Abstract

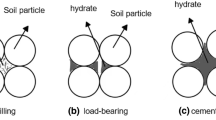

A stress-dependent porosity and permeability model is proposed to predict the microstructure evolution and the physical properties and mechanical behavior of deformable hydrate-bearing sediments (HBS) with various hydrate growth patterns under engineering disturbance. First, according to Hertzian contact theory and the proposed mesoelastic–plastic damage model (Gurson-DP model), the correction formula of the pore size under the influence of the effective confining pressure and the overburden pressure is given, and the stress-dependent porosity model is derived. Second, the fractal capillary bundle model is used to describe the stress-dependent permeability of HBS with different hydrate saturations considering the grain-cementing hydrate and the universal-growth hydrate. Finally, the proportions of hydrates with various growth patterns, such as pore filling (PF), wall coating (WC), and grain cementing (GC), are determined based on the equivalent flow assumption to reasonably evaluate the hydrate growth habit in HBS. This paper comprehensively studies the stress-dependent porosity and permeability models of deformable HBS and thus, provides a theoretical basis for quantitative evaluation and prediction of the physical properties (such as porosity and permeability) and mechanical behavior of HBS.

Similar content being viewed by others

Data availability

The authors confirm that the data supporting the findings of this study are available within the article and its supplementary materials.

References

Chen GJ, Guo TM (1996) Thermodynamic modeling of hydrate formation based on new concepts. Fluid Phase Equilib 122(1–2):43–65. https://doi.org/10.1016/0378-3812(96)03032-4

Chen GJ, Guo TM (1998) A new approach to gas hydrate modelling. Chem Eng J 71:145–151. https://doi.org/10.1016/S1385-8947(98)00126-0

Daigle H (2016) Relative permeability to water or gas in the presence of hydrates in porous media from critical path analysis. J Petrol Sci Eng 146:526–535. https://doi.org/10.1016/j.petrol.2016.07.011

Delli ML, Grozic JLH (2014) Experimental determination of permeability of porous media in the presence of gas hydrates. J Petrol Sci Eng 120:1–9. https://doi.org/10.1016/j.petrol.2014.05.011

Gangi AF (1978) Variation of whole and fractured porous rock permeability with confining pressure. Int J Rock Mech Min Sci Geomech Abstr 15(5):249–257. https://doi.org/10.1016/0148-9062(78)90957-9

Gao YH, Chen Y, Chen LT et al (2019) Experimental investigation on the permeability of a hydrate-bearing reservoir considering overburden pressure. Fuel 246:308–318. https://doi.org/10.1016/j.fuel.2019.01.166

Helgerud MB (2001) Wave Speeds in Gas Hydrate and Sediments Containing Gas Hydrate: A Laboratory and Modeling Study. Ph.D. Thesis. Stanford University, Palo Alto.

Hu GW, Li CF, Ye YG et al (2014) Observation of gas hydrate distribution in sediment pore space. Chin J Geophys (in Chinese) 57(5):1675–1682

Hyodo M, Li YH, Yoneda J et al (2014) Effects of dissociation on the shear strength and deformation behavior of methane hydrate-bearing sediments. Mar Pet Geol 51:52–62. https://doi.org/10.1016/j.marpetgeo.2013.11.015

Hyodo M, Yoneda J, Yoshimoto N et al (2013) Mechanical and dissociation properties of methane hydrate-bearing sand in deep seabed. Soils Found 53(2):299–314. https://doi.org/10.1016/j.sandf.2013.02.010

Jiang MJ, He J, Zhou YP (2014) Inter-particle bonded model of deep-sea methane hydrate-bearing soil considering methane hydrate bond thickness. Rock Soil Mech 35(5):1231–1240. https://doi.org/10.16285/j.rsm.2014.05.003

Klar A, Soga K, Ng MYA (2010) Coupled deformation-flow analysis for methane hydrate extraction. Géotechnique 60(10):765–776. https://doi.org/10.1680/geot.9.P.079-3799

