Abstract

In the last decade, biopolymers have been used as organic soil binders in ground improvement and earthen construction material modification. Although biopolymer-treated soils have substantially enhanced mechanical strength, the deformation characteristics under external loads and material durability (e.g. biodeterioration due to microbial activity) have not yet been fully understood, which limits the in situ practical application of the biopolymer-based soil treatment technology. This study investigated the efficiency of combined carrageenan and casein in strengthening a clayey soil with the biodeterioration consideration. Both mechanical tests (e.g. unconfined compressive strength and one-dimensional consolidation) and biological tests (e.g. high throughput sequencing and rating of mould growth) were conducted. Results indicated that the usage of the carrageenan–casein mixture induced a higher soil compressive strength compared with either carrageen or casein, due to the formation of a three-dimensional gel network. In addition, carrageenan–casein mixture and casein decreased the compressibility of the clayey soil, which might be attributed to the casein’s peculiarity of self-associating into micelles, leading to minimal interactions with water molecules. Carrageenan, due to its affinity for water, increased the soil compressibility. Under the impact of microbial activity, the biopolymer-treated soils underwent deterioration in both surface appearance (i.e. coloured stains and patches caused by mould growth) and compressive strength. A linear relationship was proposed, in which a reduction in compressive strength by approximately 11% is expected while the rating of mould growth is increased by one in a five-rating system. The current research demonstrates that the soil reinforcement with combined carrageenan and casein is able to improve both soil strength and deformation behaviours. It is also suggested to take into account the biodeterioration considerations in the design and implementation of biopolymer-based soil reinforcement practices.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Biopolymers with high strengthening efficiency and low environmental impact have been gaining increasing credence in sustainable geotechnical engineering practices [6, 21, 22, 29, 30, 54, 61]. Biopolymers have the potential to be used either as soil binders for ground improvement [16, 17, 47, 64, 76] or as additives applied to soil-based construction members [1, 56, 58], to improve soil performances like strength, deformation, and durability.

There are mainly three factors influencing the efficiency of biopolymers in soil strength reinforcement, namely biopolymer type, blending content, and moisture condition. If based on the physiochemical inter-particle reactions, biopolymers with surface charges are more likely to bind directly to clay particles via ionic and hydrogen bonds [16, 17, 21, 64, 76]. In addition, biopolymers that contain more functional groups and heavier molecular weight tend to have greater hydrogel viscosity and denser structure, hence showing better soil stabilizing effect [22, 23, 29, 47]. Regarding the biopolymer content, there exists an optimum biopolymer dosage, which is related to the percentage of clay particles in soils [17, 62]. Excessive blending content might induce ionic repulsion and/or hydrologic swelling, leading to a reduced soil strength. There is also an ideal initial moisture content, which not only influences the workability of biopolymer–soil mixtures during sample preparation, but also affects the soil strength after drying [64]. Moisture loss during the sample drying process transforms biopolymer gels from a rubbery state to a glassy state, resulting in increased cohesion and internal frictional angle [26, 34, 41]. The moisture path (e.g. wetting–drying cycles) during this state transformation also has an impact on the soil strength [20, 25, 77].

Compared with the well documented strength enhancement of biopolymer-treated soils, limited research has assessed the compressibility of the soils reinforced with biopolymers. Previous one-dimensional consolidation test results indicated that hydrophilic biopolymers (e.g. xanthan gum and guar gum) tend to increase the soil compressibility [14, 15, 48, 76]. Since compressibility is one of the most important soil reinforcement measurements in geotechnical engineering design [39, 40, 63]; further studies need to be conducted for obtaining a better understanding of the impact of different types of biopolymers on soil compressibility. Furthermore, since biopolymers are organic matters (e.g. polysaccharide and protein-based biopolymers), biodegradation is more sceptical to occur in the biopolymer-treated soils compared with the soils reinforced with other traditional materials (e.g. cement, fly ash, lime, etc.) [71]. The biodeterioration caused by microbial activity can induce changes in surface appearance, biochemical, physical, and mechanical properties [37, 46, 66, 74]. Therefore, it is ultra-important to probe the biodeterioration behaviour of the biopolymer-reinforced soils in particular by considering their life cycles.

Given this background, this study involved a series of mechanical and biological tests, aiming to deepen the understanding of the biopolymer-treated soil performances in terms of strength, compressibility, and biodeterioration. Three types of biopolymers (carrageenan, casein, and carrageenan–casein mixture) were chosen as the soil binders. Carrageenan and casein are polysaccharide and protein-based biopolymers, respectively. Their potential in improving soil strength has been studied recently [19, 34, 58], while their impact on soil compressibility remains unknown. The idea of using combined carrageenan and casein for soil treatment arose from the previous research in the food industry. It has been indicated that the electrostatic attraction between the negatively charged carrageenan chains and the positive region on the casein micelles leads to the formation of a three-dimensional network of biopolymer gels [45, 49, 50, 72, 73], which is possible to allow more efficient soil enhancement to occur. Furthermore, considering that carrageenan and casein contain typical nutrients such as carbon sources and nitrogen sources, respectively, they may have different impacts on microbial activity and biodeterioration.

2 Materials and methods

2.1 Base soil and biopolymers

2.1.1 Clayey soil

The clayey soil obtained from Shanghai, China, was used in this study. As a deltaic deposit, it contained both coarse-grained and fine-grained soils [55], having 33.4% of sand, 54.9% of silt, and 11.7% of clay particles. It had basic properties of liquid limit wL = 37.9%, plastic limit wP = 22.0%, optimum moisture content OMC = 23.1%, and specific gravity Gs = 2.7. The clayey soil was classified as sand lean clay based on [4].

2.1.2 Carrageenan

Carrageenan is a sulphated polysaccharide obtained from red algae [75]. It has a linear structure, with a backbone of alternating α-l,4 and β-l,3-linked galactose residues and varying proportions of half ester groups, which bestow a negative charge to the carrageenan molecules [31]. Over the last few decades, carrageenan has been widely utilized as a food additive for its excellent thickening, gelling and stabilizing abilities [2, 43]. A recent study revealed that carrageenan has the potential to serve as a soil stabilizer [58]. The κ-carrageenan powder used in this study was produced by Zhengzhou Boyan Technology Co., Ltd. with a weight-average molecular weight of 788 kDa.

