Abstract

The recent IPCC 2023 report reiterates that humans are responsible for global warming over the past 200 years, causing a rise in temperature of 1.1 °C above pre-industrial levels, urging the implementation of mitigation options, especially in the building energy sector. One strong mitigation strategy is designing and building net zero energy buildings (NZEB), although their implementation faces challenges such as opposition to change, especially in tropical countries with traditional and conservative design and construction practices. This paper uses data from a pilot NZEB Laboratory building at UCA, El Salvador, and details its results by comparing different construction system scenarios. The present work presents the results of the Life-cycle assessment (LCA) in three popular construction systems in El Salvador, comparing them with the baseline of its current operation, through 3 iterative calculation tools: structural, thermal and carbon footprint estimation, managing to visualize important findings on how vernacular systems could meet the NZEB performance with added insulation in the structural walls. In addition, a triple-axis sustainability analysis (environmental, economic and social) is conducted using the weighted criteria matrix, which provides nuanced results, such as the proportional share of embodied carbon between the proposals, there is not much difference between the results of the proposed systems, but compared to the baseline, the proposals represent a significant increase of more than 50%. Our results show that in this context, the scalability of NZEB buildings is feasible for different construction systems, paving the way for a progressive and incremental.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Energy-related CO2 emissions from buildings have been on the rise in recent years, after a period of stabilization between 2013 and 2016. The direct and indirect emissions from the energy used in buildings increased to 10 GtCO2 in 2019, the highest level ever recorded [1, 2]. The potential for emission reductions remains untapped due to the continued use of fossil fuels, the lack of effective energy efficiency policies and insufficient investment in sustainable buildings. The energy intensity of the buildings sector (final energy consumption per m2) has been decreasing steadily by 0.5–1% per year since 2010. However, this rate is significantly lower than the average annual growth in floor area, which has been around 2,5% since 2010. This is an indication of untapped energy efficiency potential, as the overall evolution of building energy codes is not keeping pace with the rapid expansion of floor area in emerging markets, while renovation rates in developing countries remain low. Similarly, the increase in direct emissions indicates that renewable energy and efficient electricity technologies are not entirely replacing fossil fuels globally. To stay on track to achieve sustainable development, global energy intensity per built-up area needs to be reduced by at least 2,5% per year. This could be achieved by 2030 through tighter building energy codes, deep energy retrofits and research [2, 3].

In the last decade, however, awareness of the value of energy resources has increased in the face of the consequences of climate change. This has encouraged the search for sustainable solutions to reduce emissions and environmental impact in the construction sector, an example of which is the NZEB (Zero Net Energy Building). A net zero energy building, NZEB, by definition, produces, through renewable sources, all the energy required for its operation within the constructive building's footprint [4,5,6]. This term has been coined since 2014 in the LCA (Life-cycle Assessment) methodology, which assesses the environmental impact of a system at all stages of its life (A1-A5, B1-B7, C1-C4, D), in this sense, the NZEB buildings, has meant an increase in materials with high insulation performance and, consequently, an increase in embodied energy A1-A3, as well as an increase in their stage of use, and maintenance B2-B5 [7]. The regulations reflect the minimum energy a building should consume in the operational stage of use, in projected lifetime ranges between 30 and 50 years, but not in embodied energy [8]. Although BIM can offer opportunities to consider sustainability indices within the design process, it often lacks the sufficient interoperability needed for LCA and carbon footprint analysis [9].

In 2007, Sartori and Hestnes defined 202 kWh/m2 as the boundary between conventional and low-energy buildings [5]. In 2015, Passive House replaced the 120 kWh/m2 consumption limit with the use of renewable energy as primary energy to meet demand. The Passive House concept is a building design methodology that advocates for a systematic optimization and integration of the building envelope and internal loads in order to achieve a passive yet comfortable performance [10, 11]. The European Union has set a limit of 45–50 kWh/m2 for the energy consumption of residential buildings for heating and cooling [2, 12] measures in the revised EPBD [13]. Embodied energy in conventional buildings ranges from 6 to 36%, and in low-energy buildings, it ranges from 10 to 83%, although in some cases, embodied energy is reduced by incorporating recycled elements. This fact leads to the addition of materials with higher thermal performance that contribute to energy efficiency, thus achieving a reduction in operating energy but an increase in embodied energy. This difference between embodied and operational energy is not constant and varies according to the type of requirement, for example, passive houses require maximum reduction of energy consumption, increasing embodied energy in materials by 30%. On the other hand, buildings that consider the use of renewable energy sources require the highest energy efficiency to ensure low consumption, as is the case of NZEB buildings, which can calculate an embodied energy of 60% against 40% of the operational energy [4].

