Abstract

Purpose

We have to transform our societies and economic systems towards social, ecological, and economic (holistic) sustainability. Bioeconomy (BE) can contribute to sustainable development by substituting fossil-based products with renewable ones; however, sustainability is not intrinsic to BE.

Methods

Therefore, we developed a holistic and integrated life cycle sustainability assessment (HILCSA) method containing 91 indicators, implemented in openLCA, using the Ecoinvent and SoCa database, and addressing 15 out of 17 Sustainable Development Goals. We applied it for the first time to show its capabilities by assessing the holistic sustainability of laminated veneer lumber (LVL) relative to hot-rolled steel beams.

Results, discussion

Our results indicate that renewable bio-based construction materials can have a better holistic sustainability than fossil-based products for nearly all indicators, by less stressing the environment, having a less negative impact on society and being economically more efficient. However, fossil-based components of LVL such as phenolic resin are main contributors of negative impacts and should be reduced and replaced. Renewable resources from agriculture and forestry have significant impacts on land use (change).

Conclusions

HILCSA demonstrates to be able to provide comprehensive sustainability assessments as well as aggregated results. BE substitutes indeed can improve sustainability; however, sustainability assessments and HILCSA need to be further developed to allow conclusions to be drawn about absolute sustainability of BE.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

A sustainable bioeconomy (BE) based on renewable resources and entailing a societal ecological transformation can potentially contribute to a good life for all within planetary boundaries (PB) (Zeug et al. 2022, 2021b). PB represent main global ecological limits, e.g., a certain GHG concentration should not be exceeded as well as there is a limit for the use of land, resources, and water (O'Neill et al. 2018). PB are not necessarily constant over time nor a deterministic constant, but most likely are scenarios in which the transgression of one PB leads to even more transgressions of other PB (e.g., climate change induces water scarcity and land degradation) as well as societal impacts (e.g., human health and well-being), which should be avoided (Rockström et al. 2009; Steffen et al. 2018). However, contributing to a good life for all within PB is not necessarily the case for the currently emerging BE and circular economy in general, and to only focus on ecotechnological efficiency is not sufficient, but societal and economic transformations entailing BE are necessary for effectiveness (Eversberg and Holz 2020; Padilla-Rivera et al. 2020; Bezama et al. 2019; Ramcilovic-Suominen and Pülzl 2018; Hausknost et al. 2017). This complex problem can be characterized as a need of double decoupling (Zeug et al. 2022): a decoupling of increasing satisfaction of societal needs from an otherwise ever greater production of material goods, as well as a decoupling of production of goods from growing negative ecological, social, and economic effects. However, a necessary absolute decoupling does not exist and also seems implausible under business-as-usual conditions in the future (Parrique et al. 2019).As a promising approach to measure and assess social, ecological, and economic sustainability, life cycle sustainability assessments (LCSA) based on life cycle assessment (LCA) methods are considered as essential for a movement towards global sustainable development by many stakeholders (Balkau and Sonnemann 2017; de Besi and McCormick 2015; Gao and Bryan 2017; OECD 2018; Onat et al. 2017; Urban et al. 2018; Zimek et al. 2019). However, as recent comprehensive reviews show (Costa et al. 2019; D'Amato et al. 2020; Fauzi et al. 2019; Troullaki et al. 2021; Wulf et al. 2019; Zimek et al. 2019), most LCSA approaches more or less follow the additive scheme of LCSA (LCSA = social LCA (S-LCA) + environmental LCA (E-LCA) + life cycle costing (LCC) and lacking a theoretically founded framework of holistic sustainability, which in practical terms leads to different social, economic, and ecological dimensions and indicators which are not integrated (Zeug et al. 2020, 2022). Broadly said, scopes, corresponding methods and indicators of the life cycle inventory (LCI), life cycle impact assessment (LCIA) as well as their individual results only have in common that they relate to the same product or functional unit which is to be assessed (cf. Ekener et al. 2018; Suwelack 2016; Urban et al. 2018)). Following a suggestion from Guinee (Guinee et al. 2011), instead of additive, we developed an integrated and holistic LCSA (HILCSA = f (S-LCA, E-LCA, LCC)) which builds on the integrated and holistic sustainability framework and integrates social, economic, and ecological aspects in a common goal and scope, LCI, LCIA, results, and interpretation (Fig. 1) (for details see our previous research Zeug et al. 2021a, 2020, 2022)). Holistic in this regard means to have a broader transdisciplinary perspective, a critical background theory of political economy and political ecology, but as well to not fall short on the implications which may have and impose fundamental societal transformations. Based on the concept of societal relations to nature (SRN) (Becker et al. 2011; Görg 2011; Hummel et al. 2017), we define social sustainability as a long-term and global fulfillment of societal needs and social well-being as an end; ecological sustainability is a long-term stability of our environment as a basis of reproduction within PB; economic sustainability stands for technologies and economic structures which are efficient, effective and just economies relating societal needs and environment. Integrated stands for an integrated model of sustainability which enables to integrate social, ecological, and economic sustainability assessment into one unified method instead of additionally combine different LCA methods.

i) Integrated and holistic sustainability framework, ii) framework of holistic and integrated life cycle sustainability assessment (HILCSA) (laminated veneer lumber, LVL; societal relations to nature, SRN; life cycle inventory, LCI; life cycle impact assessment, LCIA; integrated product systems in openLCA entail ecological, social and economic inventory data)

However, to our knowledge, neither a holistic nor integrated LCSA in general was applied to BE product systems, yet. In previous studies, we assessed the production of laminated veneer lumber (LVL) in Central Germany (Thuringia, Saxony and Saxony-Anhalt) in a social LCA (S-LCA) using the RESPONSA model (Jarosch et al. 2020) as well as in an technical and environmental LCA (E-LCA) applying the SUMINISTRO tool (Hildebrandt et al. 2019; Bezama et al. 2021): (i) RESPONSA as a context-specific S-LCA focuses on identifying social hotspots and opportunities on the organizational level of foreground activities in the production chain; (ii) SUMINISTRO assesses an technically and environmentally optimal product and feedstock composition. Thus, a number of relevant social, ecological and economic SDGs are not addressed, background activities are not considered as well as there is no common theoretical background and method of holistic and integrated sustainability assessment (Jarosch et al. 2020; Zeug et al. 2021a, b, 2019).

The case of LVL is important and of interest since any kind of sustainable BE will rely on industrial implementation of increasingly sophisticated and knowledge-intensive biotechnological processes like the wood-based BE, e.g., the efficient and sustainable use of beech wood (Hildebrandt et al. 2019; BMBF 2014). Especially the construction sector respectively the life cycle of buildings is responsible for 50% of extracted materials, 35% of anthropogenic GHG emissions, and consumes 42% of the total energy as well as 30% of the water in Europe (European Commission 2011; Asada et al. 2020). Wood, however, accounts for less than 2% of total material used by weight in the constructions sector (Herczeg et al. 2014), but the replacement of products with high GHG emissions such as steel, concrete, and aluminum with wood-based ones is thus considered as favorable to reduce GHG emissions and important for sustainable development (Asada et al. 2020; Leskinen et al. 2018; IPCC 2018). In the last decades, engineered wood products like LVL are a rapidly growing market, industrially manufactured, standardized, and slowly substituting fossil construction elements like steel beams (Leskinen et al. 2018). But for such a substitution, the potentials of available wood resources are limited and forests are already under pressure and competition for use (Egenolf et al. 2021; Palahí 2021) as well as the European Union already relies on foreign land for its biomass demand (De Laurentiis et al. 2022).

