Abstract

The failure behavior of field-scale rock masses has long been studied indirectly through laboratory compression tests on rock specimens with preexisting flaws. However, little to no attention has been paid to size effects on these cracking processes that may be governed by the relative size between the fracture process zone and the rock structure. Here, we investigate such size effects on the compressive strength and cracking behavior of flawed rocks through high-fidelity simulations of mixed-mode fracture in quasi-brittle materials. We perform a series of numerical uniaxial compression tests on geometrically similar gypsum specimens with single and double flaws, across a wide range of sizes from 0.25 times a standard laboratory specimen size to 16 times. The results suggest strong size effects on both the uniaxial compressive strength and cracking patterns. The size effect on the compressive strength appears qualitatively similar to Bažant’s size effect law derived for the tensile strength of notched structures. However, the quantitative changes in the strength deviate from the existing size effect law which does not account for mixed-mode fracture. As for the cracking behavior, three types of cracking patterns per flaw configuration are identified as the specimen size changes. Remarkably, the cracking patterns that emerge at the field scale, where the size of the fracture process zone is negligible, are analogous to those observed from laboratory experiments on highly brittle materials. The findings of this work provide important insights into how to bridge observations on rock fracturing processes across scales.

Similar content being viewed by others

Data availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Arndt D, Bangerth W, Clevenger TC, Davydov D, Fehling M, Garcia-Sanchez D, Harper G, Heister T, Heltai L, Kronbichler M, Kynch RM, Maier M, Pelteret J-P, Turcksin B, Wells D (2019) The deal.II library, version 9.1. J Numer Math 27(4):203–213

Bangerth W, Hartmann R, Kanschat G (2007) deal.II - a general purpose object oriented finite element library. ACM Trans Math Softw 33(4):24/1-24/27

Bauer E, Ebrahimian B (2021) Investigations of granular specimen size effect in interface shear box test using a micro-polar continuum description. Int J Numer Anal Meth Geomech 45(17):2467–2489

Bažant ZP (1984) Size effect in blunt fracture: concrete, rock, metal. J Eng Mech 110(4):518–535

Bažant ZP (2004) Scaling theory for quasibrittle structural failure. Proc Natl Acad Sci 101(37):13400–13407

Bažant ZP, Ožbolt J (1990) Nonlocal microplane model for fracture, damage, and size effect in structures. J Eng Mech 116(11):2485–2505

Bažant ZP, Planas J (1997) Fracture and size effect in concrete and other quasibrittle materials, vol 16. CRC Press, Florida

Bažant ZP, Xiang Y (1997) Size effect in compression fracture: splitting crack band propagation. J Eng Mech 123(2):162–172

Bažant ZP, Kim J-JH, Daniel IM, Becq-Giraudon E, Zi G (1999) Size effect on compression strength of fiber composites failing by kink band propagation. Int J Fract 95(1):103–141

Bobet A, Einstein HH (1998) Numerical modeling of fracture coalescence in a model rock material. Int J Fract 92(3):221–252

Bobet A, Einstein H (1998) Fracture coalescence in rock-type materials under uniaxial and biaxial compression. Int J Rock Mech Min Sci 35(7):863–888

Bombolakis EG (1968) Photoelastic study of initial stages of brittle fracture in compression. Tectonophysics 6(6):461–473

Borden MJ, Verhoosel CV, Scott MA, Hughes TJ, Landis CM (2012) A phase-field description of dynamic brittle fracture. Comput Methods Appl Mech Eng 217:77–95

Bourdin B, Francfort GA, Marigo J-J (2008) The variational approach to fracture. J Elast 91(1):5–148

Bryant EC, Sun W (2018) A mixed-mode phase field fracture model in anisotropic rocks with consistent kinematics. Comput Methods Appl Mech Eng 342:561–584

Burstedde C, Wilcox LC, Ghattas O (2011) p4est: scalable algorithms for parallel adaptive mesh refinement on forests of octrees. SIAM J Sci Comput 33(3):1103–1133