The development of research to measure and verify compliance with efficiency standards, as in the case of the Net Zero Energy Building (NZEB) laboratory built on the Central America University campus (UCA), enables regions that consider technology developed under quality standards and a strict regulatory framework to transfer to those that lack such standards. Located at the tropical latitude of 14 degrees north, the building's construction was accompanied by the development of research processes. These have been used as a basis for the development of this study (Fig. 1). Thanks to these efforts, the interdisciplinary integrative design methodology required for this type of project, such as the NZEB El Salvador lab [14], was implemented and its carbon footprint was estimated through life cycle analysis [15,16,17].

For this purpose, research tools are used to estimate the direct impact of building materials on two parameters of interest for the building sector: Embodied energy and CO2 equivalent in the life cycle, thanks to the use of the open access database, the ICE carbon inventory [18, 19], as well as energy efficiency standards contained in the US ASHRAE 90. 1 [20], all in order to evaluate the thermal performance from the baseline of the constructed building, in three scenarios of the most used building systems in El Salvador.

While it is true that the design of NZEB buildings benefits from the adoption of LCA methodologies, there are still positions [21] that claim that overgeneralization and reliance on unreliable tools and databases can limit the establishment of reference frameworks [22].

In this way, the Salvadoran vernacular building systems have been energetically characterized, and the insulation options required to comply with the NZEB standard have been evaluated, as well as the feasibility of this practice in the socio-economic context of the Central American country. Therefore, the objective of this study is to comparatively evaluate the characteristics and capacities of the most popular building systems in El Salvador, with respect to the laboratory baseline, to verify, through the Life Cycle Assessment, the compliance with the NZEB standard, as well as the treatments and environmental impacts required to achieve it.

2 Methodology

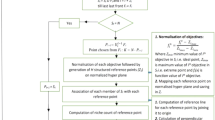

The analysis comprises an iterative process of structural and energy optimization, which begins with a calculation of the seismic-resistant pre-dimensioning based on permissible shear stresses and the El Salvador seismic regulations for traditional houses [23]. The aim of this first step is the calculation of the density of load-bearing walls. Subsequently, an energy calculation model is created to estimate the transmittance of the different types of insulation in the building envelope, thanks to the academic version of the Design Builder energy simulation software, thus allowing the calculation of the annual energy consumption and the verification of the NZEB standard.

As a result of these two calculation models, the Life Cycle Assessment (LCA) methodology is developed, which allows to analyze the environmental impact characterized by two indicators: energy cycle and global warming potential [15]. As a final model, the Weighted Criteria Matrix [24], is implemented, which allows environmental indicators to be contrasted with social and economic indicators in order to make a more holistic assessment. The comparative analysis of three building system options from the established baseline has involved a sequential iterative process. The following phases have been followed (Table 1, Fig. 2):

In the methodological process, the current state of the NZEB El Salvador 1-NZEB-LB building built with a wood-frame structural system was considered as a baseline, under the approach of a research question: In the different scenarios developed with vernacular building systems in El Salvador, is the NZEB standard met? In order to find an answer to this question, based on previous research, three construction systems were selected, named 2-NZEB-BH, 3-NZEB-MLA, 4-NZEB-MLC. They were modeled and tested under the sieve of national and international standards until finally arriving at the comparative analysis with the baseline through the LCA methodology. Table 2 shows the selection of construction systems for the performance of the analyses proposed in the work.

Charrette-type sessions were held, which are intensive interdisciplinary integrative design sessions where the solution to a problem is generated from multiples optical (Table 3), involving UCA professors from the following departments Space Organization (DOE), Energy and Fluid Sciences (DCEF) and Structural Mechanics (DME). The results have also been discussed with the professors of the Department of Architectural Technology of the UPC.

3 Phases and calculation models

3.1 Phase I) calculation and dimensioning of the different scenarios

3.1.1 Step 1: calculation of density of load bearing Walls

As the initial step of the iterative process proposed in the methodology, a minimum density of load-bearing walls has been determined as a previous step to an engineered structural verification. This step was carried out using the requirements and simplified procedure of the Provisions for the Design and Construction of Houses of El Salvador [25]. The procedure involves calculating the minimum load bearing walls density to resist a lateral load (design load) calculated as 1,5*Wts*Cs, where Wts represents the seismic weight supported by the masonry walls under a rigid diaphragm, and Cs is a seismic-static coefficient set at 0,2.