2.1.3 Casein

Casein is a protein-based biopolymer comprising phosphoproteins typically found in mammalian milk and can be extracted by acidification, centrifugation, and filtration [19, 34, 35]. Casein has the peculiarity of self-associating into micelles [42, 69]. Casein micelles are formed by the association of sub-micelles via calcium phosphate bridges. Sub-micelles are aggregates of several casein molecules linked by hydrophobic and electrostatic bonds. κ-casein is mostly located at the periphery of the casein micelle, with its hydrophilic part behaving as flexible chains in the solvent, and has a positive patch between amino acids residues 97 and 112 [72, 73]. Casein itself has found a wide range of applications in food, cosmetics, adhesive, industrial paint, pharmaceutical product, and textile industry [32, 59, 68]. In the field of geotechnical engineering, casein was found effective in sustaining soil strength after the drying–wetting treatment [19], mainly due to the hydrophobic bonds of the nonpolar side chains of amino acids in casein, which leads to minimal interactions with water molecules [60]. In this study, the casein powder manufactured by Zhengzhou Boyan Technology Co., Ltd was used. It had a high casein content and small fractions of lactose and fat: 92% protein (of which 91% was casein), 1% lactose, 0.5% minerals, 1.5% fat, and 5% water.

2.2 Sample preparation

The clayey soil was oven-dried, pulverized, and sieved using a 2-mm sieve prior to use. In the previous studies, two different mixing methods for sample preparation have been used in the laboratory: dry mixing in which the biopolymer powder is directly mixed with the dry soil before adding water [52, 56, 64, 76] and wet mixing in which the biopolymer powder is first mixed with water to form a gel before mixing in the dry soil [6, 7, 25, 47]. According to Chang et al. [21], for a relatively high biopolymer-to-water ratio (e.g. above the solubility point), wet mixing produces highly viscous biopolymer gels that might lead to poor workability and difficulty in mixing with the dry soil. Therefore, the dry mixing method was adopted here considering the level of blending content used. To facilitate hydration, the distilled water was heated to 80 °C [19, 49, 50]. To restrain fungal growth, fungicide Captan with a blending content 0.2% was added to the biopolymer–soil mixtures at this stage [28], i.e. mCaptan/(ms + mcar + mcas) = 0.2%, in which ms is the dry soil mass, mCaptan is the mass of fungicide Captan, mcar is the mass of carrageenan power, and mcas is the mass of casein powder. After dry mixing, the biopolymer–soil mixture was placed inside a cylindrical mould with an inner diameter of 39 mm and a height of 80 mm in three layers. For each layer, 25 blows were applied through a rammer (305.5 g) dropping from a height of 247 mm. This compaction procedure delivered energy of 577.7 kN·m/m3, which was slightly smaller than that from the standard proctor compaction (600 kN·m/m3) [5]. The compacted samples were extruded after compaction and cured under the controlled environment with a temperature of 20 °C and 80% relative humidity.

2.3 Unconfined compressive strength (UCS) tests

Unconfined compressive strength (UCS) tests were conducted on the soils treated with one of the biopolymers (i.e. carrageenan, casein, and carrageenan–casein mixture). The experimental variables included carrageenan-to-casein ratio, blending content, initial moisture content and curing period, see Table 1. The carrageenan-to-casein ratio (mcar/mcas) changed from 0:3 (casein only), through 1:3, 2:3, 3:3, 3:2, 3:1 to 3:0 (carrageenan only). The blending content was represented by a biopolymer-to-soil ratio, (mcar + mcas)/ms = 2%, 4%, 6%, and 8%. The initial moisture content used for sample preparation was defined as a water-to-solid ratio (mw/(ms + mcar + mcas + mCaptan)), in which mw is the mass of water. The initial moisture content varied approximately from 1.0 to 1.6 times OMC of the untreated soil (i.e. natural soil without biopolymer and fungicide), i.e. 24%, 28%, 32%, and 36%. The UCS samples were cured for 7, 14, 21, and 28 days. The untreated soil sample prepared with OMC and cured for 28 days was used for comparison. UCS tests were designed based on the orthogonal method [53, 80]. As there were one factor (FA) with seven levels and three factors (FB, FC, and FD) with four levels, an orthogonal array of L32 (81 × 43) was adopted. A virtual level (level 8) equal to level 1 was added to FA. So, level 1 of FA was repeated more times than other levels in Table 2.

When the curing period came to an end, the samples were brought to the UCS tests. A strain-controlled load-applying scheme with a loading rate of 1.5%/min was adopted in accordance with [3]. All the experiments were replicated at least five times to achieve a reliable average.

2.4 One-dimensional consolidation tests

After the analysis of UCS results, certain treatment conditions that contributed positively to enhancing soil strength were revealed and the one-dimensional consolidation tests were designed accordingly as shown in Table 3. The biopolymer–soil mixtures for consolidation tests were prepared using the dry mixing method with an initial void ratio of 1.2. The consolidation samples had slightly different initial moisture contents taking into account the effect of biopolymer on Gs. The one-dimensional consolidation tests complied with [38]. Samples were cured, saturated, and loaded under the vertical stress ranging from 25 to 800 kPa. The load was doubled each day, i.e. the ratio of load increment to existing load was 1. During the loading phase, drainage was permitted through porous stones at the bottom and top. Void ratio versus vertical stress graphs were plotted to study the compression characteristics of biopolymer-treated soils. The coefficient of volume compressibility (mv), compression index (Cc), and coefficient of consolidation (Cv) were calculated.

2.5 Biodeterioration analysis

Fungi are one of the most frequently studied microorganisms that exert microbial impacts on material properties. One of the obvious impacts of fungi contamination on material properties is coloured stains and patches on materials surfaces due to mould growth [13, 46, 74]. Moulds are a Deuteromycetes sub-group of filamentous fungi [27, 66]. Mould growth assessment can be employed to explore the surface phenomenon, according to [46, 74]. On the other hand, fungi can induce the weathering/degradation of materials by physical and chemical actions as well, for example by releasing organic acids which are responsible for the weakening of the mineral matrix [8]. Here, biodeterioration of the biopolymer–soil composite material caused by microbial activity was evaluated by fungal identification (e.g. diversity and relative abundance), change in surface appearance (e.g. rating of mould growth), and degradation in mechanical properties (e.g. UCS reduction), according to the definition of biodeterioration proposed previously by [37].