Carrasco S, Cantor D, Ovalle C (2022) Effects of particle size-shape correlations on steady shear strength of granular materials: the case of particle elongation. Int J Numer Anal Meth Geomech 46(5):979–1000

Cheng Y, Wong LNY, Zou C (2015) Experimental study on the formation of faults from en-echelon fractures in carrara marble. Eng Geol 195:312–326

Choo J (2018) Large deformation poromechanics with local mass conservation: an enriched Galerkin finite element framework. Int J Numer Meth Eng 116(1):66–90

Choo J (2019) Stabilized mixed continuous/enriched Galerkin formulations for locally mass conservative poromechanics. Comput Methods Appl Mech Eng 357:112568

Choo J, Borja RI (2015) Stabilized mixed finite elements for deformable porous media with double porosity. Comput Methods Appl Mech Eng 293:131–154

Choo J, Sun W (2018) Cracking and damage from crystallization in pores: coupled chemo-hydro-mechanics and phase-field modeling. Comput Methods Appl Mech Eng 335:347–379

Choo J, Sun W (2018) Coupled phase-field and plasticity modeling of geological materials: from brittle fracture to ductile flow. Comput Methods Appl Mech Eng 330:1–32

Cotterell B (1972) Brittle fracture in compression. Int J Fract Mech 8(2):195–208

Fei F, Choo J (2020) A phase-field model of frictional shear fracture in geologic materials. Comput Methods Appl Mech Eng 369:113265

Fei F, Choo J (2020) A phase-field method for modeling cracks with frictional contact. Int J Numer Meth Eng 121(4):740–762

Fei F, Choo J (2021) Double-phase-field formulation for mixed-mode fracture in rocks. Comput Methods Appl Mech Eng 376:113655

Fei F, Choo J, Liu C, White JA (2022) Phase-field modeling of rock fractures with roughness. Int J Numer Anal Meth Geomech 46(5):841–868

Fei F, Mia MS, Elbanna AE, Choo J (2023) A phase-field model for quasi-dynamic nucleation, growth, and propagation of rate-and-state faults. Int J Numer Anal Meth Geomech 47(2):187–211

Fei F, Sun Y, Wong LNY, Choo J (2021) Phase-field modeling of mixed-mode fracture in rocks with discontinuities: from laboratory scale to field scale, U.S. Rock Mechanics/Geomechanics Symposium

Feng D-C, Wu J-Y (2018) Phase-field regularized cohesive zone model (CZM) and size effect of concrete. Eng Fract Mech 197:66–79

Geelen RJ, Liu Y, Hu T, Tupek MR, Dolbow JE (2019) A phase-field formulation for dynamic cohesive fracture. Comput Methods Appl Mech Eng 348:680–711

Ha YD, Lee J, Hong J-W (2015) Fracturing patterns of rock-like materials in compression captured with peridynamics. Eng Fract Mech 144:176–193

Heroux MA, Willenbring JM (2012) A new overview of the Trilinos project. Sci Program 20(2):83–88

Hoek E, Bieniawski Z (1965) Brittle fracture propagation in rock under compression. Int J Fract Mech 1(3):137–155

Hoover CG, Bažant ZP (2014) Cohesive crack, size effect, crack band and work-of-fracture models compared to comprehensive concrete fracture tests. Int J Fract 187(1):133–143

Huang J, Chen G, Zhao Y, Wang R (1990) An experimental study of the strain field development prior to failure of a marble plate under compression. Tectonophysics 175(1–3):269–284

Huillca Y, Silva M, Ovalle C, Quezada JC, Carrasco S, Villavicencio GE (2021) Modelling size effect on rock aggregates strength using a dem bonded-cell model. Acta Geotech 16(3):699–709

Ingraffea AR, Heuze FE (1980) Finite element models for rock fracture mechanics. Int J Numer Anal Meth Geomech 4(1):25–43

Kumar A, Bourdin B, Francfort GA, Lopez-Pamies O (2020) Revisiting nucleation in the phase-field approach to brittle fracture. J Mech Phys Solids 142:104027