The main goal of this work is to assess how socially, ecologically, and economically sustainable is the LVL production in Central Germany, when compared to conventional building materials, utilizing the proposed HILCSA methodology in order to identify the substitution effects, hotspots, trade-offs, and synergies.

2 Methodology

In general, our methodology follows the standard approach of LCA (Fig. 1) (goal and scope, life cycle inventory (LCI), life cycle impact assessment (LCIA), interpretation and discussion). The methodical point of departure is our previously developed HILCSA sustainability framework (Zeug et al. 2020) as well as the HILCSA indicator and life cycle impact assessment framework (Zeug et al. 2021a). For HILCSA in general and for assessing the case study system, we used openLCA, as it offers not only a S-LCA functionality as well as socio-economic databases like SOCA (Eisfeldt 2017) and PSILCA (Maister et al. 2020), but also because the openLCA structure aims explicitly for a perspective of integration and implementation of LCSA (Di Noi et al. 2018; Di Noi and Ciroth 2018; Zeug et al. 2021a).

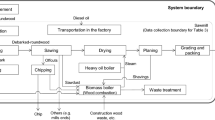

To build our LCI LVL-model in openLCA, we adapted the detailed gate-to-gate techno-ecological production system of LVL in Central Germany from the literature of the SUMINSITRO model (Hildebrandt et al. 2020, 2019, 2018), which were validated by participating stakeholders and producers, and made it a foreground system process “LVL manufacturing” in openLCA v.1.10 embodying all activities in the organization manufacturing LVL. For supply with raw materials, transportation, and background processes, we used Ecoinvent v.3.6 APOS (Allocation at the Point of Substitution) processes with social and economic data from SoCa v.1 by Green Delta. APOS integrates the treatment of wastes better than the cut-off system models, and is therefore more suitable for assessing BE and circular economy. For LVL manufacturing, we adopted the data for all social and economic indicators from SoCa by using a comparable LVL manufacturing process (laminated timber element production, for outdoor use | laminated timber element, transversally prestressed, for outdoor use | APOS, U; UUID: cdeab870-22e8-4b0c-9090-99d6595f77a5). From the RESPONSA survey and study (Jarosch et al. 2020), we took the real-world data of RESPONSA indicators for LVL manufacturing and forestry as well as activity variables. However, RESPONSA indicators are gained by surveys to a single company, are only representative for this very case, and consequently could only be applied to the foreground processes (LVL manufacturing, forestry) in this study. Primary data of RESPONSA indicators cannot be shown in this study due to privacy constraints and data protection of involved organizations. The system boundaries of this study are set by the cradle-to-gate product system (Fig. 2), for the LVL manufacturing process system boundaries are given by the primary data from the manufacturer (see chapter “3.2”) and all other processes include the up-streams given by Ecoinvent v.3.6. The system boundaries of this study are consistent with the RESPONSA and SUMINSTRO model. The risk of double counting in “LVL manufacturing” is avoided due to the manufacturing and production site only producing this final product, for all other processes we rely on Ecoinvent APOS allocation method.

For the following LCIA, we created an HILCSA-LCIA method in openLCA. Following the HILCSA indicator set (Zeug et al. 2021a), 91 SDGs and SDG subgoals serve as impact categories in openLCA and we quantified each by one mid or endpoint indicator as well as their given normalization factors from the chosen LCIA methods (RESPONSA, SoCa, ReCiPe 2016 End-/Midpoint H and Environmental Footprint (EF)) as well as weightings from stakeholder participation (Zeug et al. 2019). The SDGs are applicable as a commonly agreed on goal and indicator framework which was adapted to BE in previous studies (Bracco et al. 2019). For allocation and weighting of indicators in HILCSA, in Zeug et al. (2020) and Zeug et al. (2021a, b) certain SDGs were assigned to societal needs, economy, and PB; however, a clean analytical distinction is not possible due to the complex interactions to be discussed (de Schutter et al. 2019): societal needs (SDG 1, 2, 3, 4, 5, 11, (16, 17)); economy (SDG 6, 7, 8, 9, 10, 12); PB (SDG 13, 14, 15) (Zeug et al. 2019, 2021a, 2020).

Additionally, we added total and renewable cumulative energy demand (CED) for SDG 7.3/1 respectively SDG 7.2/4 (Table 4 in the Appendix). Since editing data in the openLCA front end can only be done manually and especially the impact factors for each impact category can easily exceed thousand flows, we exported the LCI and LCIA data to the ILCD format, edited it by using a powerful XML editor, and then imported it back to openLCA again.

Afterwards, we checked that the HILCSA-LCIA impact categories produce the same plain impact results as the used stand-alone LCIA methods, as well as for overall consistency of inventory results and impact analysis. Therefore, openLCA also provides a LCIA check, which gives information on flows which are not covered by applied LCIA methods. It is not important that all flows are covered by the LCIA, but rather that all flows with a significant impact are. To validate our inventory model and check for plausibility, we finally applied the HILCA-LCIA to our LVL product system as well as the comparable LVL manufacturing product system mentioned above, and compared the results.

To finally make a relative assumption on the sustainability of LVL production in Central Germany, we applied HILCSA-LCIA to the production system of hot-rolled steel beams (steel production, low-alloyed, hot-rolled|steel, low-alloyed, hot-rolled|APOS, U; UUID 93f61e55-d632-405e-8299-1cac3453ae7e). The functional unit (FU) of our LVL product system is an LVL beam with a mass of \({m}_{\mathrm{LVL}}^{\mathrm{FU}}=1469.0\mathrm{ kg}\). In order to make LVL and steel beams (SB) comparable regarding their functionality and the FU, we calculated a comparison factor \({C}_{\mathrm{SB}-\mathrm{LVL}}\) on basis of their average bending capacities \(q\) (load per unit length) (Pollmeier 2021), according to Eq. 1. As a result, a comparable steel beam with same functionality as our LVL beam has a mass and FU of \({m}_{\mathrm{SB}}^{\mathrm{FU}}=1720.8\mathrm{ kg}\).

Within the framework of this study, for some indicators, we can only present plain results at the level of impact categories without a further LCIA normalization entailing the distance to target (DTT) approach (Zeug et al. 2021a), since absolute sustainability assessment methods and models are still in development and not available as applicable LCIA methods yet (Bjørn et al. 2020; Ryberg et al. 2020; Sala et al. 2020). For each indicator \(i\) which is assigned to a specific subgoal SDG \(s\mathrm{SDG}\), in openLCA, we calculate values \(x\) for each process of the LVL product system \({x}_{\mathrm{sSDG}}^{\mathrm{LVL}}\), as well as cumulated (total) values for the whole product system of LVL \({x}_{\mathrm{sSDG},T}^{\mathrm{LVL}}\) and the steel beam \({x}_{\mathrm{sSDG},T}^{\mathrm{SB}}\). With all cumulated results of all indicators of our BE product system, we finally compare it to the product which can be substituted (steel beam), to assess their relative rather than absolute impact. For this purpose, we calculate a factor \({f}^{\mathrm{sSDG}}\) called substitution factor of impact of an indicator (Eq. 2), expressing the magnitude of relative sustainability. However, in this study, we cannot apply this normalization and aggregation to the 17 indicators from RESPONSA since we could not do a data survey on those indicators for the steel industry. For the remaining 74 indicators, we applied the substitution factors of impact normalization and aggregation. As aggregation on SDG level, we calculated weighted mean factors for substitution of impact for each SDG \({f}^{\mathrm{SDG}}\) (Eq. 3). As weighting factors, we used the relevances \({R}^{\mathrm{sSDG}}\) of each of the SDG subgoals which were gained in stakeholder workshops in context of the German BE-monitoring (Zeug et al. 2019). These weighting factors are dimensionless weightings ranging from 0 to 10 and represent the relevance of SDG subgoals within the Systemic Modelling and Monitoring of the German Bioeconomy (SYMOBIO) (Bringezu et al. 2020). Analogical as well a total substitution factor of impacts \(f\) is calculated on the level of all SDGs (Eq. 4).

