Abstract

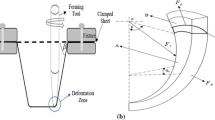

This study aims to explore the Bauschinger effect and mechanical properties of 5754 aluminum alloy and their relationship through parts manufactured by incremental forming technology. Pyramidal parts with five different wall angles were formed using incremental forming after which tensile samples from each of the parts were prepared and tested. The experimental results indicated that the Bauschinger effect existed during incremental forming of the aluminum alloy. It was also found that the level of the Bauschinger effect, yield strength, and ultimate tensile strength increased with the expanding wall angle. Compared with the influence of the Bauschinger effect, the work hardening plays a leading role in the change of mechanical properties. Based on the study results, the formulas for predicting the mechanical properties at different wall angles are obtained. Understanding the Bauschinger effect and mechanical properties can help to guide incremental forming simulation and process development of parts manufactured by incremental forming.

Similar content being viewed by others

References

Centeno G, Bagudanch I, Martínez-Donaire AJ, García-Romeu ML, Vallellano C (2014) Critical analysis of necking and fracture limit strains and forming forces in single-point incremental forming. Mater Des 63(21):20–29

Martins PAF, Bay N, Skjoedt M, Silva MB (2008) Theory of single point incremental forming. CIRP Annals - Manuf Technol 57(1):247–252

Fang Y, Lu B, Chen J, Xu DK, Ou H (2014) Analytical and experimental investigations on deformation mechanism and fracture behavior in single point incremental forming. J Mater Process Technol 214(8):1503–1515

Silva MB, Skjoedt M, Atkins AG, Bay N, Martins PAF (2008) Single-point incremental forming and formability–failure diagrams. J Strain Anal Eng Des 43(1):15–35

Allwood JM, Shouler DR, Tekkaya AE (2007) The increased forming limits of incremental sheet forming processes. Key Eng Mater 344:621–628

Shrivastava P, Tandon P (2015) Investigation of the effect of grain size on forming forces in single point incremental sheet forming. Procedia Manufacturing 2:41–45

Shanmuganatan SP, Kumar VSS (2014) Modeling of incremental forming process parameters of al 3003 (O) by response surface methodology. Procedia Engineering 97:346–356

Gatea S, Ou H, Mccartney G (2016) Review on the influence of process parameters in incremental sheet forming. Int J Adv Manuf Technol 87:479–499

Vol N (2003) Effect of wall angle on Al 3003 strain hardening for parts formed by computer numerical control incremental forming. Proc Inst Mech Eng 217(11):1571–1579

Jin K, Guo XZ, Tao J, Wang H, Kim N, Gu YB (2016) A model of one-surface cyclic plasticity with Lemaitre damage criterion for plastic instability prediction in the incremental forming process. Int J Mech Sci 114:88–97

Jun-Chao LI, Chong LI, Zhou TG (2012) Thickness distribution and mechanical property of sheet metal incremental forming based on numerical simulation. Trans Nonferrous Metals Soc China 22(10):s54–s60

Amouzegar H, Schafer BW, Tootkaboni M (2016) An incremental numerical method for calculation of residual stresses and strains in cold-formed steel members. Thin-Walled Struct 106:61–74

Hadoush A, Boogaard AHVD, Emmens WC (2011) A numerical investigation of the continuous bending under tension test. J Mater Process Technol 211(12):1948–1956

Ai S, Lu B, Chen J, Long H, Ou H (2017) Evaluation of deformation stability and fracture mechanism in incremental sheet forming. Int J Mech Sci 124-125:174

Dell HD, Eliseev VV, Shapievskaya VA (2014) Experimental study of the Bauschinger effect for anisotropic metals. Mech Solids 49(5):561–567

Balík J, Dobroň P, Chmelík F, Kužel R, Drozdenko D, Bohlen J (2015) Modeling of the work hardening in magnesium alloy sheets. Int J Plast 76:166–185

Paul JDH, Hoppe R, Appel F (2016) On the Bauschinger effect in TiAl alloys. Ac Mate 104:101–108

Kafka V, Vokoun D (2013) Causality in the Bauschinger effect generation and in other deformation processes in metals. Eur J Mech - A/Solids 42(6):395–401

Cao Z, Wang F, Wan Q, Zhang Z, Jin L, Dong J (2015) Microstructure and mechanical properties of AZ80 magnesium alloy tube fabricated by hot flow forming. Mater Des 67:64–71

Zhang X, Huang T, Yang W, Xiao R, Liu Z, Li L (2016) Microstructure and mechanical properties of laser beam-welded AA2060 Al-Li alloy. J Mater Process Technol 237:301–308

Narayanasamy R, Anandakrishnan V, Pandey KS (2008) Effect of geometric work-hardening and matrix work-hardening on new constitutive relationship for aluminium–alumina P/M composite during cold upsetting. Int J Mech Mater Des 4(3):301–315

Yi HY, Yan FK, Tao NR, Lu K (2016) Work hardening behavior of nanotwinned austenitic grains in a metastable austenitic stainless steel. Scr Mater 114:133–136

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Guo, X., Gu, Y., Wang, H. et al. The Bauschinger effect and mechanical properties of AA5754 aluminum alloy in incremental forming process. Int J Adv Manuf Technol 94, 1387–1396 (2018). https://doi.org/10.1007/s00170-017-0965-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-017-0965-y