In order to obtain a minimum density of wall that is related to a minimum net shear area a resisting lateral load capacity to resist the design load is calculated. The capacity is determined using an allowable shear stress of 0,23*f’m0.5, which is augmented by a factor of 1,33, and then multiplied by the sum of the net area of each wall that is reduced by a factor of (1,33*Li/Hi)2, where Li and Hi are the length and height of a wall and this factor should not be taken greater than 1. This procedure is applicable to design the first story of a two-story masonry house which has a relatively high degree of symmetry in the distribution of stiffness and masses.

3.1.2 Step 2: energy calculation model for insulation pre-dimensioning

The first part is the calculation of the thermal transmittance of the different components of the building envelope, taking into account the new construction systems proposed, starting from the NZEB base case, with the current constructed system of a 0.12 m thick wood structure with internal insulation of R-25 polyurethane foam (conductivity 0.04 m2K/W, density 40 kg/m3). Comparable to other systems in tropical latitudes [36, 37].

The thermal conductivity values were obtained from the Catalogue of Building Elements of the Spanish Technical Code CTE [38], as well as from the ASHRAE Handbook 2013 Chapter 26 [33] taking into account the series resistances and, therefore, the thicknesses of the materials and their thermal conductivities are used to obtain the transmittance value of the set of elements that make up the envelope. The second part is a comparative study of energy consumption through energy simulations of all the building systems in the Design Builder energy simulation program. By obtaining the transmittance values as input data to the program, the goal is to be below the maximum transmittance standard per element provided by the ASHRAE-90.1 standard [20].

In order to model the energy performance of the proposed building design, a commercial interface of the EnergyPlusTM energy simulation engine was used. Model inputs include building geometry, electric loads, building envelope properties, and schedules. Typical meteorological year weather (TMY2) data from San Salvador/Ilopango was used for modeling local climate. The main energy uses for the building are air conditioning and miscellaneous equipment, which includes computers, servers, and other electric devices used in the building. The annual energy metric of 108.28 kWh/m2/year by using open source software, monthly and annual energy generation can be estimated for the PV system. When comparing monthly consumption with monthly PV generation, it is clear that an energy surplus can be obtained every month, estimated at 42.0% annually. This was as designed, since for flexibility purposes, an oversized system was specified since the laboratory may change its energy use patterns for research purposes to investigate different building energy uses.

3.1.3 Step 3: calculation model for Life Cycle Assessment (LCA)

Life Cycle Assessment (LCA) is the estimated evaluation of the total environmental impacts generated throughout the life cycle of a product or service. This methodology is internationally accepted as an unbiased way to evaluate and compare environmental impacts, although it is important to note that there are variations in the impacts depending on the country in which each analysis is performed, since the impacts are related to the energy matrix of the site [39]. Ingrao [40] confirms that LCA is a suitable method to profile the sustainability of buildings, since it considers all phases, such as the acquisition of raw materials and the construction of structures and facilities, their operation, maintenance and renovation, as well as their demolition and waste management at the end of their useful life. The LCA methodology has as its regulatory framework the International Organization for Standardization (ISO), specifically ISO 14044. Muralikrishna & Manickam mention that the life cycle consists of phases, objective and scope, inventory, impact assessment and interpretation [41]. The life cycle stages analyzed according to ISO 14044 [7] are:

-

A1-A3 materials

-

A4-A5 construction

-

B1 operation

-

B2-B5 maintenance

-

C1-C3 end of life

-

D (B1) benefits beyond limits

-

D (C1-C3) benefits beyond limits

This analysis is carried out using a computational model. It takes into account the open ICE database of the University of Bath, United Kingdom [18]. In this phase, the volume of work (measurements) of the building, composed of nine construction systems for each of the three proposed alternatives, is decomposed. Once the decomposition is completed and the ICE carbon inventory factor is selected, the results of the carbon incorporated in the life cycle stages and the respective comparisons between the alternatives were analyzed. The LCA was considered under the cradle-to-cradle approach, considering the circularity factors developed by the European Sustainability Framework Level(s) [35].