3 Application of HILCSA to LVL

3.1 Goal and scope

Goal of this first HILCSA application is to assess the relative social, environmental, and economic impacts as risks and chances of regional BE product systems, their contributions to the SDGs and a socio-ecological transformation. In the present case, it is the comparison of LVL based on renewable raw materials with steel beams made of fossil raw materials, both having the same functionality per FU. As previously mentioned, HILCSA aims for absolute sustainability assessment methods; however, since applicable absolute LCIAs are not available, we apply HILCSA as relative sustainability assessment.

Beech wood is the main resource for the product system of LVL production in Central Germany and LVL serves as supporting structures in timber construction and also can be processed further to beams, panels, floor, and components for other structural applications (Jarosch et al. 2020; Pollmeier 2018). Most of the companies involved are members or former members of the Leading-Edge Cluster BioEconomy (BioEconomy Cluster 2019) and connected by diverse regional material flows of (renewable) resources, semi-finished products, chemicals, infrastructure, and knowledge (Hildebrandt et al. 2020). We speak about regional BE, as it is the case here, when a predominant share of resource extraction, semi-finished products, and manufacturing take place within a spatial area of no more than a 100-km radius. Besides, this radius is the average transport distance for roundwood in Germany (Schusser et al. 2019; Obkircher et al. 2013) and the assumed distance of transportation in our study.

Economic system boundaries are defined by the involved organizations performing foreground activities in LVL production, resulting in a cradle-to-gate product system (Fig. 2). In this product systems, as a first foreground activity beech saw and veneer log is provided by the “hardwood forestry, beech, UUID: bd06b5b9-0824-44c6-827b-650c59fbdb5f” process, which is then transported to the LVL manufacturing site by the “provisioning of beech roundwood” and “transport, freight, lorry, UUID: 28b69524-cdef-4d3c-93f8-54a48dc8d51a” processes (“provisioning of beech roundwood” only serves for a separate balancing of the transport service but has no additional inputs nor outputs). Finally, it is processed to a finished LVL beam by the “LVL manufacturing” process. All other processes are background activities and provide foreground processes with energy and ancillary by-educts material flows, such as the “phenolic resin production, UUID: b81f0c27-7ea1-4e3d-bd4c-c4972fd28bdd” process needed for gluing veneer sheets, the “electricity voltage transformation, UUID: 8675c4d1-60e3-40c4-b75c-a93553c86bed.” In the background as well, there are a multitude of not displayed processes providing input flows for shown foreground and background activities. These background processes do not necessarily take place in Central Germany and are fully covered by Ecoinvent upstream processes.

The LVL manufacturing process is an aggregated system process derived from a number of processes within the site of LVL manufacturing that was modeled in openLCA: debarking (also providing bark for heat production*), cooking in steam pit*, veneer peeling, cutting and drying*, laying and gluing, pressing in continuous press*, veneer layer sawing gluing with phenolic resin, pressing LVL in batch press). These processes in technical detail were assessed and validated in previous studies (Hildebrandt et al. 2019, 2020; Jarosch et al. 2020). In this study, they are only considered as an aggregated system process, since technical processes per se are not relevant in meso-scale regional LCSA, as long as they do not have a significant impact beyond the organization and especially socio-economic effects cannot be balanced separately (Zeug et al. 2020, 2021a).

3.2 Life cycle inventory

The LCI in this case is founded on the holistic and integrated sustainability framework (Zeug et al. 2020) and indicator system (Zeug et al. 2021a) of HILCSA. Our indicator system entails 91 social, ecological, and economic indicators, which are assigned to 25 SDGs (Table 4 in the Appendix). We derive each indicator from a specific LCIA model: SoCa, RESPONSA, Recipe or EF 3.0. Indicators contain qualitative (mostly social and economic) and/or quantitative (mostly economic and ecological) primary data. For each process of the foreground system, the indicator data is adopted and added from our previous studies (Hildebrandt et al. 2020; Jarosch et al. 2020); however, data for RESPONSA indicators is only available for the forestry process and manufacturing process but not for the transport process or background processes. All other indicator inventory data comes with the processes from Ecoinvent 3.3 with SoCa v.1, especially in case of the background processes as well as the forestry process and transport process. An overview of the main input and output flows is shown in Table 1. Despite the process “LVL manufacturing,” all processes come from the SoCa database and are considered with their corresponding up- and downstream flows. LVL manufacturing, however, is a system process compiled from a value chain of unit processes (Debarking–Steaming–Veneer Peeling–Cutting–Drying–Laying and Gluing–Pressing–Sawing) compiled of validated primary data coming from the manufacturer in Central Germany. Due to data protection of process details, we cannot provide quantitative LCI data but an aggregated system process for LVL manufacturing entailing all inputs, outputs, and emissions. Qualitatively, the LVL manufacturing processes are at the technical level of 2010; the thermal energy for steaming, drying, and pressing is provided by a bark-fired steam boiler (bark from roundwood and use of secondary fossil fuels); as well as residues from veneer peeling, cutting, and sawing are further processed to wood pellets for an external market which is not regarded and outside the system boundaries of this study.

For each process, we have material flow (mf) inputs as well as outputs, with one output flow being the reference flow and FU of this very process (e.g., for the forestry process the FU is 1 m3 saw log and veneer log, measured as solid wood under bark, UUID c00cac00-a885-42b0-88f5-fb5dce2a9a6f). We know from our S-LCA results (Jarosch et al. 2020) and the SoCa database that producing our final product FU, an LVL beam with \({m}_{\mathrm{LVL}}^{\mathrm{FU}}\), requires specific amounts of working time in each upstream process (e.g., 0.72 h for 1 m3 saw log and veneer log, 9.08 h for \({m}_{\mathrm{LVL}}^{\mathrm{FU}}\)). This working time per FU of a specific process is the activity variable (AV) for all social and economic indicators of SoCa and RESPONSA. Such indicators are balanced and handled as output flows of specific risk levels (very low risk; low risk; medium risk; high risk; very high risk; no data) with an AV within a process in openLCA. These risk levels are determined and deposited in the social aspects/assessment tab of a process in openLCA. Processes containing social, economic, and ecological data ready for being further calculated in openLCA with HILCSA are integrated processes. In case of RESPONSA indicators, we assign risk levels to performance reference points (PRPs) according to the evaluation scheme in (Table 4 in the Appendix). PRPs are determined before by using the RESPONSA model (Jarosch et al. 2020; Siebert et al. 2018; Zeug et al. 2021a). All indicators have a unit of measurement at primary data level, in case of social and economic indicators of SoCa and RESPONSA indicator values get dimensionless in the inventory when being transformed to risk levels.