2.5.1 UCS degradation evaluation

The procedure for preparing the fungi-contaminated samples (i.e. soils are treated with biopolymer but without fungicide) was the same as that described in Sect. 2.2, except that fungicide Captan was not added in the biopolymer–soil mixtures. All the treatment conditions applied on the biopolymer-treated samples (with fungicide) were repeated on the fungi-contaminated samples, see Table 2.

2.5.2 High-throughput sequencing (HTS)

Amplicon sequencing was used to identify the fungal genus in the samples that were treated with pure carrageenan (sample No. 19 in Table 2), pure casein (sample No. 23), and carrageenan–casein mixture (sample No. 27), after the UCS tests. Total soil DNA was extracted by the E.Z.N.A. Soil DNA Kit (OMEGA, USA). Samples, processed on 2% agarose gel electrophoresis, were used to construct a library. PCR amplification was conducted on the total microbial DNA, by using specific primers for the fungal ITS1 region [33]. Finally, the Illumina MiSeq was used for high-throughput sequencing (HTS). Initial data were filtered and optimized via FLASH and Trimmomatic software. The high-quality sequences were divided into operational taxonomic units (e.g. OTUs) based on 97% similarity level by Usearch software. According to the Unite Fungus Database, the RDP Classifier Bayesian Algorithm was used for species annotation and classification. Three specimens were extracted from each of the three soil samples (No. 19, No. 23, and No. 27) and tested, in order to obtain a reliable average.

2.5.3 Rating of mould growth (RMG)

Before UCS tests, the fungi-contaminated samples were observed with respect to the fungus mycelial that had grew on the exterior surface of the soil samples, for the assessment of rating of mould growth (RMG). RMG can be detected by either unaided eyes and/or a microscope. In this study, RMG was visually evaluated by experienced researchers with unaided eyes under good illumination conditions. A five-rating system [46] was employed to describe RMG from no growth (RMG = 0) to very heavy growth (RMG = 4), see Table 4. To eliminate the uncertainty that occurred due to the nature of the visual observation, each sample was evaluated by three individual observers and an agreement on the final rating was reached.

3 Results and analysis

3.1 UCS test results for the biopolymer-treated samples with fungicide

3.1.1 Synergetic interaction between carrageenan and casein

Table 2 presents the results of the UCS tests for the biopolymer-treated samples with fungicide, based on which the variation in UCS against the carrageenan-to-casein ratio is shown in Fig. 1a. Due to the nature of the orthogonal method, Fig. 1a was plotted according to the following procedure which was also applicable to the rest panels of Figs. 1, 8, 9, and 10. In Fig. 1a, for mcar/mcas = 0:3 (Influencing Factor: FA and Level: 1, see Table 1), the UCS values corresponding to the samples No. 1, 4, 9, 13, 17, 23, 28, and 31 in Table 2 were averaged to obtain a representative value of 2.75 MPa. The error bar, in addition, gave the extra information of the maximum and minimum UCS values for the samples with mcar/mcas = 0:3.

The carrageenan-treated soils had a slightly increased UCS (i.e. 2.15 MPa) compared with the untreated soil (i.e. denoted by the red dotted line). The soil strength enhancement was attributed to the ionic bonding between the negatively charged sulphate group of carrageenan and clay particles enhanced by the cations (i.e. K+, Na+, Mg2+, and Ca2+) present in the natural soil [58]. However, carrageenan’s adsorption capacity for metal ions is relatively low [70]. The casein-treated soils had a more evident UCS improvement (i.e. 2.75 MPa), as a result of the chemical bonds between the large number of protein groups (i.e. amide group, amine group, phosphate group, and carboxylic acid) and soil particles [34, 35].

The soils treated with carrageenan–casein mixtures presented the highest UCS of 3.21 MPa at mcar/mcas = 1:3 due to the synergetic interaction between carrageenan and casein. Several researchers have conducted in-depth analyses of the strengthening mechanism of biopolymer-treated soils [17, 21, 47, 62, 77]. In soil containing both fine and coarse particles, the biopolymer molecules may first interact with the clay particles, forming a clay-biopolymer matrix [17, 62]. Hence, the silt and sand particles present in the soil could be connected by either biopolymer or clay-biopolymer matrix, as shown in Fig. 2a. Basically, for a composite material like biopolymer-treated soil, two internal forces, namely the cohesive force of biopolymers and the adhesive force between biopolymers and soil particles, influence its macro-mechanical performance [47]. At temperatures above the coil-helix transition temperature, carrageenan chains exist as random coils [67]. Upon cooling, carrageenan has a conformational transition from random coils to intertwined helices [67]. During this process, carrageenan adsorbs onto the casein micelles mainly through an electrostatic attraction between the negatively charged carrageenan chains (i.e. sulphate half ester groups) and the positive patch between amino acid residues near the surface of casein micelles, according to [72, 73]. The underlying mechanism of a helical form being more prone to interact with casein lies in the variation in the electrostatic charge density. According to [65], the mean distance between sulphate groups reduces approximately by one-half as carrageenan undergoes the coil to helix transition, which leads to an increase in the charge density and hence a stronger electrostatic interaction with casein micelles. Considering the relatively high carrageenan concentration adopted in the current research, there might be a three-dimensional gel network formed by the association of two networks forming on cooling [45, 49, 50], as shown in Fig. 2b. One is the carrageenan/casein network formed by linking casein micelles by the adsorbed helical parts of carrageenan chains. The other one is carrageenan/carrageenan network formed by the interactions between carrageenan chains. As a result, the carrageenan–casein mixture renders a more continuous and denser gel structure, leading to a relatively high cohesive force compared with the pure carrageenan or pure casein. On the other hand, the carrageenan–casein mixture has the functional groups encountered in both carrageenan and casein, promoting the establishment of chemical bonds between biopolymers and soil particles, and hence leading to an elevated adhesive force [47].

3.1.2 Other influencing factors

The variation in UCS, with the curing period, is shown in Fig. 1b. UCS values monotonically increased with the extension of the curing period and reached a peak value of 3.05 MPa for the 28-day curing period. With 7-day curing period, UCS slightly increased, as the biopolymer gels were still at a relatively wet state. When the curing period was extended to 14 days, an impressive improvement in the UCS was observed. The phenomenon that the biopolymeric cementation became more evident with the increasing curing period was in part a result of continuous biopolymer gel hardening due to the dehydration process [7, 16, 51]. The restrained particle breakage due to the presence of biopolymer fibres was also part of the cause [78].

