Abstract

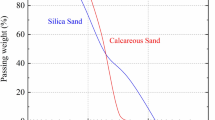

One-dimensional compression tests on quartz sands treated by microbially induced carbonate precipitation (MICP) were carried out to evaluate the effects of gradation and calcium carbonate (CaCO3) content on compression behaviors. The experimental results reveal that the compressibility of specimens increases with increasing coefficient of uniformity or decreasing CaCO3 content. The evolution of void ratio with vertical stress could be generally characterized into three stages based on the underlying mechanisms. The initiation of bond breakage occurs around vertical stress of 0.036 MPa, and the dominating mechanism transits to particle breakage around vertical stress of 8.3 MPa. Scanning electron microscope analyses demonstrate that bonding effect and coating effect of CaCO3 precipitation are responsible for the lower compressibility of MICP-treated specimen. The presence of small particles leads to more interparticle CaCO3 bonds whose breakage would still allow the small particles to fill the intercoarse-grain voids.

Similar content being viewed by others

References

Al Qabany A, Soga K (2013) Effect of chemical treatment used in micp on engineering properties of cemented soils. Géotechnique 63:331–339

Al Qabany A et al (2012) Factors affecting efficiency of microbially induced calcite precipitation. J Geotech Geoenviron Eng 138:992–1001

Ben-Nun O et al (2010) Force attractor in confined comminution of granular materials. Phys Rev Lett 104:108001

Bosak T et al (2004) Micrometer-scale porosity as a biosignature in carbonate crusts. Geology 32:781–784

Buikema ND et al (2018) Stabilisation of iron mine tailings through biocalcification. Environ Geotech 5:94–106

Chen X, Zhang J (2016) Effect of load duration on particle breakage and dilative behavior of residual soil. J Geotech Geoenviron Eng 142:06016008

Cheng L et al (2013) Cementation of sand soil by microbially induced calcite precipitation at various degrees of saturation. Can Geotech J 50:81–90

Cheng L et al (2017) Influence of key environmental conditions on microbially induced cementation for soil stabilization. J Geotech Geoenviron Eng 143:04016083

Cheng L et al (2019) Soil bio-cementation using a new one-phase low-ph injection method. Acta Geotech 14:615–626

Choi S-G et al (2016) Properties of biocemented, fiber reinforced sand. Constr Build Mater 120:623–629

Chou C-W et al (2011) Biocalcification of sand through ureolysis. J Geotech Geoenviron Eng 137:1179–1189

Chu J et al (2013) Microbial method for construction of an aquaculture pond in sand. Géotechnique 63:871–875

Chu J et al (2014) Optimization of calcium-based bioclogging and biocementation of sand. Acta Geotech 9:277–285

Ciantia MO et al (2015) An approach to enhance efficiency of DEM modelling of soils with crushable grains an approach to enhance efficiency of DEM modelling of soils with crushable grains. Geotechnique 65:91–110

Cil MB et al (2020) Dem modeling of grain size effect in brittle granular soils. J Eng Mech 146:04019138

Cui M et al (2017) Influence of cementation level on the strength behaviour of bio-cemented sand. Acta Geotech 12:971–986

Das SK, Das A (2019) Influence of quasi-static loading rates on crushable granular materials: a DEM analysis. Powder Technol 344:393–403

DeJong JT et al (2006) Microbially induced cementation to control sand response to undrained shear. J Geotech Geoenviron Eng 132:1381–1392

Dhami NK et al (2013) Biomineralization of calcium carbonate polymorphs by the bacterial strains isolated from calcareous sites. J Microbiol Biotechnol 23:707–714

Einav I (2007) Breakage mechanics-part I: theory. J Mech Phys Solids 55:1274–1297

Feng K, Montoya BM (2016) Influence of confinement and cementation level on the behavior of microbial-induced calcite precipitated sands under monotonic drained loading. J Geotech Geoenviron Eng 142:04015057

Ferris FG et al (2004) Kinetics of calcite precipitation induced by ureolytic bacteria at 10 to 20 degrees c in artificial groundwater. Geochim Cosmochim Acta 68:1701–1710

Gao Y et al (2019) Mechanical behaviour of biocemented sands at various treatment levels and relative densities. Acta Geotech 14:697–707