3.3 Life cycle impact assessment

Our LCIA in general aims at calculating, understanding, and evaluating the magnitude and significance of impacts of the LVL product system (Zeug et al. 2021a, b). Each indicator is assigned to SDGs of the sustainability framework as end point impact categories (Table 4 in the Appendix). To some SDGs, a number of indicators are assigned, i.e., SDG 3.9 (reduce pollution of air/water/soil, health protection), SDG 8.7 and 8.8 (worker rights, labor protection rights, promoting safe work environment, abolition of forced labor/trafficking/child labor), SDG 13 (take urgent action to combat climate change and its impacts). However, there is no indicator which is assigned to several impact categories (SDGs) in exactly the same way, only if production sites are in urban regions (SDG 11.6), then indicator ID14 is used there instead.

At this early stage of overall method development, we do not change the different LCIA methods or characterization factors while integrating into LCSA, in order to keep consistency and only present rather plain results. Only in the CED LCIA we excluded the energetic gross calorific value of biomass flows (UUID: 01c12fca-ad8b-4902-8b48-2d5afe3d3a0f). Otherwise, this energy content of wood would be handled as if this energy is already consumed, although it is still contained by the LVL beam.

SoCa, as the socio-economic extension of openLCA, handles the variety of units and characteristics of social and economic indicators by applying common ordinal risks levels and according impact factors to different specific values of each indicator, assessed by its specific context (Social Impacts Weighting Method) (Eisfeldt 2017; Maister et al. 2020). SoCa, as well as our PRP-based social LCIA in RESPONSA, corresponds to an external normalization approach, which is recommended in general in the LCSA literature (Prado et al. 2012; Wulf et al. 2017; Troullaki et al. 2021) and also chosen for HILCSA (Zeug et al. 2021a). However, external normalization factors can increase the uncertainty of the whole assessment (Wulf et al. 2017) and the choice and transparency of the reference values plays a vital role (Sala et al. 2012). Due to the complexity in this regard, we refer in this study to the literature: SoCa relies on the PSILCA data of GreenDelta and its indicator values are based on international conventions and standards, labor laws, expert opinions but also own experience and evaluation (Maister et al. 2020); RESPONSA calculates PRPs as a regional and context-specific LCIA (Jarosch et al. 2020; Siebert et al. 2018; Zeug et al. 2021a). All socio-economic indicators from SoCa and RESPONSA in our HILCSA are comparable on from being transferred to risk levels (normalization) and share the same impact factor of the Social Impact Weighting Method (Table 2). For aggregation and balancing social indicators along the value chain, we use the implemented method of SoCa in openLCA based on the activity variable.

However, as discussed before, absolute sustainability assessment methods in forms of distance to target (DTT) as impact pathway approaches are not robustly available in LCA, yet (Zeug et al. 2021a). But as soon as they are, absolute sustainability assessment methods and DTT will allow to calculate a product system and regional specific environmental threshold in regard to PB, e.g., how much kg CO2 eq. per product or regional BE network can be considered as (un-)sustainable. We are confident that the specific indicator values of mostly environmental indicators can be assigned to the same risks levels as above, in regard to the risk of transgressing PB when producing a specific product or operating a regional economy. In the meanwhile, the stress on PB has been adopted as normalization factors in the EF 3.0 method (Bjørn et al. 2020; Bjørn and Hauschild 2015; Sala et al. 2020) and as well as the Recipe Endpoint indicators which are assigned to PB SDGs of our sustainability framework (Zeug et al. 2021a).

Finally, for all indicators (except of RESPONSA, since RESPONSA inventory data is not available for steel), we compare the values of the LVL to the steel beam to assess their relative rather than absolute impact. For this normalization, we calculate substitution factors of impact \({f}^{\mathrm{sSDG}}\) (Eq. 2) for each indictor. In a following aggregation of these normalized factors, we apply a weighted mean factor \({f}^{\mathrm{SDG}}\) (Eq. 3) for each SDG the \({f}^{\mathrm{sSDG}}\) is assigned to. The weightings are based on the relevance of SDG subgoals, we determined for the German BE-monitoring by stakeholder participation (Zeug et al. 2019). As a highest level of aggregation by aggregating all SDGs, we analogically calculate a total substitution factor of impacts \(f\) of all SDGs (Eq. 4). According to the impact factors from the Social Impact Weighting Method from above, we assign them the according risk level and color as described in Table 2. The values of the individual indicators as well as all substitution factors of impact are presented in Table 3.

3.4 Interpretation

The aggregated results of the HILCSA are presented within the HILCSA sustainability framework in Fig. 3 in which the share of areas in the chart of each SDG indicates their relevance \({R}^{\mathrm{sSDG}}\). Their substituiton factor of impact \({f}^{\mathrm{SDG}}\), and a total substitution factor of impact \(f\) as well as their colors of risk levels are indicated.

Relative holistic sustainability of LVL compared to steel beam production, presented in form of the holistic sustainability framework for HILCSA of the BE (Zeug et al. 2020) (SDGs are viewed in size according to their relevance for German BE assessments from (Zeug et al. 2019); colors and values represent the substitution factors of impacts (Table 2); white = no data)

At the highest aggregation level over all SDGs, the total substitution factor of impact of this case study of LVL relative to steal beams is \(f=0.61\). Regarding the results of our LCI and LCIA, this means that the holistic risks and impacts of LVL production in Central Germany are considered to be lower according to this factor compared to the production of steel beams. Positive effects of this substitution will especially entail a better social sustainability (societal needs; SDG 1, 2, 3, 4, 5, 11) as well as economic sustainability (economy; SDG 6, 8, 12, 16) and mostly ecological sustainability (PB; SDG 13, 14). For those SDGs, the substituion factors of impact are below 1.0. However, LVL production has some partly significant risks compared to steal production when it comes to SDG 7 (energy) and SDG 15 (life on land) with weighted impacts above 1.0.

To understand these general and relative results in more detail, we need to take a look at the substitution factors of impact on SDG-subgoal level and the openLCA model results with focus on some remarkable ones (Table 3). First to say, out of 74 indicators (excluding RESPONSA, see above) for which we calculated \(f\), for 70 indicators \({f}^{\mathrm{sSDG}}<1.0\) and for 56 indicators \({f}^{\mathrm{sSDG}}<0.5\) which means that the LVL production can be considered as reletivley more sustainable and mostly has half of the weighted impacts than steel beam production. Besides overall good relative social sustainability, in other words low risks and low \(f\), there are relatively very low impacts on human health toxicity \(({f}^{\mathrm{ID}15}=0.02; {f}^{\mathrm{ID}16}=0.09\)) which we trace back to the high impacts of mining, treating slag and sulfidic tailings in steel production. On the other side, SDG 7 (energy) as part of economic sustainability in the provisioning sytem, only has a medium risk level and \({f}^{\mathrm{SDG}7}=0.98\), which means there is no advantage of LVL in this regard. The two relevant indicators are CED (ID25) and Share of fossil energies in CED (sfCED) (ID24) with \({f}^{\mathrm{ID}25}=0.91\) and \({f}^{\mathrm{ID}24}=1.05\), respectivley \({\mathrm{CED}}^{\mathrm{LVL}}=36375\mathrm{ MJ}\) and \({\mathrm{CED}}^{\mathrm{SB}}=39982\mathrm{ MJ}\) as well as \({\mathrm{sfCED}}^{\mathrm{LVL}}=0.98\) and \({\mathrm{sfCED}}^{\mathrm{SB}}=0.93\). These results show us that the CED of LVL and steel beam production is comparable, although in case of LVL phenolic resin production is accountable for 91% of LVLs CED. Interestingly, the share of fossil energies in LVL production is slightly higher than of steel, since on the one hand they share more or less the same comparable power grids for electricity, but wood is mainly harvested and transported by diesel fuel driven machines with a \(\mathrm{sfCED}=0.99\). As it can be expected, most significant negetive impacts of LVL production come from forestry and its effects on land use (ID83) represented in SDG 15 (life on land) with \({f}^{\mathrm{ID}83}=18.15\) respectivley \({f}^{\mathrm{SDG}15}=2.14\). However, the climate change due to land use change (ID73) in total is better than of steel \({f}^{\mathrm{ID}73}=0.96\) as well as the overall negative effects on climate change (ID70) are far less \({f}^{\mathrm{ID}70}=0.39\). In general, it is striking that phenolic resin production for 70 out of 74 indicators is the main contributer of negative impacts in LVL production (except level of industrial renewable water use (ID57), extraction of biomass related to area (ID61), climate change due to land use change (ID73), land use (ID83)), even thouh its mass fraction of the final product is only 18.2%. Our results suggest that substituting steel beams by LVL beams can make a significant contribution towards holistic sustainability and contributing to the SDGs. However, LVL would be even much more sustainable and favorable when fossil components like phenolic resin are substituted by renewable alternatives, which is not only true for ecological (cf. (Hildebrandt et al. 2020)) but also for social and economic sustainability. Nonetheless, it remains of high importance to reduce land use and negative land use change impacts of forestry and to at least only use FSC certified wood is highly recommended.