Lale E, Cusatis G (2021) Symmetric high order microplane model for damage localization and size effect in quasi-brittle materials. Int J Numer Anal Meth Geomech 45(10):1458–1476

Lee H, Jeon S (2011) An experimental and numerical study of fracture coalescence in pre-cracked specimens under uniaxial compression. Int J Solids Struct 48(6):979–999

Lee J, Ha YD, Hong J-W (2017) Crack coalescence morphology in rock-like material under compression. Int J Fract 203(1–2):211–236

Lee J, Hong J-W, Jung J-W (2017) The mechanism of fracture coalescence in pre-cracked rock-type material with three flaws. Eng Geol 223:31–47

Miehe C, Welschinger F, Hofacker M (2010) Thermodynamically consistent phase-field models of fracture: Variational principles and multi-field fe implementations. Int J Numer Meth Eng 83(10):1273–1311

Morgan SP, Johnson CA, Einstein HH (2013) Cracking processes in barre granite: fracture process zones and crack coalescence. Int J Fract 180(2):177–204

Palmer AC, Rice JR (1973) The growth of slip surfaces in the progressive failure of over-consolidated clay. Proc R Soc Lond A Math Phys Sci 332(1591):527–548

Park CH, Bobet A (2009) Crack coalescence in specimens with open and closed flaws: a comparison. Int J Rock Mech Min Sci 46(5):819–829

Peng J, Wong LNY, Teh CI (2017) Effects of grain size-to-particle size ratio on micro-cracking behavior using a bonded-particle grain-based model. Int J Rock Mech Min Sci 100:207–217

Peng J, Wong LNY, Teh CI (2017) Influence of grain size heterogeneity on strength and microcracking behavior of crystalline rocks. J Geophys Res Solid Earth 122(2):1054–1073

Sagong M, Bobet A (2002) Coalescence of multiple flaws in a rock-model material in uniaxial compression. Int J Rock Mech Min Sci 39(2):229–241

Shen B, Stephansson O (1994) Modification of the G-criterion for crack propagation subjected to compression. Eng Fract Mech 47(2):177–189

Tanné E, Li T, Bourdin B, Marigo JJ, Maurini C (2018) Crack nucleation in variational phase-field models of brittle fracture. J Mech Phys Solids 110:80–99

Wong NY (2008) Crack coalescence in molded gypsum and carrara marble. Ph.D. thesis, Massachusetts Institute of Technology

Wong LNY, Einstein HH (2009) Crack coalescence in molded gypsum and Carrara marble: part 1. Macrosc Obs Interpret Rock Mech Rock Eng 42(3):475–511

Wong LNY, Einstein HH (2009) Crack coalescence in molded gypsum and Carrara marble: part 2–microscopic observations and interpretation. Rock Mech Rock Eng 42(3):513–545

Wong LNY, Einstein HH (2009) Systematic evaluation of cracking behavior in specimens containing single flaws under uniaxial compression. Int J Rock Mech Min Sci 46(2):239–249

Wong LNY, Zhang X-P (2014) Size effects on cracking behavior of flaw-containing specimens under compressive loading. Rock Mech Rock Eng 47(5):1921–1930

Wu J-Y (2017) A unified phase-field theory for the mechanics of damage and quasi-brittle failure. J Mech Phys Solids 103:72–99

Wu Z, Wong LNY (2012) Frictional crack initiation and propagation analysis using the numerical manifold method. Comput Geotech 39:38–53

Wu J-Y, Yao J-R (2022) A model scaling approach for fracture and size effect simulations in solids: cohesive zone, smeared crack band and phase-field models. Comput Methods Appl Mech Eng 400:115519

Zhang X-P, Wong LNY (2013) Crack initiation, propagation and coalescence in rock-like material containing two flaws: a numerical study based on bonded-particle model approach. Rock Mech Rock Eng 46(5):1001–1021

Zhao X, Zhu J, Jia Y, Colliat J-B, Bian H, Zhang Q. Experimental and numerical study of size effects on the crushing strength of rockfill particles. Int J Numer Anal Methods Geomech

Acknowledgements

Financial support for this work was provided by the Research Grants Council of Hong Kong (Project No. 17201419). Portions of this work were performed under the auspices of the US Department of Energy by Lawrence Livermore National Laboratory under Contract DE-AC52-07NA27344.