The change in UCS with the blending content is shown in Fig. 1c. The UCS decreased from 3.52 to 2.32 MPa when the blending content increased from 2 to 8%. It was reported that there exists an optimum biopolymer content affected by both soil composition (e.g. particle size distribution) and biopolymer types [17, 62]. Excessive dosage of biopolymers has an adverse effect on soil reinforcement. This might be attributed to two factors. First, a high viscosity of the biopolymer gel resulted from a high blending content could lead to a poor workability of the biopolymer–soil mixture, which increased the probability of air voids entraining and the existence of weak planes [21]. Secondly, surplus biopolymer monomers could cause ionic repulsion, resulting in a reduced soil strength [17, 62]. As only a descent trend in UCS with the blending content was observed, it was speculated that the optimum blending content of carrageenan–casein mixture for this clayey soil is 2% or less. Supplementary tests were conducted on the soils treated with less than 2% carrageenan–casein mixture after the orthogonal tests, with other influencing factors fixed, e.g. mcar/mcas = 1:3, initial moisture content = 36%, and curing period = 14 d. The results indicated that the optimum blending content was around 1%, as shown in Fig. 3.

The trend of UCS with the increasing initial moisture content is shown in Fig. 1d. The initial moisture content is important to the efficiency of soil treatment. While inadequate water results in a poorly dissolved biopolymer solution, adversely affecting the workability of the biopolymer–soil matrix and its consequent mechanical strength [21], too much water leads to a less viscous biopolymer gel and a more porous biopolymer–soil matrix after water evaporates. With the ideal initial moisture content, maximum strengthening efficiency can be expected [62, 64]. Since no inflection point is observed in Fig. 2d, it was speculated that the ideal initial moisture content is even larger than 36% due to the relatively high blending content.

3.2 Results of one-dimensional consolidation tests

3.2.1 Relationship between void ratio and vertical stress

The e-logσ'v curves plotted in Fig. 4a reveal the settlements from large to small are in the order of carrageenan-treated soil, untreated soil, carrageenan–casein mixture-treated soil, and casein-treated soil. That the carrageenan-treated soil having a greater change in the void ratio than the untreated soil is not unexpected, due to the repulsion force between the excessive hydroxyl group of carrageenan and negatively charged clay particles. The similar phenomenon has been reported for other hydrophilic biopolymers like xanthan gum and guar gum [14, 15, 48, 76]. By contrast, casein molecules are linked by hydrophobic and electrostatic bonds to form sub-micelles which are further associated together by calcium phosphate to form casein micelles. The hydrophilic zones of casein are oriented to the exterior surface of the casein micelles, therefore leading to minimal interactions with water molecules [60]. Furthermore, the decreased compressibility of casein-treated soil is in part attributed to the channel blocking effect due to the cheesy state of casein [34]. The carrageenan–casein gel with the three-dimensional network had a relatively high resistance to compression. The replacement of carrageenan with casein reduced the repulsion force between the hydroxyl group of carrageenan and clay particles. Therefore, carrageenan–casein mixture-treated soil had a smaller change in the void ratio compared with the untreated soil.

The effect of blending content on e-logσ'v relationship is shown in Fig. 4b, implying that increasing the dosage of the carrageenan–casein mixture can reduce the soil compressibility. On drying, the treated soils lost moisture due to evaporation and the moisture loss varied with the curing period, i.e. the moisture contents after curing were 31.9%, 15.6%, 7.4%, and 3.2%, respectively, for 0-day, 7-day, 14-day, and 28-day curing periods. However, Fig. 4c shows a negligible difference in void ratios corresponding to various curing periods. This phenomenon suggests that the carrageenan–casein mixture-treated soils with diverse curing periods had similar inter-particle spaces or voids where the dried biopolymer fibres absorbed water and swelled back into a gel form. The explanation for this phenomenon might be that biopolymer gels become stiffer fibres tangling between soil particles upon dehydration, enhancing the soil resistance to the volumetric attraction [24]. A previous study has shown that the ability of dried soil to recover to its initial moisture content under a resubmerged condition was related to the amount of biopolymer added [18]. For example, 2.0% gellan gum-treated soil recovered to 98% of the initial moisture content, while 0.5% and 1.0% only recovered to 87% and 93% of the initial moisture content.

3.2.2 Coefficient of volume compressibility and compression index

The coefficient of volume compressibility (mv) is defined as the volume change per unit volume per unit increase in effective stress. If, for an increase in effective stress from σ'v0 to σ'v1, the void ratio decreases from e0 to e1, then

Values of mv for casein-treated soil and carrageenan–casein mixture-treated soil were smaller than that of the untreated one (Fig. 5a). The reduction in mv was positively related to the blending content (Fig. 5b). In addition, there did not seem to be a clear trend of compressibility with the curing period (Fig. 5c). The obvious difference in compressibility between biopolymer-treated and untreated soil mainly exists at σ'v ≤ 50 kPa. This might be attributed to the pore-clogging effect of viscous biopolymer gels [44, 54], resulting in a very slow rate of pore water expulsion at a low vertical stress [76].

The low compressibility of biopolymer-treated soils at relatively low σ'v is also reflected in Fig. 4. There are mainly two linear portions of the e-logσ'v plot, implying that the evolution of void ratio with vertical stress could be generally characterized into two stages based on the potential mechanisms: (I) inter-particle friction and possible shear at the interface between biopolymer gels and soil particles, with a marginal reduction in void ratios at low σ'v (i.e. from 12.5 to 50 kPa); (II) soil particle rearrangement and breakage of the chemical bonds between biopolymers and soil particles, with an evident decrease in void ratios at high σ'v (i.e. from 50 to 800 kPa). For MICP-treated sand, an obvious increase in compressibility has been also observed due to the breakage of CaCO3 cementation and abrasion/attrition of sand grains [79]. The compression index (Cc) under each σ'v was calculated based on the following equation

Table 3 shows that Cc values continued to increase with the increasing σ'v for both biopolymer-treated and untreated soils. The untreated soil did not present an obvious increment in Cc at the initial stage of loading due to the absence of pore clogging effect. For each loading stage, Cc values decreased with the increasing blending content and were almost not affected by the curing period.