3.2 Phase II) sustainability assessment through weighted criteria matrix

The weighted criteria matrix is a methodology used in the document "Circular Economy Strategy for El Salvador: Sustainable Housing Solutions" [24] and is a tool to evaluate different factors through indicator scores. In assigning the scores, 3 points are given to positive values of the indicators, 2 points to intermediate values, and 1 point to negative values of the indicators, which are grouped into four factors: economic factor, technical factor, environmental factor, and socio-cultural factor.

4 Results

4.1 Results of calculation and dimensioning of the different scenarios

Table 4 shows the pre-dimensioning of the structural walls using the simplified method [25]. The first structural system is reinforced concrete block masonry walls 2-NZEB-BH.

Using a compressive strength of f’m = 8.8 MPa and a total seismic weigh of 663,8 kN a maximum spacing of 0,6 m between filled cells is required when using concrete blocks with a nominal width of 15 cm.

The second system is confined clay brick masonry 3-NZEB-MLA, which meets the code requirements considering the clay brick's characteristics of f’m = 4.8 MPa, an effective width of 14 cm and a total seismic weigh of 628.2 kN.

The third system is confined soil–cement bricks 4-NZEB-MLA, differing by different strength and weight properties due to the density of the bricks, with f’m = 4.1 MPa, an effective width of 14 cm and a total seismic weigh of 651.4 kN.

4.2 Results of energy calculation model for insulation pre-dimensioning

Five envelopes are evaluated by the calculation model: structural walls, lightweight partitions, roof, mezzanine and floor. It should be noted that of all the aforementioned envelopes, only the structural walls are the element that varies in the different construction systems, since they are load-bearing structural walls. An example of an envelope component is the concrete block walls with cells filled with insulation; such insulation has a thickness according to the manufacturer; in this case the fiberglass insulation was evaluated with a thickness of 0.12 m, this being the necessary thickness calculated to comply with the transmittance U value of 0.151 W/m2.K according to the standard for masonry walls (ANSI/ASHRAE/IES Standard 90.1, 2013, 28) [20] and 0.25 m for mineral wool (Figs. 3 and 4, Table 5).

Using this methodology, the same analyses were carried out for the adobe and earth-cement construction systems, separating their components, determining their thicknesses and conductivities, and finally complying with the transmittance value specified in the regulations for each element. Table 6 shows a summary of the calculation tool, which includes the resistances of the systems, their transmittances, insulation thicknesses, conductivities and the data on energy consumption per year, measured in kWh/m2, obtained through the Design Builder simulator and the consequent comparison with the increase in energy consumption with respect to the baseline, in absolute and percentage values, for each system. It can be seen that all the construction systems with fiberglass insulation are the ones that result in lower energy consumption per year, combined with the lower thickness of insulation required, without reaching the same energy efficiency of the baseline demonstrated in previous works [14, 42].

4.3 Results of calculation model for Life Cycle Assessment (LCA)

The calculation model developed in the doctoral thesis, part of the Doctoral Program in Technology of Architecture, Building and Urbanism of the Polytechnic University of Catalonia (UPC), has been taken as a reference. The research is entitled "Comparative analysis of the life cycle of buildings constructed with industrialized prefabrication in Mediterranean and tropical latitudes"[39]. The results of the calculation of the impact embodied in the EC (Embodied Carbon) CO2e materials for the nine construction systems that make up the NZEB El Salvador baseline building are presented simultaneously for the three construction alternatives studied (Fig. 5), considering mineral wool insulation in all alternatives.

It should be noted that in all the alternatives studied, the same data on the dimensions of the materials, the quantity of materials, the density of materials and the selection of the ICE factor presented in the 1-NZEB-LB baseline have been maintained in the following construction systems: Foundations, finishes, hydraulic installations, electrical installations and photovoltaic system, varying only the structure and the envelope. This is due to the fact that the installations and finishes include active design measures that are energy-optimized; therefore, it is verified that the optimization is still valid in the different envelope scenarios.

Figure 6 shows that version 2-NZB-BH, which corresponds to the modulation with concrete blocks, is the building with the highest value of CO2e, because this construction system incorporates more concrete in the cells in both axes at every 0,60 m. However, there is no significant difference between the three alternatives studied.

A comparison of Figs. 6 and 7 shows that the CO2e impact is not directly proportional to the weight of the building. On the contrary, the relationship between low weight and low transportation impact is evident in the case of wood buildings [43].