Kleinberg RL, Flaum C, Griffin DD et al (2003) Deep sea NMR: Methane hydrate growth habit in porous media and its relationship to hydraulic permeability, deposit accumulation, and submarine slope stability. J Geophys Res Solid Earth. https://doi.org/10.1029/2003jb002389

Kumar A, Maini B, Bishnoi PR et al (2010) Experimental determination of permeability in the presence of hydrates and its effect on the dissociation characteristics of gas hydrates in porous media. J Petrol Sci Eng 70(1–2):114–122. https://doi.org/10.1016/j.petrol.2009.10.005

Le TX, Bornert M, Aimedieu P et al (2020) An experimental investigation on methane hydrate morphologies and pore habits in sandy sediment using synchrotron X-ray computed tomography. Mar Pet Geol 122:104646. https://doi.org/10.1016/j.marpetgeo.2020.104646

Lei G, Liao QZ, Zhang DX et al (2020) A mechanistic model for permeability in deformable gas hydrate-bearing sediments. J Nat Gas Sci Eng 83(2–3):103554. https://doi.org/10.1016/j.jngse.2020.103554

Liang H, Song Y, Chen Y et al (2011) The measurement of permeability of porous media with methane hydrate. Pet Sci Technol 29(1):79–87. https://doi.org/10.1080/10916460903096871

Liu CW, Zhang CR, Zhou CR et al (2020) Effects of the solidification of capillary bridges on the interaction forces between hydrate particles. Energy Fuels 34(4):4525–4533. https://doi.org/10.1021/acs.energyfuels.0c00463

Liu XQ, Qu ZQ, Guo TK et al (2021) A coupled thermo-hydrologic-mechanical (THM) model to study the impact of hydrate phase transition on reservoir damage. Energy 216:119222. https://doi.org/10.1016/j.energy.2020.119222

Liu ZC, Kim JC, Lei L et al (2019) Tetrahydrofuran hydrate in clayey sediments–laboratory formation, morphology, and wave characterization. J Geophys Res Solid Earth 124(4):3307–3319. https://doi.org/10.1029/2018JB017156

Mahabadi N, Dai S, Seol Y et al (2019) Impact of hydrate saturation on water permeability in hydrate-bearing sediments. J Petrol Sci Eng 174:696–703. https://doi.org/10.1016/j.petrol.2018.11.084

Ning FL, Liang JQ, Wu NY et al (2020) Reservoir characteristics of natural gas hydrates in China. Nat Gas Ind 40(8):1–24. https://doi.org/10.3787/j.issn.1000-0976.2020.08.001

Rowe PW (1962) The stress-dilatancy relation for static equilibrium of an assembly of particles in contact. Proc R Soc Lond Ser A Math Phys Sci 269(1339):500–527. https://doi.org/10.1098/rspa.1962.0193

Sakamoto Y, Komai T, Miyazaki K et al (2010) Laboratory-scale experiments of the methane hydrate dissociation process in a porous media and numerical study for the estimation of permeability in methane hydrate reservoir. J Thermodyn 2010:1–13. https://doi.org/10.1155/2010/452326

Santamarina JC, Dai S, Terzariol M et al (2015) Hydro-bio-geomechanical properties of hydrate-bearing sediments from Nankai Trough. Mar Pet Geol 66:434–450. https://doi.org/10.1016/j.marpetgeo.2015.02.033

Shen WQ, Zhang J, Shao JF et al (2017) Approximate macroscopic yield criteria for Drucker–Prager type solids with spheroidal voids. Int J Plast 99:221–247. https://doi.org/10.1016/j.ijplas.2017.09.008

Uchida S, Soga K, Yamamoto K (2012) Critical state soil constitutive model for methane hydrate soil. J Geophys Res Solid Earth 117(B3):1–13

Wang LB, Cui JL, Sun CY et al (2021) Review on the applications and modifications of the Chen-Guo model for hydrate formation and dissociation. Energy Fuels. https://doi.org/10.1021/acs.energyfuels.0c03977