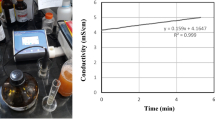

3.2.3 Coefficient of consolidation

The coefficients of consolidation (cv) calculated by Casagrande log time method for different types of biopolymer-treated soils are shown in Fig. 6. The data points of cv for samples cured for different periods are not plotted in Fig. 6 as they show little difference against the curing period. For both biopolymer-treated and untreated soils, cv decreased with the decrease in the void ratio. The usage of biopolymers in soils reduced the coefficient of consolidation, mainly due to the marked reduction in the coefficient of permeability [11, 48, 77]. In addition, cv decreased as the blending content increased from 1 to 4%. With 1% blending content, cv decreased by 15–25% compared with the untreated soil. Increasing the blending content to 4%, a further reduction in cv by 15–25% was observed. Hence, cv was mostly affected by a relatively low blending content, which might be attributed to the sharp reduction in coefficient of permeability for blending content up to 1% [14].

3.3 Results of biodeterioration in the fungi-contaminated samples

3.3.1 Soil microbe activities obtained by HTS

Through Miseq platform, overall 595,936 quality sequences from nine specimens obtained from the three soil samples (specimens No. 19, No. 23, and No. 27) were identified. For each specimen, around 59,473 to 73,684 sequences were obtained. The read lengths varied from 185 to 505 bp, with an average of 246 bp. After classification, 66 distinct fungal Operational Taxonomic Units (OTUs) within all the specimens were identified. The results are shown in Fig. 7. It can be seen that the fungi in the three biopolymer-treated samples were different in terms of diversity and proportion due to the distinctive chemical structures and carbon/nitrogen contents of the different biopolymers. For example, the total numbers of the fungal genus were found to be 31, 22 and 19 in carrageenan-treated, casein-treated, and carrageenan–casein mixture-treated soils, respectively. Among various fungi, Penicillium was observed to be the dominant fungus in all the samples. This is probably because Penicillium can secrete penicillin during growth, which might inhibit the growth of other surrounding microorganisms [57]. In addition, the relative abundance of Penicillium was the highest in the soil treated with the carrageenan–casein mixture. This could be attributed to the coexistence of nitrogen (e.g. casein) and carbon sources (e.g. carrageenan) that significantly improved the utilization efficiency of Penicillium on nutrients [36]. As a result, the diversity of fungal genus in carrageenan–casein mixture-treated soil reduced.

3.3.2 Results of rating of mould growth (RMG)

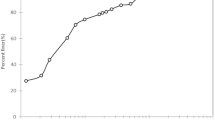

The assessment of RMG for each treatment condition is listed in Table 2, based on which Fig. 8 is drawn in order to investigate the effect of the four influencing factors on mould growth.

Figure 8a shows the effect of the carrageenan-to-casein ratio on RMG. In general, the samples treated with carrageenan–casein mixtures underwent severer mould growth than with pure casein or pure carrageenan, due to the promoted microbial activity by diverse nutrients. The highest RMG was found for mcar/mcas = 1:3. When a single biopolymer treatment was applied, the soils treated with casein suffered a slightly higher coverage of mycelia compared with those with carrageenan, indicating that the microorganism in this clayey soil had a higher intake of nitrogen source.

Figure 8b indicates that a relatively short curing period, e.g. 7 days, was sufficient to trigger mould growth. As the curing period increased from 7 to 21 days, the samples were gradually subjected to severer fungal growth with RMG increasing from 1.7 to 3.2. It is worth noting that further extending the curing period did not necessarily increase the severity of mould growth. It was observed that some mycelia previously attached to the surfaces of the samples fell off at the end of the 28-day curing period, leading to a decreased RMG for 28-day curing period. This could be explained by the fact that fungal spores grew rapidly at the early stage owing to the suitable environment (e.g. sufficient nutrients and moisture content). After the nutrients had been used up and water had evaporated, the rate of mould growth gradually slowed down and even stopped.

Figure 8c, d shows that the dependence of mould growth on total amount of nutrients and moisture, respectively. RMG increased from 2.1 to 3.1 by 50%, as the blending content quadrupled from 2 to 8%. RMG was also positively correlated with the initial moisture content, increasing monotonically as the initial moisture content increased from 24 to 36%.

3.3.3 Degradation in the mechanical behaviour of fungi-contaminated samples

The UCS tests on the fungi-contaminated samples were conducted to demonstrate the degradation in the mechanical behaviour of the biopolymer-treated soils due to microbial activities. In our opinion, the following key questions are of most interest: (1) whether biopolymers are effective in enhancing soil strength in case microbial activities are encountered; (2) how the mechanical performances of the fungi-contaminated samples differ from the biopolymer-treated samples with fungicide; (3) whether there is an explicit relationship between the degradation in mechanical performance and mould growth. The following contents will clarify these questions in detail.

UCS values for the fungi-contaminated samples are listed in Table 2, based on which the variations in UCS against the carrageenan-to-casein ratio, curing period, blending content, and initial moisture content are shown in Fig. 9. The first question can be answered by comparing the UCS values between the fungi-contaminated and untreated soils. The biopolymer-treated soil under the impact of fungal growth had only marginal improvement or even reduction in UCS.

Figure 9a shows that the fungi-contaminated samples treated with a carrageenan–casein mixture did not necessarily have a higher UCS than those treated with either pure carrageenan or pure casein, indicating that the synergistic interaction of carrageenan and casein was impaired to some extent. Figure 9b shows that the UCS of fungi-contaminated samples increased in the first two weeks and reached to 2.09 MPa at the end of 14-day curing period. Afterwards, it was surprising to observe that further increasing the curing period lowered the UCS. For 21-day and 28-day curing periods, the UCS reduced to 1.96 and 1.94 MPa, respectively. This abnormal phenomenon that mechanical strength and curing periods are negatively correlated for biopolymer-treated soils was not observed in other literatures where microbial activities were not considered [16, 21, 29, 51]. For the biopolymer-treated soils subjected to fungal growth, two contradictory actions might occur simultaneously along with time, namely soil strengthening due to biopolymer gel dehydration and deterioration due to microbial impacts. Their combined effect led to either increased or decreased UCS, for example, the microbial activity-induced deterioration surpassed the hardening effect of biopolymer gels in the last two weeks, leading to a decreasing trend of UCS with the curing period. The UCS tends of fungi-contaminated samples with blending content and initial moisture content (Fig. 9c, d) were similar to those of the biopolymer-treated soil with fungicide (Fig. 1c, d).