Author information

Authors and Affiliations

Contributions

JC involved in conceptualization, methodology, software, investigation, writing—original draft, writing—review and editing, visualization, supervision, project administration, and funding acquisition. YS involved in methodology, software, validation, formal analysis, investigation, data curation, writing—review, and visualization. FF involved in methodology, software, validation, investigation, writing—review, and visualization.

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

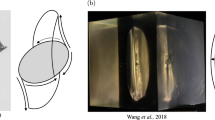

Appendix 1: Validation of the phase-field model for investigating energetic size effects

This appendix validates that under pure tensile failure, the phase-field model used in this study produces nominal strengths that follow Bažant’s size effect law. To this end, we use the phase-field model to simulate a series of three-point bending tests, which is a standard problem used for examining size effects on tensile strengths. Figure 12 depicts the setup of the three-point bending tests conducted herein. To investigate size effects, the tests are repeated for specimens of ten different size factors: \(D=0.01,0.0625,0.125,0.25,0.5,1,2,4,8\), and 16. The numerical tests use the same material parameters and the discretization scheme as those in the uniaxial compression tests on the flawed specimens.

Figure 13 presents the nominal strengths of the notched beam specimens with varied D. Also shown is Bažant’s size effect law, Eq. (1), fitted to the nominal strengths. One can see that the nominal strengths show size dependence that is well-described by the existing size effect law—an analytical expression derived for notched structures made of quasi-brittle materials. As such, it is confirmed that the phase-field model is a suitable means for investigating energetic (FPZ-related) size effects.

Nominal strengths in the three-point bending tests with varied D, and Bažant’s size effect law fitted to the nominal strengths (\(\sigma _0=4.2\) MPa and \(D_0=0.257\) for Eq. 1)

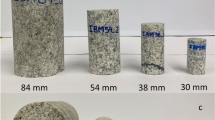

Appendix 2: Selection of the phase-field length parameter

This appendix describes how the value of the phase-field length parameter, L, is selected for the numerical experiments in this study. We note that although the double-phase-field model is built on formulations where stress–strain responses are insensitive to L at the material point level, it can still show some degree of sensitivity to L at the structural level, see, e.g., [29, 32]. For our purpose, a good value of L should be (i) small enough to produce physically meaningful results and (ii) large enough to be computationally affordable. To find such a value, we test three different values of L for conducting a series of numerical uniaxial compression tests on the 45-single specimens with varied D.

Figure 14 shows how the UCS and their size dependence are affected by the value of L. It can be seen that as L becomes smaller, the UCS slightly increase particularly when the structure size is larger. This trend may be explained by that as the structure becomes larger, it fails in a more brittle manner, and hence its strength becomes more dependent on the width of the phase-field regularization. Note, however, that our interest in this study is not the values of UCS per se. Instead, we are interested in the decay rate (the slope in the bi-logarithmic plot) of UCS, which quantifies the energetic size effects. From the figure, one can find that the decay rate shows a convergent value of 1/1.34 from \(L=0.15D\) mm. So it can be concluded that the choice of \(L=0.15D\) mm is physically meaningful, while involving less computational cost than a smaller value of L. Also, while not presented for brevity, the cracking patterns obtained with the three values of L are virtually identical. Therefore, we select \(L=0.15D\) mm for the numerical experiments in this study.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Choo, J., Sun, Y. & Fei, F. Size effects on the strength and cracking behavior of flawed rocks under uniaxial compression: from laboratory scale to field scale. Acta Geotech. 18, 3451–3468 (2023). https://doi.org/10.1007/s11440-023-01806-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11440-023-01806-7