Abstract

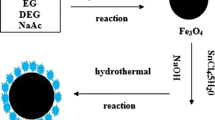

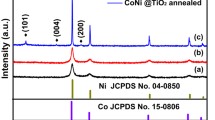

Uniform core-shell SiO2@Fe3O4@C microspheres were prepared by a one-step hydrothermal method with SiO2 microspheres as the template, and the hollow Fe3O4@C (HFC) microspheres were achieved via etching SiO2 template. By changing the sizes of SiO2 microspheres, a series of HFC microspheres with variable cavity sizes were obtained to study the relationship between cavity size and microwave absorbing (MA) performance for the first time. The morphology and structure of samples were characterized in detail. The results showed that the MA performance of HFC sample depended on its cavity size. In particular, the hollow structure was good for improving MA performance and could make MA move to the high-frequency region. More importantly, as the cavity size increases, the resonance frequency of HFC-i (i=1, 2, 3, 4) samples moved to a low frequency, and the optimal matching thickness of HFC-i samples was increasing. Among all HFC-i samples, HFC-3 showed the most excellent MA performance, which could be mainly explained by the quarter-wavelength matching model, intrinsical magnetic and dielectric loss. Furthermore, the MA performance of HFC mixture blended by the equal mass fraction of HFC-2, HFC-3 and HFC-4 was the comprehensive results of three HFC-i samples. All the above suggested that the cavity size in HFC sample had a great influence on the MA performance.

Similar content being viewed by others

References

Lv Y, Yu L, Li C, Yang L. Sci China Chem, 2016, 59: 142–149

Liu Z, Lu G, Yin H, Dang Z, Rittmann B. Environ Sci Technol, 2015, 49: 5288–5300

Zeng Z, Jin H, Chen M, Li W, Zhou L, Zhang Z. Adv Funct Mater, 2016, 26: 303–310

Kar GP, Biswas S, Rohini R, Bose S. J Mater Chem A, 2015, 3: 7974–7985

Liu JW, Xu JJ, Liu ZW, Liu XL, Che RC. Sci China Chem, 2014, 57: 3–12

Fang J, Liu T, Chen Z, Wang Y, Wei W, Yue X, Jiang Z. Nanoscale, 2016, 8: 8899–8909

Zhao B, Shao G, Fan B, Wang C, Xie Y, Zhang R. Powder Technol, 2015, 270: 20–26

Zhu W, Wang L, Zhao R, Ren J, Lu G, Wang Y. Nanoscale, 2011, 3: 2862–2864

Sözeri H, Mehmedi Z, Kavas H, Baykal A. Ceram Int, 2015, 41: 9602–9609

Zeng M, Liu J, Yue M, Yang HZ, Dong HR, Tang WK, Jiang H, Liu XF, Yu RH. J Appl Phys, 2015, 117: 17B527

Shen JH, Chen KY, Li LC, Ding Y, Li JB, Kong WQ. Sci China Tech Sci, 2014, 57: 1858–1864

Venkatachalam S, Bertin D, Ducournau G, Lampin JF, Hourlier D. Carbon, 2016, 100: 158–164

Lee SE, Lee WJ, Oh KS, Kim CG. Carbon, 2016, 107: 564–572

Chen Y, Zhang W, Yang S, Hobiny A, Alsaedi A, Wang X. Sci China Chem, 2016, 59: 412–419

Shen J, Chen K, Li L, Wang W, Jin Y. J Alloy Compd, 2014, 615: 488–495

Yu L, Liu Y, Yang F, Evans J, Rodriguez JA, Liu P. J Phys Chem C, 2015, 119: 16614–16622

Shen J, Feng J, Li L, Tong G, He Y. J Alloy Compd, 2015, 632: 490–499

Yuan K, Che R, Cao Q, Sun Z, Yue Q, Deng Y. ACS Appl Mater Interfaces, 2015, 7: 5312–5319

Zhao B, Shao G, Fan B, Zhao W, Xie Y, Zhang R. J Mater Chem A, 2015, 3: 10345–10352

Li Y, Wu T, Jiang K, Tong G, Jin K, Qian N, Zhao L, Lv T. J Mater Chem C, 2016, 4: 7119–7129

Panigrahi R, Srivastava SK. Sci Rep, 2015, 5: 7638

Lv H, Ji G, Liu W, Zhang H, Du Y. J Mater Chem C, 2015, 3: 10232–10241

Han M, Yin X, Kong L, Li M, Duan W, Zhang L, Cheng L. J Mater Chem A, 2014, 2: 16403–16409

Zhang Y, Huang Y, Zhang T, Chang H, Xiao P, Chen H, Huang Z, Chen Y. Adv Mater, 2015, 27: 2049–2053

Moyer JA, Gao R, Schiffer P, Martin LW. Sci Rep, 2015, 5: 10363

Sun X, He J, Li G, Tang J, Wang T, Guo Y, Xue H. J Mater Chem C, 2013, 1: 765–777

Shen J, Ma G, Zhang J, Quan W, Li L. Appl Surface Sci, 2015, 359: 455–468

Sato T, Iijima T, Seki M, Inagaki N. J Magn Magn Mater, 1987, 65: 252–256

Wen F, Zhang F, Liu Z. J Phys Chem C, 2011, 115: 14025–14030

Hsiao YC, Wu T, Zang H, Li M, Hu B. Sci China Chem, 2015, 58: 239–247

Huang Y, Wang Y, Li Z, Yang Z, Shen C, He C. J Phys Chem C, 2014, 118: 26027–26032

Jazirehpour M, Seyyed Ebrahimi SA. J Alloy Compd, 2015, 639: 280–288

Zhao B, Zhao W, Shao G, Fan B, Zhang R. ACS Appl Mater Interfaces, 2015, 7: 12951–12960

Acknowledgments

This work was supported by the National Natural Science Foundation of China (20104017), and the College Students’ Science and Technology Innovation Activities Plan of Zhejiang (2014R404056).

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Rights and permissions

About this article

Cite this article

Hou, Y., Yuan, H., Chen, H. et al. Controlled fabrication and microwave absorbing mechanism of hollow Fe3O4@C microspheres. Sci. China Chem. 60, 740–747 (2017). https://doi.org/10.1007/s11426-016-9001-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11426-016-9001-5