We consider our results as plausible and consistent within the limits of data quality of Ecoinvent and SoCa as well as cradle-to-gate LCA in general. The LCI of the LVL manufacturing process was validated with the involved organizations (Hildebrandt et al. 2020), and comparing it to the Ecoinvent laminated timber element production produced comparable results of the same magnitude. A LCIA check in openLCA suggests that all relevant flows are covered by our HILCSA-LCIA, only a number of flows with very small fractions are not covered which would also be the case in stand-alone methods like ReCiPe or EF3.0. Our results suggest that the social, economic, and environmental impacts and sustainability of LVL production are very sensitive to the quantity and quality of binder which is applicated, in this case fossil-based phenolic resin, as well as the sustainability of forestry. Within our method, most sensitiveness of aggregated results comes from the weighting factors for SDGs from stakeholder participation, which should be carefully applied in other case studies within the same context and should be revised and newly determined in other regional contexts. A consistent data quality check and methodology cannot be applied in context of this very first case study, but partially data quality indications can be gained from the source of the used data and in further case studies build in data quality checks will be used.

4 Discussion and conclusions

This first case study of HILCSA applied as a relative sustainability assessment to LVL compared to steel beams, asks on the one hand for the holistic sustainability of LVL, and on the other hand for the lessons learned from this first application.

We defined holistic sustainability as ecological, economic and social sustainability in the sense given above on the background of the double decoupling problem and potential trade-offs and synergies. In general, with regard to the weightings, our total factor of substitution aggregated for all SDGs and indicators \(f=0.61\) gives a rough approximation on how much less unsustainable LVL can be, compared to steel. In other words, LVL has only 60% of the negative impacts in terms of social, ecological, and economic sustainability. Of course, such a highly aggregated index provides a limited analytical understanding and primarily a first orientation, as well as it can be discussed and criticized due to a number of assumptions, weightings, data quality issues, and much more. The aggregated substitution factors of impact \(f\) and \({f}^{\mathrm{SDG}}\) are more subjective and depend on stakeholder relevances compared to the non-aggregated substitution factors of impact at the level of indicators \({f}^{\mathrm{sSDG}}\) (Table 3).

When the substitution factor of impact is calculated for social \({f}_{\mathrm{social}}=0.31\), ecological \({f}_{\mathrm{ecological}}=1.01\), and economic \({f}_{\mathrm{economic}}=0.60\) sustainability (according to the sustainability framework Table 3, the picture begins to differentiate. LVL seems to have a way better social sustainability, having a look at the indicator data and inventory, this is mainly due to the less toxicity of materials, impacts on humans and their working environments, but also higher expenditures for social security and education as well as a lower gender wage gap. However, backed up by literature (Backhouse et al. 2021), we suggest that the different technical production processes are not the main cause, but the far more global distribution of primary production chains and thereby externalization of social deprivations is much higher in the steel industry, and globalized BE would have such negative externalized effects likewise. When looking at \({f}_{\mathrm{ecological}}=1.01\), we expect a quite limited better ecological sustainability, which is foremost because of the high land use (change) effects of forestry in a way compensating the significant GWP savings and much lower ecotoxicity. In terms of economic sustainability and a moderately good \({f}_{\mathrm{economic}}=0.60\), we can observe mostly low and very low \(f\) in the forestry and manufacturing sector of LVL (except fossil fuel-driven machinery); indeed, the phenolic resin production is responsible for a large share of negative impacts for nearly every indicator. Again, global externalization of fossil raw material production seems to be a major issue and phenol in this case is an example for pareto effects (a relatively small number of causes responsible for a major portion of the effects (Halog and Manik 2011).

In a nutshell, we conclude that bio-based renewable materials in this case can substitute fossil materials and can lead to partially significant lower impacts and increasing sustainability. We also see that processes based on renewable resources in specific regions do not only have a better ecological, but also better social and economic sustainability and that there seem to be synergies between these aspects of sustainability. However, the dependency of sustainability from regions does not only apply to fossil industries, but bioeconomy can be very unsustainable as well when renewable material flows reproduce global social and economic inequalities and externalization of effects of sourcing and production (Backhouse et al. 2021; Eversberg and Holz 2020; Asada et al. 2020). In this regard, we see a high potential for regional, holistic, and integrated HILCSA: to not only identify trade-offs or synergies between different aspects of sustainability but also in shifting them to other regions. Besides, a significant and well known trade-off is striking and mostly independent from regions: forestry and agriculture use relatively much more land than fossil resources (in our case by factor 18) setting a major barrier for bioeconomy and simple substitution (Bringezu et al. 2020; O’Brien et al. 2017; Liobikiene et al. 2020). A sustainable bioeconomy requires that the rate of extraction does not exceed the rate of regeneration and that PB are not transgressed (Lindqvist et al. 2019; Zeug et al. 2021a). As a consequence, we suggest that different strategies for specific sectors on using renewable resources should be put in a common context. This can be done by building up a strategy and sector overarching holistic bioeconomy monitoring on national and European level (cf. Bringezu et al. 2020; BioMonitor 2018)), to avoid the double counting of resources in each strategy and sector as well as to foster synergies and to avoid trade-offs, externalization and overuse of renewable resources.

