in MBS

- ε xx, ε yy, ε zz :

-

Normal strain along rolling direction, transverse direction and thickness direction, respectively

- \({\bar \varepsilon}\) :

-

Equivalent strain

- μ :

-

Friction coefficient

- δ i :

-

Strain error

References

Wu R H, Liu X M, Li M, Chen J. Investigations on deformation mechanism of double-sided incremental sheet forming with synchronous thermomechanical steel-aluminum alloy bonding. Journal of Materials Processing Technology, 2021, 294: 117147

Vahdani M, Mirnia M J, Bakhshi-Jooybari M, Gorji H. Electric hot incremental sheet forming of Ti—6Al—4V titanium, AA6061 aluminum, and DC01 steel sheets. The International Journal of Advanced Manufacturing Technology, 2019, 103(1): 1199–1209

Khazaali H, Fereshteh-Saniee F. Process parameter enhancement for incremental forming of titanium Ti—6Al—4V truncated cone with varying wall angle at elevated temperatures. International Journal of Precision Engineering and Manufacturing, 2019, 20(5): 769–776

Yang Z Y, Chen F. Mechanism of twist in incremental sheet forming of thermoplastic polymer. Materials & Design, 2020, 195: 108997

Wei H Y, Hussain G, Heidarshenas B, Alkahtani M. Post-forming mechanical properties of a polymer sheet processed by incremental sheet forming: insights into effects of plastic strain, and orientation and size of specimen. Polymers, 2020, 12(9): 1870

Yang Z Y, Chen F, Gatea S, Ou H A. Design of the novel hot incremental sheet forming experimental setup, characterization of formability behavior of polyether-ether-ketone (PEEK). The International Journal of Advanced Manufacturing Technology, 2020, 106(11–12): 5365–5381

Durante M, Formisano A, Lambiase F. Incremental forming of polycarbonate sheets. Journal of Materials Processing Technology, 2018, 253: 57–63

Harhash M, Palkowski H. Incremental sheet forming of steel/polymer/steel sandwich composites. Journal of Materials Research and Technology, 2021, 13: 417–430

Xiao X, Kim J J, Oh S H, Kim Y S. Study on the incremental sheet forming of CFRP sheet. Composites Part A: Applied Science and Manufacturing, 2021, 141: 106209

Sarkar D. Wear of Metals. Oxford: Pergamon Press, 1976

Hutchings I M. Tribology: Friction and Wear of Engineering Materials. London: Edward Arnold, 1992

Affatato S, Grillini L. Topography in bio-tribocorrosion. In: Yan Y, ed. Bio-Tribocorrosion in Biomaterials and Medical Implants. Ginny Mills: Woodhead Publishing, 2013, 1–22a

Hagan E, Jeswiet J. Analysis of surface roughness for parts formed by computer numerical controlled incremental forming. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, 2004, 218(10): 1307–1312

Durante M, Formisano A, Langella A. Comparison between analytical and experimental roughness values of components created by incremental forming. Journal of Materials Processing Technology, 2010, 210(14): 1934–1941

Bhattacharya A, Singh S, Maneesh K, Reddy N V, Cao J. Formability and surface finish studies in single point incremental forming. Journal of Manufacturing Science and Engineering, 2011, 133(6): 061020

Basak S, Prasad K S, Mehto A, Bagchi J, Ganesh Y S, Mohanty S, Sidpara A M, Panda S K. Parameter optimization and texture evolution in single point incremental sheet forming process. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, 2020, 234(1–2): 126–139

Behera A K, Alves de Sousa R, Ingarao G, Oleksik V. Single point incremental forming: an assessment of the progress and technology trends from 2005 to 2015. Journal of Manufacturing Processes, 2017, 27: 37–62

Liu Z B, Liu S, Li Y L, Meehan P A. Modeling and optimization of surface roughness in incremental sheet forming using a multi-objective function. Materials and Manufacturing Processes, 2014, 29(7): 808–818

Zhai W D, Li Y L, Cheng Z N, Sun L L, Li F Y, Li J F. Investigation on the forming force and surface quality during ultrasonic-assisted incremental sheet forming process. The International Journal of Advanced Manufacturing Technology, 2020, 106(7): 2703–2719

Kim Y H, Park J J. Effect of process parameters on formability in incremental forming of sheet metal. Journal of Materials Processing Technology, 2002, 130–131: 42–46

Lu B, Fang Y, Xu D K, Chen J, Ou H, Moser N H, Cao J. Mechanism investigation of friction-related effects in single point incremental forming using a developed oblique roller-ball tool. International Journal of Machine Tools and Manufacture, 2014, 85: 14–29

Mohanty S, Regalla S P, Daseswara Rao Y V. Investigation of influence of part inclination and rotation on surface quality in robot assisted incremental sheet metal forming (RAISF). CIRP Journal of Manufacturing Science and Technology, 2018, 22: 37–48