Wu P, Li YH, Sun X et al (2021) Mechanical characteristics of hydrate-bearing sediment: a review. Energy Fuels 35(2):1041–1057. https://doi.org/10.1021/acs.energyfuels.0c03995

Xiao R, Zhang W, Xu L et al (2017) Observation of pore structure evolution during three axis compression test of Nanjing silty-fine sand. J Eng Geol 25(s1):0213–0219. https://doi.org/10.13544/j.cnki.jeg.2017.s1.035

Xu CG, Li XS (2015) Research progress on methane production from natural gas hydrates. RSC Adv. https://doi.org/10.1039/c4ra10248g

Xu P, Qiu SX, Yu BM (2013) Prediction of relative permeability in unsaturated porous media with a fractal approach. Int J Heat Mass Transf 64:829–837

Yang L, Zhao J, Liu W et al (2015) Microstructure observations of natural gas hydrate occurrence in porous media using microfocus x-ray computed tomography. Energy Fuels 29(8):4835–4841. https://doi.org/10.1021/acs.energyfuels.5b00881

Yu BM, Cheng P (2002) A fractal permeability model for bi-dispersed porous media. Int J Heat Mass Transf 45(14):2983–2993. https://doi.org/10.1016/S0017-9310(02)00014-5

Yu BM, Li JH (2001) Some fractal characters of porous media. Fractals 9(3):365–372. https://doi.org/10.1142/S0218348X01000804

Zhang N, Wang HN, Jiang MJ (2022) A mesoelastic-plastic damage model for hydrate-bearing sediments with various hydrate-growth patterns. Ocean Eng 266(3):112919. https://doi.org/10.1016/j.oceaneng.2022.112919

Acknowledgements

This study was supported by the National Natural Science Foundation of China (Grant Nos. 12272274, 51890911), Hainan Province Science and Technology Special Fund (Grant No. ZDYF2021SHFZ264) and the State Key Laboratory of Disaster Reduction in Civil Engineering (Grant No. SLDRCE19-A-06). This support was greatly appreciated.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix 1: Derivation of stress-dependent permeability for HBS

1.1 Fractal capillary bundle permeability model of sediments in the absence of hydrates

Experimental results show that pores in the sediments have similar fractal scaling laws, so that fractal theory can be used to describe the complex and random geometric microstructure of the pores. According to fractal geometry theory, regardless of the influence of hydrates, the cumulative size distribution of the pores in the sediments obeys the fractal scale law and satisfies the scale law [34, 35]:

where N is the number of pores or capillary bundles, ε is the length scale, r is the pore size, the minimum and maximum pore radii are defined as rmin and rmax, respectively, and the pore fractal dimensions Df in two and three dimensions are taken as 0 < Df < 2 and 0 < Df < 3, respectively.

Differentiation of Eq. (40) yields the number of pores with a scale distribution between radius r and r + dr:

According to Eq. (40), the total number of pores Nt is given by:

Dividing Eq. (41) by Eq. (42), the probability density function of the pore size distribution in fractal porous media can be obtained as:

According to fractal theory, the Sierpinski carpet model can be used to determine the fractal dimension of the pores [35]:

where the parameter d is the Euclidean dimension. In the two (or three) dimensional space, the parameter should be set to 2 (or 3). In this paper, we assume that the capillary radius does not vary along the flow direction; thus, the Euclidean dimension is set to d = 2. The relationship between the porosity and fractal dimension of fractal porous media is obtained by Eq. (44):

The cross section of the pores is approximated as a circle, and its total area is determined according to the fractal scalar law of the pores [34]:

Substituting Eq. (45) into Eq. (46) can induce the effective area of the representative element volume (REV):

The representative element volume (REV) area A and the representative capillary length L are as follows [32]:

According to fractal theory [35], the length of the curved capillary Lτ should satisfy the following equation:

where DT is the tortuous fractal dimension corresponding to the two-dimensional (1≦DT < 2) or three-dimensional (1≦DT < 3) space. A larger value of parameter DT indicates a more tortuous capillary. In this paper, the Euclidean dimension is set as 2, and the parameters are between 1 and 2. Yu and Cheng [34] suggested that DT can be expressed as:

where

If the aperture ratio ζ = rmin/rmax is reasonably determined, the fractal dimension of pores and tortuosity can be accurately determined by using Eqs. (44) and (52), respectively. Otherwise, substituting Eq. (45) into Eq. (52), we obtain:

For the convenience of derivation, we define:

When the pressure drop is ∆p, the flow rate q(r) of the fluid through the capillary with radius r and length Lτ in the porous medium satisfies the modified Hagen–Poiseuille equation [34]:

where μm is the fluid viscosity and the subscript m is the movable fluid (m = g for the gas phase and m = mw for the movable water phase). The total flow rate in the pore medium is given by:

According to Eq. (55) and Darcy's law, in the absence of hydrate, the permeability K0 of the sediments is given by:

According to Eqs. (48)–(49), Eq. (56) can be simplified as:

1.2 Permeability model of wetting and non-wetting phases for sediments in the absence of hydrates

All capillaries of radius r ≦ rc are assumed to be completely saturated with the wetting fluid (such as water), while capillaries of size r ≥ rc are occupied only by the non-wetting fluid (such as gas) at a given capillary pressure value. The saturation of wetting fluid is given by [32]:

The effective pressure at the critical capillary radius rc can be expressed as \(p = 2\sigma \cos \theta /r_{c}\), where σ is the surface tension of the wetting phase and θ is the liquid–solid contact angle. Then, Eq. (58) can be rewritten as:

Assuming that the incompressible fluid is in steady and laminar flow in the capillary, according to the Hagen–Poiseuille equation, the wetting and non-wetting phase volume flow rates Qw and Qnw, respectively, are given by:

According to Eqs. (60), (61) and Darcy's law, the effective permeability of the wetting phase Kw and non-wetting Knw is written as:

According to Eqs. (43)–(57), Eqs. (62), (63) are, respectively, rewritten as follows:

1.3 Stress-dependent permeability of HBS with a universal growth pattern

In the presence of hydrates, considering the particle arrangement of the maximum effective porosity, the effective porosity is substituted into Eqs. (57) and (64), (65), and the relative permeability of HBS (\(k_{h}\)), the wetting phase (\(k_{h}^{w}\)) and the non-wetting phase (\(k_{h}^{nw}\)) are written as:

Ignoring the influence of saturation Sh on rc and considering the attenuation effect of the sediment on the permeability and the correction of the effective pressure on the pore size, Eq. (14) is substituted into Eqs. (57) and (64), (65) to obtain the stress-dependent absolute permeability for HBS (\(K_{h}\)), the wetting phase (\(K_{h}^{w}\)) and the non-wetting phase (\(K_{h}^{nw}\)), respectively:

where N is the permeability attenuation index.

1.4 Stress-dependent permeability model of HBS with various hydrate growth patterns

With a pressure drop ∆p, the flow rate equations of PF-hydrate and WC-hydrate are as follows [16]:

Integrating Eqs. (72) and (73), the volume flow rates of PF-hydrate and WC-hydrate in a single capillary, respectively, are:

According to Eqs. (74) and (75), the total volume flow rates of PF-hydrate and WC-hydrate are, respectively, given by:

where \(\delta_{{{\text{wc}}}} = (1 - \sqrt {1 - S_{h} } )r\), δw is the water film thickness, the parameters a1, a2, and a3 are constants, and μrw is the viscosity of the residual water. When the water film thickness δw is ignored, according to Eqs. (14), (76)–(77) and Darcy's law, the stress-dependent permeability of HBS with pore-filling and wall-coating patterns can be written as:

The stress-dependent permeability of HBS with grain-cementing pattern is given by:

and its derivation is shown in Appendix 2.