This leads to the lessons learned, and the potential which can be unlocked when absolute sustainability assessments and PB are covered by HILCSA and LCA in general. As discussed above and in previous research (Zeug et al. 2021a), absolute sustainability assessments can address PB by downscaling them to regions, production systems and products, and thereby not only give us information on absolute sustainability, but also relative sustainability if a substitution in a specific context is feasible and in fact relatively sustainable. Currently, environmental footprint methods as the basis for absolute sustainability assessments and their implementation in LCIAs are in a final transition phase (JRC 2019) and will be applicable in context of SDG frameworks like HILCSA (Sala 2019). As main lessons learned, instead of plain results for ecological indicators, context-specific risk levels like for the other indicators could be applied in future case studies entailing absolute sustainability assessments, resulting in a higher consistency as well. Important in this regard is that such LCIA methods are implemented timely in openLCA and that openLCA is constantly developed further to integrate social and economic aspects. S-LCA specific functionalities should be improved regarding a better documentation, more straight-forward implementation in the LCI and especially more flexible option in creating complex and multi-level LCIA methods. Partly quite inconvenient work flows by lack of automatization, linkage of data and working interfaces (e.g., with Excel) result in using the ILCD format and editing in XML language. Despite some lack of functionalities, e.g., parameters seem not to be supported in ILCD, there are as well no manuals on scripting ILCD and a lack of documentation. The HILCSA sustainability framework and LCSA methodology turned out to be functional and powerful to analyze the social, ecological, and economic impacts of product systems. However, the existing indicators should be further streamlined with the sustainability framework, e.g., to implement more specific indicators for contribution of product systems to fulfill societal needs and their contribution to human well-being or to describe economic effectiveness and justice of allocation of the produced goods. As well the substitution factors of impacts work well for the purpose of relative sustainability assessment of two products, but in the current form not applicable to more complex products systems on a meso- and macro-economic scale. For future developments of HILCSA, the extension to hybrid LCSA entailing multi regional input–output analyses (MRIO) (Asada et al. 2020; Budzinski et al. 2017; Crawford et al. 2018; Teh et al. 2017) as well as implementation of circular economy indicators is aimed at (Calisto Friant et al. 2020; Leipold 2021a, b; D’Amato 2021; Moraga et al. 2019; Padilla-Rivera et al. 2020).

The results of our method are depending on the chosen reference. Not to be neglected neither should be the sensitivity due to the weighting factors on aggregated levels of SDG \({f}^{\mathrm{SDG}}\) and in total \(f\). A small sensitivity analyses, however, shows that the overall aggregated results do not change qualitatively, e.g., when all weightings \({R}^{\mathrm{sSDG}}\) and resulting \({R}^{\mathrm{SDG}}\) are set as equal (\(R=1\)), then \(f=0.57\), \({f}_{\mathrm{social}}=0.33\), \({f}_{\mathrm{ecological}}=1.02\), and \({f}_{\mathrm{economic}}=0.59\). Nevertheless, in other regional contexts, the weightings should be newly determined and the indicators set should be revised as well, e.g., when child labor, hunger, or modern forms of slavery play a more significant role. Further participation formats with involved stakeholders would also be necessary to ensure collaborative creation, collaboration, and cooperation. Consequently, performance- and values-based methods can be combined in LCSA application as well as drivers and receivers of impact are regarded (Troullaki et al. 2021). In this sense, in future case studies, the data of RESPONSA indicators has to be collected from all involved stakeholders (organizations, workers, local communities) in foreground activities. Furthermore, future case studies of HILCSA should aim at the full life cycle of products, including use and end-of-life phase, as well as recycling and cascading use. Especially for substitutes, it is important to know, if the same use value can be provided for the same life span (Zeug et al. 2021a).

We emphasize that some methodological approaches in this early stage of holistic and integrated LCSA may vary from traditional LCA and concise established methodologies of environmental LCA, but that transdisciplinary and transformational science calls for less rigidly framed methods as well (Troullaki et al. 2021). In this regard, HILCSA lacks of analyzing structural societal elements of economies, e.g., ownership, control, agency, and power relations (Plank et al. 2021). For the double decoupling problem, such aspects in relation to technologies and systemic interlinkages between societal processes and the biophysical dimensions are decisive (Plank et al. 2021). Though, HILCSA does not aim for integrating everything, but to be a valuable interdisciplinary tool together with social science studies on changing and persistent mentalities (Eversberg and Holz 2020; Eversberg 2021) as well as political economy and ecology (Pichler et al. 2020). Ultimately, bioeconomy will not be successful if it is simply a substitution of resources and impacts, but if it is part of a socio-ecological transformation beyond the existing societal relations to nature (Zeug et al. 2022).

Data availability

The data generated and analyzed in this study are available from the corresponding author upon request.

References

Asada R, Cardellini G, Mair-Bauernfeind C, Wenger J, Haas V, Holzer D, Stern T (2020) Effective bioeconomy? A MRIO-based socioeconomic and environmental impact assessment of generic sectoral innovations. 153:119946. https://doi.org/10.1016/j.techfore.2020.119946

Backhouse M, Lehmann R, Lorenzen K, Lühmann M, Puder J, Rodríguez F, Tittor A (2021) Bioeconomy and global inequalities. Springer Nature. https://doi.org/10.1007/978-3-030-68944-5

Balkau F, Sonnemann G (2017) Synthesis - life cycle approaches and perspectives for sustainable regional development. Life cycle approaches for sustainable regional development. Routledge, New York, pp 322–329

Becker E, Hummel D, Jahn T (2011) Societal relations to nature as a common frame of reference for integrated environmental research. Unpublished English translation. Originally published in German. In: Groß M (ed) Handbuch Umweltsoziologie. VS Verlag für Sozialwissenschaften, Wiesbaden, pp 75–96

Bezama A, Hildebrandt J, Thran D (2021) Integrating regionalized socioeconomic considerations onto life cycle assessment for evaluating bioeconomy value chains: a case study on hybrid wood-concrete ceiling elements. Sustainability-Basel 13:4221.https://doi.org/10.3390/su13084221

Bezama A, Ingrao C, O’Keeffe S, Thran D (2019) Resources, collaborators, and neighbors: the three-pronged challenge in the implementation of bioeconomy regions. Sustainability 11:7235. https://doi.org/10.3390/su11247235

BioEconomy Cluster (2019) Chemistry meets the timber industry – the BioEconomy Cluster. BioEconomy e.V. http://en.bioeconomy.de/cluster/. Accessed 08 June 2020

BioMonitor (2018) BioMonitor - monitoring the bioeconomy. http://biomonitor.eu/. Accessed 20 Dec 2018

Bjørn A et al (2020) Review of life-cycle based methods for absolute environmental sustainability assessment and their applications. Environ Res Lett 15:083001. https://doi.org/10.1088/1748-9326/ab89d7

Bjørn A, Hauschild MZ (2015) Introducing carrying capacity-based normalisation in LCA: framework and development of references at midpoint level. Int J Life Cycle Ass 20:1005–1018. https://doi.org/10.1007/s11367-015-0899-2

BMBF B (2014) Bioökonomie in Deutschland - Chancen für eine biobasierte und nachhaltige Zukunft. Bundesministerium für Bildung und Forschung (BMBF), Bundesministerium für Ernährung Landwirtschaft (BMEL), Berlin

Bracco S, Tani A, Çalıcıoğlu Ö, Juan MGS, Bogdanski A (2019) Indicators to monitor and evaluate the sustainability of bioeconomy. FAO (Food and Agriculture Organization of the United Nations), Rome. 978-92-5-131796-9

Bringezu S et al (2020) Pilotbericht zum Monitoring der deutschen Bioökonomie. Center for Environmental Systems Research (CESR), Kassel. https://doi.org/10.17170/kobra-202005131255

Budzinski M, Bezama A, Thran D (2017) Monitoring the progress towards bioeconomy using multi-regional input-output analysis: the example of wood use in Germany. J Clean Prod 161:1–11. https://doi.org/10.1016/j.jclepro.2017.05.090

Calisto Friant M, Vermeulen WJV, Salomone R (2020) A typology of circular economy discourses: navigating the diverse visions of a contested paradigm. 161. https://doi.org/10.1016/j.resconrec.2020.104917