Xu D K, Wu W C, Malhotra R, Chen J, Lu B, Cao J. Mechanism investigation for the influence of tool rotation and laser surface texturing (LST) on formability in single point incremental forming. International Journal of Machine Tools and Manufacture, 2013, 73: 37–46

Ham M, Powers B M, Loiselle J. Surface topography from single point incremental forming using an acetal tool. Key Engineering Materials, 2013, 549: 84–91

Skjoedt M, Silva M B, Bay N, Martins P A F, Lenau T A. Single point incremental forming using a dummy sheet. International Conference on New Forming Technology, 2007, 2: 267–276

Alves M L, Silva M B, Alves L M, Martins P A F. On the formability, geometrical accuracy, and surface quality of sheet metal parts produced by SPIF. In: He X, Xie H, Kang Y, eds. Proceedings Volume 7375, ICEM 2008: International Conference on Experimental Mechanics 2008. Nanjing: SPIE, 2009, 176–182

Li X Q, Han K, Song X, Wang H B, Li D S, Li Y L, Li Q. Experimental and numerical investigation on surface quality for two-point incremental sheet forming with interpolator. Chinese Journal of Aeronautics, 2020, 33(10): 2794–2806

Attanasio A, Ceretti E, Giardini C, Mazzoni L. Asymmetric two points incremental forming: improving surface quality and geometric accuracy by tool path optimization. Journal of Materials Processing Technology, 2008, 197(1–3): 59–67

Chang Z D, Huang W S, Chen J. A new tool path with point contact and its effect on incremental sheet forming process. The International Journal of Advanced Manufacturing Technology, 2020, 110(5–6): 1515–1525

Xu C X, Li Y L, Wang Z J, Cheng Z N, Liu F Y. The influence of self-lubricating coating during incremental sheet forming of TA1 sheet. The International Journal of Advanced Manufacturing Technology, 2020, 110(9): 2465–2477

Li Z F, Lu S H, Zhang T, Mao Z X, Zhang C. A simple and lowcost lubrication method for improvement in the surface quality of incremental sheet metal forming. Transactions of the Indian Institute of Metals, 2018, 71(7): 1715–1719

Zhang H R, Chu X R, Bao W K, Gao J, Chen L. Microstructure evolution of AZ31B sheet deformed by electric hot temperature-controlled single point incremental forming. Materials Science and Engineering: A, 2021, 823: 141732

Mishra S, Yazar K U, More A M, Kumar L, Lingam R, Reddy N V, Prakash O, Suwas S. Elucidating the deformation modes in incremental sheet forming process: insights from crystallographic texture, microstructure and mechanical properties. Materials Science and Engineering: A, 2020, 790: 139311

Li Y L, Zhai W D, Wang Z J, Li X Q, Sun L L, Li J F, Zhao G Q. Investigation on the material flow and deformation behavior during ultrasonic-assisted incremental forming of straight grooves. Journal of Materials Research and Technology, 2020, 9(1): 433–454

Hajavifard R, Maqbool F, Schmiedt-Kalenborn A, Buhl J, Bambach M, Walther F. Integrated forming and surface engineering of disc springs by inducing residual stresses by incremental sheet forming. Materials, 2019, 12(10): 1646

Li Y L, Daniel W J T, Meehan P A. Deformation analysis in single-point incremental forming through finite element simulation. The International Journal of Advanced Manufacturing Technology, 2016, 88(1–4): 1–13

Maqbool F, Bambach M. Dominant deformation mechanisms in single point incremental forming (SPIF) and their effect on geometrical accuracy. International Journal of Mechanical Sciences, 2018, 136: 279–292

Mirnia M J, Shamsari M. Numerical prediction of failure in single point incremental forming using a phenomenological ductile fracture criterion. Journal of Materials Processing Technology, 2017, 244: 17–43

Mirnia M J, Vahdani M, Shamsari M. Ductile damage and deformation mechanics in multistage single point incremental forming. International Journal of Mechanical Sciences, 2018, 136: 396–412

Mohammadi A, Vanhove H, Van Bael A, Duflou J R. Towards accuracy improvement in single point incremental forming of shallow parts formed under laser assisted conditions. International Journal of Material Forming, 2016, 9(3): 339–351

Cheng Z N, Li Y L, Li J H, Li F Y, Meehan P A. Ultrasonic assisted incremental sheet forming: constitutive modeling and deformation analysis. Journal of Materials Processing Technology, 2022, 299: 117365

Han K, Li X Q, Peng X Y, Wang H B, Li D S, Li Y L, Li Q. Experimental and numerical study on the deformation mechanism of straight flanging by incremental sheet forming. International Journal of Mechanical Sciences, 2019, 160: 75–89

Jin K, Guo X Z, Tao J, Wang H, Kim N, Gu Y B. A model of one-surface cyclic plasticity with Lemaitre damage criterion for plastic instability prediction in the incremental forming process. International Journal of Mechanical Sciences, 2016, 114: 88–97