The degradation of mechanical performance in terms of the rate of reduction in UCS obtained by comparing UCS values between the biopolymer-treated soils with fungicide and without fungicide was linked with RMG, as shown in Fig. 10. In general, a higher RMG resulted in a more remarkable decrease in UCS. This positive correlation is further clarified in Fig. 11, where the data for all the influencing factors in Fig. 10 were drawn in a single plot. A linear fitting curve was applied to these data. Suggested by the proposed linear relationship, RMG increased by one will cause a reduction in UCS by approximately 11%.

Soil degradation induced by fungal growth can be promoted by the fungi themselves using the biopolymer–soil composite material as a nutrient. Carrageenan is a polysaccharide biopolymer and casein is a protein-based biopolymer, both of which contain typical nutrients as carbon sources and nitrogen sources that are supportive of the growth of fungi [10]. While the consumption of carrageenan and casein furnishes nutrients for fungal growth, their reinforcing effect diminishes gradually as well. On the other hand, the metabolites produced by fungi have been reported to be involved in the weakening of soil minerals [8]. A mineralogical analysis of the clayey soil used in the current study was previously conducted using the X-ray powder diffraction test, indicating that the clayey soil included silicates, feldspars and micas [64]. All fungi produce organic acids during their metabolisms which lead to solubilization or chelation of minerals such as A1, K, Ca and Fe from stone/soil substrates containing silicates, feldspars and micas [37]. A complex microflora obtained during partial sterilization of soils was found to produce complexing agents that destroyed primary chlorite, vermiculite and biotite, transforming biotite into vermiculite and into an alumino-silicate residue [9]. According to [12], the corrosion acids produced by Aspergillus niger lead to the removal of octahedral ions from micas, leaving a fragile matrix of amorphous material. This Aspergillus was also identified as present in the biopolymer–soil mixtures involved in the current study (Fig. 7). Hence, the biodeterioration of biopolymer-treated soils caused by microbial activity can be summed up as a result of the consumption of soil binders (i.e. biopolymers) and corrosion of soil minerals caused by the organic acids produced by microbial metabolisms.

4 Conclusions

A series of mechanical and biological tests were conducted on a clayey soil treated with different biopolymers (i.e. carrageenan, casein, and carrageenan–casein mixture). Results indicated that the carrageenan–casein mixture was more efficient in enhancing the soil compressive strength compared with pure carrageenan or pure casein, due to the formation of a three-dimensional gel network. Both carrageenan–casein mixture and casein were able to reduce soil compressibility, which could be mainly attributed to the casein’s peculiarity of self-associating into micelles. The hydrophilic zones of casein are oriented to the exterior surface of the casein micelles, and inside casein micelles, there are hydrophobic bonds of the nonpolar side chains of amino acids, leading to minimal interactions with water molecules. Carrageenan, due to its affinity for water, might induce repulsive force between the functional groups of carrageenan and the negatively charged clay particles, resulting in an increased soil compressibility. The degradation of biopolymer-treated soils under the impact of microbial activity was also probed. Accompanied by the coloured stains and patches on the sample surfaces caused by the growth of mould, the soil mechanical performances underwent deterioration as well. By employing RMG as an indicator, each increment in RMG implies a reduction in UCS by approximately 11%.

Based on the current research, the utilization of carrageenan and casein in combination has a potential of improving both soil strength and compressibility and hence is recommended for application in ground improvement. It is also suggested to take into account the biodeterioration considerations when implementing biopolymer-based soil reinforcement practices.

Data availability

The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

References

Aguilar R, Nakamatsu J, Ramírez E, Elgegren M, Ayarza J, Kim S, Pando MA, Ortega-San-Martin L (2016) The potential use of chitosan as a biopolymer additive for enhanced mechanical properties and water resistance of earthen construction. Constr Build Mater 114:625–637

Arltoft D, Madsen F, Ipsen R (2008) Relating the microstructure of pectin and carrageenan in dairy desserts to rheological and sensory characteristics. Food Hydrocolloids 22(4):660–673

ASTM D2166/2166M-16 (2016) Standard test method for unconfined compressive strength of cohesive soil. ASTM International, West Conshohocken

ASTM D2487 (2020) Standard practice for classification of soils for engineering purposes (Unified Soil Classification System). ASTM International, West Conshohocken

ASTM D698-12 (2021) Standard test methods for laboratory compaction characteristics of soil using standard effort. ASTM International, West Conshohocken

Ayeldeen M, Negm A, El-Sawwaf M, Kitazume M (2017) Enhancing mechanical behaviors of collapsible soil using two biopolymers. J Rock Mech Geotech 9(2):329–339

Ayeldeen MK, Negm AM, El Sawwaf MA (2016) Evaluating the physical characteristics of biopolymer/soil mixtures. Arab J Geosci 9:371

Berthelin J (1988) Microbial weathering processes in natural environments. Springer Netherlands, Dordrecht

Berthelin J, Belgy G (1979) Microbial degradation of phyllosilicates during simulated podzolisation. Geoderma 21:297–310

Birkinshaw JH (1937) Biochemistry of the lower fungi. Biol Rev 12(3):357–392

Bouazza A, Gates WP, Ranjith PG (2009) Hydraulic conductivity of biopolymer-treated silty sand. Géotechnique 59(1):71–72

Boyle J, Voigt GK, Sawhney BL (1967) Biotite flakes: alteration by chemical and biological treatment. Sci 155:193–219

Brischke C, Thelandersson S (2014) Modelling the outdoor performance of wood products—a review on existing approaches. Constr Build Mater 66:384–397

Cabalar AF, Awraheem MH, Khalaf MM (2018) Geotechnical properties of a low-plasticity clay with biopolymer. J Mater Civ Eng 30(8):04018170

Cabalar AF, Wiszniewski M, Skutnik Z (2017) Effects of xanthan gum biopolymer on the permeability, odometer, unconfined compressive and triaxial shear behavior of a sand. Soil Mech Found Eng 54(5):356–361

Chang I, Cho G-C (2012) Strengthening of Korean residual soil with β-1,3/1,6-glucan biopolymer. Constr Build Mater 30:30–35

Chang I, Cho G-C (2019) Shear strength behavior and parameters of microbial gellan gum-treated soils: from sand to clay. Acta Geotech 14(2):361–375