Costa D, Quinteiro P, Dias AC (2019) A systematic review of life cycle sustainability assessment: current state, methodological challenges, and implementation issues. Sci Total Environ 686:774–787. https://doi.org/10.1016/j.scitotenv.2019.05.435

Crawford RH, Bontinck P-A, Stephan A, Wiedmann T, Yu M (2018) Hybrid life cycle inventory methods – a review. 172:1273–1288. https://doi.org/10.1016/j.jclepro.2017.10.176

D’Amato D, Gaio M, Semenzin E (2020) A review of LCA assessments of forest-based bioeconomy products and processes under an ecosystem services perspective. Sci Total Environ 706:135859. https://doi.org/10.1016/j.scitotenv.2019.135859

D’Amato D (2021) Sustainability Narratives as Transformative Solution Pathways: Zooming in on the Circular Economy 1:231–242. https://doi.org/10.1007/s43615-021-00008-1

De Besi M, McCormick K (2015) Towards a bioeconomy in Europe: national, regional and industrial strategies. 7:10461–10478. https://doi.org/10.3390/su70810461

De Laurentiis V, Galli A, Sala S (2022). Modelling the Land Footprint of EU Consumption. https://doi.org/10.2760/97417

De Schutter L, Giljum S, Hayha T, Bruckner M, Naqvi A, Omann I, Stagl S (2019) Bioeconomy transitions through the lens of coupled social-ecological systems: a framework for place-based responsibility in the global resource system. Sustainability-Basel 11:5705. https://doi.org/10.3390/su11205705

Di Noi C, Ciroth A (2018) Environmental and social pressures in mining. Results from a sustainability hotspots screening. Resources 7:80. https://doi.org/10.3390/resources7040080

Di Noi C, Eisfeldt F, Ciroth A, Bizarro D (2018) Complementarity of social and environmental indicators and risks. An example of the mining industry. Paper presented at the S-LCA 2018, Pescara, September 2018

Egenolf V, Vita G, Distelkamp M, Schier F, Hufner R, Bringezu S (2021) The timber footprint of the German bioeconomy-state of the art and past development. Sustainability-Basel 13:3878. https://doi.org/10.3390/su13073878

Eisfeldt F (2017) Soca v.1 add-on – adding social impact information to ecoinvent. GreenDelta GmbH, Berlin

Ekener E, Hansson J, Larsson A, Peck P (2018) Developing life cycle sustainability assessment methodology by applying values-based sustainability weighting - tested on biomass based and fossil transportation fuels. 181:337–351. https://doi.org/10.1016/j.jclepro.2018.01.211

European Commission (2011) Roadmap to a resource efficient Europe. COM (2011) 571 Final. European Commission, Bruxelles

Eversberg D (2021) The social specificity of societal nature relations in a flexible capitalist society. Environ Value 30:319–343. https://doi.org/10.3197/096327120x15916910310581

Eversberg D, Holz J (2020) Empty promises of growth: the bioeconomy and its multiple reality checks. Working Paper #2 of the BMBF Junior Research Group "Mentalitites in Flux" (flumen). Friedrich-Schiller-Universität Jena, Jena. https://doi.org/10.13140/RG.2.2.30275.84007

Fauzi RT, Lavoie P, Sorelli L, Heidari MD, Amor B (2019) Exploring the current challenges and opportunities of life cycle sustainability assessment. Sustainability 11:636. https://doi.org/10.3390/su11030636

Gao L, Bryan BA (2017) Finding Pathways to National-Scale Land-Sector Sustainability 544:217. https://doi.org/10.1038/nature21694

Görg C (2011) Societal relationships with nature: a dialectical approach to environmental politics. In: Biro A (ed) Critical Ecologies. University of Toronto Press, Toronto

Guinee JB et al (2011) Life cycle assessment: past, present, and future. Environ Sci Technol 45:90–96. https://doi.org/10.1021/es101316v

Halog A, Manik Y (2011) Advancing integrated systems modelling framework for life cycle sustainability assessment

Hausknost D, Schriefl E, Lauk C, Kalt G (2017) A transition to which bioeconomy? An exploration of diverging techno-political choices. Sustainability 9:669. https://doi.org/10.3390/su9040669

Herczeg M, McKinnon D, Milios L, Bakas I, Klaassens E, Svatikova K, Widerberg O (2014) Resource efficiency in the building sector: final report

Hildebrandt J, Bezama A, Thran D (2020) Insights from the sustainability monitoring tool SUMINISTRO applied to a case study system of prospective wood-based industry networks in Central Germany. Sustainability 12:3896. https://doi.org/10.3390/su12093896

Hildebrandt J, Budzinski M, Nitzsche R, Weber A, Krombholz A, Thrän D, Bezama A (2019) Assessing the technical and environmental performance of wood-based fiber laminates with lignin based phenolic resin systems. Resour Conserv Recy 141:455–464. https://doi.org/10.1016/j.resconrec.2018.10.029

Hildebrandt J, O’Keeffe S, Bezama A, Thrän D (2018) Revealing the environmental advantages of industrial symbiosis in wood-based bioeconomy networks: an assessment from a life cycle perspective. J Ind Ecol 23:808–822. https://doi.org/10.1111/jiec.12818

Hummel D, Jahn T, Keil F, Liehr S, Stieß I (2017) Social ecology as critical, transdisciplinary science—conceptualizing, analyzing and shaping societal relations to nature 9:1050

IPCC IPoCC (2018) Global Warming of 1.5°. Switzerland

Jarosch L, Zeug W, Bezama A, Finkbeiner M, Thran D (2020) A regional socio-economic life cycle assessment of a bioeconomy value chain. Sustainability. https://doi.org/10.3390/su12031259

JRC JRC (2019) European Platform on Life Cycle Assessment. https://eplca.jrc.ec.europa.eu/. Accessed 1 Dec 2019

Leipold S (2021a) Transforming ecological modernization ‘from within’ or perpetuating it? The Circular Economy as EU Environmental Policy Narrative 30:1045–1067. https://doi.org/10.1080/09644016.2020.1868863

Leipold S et al (2021b) Lessons, narratives and research directions for a sustainable circular economy. https://doi.org/10.21203/rs.3.rs-429660/v1

Leskinen P et al (2018) Substitution effects of wood-based productsin climate change mitigation. European Forest Institute

Lindqvist AN, Broberg S, Tufvesson L, Khalil S, Prade T (2019) Bio-based production systems: why environmental assessment needs to include supporting systems. Sustainability 11:4678. https://doi.org/10.3390/su11174678

Liobikiene G, Chen X, Streimikiene D, Balezentis T (2020) The Trends in Bioeconomy Development in the European Union: Exploiting Capacity and Productivity Measures Based on the Land Footprint Approach 91:104375. https://doi.org/10.1016/j.landusepol.2019.104375

Maister K, Noi CD, Ciroth A, Srocka M (2020) PSILCA database v.3 documentation (Product Social Impact Life Cycle Assessment database). Green Delta, Berlin

Moraga G et al (2019) Circular economy indicators: what do they measure? 146:452–461. https://doi.org/10.1016/j.resconrec.2019.03.045

O’Neill DW, Fanning AL, Lamb WF, Steinberger JK (2018) A good life for all within planetary boundaries. Nat Sustain 1:88–95. https://doi.org/10.1038/s41893-018-0021-4

O’Brien M, Wechsler D, Bringezu S, Schaldach R (2017) Toward a systemic monitoring of the European bioeconomy: gaps, needs and the integration of sustainability indicators and targets for global land use. 66:162–171. https://doi.org/10.1016/j.landusepol.2017.04.047