Guida G et al (2018) Breakage mechanisms of highly porous particles in 1D compression revealed by X-ray tomography. Geotech Lett 8:155–160

Guida G et al (2020) Linking micro grainsize polydispersity to macro porosity. Int J Solids Struct 187:75–84

Hao Y et al (2018) Enhancing fiber/matrix bonding in polypropylene fiber reinforced cementitious composites by microbially induced calcite precipitation pre-treatment. Cement Concr Compos 88:1–7

He J, Chu J (2014) Undrained responses of microbially desaturated sand under monotonic loading. J Geotech Geoenviron Eng 140:04014003

Indraratna B et al (2016) Laboratory assessment of the role of particle size distribution on the deformation and degradation of ballast under cyclic loading. J Geotech Geoenviron Eng 142:04016016

Jiang N-J et al (2017) Microbially induced carbonate precipitation for seepage-induced internal erosion control in sand–clay mixtures. J Geotech Geoenviron Eng 143:04016100

Ladd RS (1978) Preparing test specimens using undercompaction. Geotech Test J 1:16–23

Li M et al (2016) Influence of fiber addition on mechanical properties of MICP-treated sand. J Mater Civil Eng 28:04015166

Li M et al (2017) Impact of oxygen availability on microbially induced calcite precipitation (MICP) treatment. Geomicrobiol J 35:15–22

Lin H et al (2016) Mechanical behavior of sands treated by microbially induced carbonate precipitation. J Geotech Geoenviron Eng 142:04015066

Liu L et al (2019) Strength, stiffness, and microstructure characteristics of biocemented calcareous sand. Can Geotech J 56:1502–1513

Mahawish A et al (2018) Effect of particle size distribution on the bio-cementation of coarse aggregates. Acta Geotech 13:1019–1025

Marks B, Einav I (2015) A mixture of crushing and segregation: the complexity of grainsize in natural granular flows. Geophys Res Lett 42:274–281

Martinez BC et al (2013) Experimental optimization of microbial-induced carbonate precipitation for soil improvement. J Geotech Geoenviron Eng 139:587–598

McDowell GR, Bolton MD (1998) On the micromechanics of crushable aggregates. Geotechnique 48:667–679

Miao G, Airey D (2013) Breakage and ultimate states for a carbonate sand. Geotechnique 63:1221–1229

Montoya BM, DeJong JT (2015) Stress–strain behavior of sands cemented by microbially induced calcite precipitation. J Geotech Geoenviron Eng 141:04015019

Mortensen BM et al (2011) Effects of environmental factors on microbial induced calcium carbonate precipitation. J Appl Microbiol 111:338–349

Nafisi A et al (2020) Shear strength envelopes of biocemented sands with varying particle size and cementation level. J Geotech Geoenviron Eng 146:04020002

Nemati M, Voordouw G (2003) Modification of porous media permeability, using calcium carbonate produced enzymatically in situ. Enzyme Microb Technol 33:635–642

Oliveira PJV et al (2017) Effect of soil type on the enzymatic calcium carbonate precipitation process used for soil improvement. J Mater Civil Eng 29:04016263

Pan X et al (2020) A new biogrouting method for fine to coarse sand. Acta Geotech 15:1–16

Polito CP, Martin Ii JR (2001) Effects of nonplastic fines on the liquefaction resistance of sands. J Geotech Geoenviron Eng 127:408–415

Sammis C et al (1987) The kinematics of gouge deformation. Pure appl Geophys 125:777–812

Sasaki T, Kuwano R (2016) Undrained cyclic triaxial testing on sand with non-plastic fines content cemented with microbially induced CaCO3. Soils Found 56:485–495

Suescun-Florez E et al (2020) Evolution of particle damage of sand during axial compression via arrested tests. Acta Geotech 15:95–112

Tsoungui O et al (1999) Numerical model of crushing of grains inside two-dimensional granular materials. Powder Technol 105:190–198

Tyler SW, Wheatcraft SW (1992) Fractal scaling of soil particle-size distributions: analysis and limitations. Soil Sci Soc Am J 56:362–369

van Paassen LA et al (2010) Quantifying biomediated ground improvement by ureolysis: large-scale biogrout experiment. J Geotech Geoenviron Eng 136:1721–1728

Wang X, Tao J (2018) Polymer-modified microbially induced carbonate precipitation for one-shot targeted and localized soil improvement. Acta Geotech 14:657–671