Esmaeilpour R, Kim H, Park T, Pourboghrat F, Mohammed B. Comparison of 3D yield functions for finite element simulation of single point incremental forming (SPIF) of aluminum 7075. International Journal of Mechanical Sciences, 2017, 133: 544–554

Esmaeilpour R, Kim H, Park T, Pourboghrat F, Xu Z, Mohammed B, Abu-Farha F. Calibration of barlat Yld2004-18P yield function using CPFEM and 3D RVE for the simulation of single point incremental forming (SPIF) of 7075-O aluminum sheet. International Journal of Mechanical Sciences, 2018, 145: 24–41

He S, Van Bael A, Van Houtte P, Duflou J R, Szekeres A, Henrard C, Habraken A M. Finite element modeling of incremental forming of aluminum sheets. Advanced Materials Research, 2005, 6–8: 525–532

Belchior J, Leotoing L, Guines D, Courteille E, Maurine P. A process/machine coupling approach: application to robotized incremental sheet forming. Journal of Materials Processing Technology, 2014, 214(8): 1605–1616

Memicoglu P, Music O, Karadogan C. Simulation of incremental sheet forming using partial sheet models. Procedia Engineering, 2017, 207: 831–835

Guzmán C F, Gu J, Duflou J, Vanhove H, Flores P, Habraken A M. Study of the geometrical inaccuracy on a SPIF two-slope pyramid by finite element simulations. International Journal of Solids and Structures, 2012, 49(25): 3594–3604

Ndip-Agbor E, Smith J, Ren H Q, Jiang Z, Xu J C, Moser N, Chen W, Xia Z C, Cao J. Optimization of relative tool position in accumulative double sided incremental forming using finite element analysis and model bias correction. International Journal of Material Forming, 2016, 9(3): 371–382

Silva M B, Skjoedt M, Martins P A F, Bay N. Revisiting the fundamentals of single point incremental forming by means of membrane analysis. International Journal of Machine Tools and Manufacture, 2008, 48(1): 73–83

Silva M B, Martins P A F. Two-point incremental forming with partial die: theory and experimentation. Journal of Materials Engineering and Performance, 2013, 22(4): 1018–1027

Fang Y, Lu B, Chen J, Xu D K, Ou H. Analytical and experimental investigations on deformation mechanism and fracture behavior in single point incremental forming. Journal of Materials Processing Technology, 2014, 214(8): 1503–1515

Zhang H, Zhang Z X, Ren H Q, Cao J, Chen J. Deformation mechanics and failure mode in stretch and shrink flanging by double-sided incremental forming. International Journal of Mechanical Sciences, 2018, 144: 216–222

Basak S, Prasad K S, Sidpara A M, Panda S K. Single point incremental forming of AA6061 thin sheet: calibration of ductile fracture models incorporating anisotropy and post forming analyses. International Journal of Material Forming, 2019, 12(4): 623–642

Chang Z D, Li M, Chen J. Analytical modeling and experimental validation of the forming force in several typical incremental sheet forming processes. International Journal of Machine Tools and Manufacture, 2019, 140: 62–76

Li Y L, Daniel W J T, Liu Z B, Lu H B, Meehan P A. Deformation mechanics and efficient force prediction in single point incremental forming. Journal of Materials Processing Technology, 2015, 221: 100–111

Liu F Y, Li X Q, Li Y L, Wang Z J, Zhai W D, Li F Y, Li J F. Modelling of the effects of process parameters on energy consumption for incremental sheet forming process. Journal of Cleaner Production, 2020, 250: 119456

Li Y L, Chen X X, Zhai W D, Wang L M, Li J F, Zhao G Q. Effects of process parameters on thickness thinning and mechanical properties of the formed parts in incremental sheet forming. The International Journal of Advanced Manufacturing Technology, 2018, 98(9): 3071–3080

Guo X Z, Gu Y B, Wang H, Jin K, Tao J. The Bauschinger effect and mechanical properties of AA5754 aluminum alloy in incremental forming process. The International Journal of Advanced Manufacturing Technology, 2018, 94(1): 1387–1396

Li Y L, Wang Z J, Zhai W D, Cheng Z N, Li F Y, Li X Q. The influence of ultrasonic vibration on parts properties during incremental sheet forming. Advances in Manufacturing, 2021, 9(2): 250–261

Acknowledgements

The authors thank the support from the National Natural Science Foundation of China (Grant Nos. 51575028 and 51975328), and the Fundamental Research Funds for the Central Universities of China (Grant No. YWF-18-BJ-J-75). Also, the authors thank the suggestions of editors and reviewers.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Han, K., Li, X., Li, Y. et al. Formation mechanism and modeling of surface waviness in incremental sheet forming. Front. Mech. Eng. 17, 23 (2022). https://doi.org/10.1007/s11465-022-0679-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11465-022-0679-1