Appendix 2: Derivation of stress-dependent permeability for HBS with grain-cementing hydrates

Figure

13 shows a representative element volume (REV) of the particle arrangement for maximum effective porosity, and the area of particles is πd2/4; thus, the area AREV can be expressed as:

where the average diameter of particles is defined as \(\overline{d}\). If the pore is equivalent to a circle, the maximum pore area can be written as:

According to the geometric relationship, the maximum pore radius and the average particle diameter are related by:

In the following derivation, the diameter d is the particle diameter corresponding to the distribution of pore radius r. According to the geometric relationships, the area of REV (AREV), the area of pore space (Ap) and the area of hydrate (Ah) are, respectively:

Figure

14 shows the simplified diagram of intergranular cementation of hydrates in sediments. According to the geometric relationship of GC hydrates:

Assuming that the cementation thickness hcr is proportional to the pore size, such as the radius r, i.e., \(h_{cr} \user2{(}r\user2{)} \propto r\) and \(h_{cr}^{max} \user2{(}r\user2{)} \propto r\), we obtain:

Meanwhile, the cementation thickness is assumed to be related to the growth law \(f_{{{\text{grow}}}}^{h} (S_{h} )\):

where β0 and γ0 are the ratios of pore spacings H1 and H2 to the particle size at the maximum hydrate saturation, respectively. Arranging Eqs. (88), (90)–(92), we can deduce that:

When B/d is small, the second-order Taylor expansion form is:

Combining Eqs. (87)–(92), we obtain:

We note that the area equality of Eqs. (87) and (89) cannot be strictly guaranteed, and we therefore ignore the geometry of GC hydrates here. The effective pore area \(A_{p}^{e}\) of a single capillary bundle and the total pore area \(A_{p}^{t}\) of the REV are given by:

According to the definition of Eq. (100) and porosity, the total cross-sectional area A of REV is given by:

According to the effective pore radius (\(r = \sqrt {1 - S_{h} } r_{0}\)), combining Eqs. (49), (55), (101) and Darcy's law, the fractal capillary bundle permeability of hydrate-bearing sediments (HBS) with a grain-cementing pattern is given by:

Considering the effect of the permeability attenuation index and effective pressure on sediments, Eq. (14) is substituted into Eq. (102) to obtain the stress-dependent permeability expression of HBS with a grain-cementing pattern:

Appendix 3: Derivation of cementation thickness

In Fig. 14, according to the area relationship:

Rearranging Eq. (104), the maximum pore diameter is related to the average particle diameter as follows:

Substituting Eqs. (48), (49) and (105) into (102), the following can be obtained:

Substituting Eqs. (49) and (84) into (107) yields the permeability expression of HBS with a grain-cementing pattern:

Combining Eqs. (9), (57), and (84), it is derived that:

Comparing Eqs. (108) and (109), the maximum cementation thickness \(H_{cr}^{\max }\) of GC hydrates is obtained as:

Equation (110) can be abbreviated as \(H_{2} = \delta \overline{d}\), where δ is defined as follows:

Assuming that the particles have the same volume (area) shape factor, the fractal dimension Dp of the pore radius with the GC-growth pattern is equal to the fractal dimension Ds of the particle size:

The median particle size and the mean radius are considered to be approximately equal, \(r_{50} = \overline{r}\) and \(d_{50} = \overline{d}\). By definition:

The sorting coefficient δp and the variation coefficient Cp are the parameters reflecting the uniformity of the pores. A smaller value of δp corresponds to better uniformity. Considering the continuity of the pore radius distribution:

The variation coefficient Cp is the ratio of the sorting coefficient (standard deviation) to the mean radius and can be written as:

The median (or average) hydrate cementation thickness can be written as:

Finally, the ratio of the average cementation thickness to the median particle size can be obtained:

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhang, N., Wang, H.N. & Jiang, M.J. A mechanistic model for porosity and permeability in deformable hydrate-bearing sediments with various hydrate growth patterns. Acta Geotech. 19, 855–880 (2024). https://doi.org/10.1007/s11440-023-01954-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11440-023-01954-w