Obkircher C, Lengwenat E, Ohnesorge DD (2013) Greenhouse gas balance of truck raw wood transports in Germany taking into account an increase in the permissible total weight. Technische Universität München, Freising

OECD (2018) Meeting policy challenges for a sustainable bioeconomy. OECD Publishing, Paris. https://doi.org/10.1787/9789264292345-en

Onat NC, Kucukvar M, Halog A, Cloutier S (2017) Systems thinking for life cycle sustainability assessment: a review of recent developments, applications, and future perspectives. Sustainability 9:706. https://doi.org/10.3390/su9050706

Padilla-Rivera A, Russo-Garrido S, Merveille N (2020) Addressing the social aspects of circular economy: a systematic literature review. https://doi.org/10.20944/preprints202009.0044.v1

Palahí M (2021) Is forest harvesting increasing in Europe? European Forest Institute. https://efi.int/articles/nature. Accessed 15 June 2022

Parrique TBJ, Briens F, Kerschner C, Kraus-Polk A, Kuokkanen A, Spangenberg JH (2019) Decoupling debunked - evidence and arguments against green growth as a sole strategy for sustainability. The European Environmental Bureau, Brussels

Pichler M, Brand U, Görg C (2020) The Double Materiality of Democracy in Capitalist Societies: Challenges for Social-Ecological Transformations 29:193–213. https://doi.org/10.1080/09644016.2018.1547260

Plank C, Liehr S, Hummel D, Wiedenhofer D, Haberl H, Görg C (2021) Doing More with Less: Provisioning Systems and the Transformation of the Stock-Flow-Service Nexus 187:107093. https://doi.org/10.1016/j.ecolecon.2021.107093

Pollmeier (2018) Pollmeier Buche. eine Holzart. 1000 Möglichkeiten [Pollmeier beech. A type of wood. 1000 possibilities]. Pollmeier, Creuzburg, Germany

Pollmeier (2021) BauBuche und andere Werkstoffe im Vergleich. Creuzburg

Prado V, Rogers K, Seager TP (2012) Integration of MCDA tools in valuation of comparative life cycle assessment. In: Life cycle assessment handbook. pp 413–431. https://doi.org/10.1002/9781118528372.ch19

Ramcilovic-Suominen S, Pülzl H (2018) Sustainable development – a ‘selling point’ of the emerging EU bioeconomy policy framework? J Clean Prod 172:4170–4180. https://doi.org/10.1016/j.jclepro.2016.12.157

Rockström J et al (2009) A Safe Operating Space for Humanity 461:472. https://doi.org/10.1038/461472a

Ryberg MW, Andersen MM, Owsianiak M, Hauschild MZ (2020) Downscaling the planetary boundaries in absolute environmental sustainability assessments – a review. 276:123287. https://doi.org/10.1016/j.jclepro.2020.123287

Sala S (2019) Life cycle assessment and evaluation of solutions towards sustainable development goals. In: Leal Filho W, Azul AM, Brandli L, Özuyar PG, Wall T (eds) Partnerships for the goals. Encyclopedia of the UN Sustainable Development Goals. Springer International Publishing, Cham, pp 1–13. https://doi.org/10.1007/978-3-319-71067-9_33-1

Sala S, Crenna E, Secchi M, Sanye-Mengual E (2020) Environmental sustainability of European production and consumption assessed against planetary boundaries. J Environ Manage 269:110686. https://doi.org/10.1016/j.jenvman.2020.110686

Sala S, Farioli F, Zamagni A (2012) Progress in sustainability science: lessons learnt from current methodologies for sustainability assessment: Part 1. Int J Life Cycle Ass 18:1653–1672. https://doi.org/10.1007/s11367-012-0508-6

Schusser M, Gößwein S, Borchert H (2019) Market study of round wood logistics. Bayerische Landesanstalt für Wald und Forstwirtschaft, Freising

Siebert A, O’Keeffe S, Bezama A, Zeug W, Thrän D (2018) How not to compare apples and oranges: generate context-specific performance reference points for a social life cycle assessment model. J Clean Prod 198:587–600. https://doi.org/10.1016/j.jclepro.2018.06.298

Steffen W et al (2018) Trajectories of the Earth System in the Anthropocene 115:8252–8259. https://doi.org/10.1073/pnas.1810141115

Suwelack K (2016) Conversion technology and life cycle assessment of renewable resources. Hohenheim University, Hohenheim

Teh SH, Wiedmann T, Schinabeck J, Moore S (2017) Replacement scenarios for construction materials based on economy-wide hybrid LCA. 180:179–189. https://doi.org/10.1016/j.proeng.2017.04.177

Troullaki K, Rozakis S, Kostakis V (2021) Bridging barriers in sustainability research: a review from sustainability science to life cycle sustainability assessment. 184:107007. https://doi.org/10.1016/j.ecolecon.2021.107007

Urban K et al (2018) Markets, sustainability management and entrepreneurship. In: Lewandowski I (ed) Bioeconomy. Springer International Publishing, Cham, pp 231–286. https://doi.org/10.1007/978-3-319-68152-8_8

Wulf C, Werker J, Ball C, Zapp P, Kuckshinrichs W (2019) Review of sustainability assessment approaches based on life cycles. Sustainability 11:5717. https://doi.org/10.3390/su11205717

Wulf C, Zapp P, Schreiber A, Marx J, Schlor H (2017) Lessons learned from a life cycle sustainability assessment of rare earth permanent magnets. J Ind Ecol 21:1578–1590. https://doi.org/10.1111/jiec.12575

Zeug W, Bezama A, Moesenfechtel U, Jähkel A, Thrän D (2019) Stakeholders’ interests and perceptions of bioeconomy monitoring using a sustainable development goal framework. Sustainability 11:1511. https://doi.org/10.3390/su11061511

Zeug W, Bezama A, Thrän D (2020) Towards a holistic and integrated life cycle sustainability assessment of the bioeconomy – background on concepts, visions and measurements vol 07. Helmholtz-Centre for Environmental Research (UFZ), Leipzig. https://doi.org/10.13140/RG.2.2.16912.02564

Zeug W, Bezama A, Thran D (2021a) A framework for implementing holistic and integrated life cycle sustainability assessment of regional bioeconomy. Int J Life Cycle Ass. https://doi.org/10.1007/s11367-021-01983-1

Zeug W, Bezama A, Thrän D (2022) Life cycle sustainability assessment for sustainable bioeconomy, societal-ecological transformation and beyond. In: Progress in life cycle assessment. Sustainable Production, Life Cycle Engineering and Management. Springer

Zeug W, Kluson F, Mittelstädt N, Bezama A, Thrän D (2021b) Results from a stakeholder survey on bioeconomy monitoring and perceptions on bioeconomy in Germany. Helmholtz-Centre for Environmental Research, Leipzig. https://doi.org/10.13140/RG.2.2.35521.28000

Zimek M, Schober A, Mair C, Baumgartner RJ, Stern T, Füllsack M (2019) The third wave of LCA as the “decade of consolidation.” Sustainability 11:3283. https://doi.org/10.3390/su11123283

Funding

Open Access funding enabled and organized by Projekt DEAL.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Communicated by Jörg Schweinle.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Zeug, W., Bezama, A. & Thrän, D. Application of holistic and integrated LCSA: Case study on laminated veneer lumber production in Central Germany. Int J Life Cycle Assess 27, 1352–1375 (2022). https://doi.org/10.1007/s11367-022-02098-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11367-022-02098-x