Wang K et al (2020) Stress–strain behaviour of bio-desaturated sand under undrained monotonic and cyclic loading. Géotechnique. https://doi.org/10.1680/jgeot.1619.P.1080

Wei H et al (2020) Quantifying the morphology of calcareous sands by dynamic image analysis. Int J Geomech 20:04020020

Wen K et al (2019) Evaluation of MICP treatment through EC and PH tests in urea hydrolysis process. Environ Geotech. https://doi.org/10.1680/jenge.17.00108

Wen K et al (2018) Experimental investigation of flexure resistance performance of bio-beams reinforced with discrete randomly distributed fiber and bamboo. Constr Build Mater 176:241–249

Wen K et al (2019) Impact of bacteria and urease concentration on precipitation kinetics and crystal morphology of calcium carbonate. Acta Geotech 15:17–27

Whiffin VS (2004) Microbial CaCO3 precipitation for the production of biocement. Ph.D. thesis, Morduch University

Whiffin VS et al (2007) Microbial carbonate precipitation as a soil improvement technique. Geomicrobiol J 24:417–423

Wu C et al (2019) Quantifying the permeability reduction of biogrouted rock fracture. Rock Mech Rock Eng 52:947–954

Wu C et al (2019) Biogrouting of aggregates using premixed injection method with or without ph adjustment. J Mater Civil Eng 31:06019008

Wu C et al (2019) Microbially induced calcite precipitation along a circular flow channel under a constant flow condition. Acta Geotech 14:673–683

Xiao Y et al (2017) Particle breakage and deformation of carbonate sands with wide range of densities during compression loading process. Acta Geotech 12:1177–1184

Xiao P et al (2018) Liquefaction resistance of bio-cemented calcareous sand. Soil Dyn Earthq Eng 107:9–19

Xiao P et al (2019) Effect of relative density and bio-cementation on the cyclic response of calcareous sand. Can Geotech J 56:1849–1862

Xiao Y et al (2019) Strength and deformation responses of biocemented sands using a temperature-controlled method. Int J Geomech 19:04019120

Xiao Y et al (2019) Effect of particle shape on strength and stiffness of biocemented glass beads. J Geotech Geoenviron Eng 145:06019016

Xiao Y et al (2019) Effect of particle shape on stress-dilatancy responses of medium-dense sands. J Geotech Geoenviron Eng 145:04018105

Xiao Y et al (2019) Unconfined compressive and splitting tensile strength of basalt fiber-reinforced biocemented sand. J Geotech Geoenviron Eng 145:04019048

Xiao Y et al (2019) Particle breakage and energy dissipation of carbonate sands under quasi-static and dynamic compression. Acta Geotech 14:1741–1755

Xiao Y et al (2020) Restraint of particle breakage by biotreatment method. J Geotech Geoenviron Eng 146:04020123

Xiao Y et al (2020) Toe bearing capacity of precast concrete piles through biogrouting improvement. J Geotech Geoenviron Eng 146:06020026

Xiao Y et al (2020) Thermal conductivity of granular soil mixtures with contrasting particle shapes. J Geotech Geoenviron Eng 146:06020004

Yang S et al (2006) Determination of the transitional fines content of mixtures of sand and non-plastic fines. Geotech Test J 29:102–107

Zhang Y et al (2014) Influences of calcium sources on microbially induced carbonate precipitation in porous media. Mater Res Innov 18:79–84

Zhang R et al (2017) Experimental investigation on effect of curing stress on the strength of cement-stabilized clay at high water content. Acta Geotech 12:921–936

Zhao Q et al (2014) Factors affecting improvement of engineering properties of MICP-treated soil catalyzed by bacteria and urease. J Mater Civ Eng 26:04014094

Acknowledgements

The authors would like to acknowledge the financial support from the National Natural Science Foundation of China (Grant Nos. 41831282, 51922024, 52078085 and 51678094) and Natural Science Foundation of Chongqing, China (Grant No. cstc2019jcyjjqX0014).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Xiao, Y., Zhao, C., Sun, Y. et al. Compression behavior of MICP-treated sand with various gradations. Acta Geotech. 16, 1391–1400 (2021). https://doi.org/10.1007/s11440-020-01116-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11440-020-01116-2