Abstract

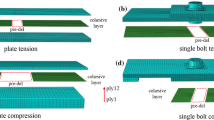

Experimental and finite element research was conducted on the bolted interference fit of a single-lap laminated structure to reveal the damage propagation mechanism and strength change law. A typical single-lap statically loading experiment was performed, and a finite element damage prediction model was built based on intralaminar progress damage theory. The model was programmed with a user subroutine and an interlaminar cohesive zone method. The deformation and damage propagation of the specimen were analyzed, and the failure mechanism of intralaminar and interlaminar damage during loading was discussed. The effect of secondary bending moment on load translation and damage distribution was revealed. The experimental and simulated load-displacement curves were compared to validate the developed model’s reliability, and the ultimate bearing strengths under different fit percentages were predicted. An optimal percentage was also recommended.

Similar content being viewed by others

References

Cao Z Q, Cardew-Hall M. Interference-fit riveting technique in fiber composite laminates. Aerospace Science and Technology, 2006, 10(4): 327–330

Li J, Li Y, Zhang K, et al. Interface damage behaviour during interference-fit bolt installation process for CFRP/Ti alloy joining structure. Fatigue & Fracture of Engineering Materials & Structures, 2015, 38(11): 1359–1371

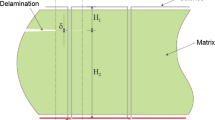

Zou P, Li Y, Zhang K, et al. Mode I delamination mechanism analysis on CFRP interference-fit during the installation process. Materials & Design, 2017, 116: 268–277

Zou P, Li Y, Zhang K, et al. Influence of interference-fit percentage on stress and damage mechanism in hi-lock pin installation process of CFRP. Journal of Composite Materials, 2017, 51(25): 3525–3538

Liu F L, Liu D, Liu J G. The controlling and application technology of composite structure interference installation. Aviation Precision Manufacturing Technology., 2011, 47(6): 36–38 (in Chinese)

Liu L Q, Zhang J Q, Chen K K, et al. Combined and interactive effects of interference fit and preloads on composite joints. Chinese Journal of Aeronautics, 2014, 27(3): 716–729

Zou P, Zhang K, Li Y, et al. Bearing strength and failure analysis on the interference-fit double shear-lap pin-loaded composite. International Journal of Damage Mechanics, 2016, 27(2): 179–200

Kim S Y, Hennigan D J, Kim D, et al. Fatigue enhancement by interference-fit in a pin-loaded glass fibre-reinforced plastics laminate. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science, 2012, 226(6): 1437–1446

Wei J C, Jiao G Q, Jia P R, et al. The effect of interference fit size on the fatigue life of bolted joints in composite laminates. Composites. Part B, Engineering, 2013, 53: 62–68

Isbilir O, Ghassemieh E. Finite element analysis of drilling of carbon fibre reinforced composites. Applied Composite Materials, 2012, 19(3–4): 637–656

Jiang H, Ren Y, Jin Q, et al. Flexural performances of fiber face-sheets/corrugated core sandwich composite structures reinforced by horizontal stiffeners. International Journal of Mechanical Sciences, 2020, 168: 105307

Jiang H, Ren Y, Liu Z, et al. Evaluations of failure initiation criteria for predicting damages of composite structures under crushing loading. Journal of Reinforced Plastics and Composites, 2018, 37(21): 1279–1303

Ren Y, Jiang H, Gao B, et al. A progressive intraply material deterioration and delamination based failure model for the crashworthiness of fabric composite corrugated beam: Parameter sensitivity analysis. Composites. Part B, Engineering, 2018, 135: 49–71

Camanho P P, Matthews F L. A progressive damage model for mechanically fastened joints in composite laminates. Journal of Composite Materials, 1999, 33(24): 2248–2280

Olmedo A, Santiuste C, Barbero E. An analytical model for the secondary bending prediction in single-lap composite bolted-joints. Composite Structures, 2014, 111(1): 354–361

Xiao Y, Ishikawa T. Bearing strength and failure behavior of bolted composite joints (part I: Experimental investigation). Composites Science and Technology, 2005, 65(7–8): 1022–1031

Zhao L, Gong Y, Zhang J, et al. Simulation of delamination growth in multidirectional laminates under mode I and mixed mode I/II loadings using cohesive elements. Composite Structures, 2014, 116: 509–522

Chen J F, Morozov E V, Shankar K. Simulating progressive failure of composite laminates including in-ply and delamination damage effects. Composites. Part A, Applied Science and Manufacturing, 2014, 61: 185–200

Camanho P P, Davila C G, de Moura M F. Numerical simulation of mixed-mode progressive delamination in composite materials. Journal of Composite Materials, 2003, 37(16): 1415–1438

Riccio A, Caputo F, Di Felice G, et al. A joint numerical-experimental study on impact induced intra-laminar and interlaminar damage in laminated composites. Applied Composite Materials, 2016, 23: 219–237

Durão L M P, de Moura M F S F, Marques A T. Numerical simulation of the drilling process on carbon/epoxy composite laminates. Composites. Part A, Applied Science and Manufacturing, 2006, 37(9): 1325–1333

Durão L M P, de Moura M F S F, Marques A T. Numerical prediction of delamination onset in carbon/epoxy composites drilling. Engineering Fracture Mechanics, 2008, 75(9): 2767–2778

Feito N, Lopez-Puente J, Santiuste C, et al. Numerical prediction of delamination in CFRP drilling. Composite Structures, 2014, 108: 677–683

Camanho P M P R de C. Application of numerical methods to the strength prediction of mechanically fastened joints in composite laminates. Dissertation for the Doctoral Degree. London: Imperial College London (University of London), 1999

Xiao Y, Ishikawa T. Bearing strength and failure behavior of bolted composite joints (part II: Modeling and simulation). Composites Science and Technology, 2005, 65(7–8): 1032–1043

Acknowledgements

The authors declare no potential conflicts of interest with respect to the research, authorship, and/or publication of this article. This work was supported by the Aviation Science Foundation of China (Grant No. 2018ZE23011) and the National Natural Science Foundation of China (Grant No. 51275410). The authors are thankful for the support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zou, P., Chen, X., Chen, H. et al. Damage propagation and strength prediction of a single-lap interference-fit laminate structure. Front. Mech. Eng. 15, 558–570 (2020). https://doi.org/10.1007/s11465-020-0591-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11465-020-0591-5