Chang I, Im J, Cho G-C (2016) Geotechnical engineering behaviors of gellan gum biopolymer treated sand. Can Geotech J 53:1658–1670

Chang I, Im J, Chung M, Cho G-C (2018) Bovine casein as a new soil strengthening binder from diary wastes. Constr Build Mater 160:1–9

Chang I, Im J, Lee S, Cho G-C (2017) Strength durability of gellan gum biopolymer-treated Korean sand with cyclic wetting and drying. Constr Build Mater 143:210–221

Chang I, Im J, Prasidhi AK, Cho G (2015) Effects of Xanthan gum biopolymer on soil strengthening. Constr Build Mater 74:65–72

Chang I, Lee M, Tran ATP, Lee S, Kwon Y-M, Im J, Cho G-C (2020) Review on biopolymer-based soil treatment (BPST) technology in geotechnical engineering practices. Transp Geotech 24:100385

Chang I, Prasidhi AK, Im J, Cho G-C (2015) Soil strengthening using thermo-gelation biopolymers. Constr Build Mater 77:430–438

Chang I, Prasidhi AK, Im J, Shin H-D, Cho G-C (2015) Soil treatment using microbial biopolymers for anti-desertification purposes. Constr Build Mater 253–254:39–47

Chen C, Wu L, Harbottle M (2020) Exploring the effect of biopolymers in near-surface soils using xanthan gum—modified sand under shear. Can Geotech J 57:1109–1118

Chen C, Wu L, Perdjon M, Huang X, Peng Y (2019) The drying effect on xanthan gum biopolymer treated sandy soil shear strength. Constr Build Mater 197:271–279

Clarke JA, Johnstone CM, Kelly NJ, McLean RC, Anderson JA, Rowan NJ, Smith JE (1999) A technique for the prediction of the conditions leading to mould growth in buildings. Build Environ 34:515–521

Colinas C, Ingham E, Molina R (1994) Population responses of target and non-target forest soil organisms to selected biocides. Soil Biol Biochem 26(1):41–47

Dehghan H, Tabarsa A, Latifi N, Bagheri Y (2019) Use of xanthan and guar gums in soil strengthening. Clean Technol Environ 21(1):155–165

DeJong JT, Soga K, Kavazanjian E, Burns S, Van Paassen LA, Al Qabany A, Aydilek A, Bang SS, Burbank M, Caslake LF, Chen CY, Cheng X, Chu J, Ciurli S, Esnault-Filet A, Fauriel S, Hamdan N, Hata T, Inagaki Y, Jefferis S, Kuo M, Laloui L, Larrahondo J, Manning DAC, Martinez B, Montoya BM, Nelson DC, Palomino A, Renforth P, Santamarina JC, Seagren EA, Tanyu B, Tsesarsky M, Weaver T (2013) Biogeochemical processes and geotechnical applications: progress, opportunities and challenges. Géotechnique 63(4):287–301

Drohan DD, Tziboula A, McNulty D, Horne DS (1997) Milk protein–carrageenan interactions. Food Hydrocolloids 11(1):101–107

Elzoghb AO, Abo El-Fotoh WS, Elgindy NA (2011) Casein-based formulations as promising controlled release drug delivery systems. J Control Release 153(3):206–216

Ettenauer JD, Piñar G, Lopandic K, Spangl B, Ellersdorfer G, Voitl C, Sterflinger K (2012) Microbes on building materials—evaluation of DNA extraction protocols as common basis for molecular analysis. Sci Total Environ 439:44–53

Fatehi H, Abtahi SM, Hashemolhosseini H, Hejazi SM (2018) A novel study on using protein based biopolymers in soil strengthening. Constr Build Mater 167:813–821

Fox PF, Uniacke-Lowe T, McSweeney PLH, O’Mahony JA (2015) Dairy chemistry and biochemistry, 2nd edn. Springer International Publishing, New York

Ganie AH, Ahmad A, Yousuf PY, Pandey R, Ahmad S, Aref IM, Iqbal M (2017) Nitrogen-regulated changes in total amino acid profile of maize genotypes having contrasting response to nitrogen deficit. Protoplasma 254(6):2143–2153

Gaylarde C, Silva MR, Warscheid T (2003) Microbial impact on building materials: an overview. Mater Struct 36(5):342–352

GB/T 50123-2019 (2019) Standard for geotechnical testing method. China Planning Press, Beijing

Geng XY, Indraratna B, Rujikiatkamjorn C (2011) Effectiveness of partially penetrating vertical drains under a combined surcharge and vacuum preloading. Can Geotech J 48:970–983

Geng XY, Yu HS (2017) A large-strain radial consolidation theory for soft clays improved by vertical drains. Géotechnique 67(11):1020–1028

Hataf N, Ghadir P, Ranjbar N (2018) Investigation of soil stabilization using chitosan biopolymer. J Clean Prod 170:1493–1500

Holt C (1992) Structure and stability of bovine casein micelles. Adv Protein Chem 43:63–151

Huang M, Kennedy JF, Li B, Xu X, Xie BJ (2007) Characters of rice starch gel modified by gellan, carrageenan, and glucomannan: a texture profile analysis study. Carbohydr Polym 69(3):411–418

Ivanov V, Chu J (2008) Applications of microorganisms to geotechnical engineering for bioclogging and biocementation of soil in situ. Rev Environ Sci Biotechnol 7(2):139–153

Ji S, Corredig M, Goff HD (2008) Aggregation of casein micelles and κ-carrageenan in reconstituted skim milk. Food Hydrocolloids 22(1):56–64

Johansson P, Ekstrand-Tobin A, Svensson T, Bok G (2012) Laboratory study to determine the critical moisture level for mould growth on building materials. Int Biodeterior Biodegrad 73:23–32

Khatami HR, O’Kelly BC (2013) Improving mechanical properties of sand using biopolymers. J Geotech Geoenviron 139(8):1402–1406

Kwon Y-M, Chang I, Lee M, Cho G-C (2019) Geotechnical engineering behavior of biopolymer-treated soft marine soil. Geomech Eng 17(5):453–464

Langendorff V, Cuvelier G, Launay B, Michon C, Parker A, De Kruif CG (1999) Casein micelle/iota carrageenan interactions in milk: influence of temperature. Food Hydrocolloids 13(3):211–218

Langendorff V, Cuvelier G, Michon C, Launay B, Parker A, De Kruif CG (2000) Effects of carrageenan type on the behaviour of carrageenan/milk mixtures. Food Hydrocolloids 14(4):273–280

Latifi N, Horpibulsuk S, Meehan CL, Majid MZA, Rashid ASA (2016) Xanthan gum biopolymer: an eco-friendly additive for stabilization of tropical organic peat. Environ Earth Sci 75:825

Lee S, Chung M, Park HM, Song K-I, Chang I (2019) Xanthan gum biopolymer as soil-stabilization binder for road construction using local soil in Sri Lanka. J Mater Civ Eng 31(11):06019012

Lv W, Li A, Ma J, Cui H, Zhang X, Zhang W, Guo Y (2020) Relative importance of certain factors affecting the thermal environment in subway stations based on field and orthogonal experiments. Sustain Cities Soc 56(8):102107

Mitchell JK, Santamarina JC (2005) Biological considerations in geotechnical engineering. J Geotech Geoenviron Eng 131(10):1222–1233

Mitchell JK, Soga K (2005) Fundamentals of soil behavior, 3rd edn. Wiley, New York

Muguda S, Booth SJ, Hughes PN, Augarde CE, Perlot C, Bruno AW, Gallipoli D (2017) Mechanical properties of biopolymer-stabilised soil-based construction materials. Géotech Lett 7(4):309–314

Murphy MP, Niedziela DA, Keane OM (2017) EHS matrix incubated in media containing penicillin retains sufficient concentrations of antibiotic to inhibit growth of susceptible microorganisms. J Microbiol Methods 139:103–106

Nakamatsu J, Kim S, Ayarza J, Ramírez E, Elgegren M, Aguilar R (2017) Eco-friendly modification of earthen construction with carrageenan: water durability and mechanical assessment. Constr Build Mater 139:193–202

Neethirajan S, Jayas DS (2011) Nanotechnology for the food and bioprocessing industries. Food Bioprocess Technol 4(1):39–47

Nemethy G, Scheraga HA (1962) Structure of water and hydrophobic bonding in proteins. I. A model for the thermodynamic properties of liquid water. J Chem Phys 36(12):3382–3400

Ng CWW, So PS, Lau SY, Zhou C, Coo JL, Ni JJ (2020) Influence of biopolymer on gas permeability in compacted clay at different densities and water contents. Eng Geol 272:105631

Ni J, Hao GL, Chen JQ, Ma L, Geng XY (2021) The optimisation analysis of sand-clay mixtures stabilised with xanthan gum biopolymers. Sustainability 13(7):3732

Ni J, Indraratna B, Geng XY, Carter JP, Rujikiatkamjorn C (2013) Radial consolidation of soft soil under cyclic loads. Comput Geotech 50:1–5

Ni J, Li S, Ma L, Geng XY (2020) Performance of soils enhanced with eco-friendly biopolymers in unconfined compression strength tests and fatigue loading tests. Constr Build Mater 263:120039

Nilsson S, Piculell L (1991) Helix–coil transitions of ionic polysaccharides analysed within the Poisson-Boltzmann cell model. 4—Effects of site specific counterion binding. Macromolecules 24:3804–3811

Quagliarini E, Gianangeli A, D’Orazio M, Gregorini B, Osimani A, Aquilanti L, Clementi F (2019) Effect of temperature and relative humidity on algae biofouling on different fired brick surfaces. Constr Build Mater 199:396–405

Rees DA, Steele IW, Williamson FB (1969) Conformational analysis of polysaccharides. III. The relation between stereochemistry and properties of some polysaccharide sulfates (1). J Polym Sci C 28:261–276

Rehan F, Ahemad N, Gupta M (2019) Casein nanomicelle as an emerging biomaterial—a comprehensive review. Colloids Surf B 179:280–292

Schmidt DG (1982) Association of caseins and casein micelle structure. In: Fox PF (ed) Development in dairy chemistry, vol 1. Applied Science Publishers, London, pp 61–85

Sheibani E, Hosseini A, Sobhani Nasab A, Adib K, Ganjali MR, Pourmortazavi SM et al (2021) Application of polysaccharide biopolymers as natural adsorbent in sample preparation. Crit Rev Food Sci. https://doi.org/10.1080/10408398.2021.1978385

Smagin A, Sadovnikova N, Vasenev V, Smagina MV (2018) Biodegradation of some organic materials in soils and soil constructions: experiments, modeling and prevention. Materials 11(10):1889

Snoeren THM (1976) Kappa-carrageenan. A study on its physicochemical properties, sol–gel transition and interactions with milk proteins. Ph.D. thesis, Wageningen, The Netherlands

Snoeren THM, Payens TJ, Jeunink J, Both P (1975) Electrostatic interaction between κ-carrageenan and κ-casein. Milchwissenschaft 30:393–396

So H, Jang H, Lee B, So S (2016) Antifungal performance of BFS mortar with various natural antifungal substances and their physical properties. Constr Build Mater 108:154–162

Tye RJ (1988) The rheology of starch/carrageenan systems. Food Hydrocolloids 2(4):259–266

Vydehi KV, Moghal AAB (2022) Effect of biopolymeric stabilization on the strength and compressibility characteristics of cohesive soil. J Mater Civ Eng 34(2):04021428

Wen K, Li Y, Huang W, Armwood C, Amini F, Li L (2019) Mechanical behaviors of hydrogel-impregnated sand. Constr Build Mater 207:174–180

Xiao Y, Chen H, Stuedlein AW, Evans TM, Chu J, Cheng L et al (2020) Restraint of particle breakage by biotreatment method. J Geotech Geoenviron 146(11):4020123

Xiao Y, Zhao C, Sun Y, Wang S, Wu H, Chen H et al (2021) Compression behavior of MICP-treated sand with various gradations. Acta Geotech 16(5):1391–1400

Zhong L, Zhang Y, Wang T, Ji Y, Norris P, Pan W (2019) Optimized methods for preparing activated carbon from rock asphalt using orthogonal experimental design. J Therm Anal Calorim 136(5):1989–1999

Acknowledgements

The work described in this paper was supported by the National Natural Science Foundation of China (51978533, 51608323).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Ni, J., Li, SS. & Geng, XY. Mechanical and biodeterioration behaviours of a clayey soil strengthened with combined carrageenan and casein. Acta Geotech. 17, 5411–5427 (2022). https://doi.org/10.1007/s11440-022-01588-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11440-022-01588-4