On the other hand, a comparative analysis between the choice of mineral wool insulation with a thickness of 0.25 m and fiberglass insulation with a thickness of 0.12 m, taking into account their ICE factors (Figs. 8, 9), shows that the building with fiberglass insulation, despite its lower thickness, has a higher percentage of impact than the percentage obtained with mineral wool insulation, which is approximately twice as thick, according to Table 7.

Figure 10 shows the complete life cycle and shows how the A1-A3 stage, which corresponds to the carbon incorporated in the building materials, is the one that contains the most significant amount of CO2e. At the end of the graph in the total LCA, the 1-NZEB-LB bar decreases, reflecting that it is the version of the building that produces less impact in its life cycle; this makes sense as confirmed by other authors [44] wood achieves reductions of up to 40% of CO2e emissions, so it is a fundamental material to decarbonize buildings and reduce the environmental impact of the sector.

4.4 Results of sustainability assessment through weighted criteria matrix

4.4.1 Economic factor

For the economic factor, the direct cost of each stage of the construction process of a basic 100 m2 two-story building was considered, considering labor and materials, with the following indicators: layout and leveling ($/m2), excavation and compaction ($/m3), foundation ($/m3), walls ($/m2), roof covering ($/m2), floor ($/m2), wall finishes ($/m2), doors and windows ($/U), electrical installations ($/SG), plumbing installations ($/SG).

Table 8 shows the sum of the indicators. As shown in Fig. 11, the system with the highest cost is the 1-NZEB-LB. Therefore, it obtained a score of 1 point, w hile the system with the lowest cost is the 2-NZEB-BH, receiving a score of 3 points, which is reflected in a better evaluation of the most economical system in Fig. 11.

4.4.2 Technical factor

Table 9 considers four technical indicators:

-

1.

Feasibility of material procurement, measured in a range of distances (km). This factor evaluates the range of kilometers for the acquisition of materials. The 2-NZEB-BH system was given 3 points since there are national companies that manufacture concrete blocks. In contrast, the 1-NZEB-LB system has been scored with one since these materials are imported.

-

2.

Feasibility of self-construction, measured in terms of the yield of built area per person per day (m2d/h). The 1-NZEB-LB system has been rated with 3 points since it is a prefabricated system to be assembled, and a higher construction performance is obtained since it does not require setting processes. The masonry systems have been rated with 1 point, since in the structural regulations, it is indicated that at day, the height of 1 m should not be exceeded due to the setting processes [24].

-

3.

Maintenance feasibility, the maintenance cost to be given in 50 years is considered. The 2-NZEB-BH system obtains a score of 3 points, while with 1 point the 1-NZEB-LB version obtains the lowest score, since the wood requires more maintenance in humid climates.

-

4.

Structural load-bearing capacity, measured in weight per square meter (kg/m2). This parameter evaluates the dead weight, where the lower the weight, the more favorable it is since it implies lower loads and reinforcements at the time of designing the structure. 1-NZEB-LB obtained the highest score of 3 points, while the three masonry systems obtained the lowest score of 1 point because they have greater weight because they are load-bearing wall systems with reinforced concrete.

4.4.3 Environmental factor

Table 10 corresponds to the environmental factor; the following indicators were considered:

-

1.

The transmittance value of each system W/m2.K in this indicator the highest value is considered as favorable, being the 1-NZEB-LB system the one that obtains 3 points. In contrast, the masonry systems obtain 1 point since they require insulation layers to guarantee compliance with the NZEB standard.

-

2.

Energy consumption per m2 per year of each system kWh/m2 in this indicator, l

-

3.

Ower annual energy consumption is more favorable. The 1-NZEB-LB version scores 3 points while the three versions proposed score 2 points.

-

4.

Embodied carbon obtained in stage A1-A3 (kgCO2e/m2). This indicator evaluates the product stage of the life cycle, where the lower impact is more favorable; the highest result is 1-NZEB-LB with 3 points, contrary to the other versions that obtained 1 point since, as shown in Fig. 6, the masonry systems have a higher embodied carbon in the manufacture of their materials.

4.4.4 Socio-cultural factor

Table 11 considers the socio-cultural factor as indicators:

-

1.

The evacuation time available in case of fire (minutes). Considering as favorable the system with the longest evacuation time since in case of fire it generates greater reliability in the users. The 3-NZEB-MLA and 4-NZEB-MLC systems were rated with 3 points, since the Barcelona Research and Technical Assistance Center indicates that these masonry systems have an evacuation period of 180 min once the fire has started; on the other hand, the 1-NZEB-LB system was rated with 1 point, since Arauco's technical catalog records that the wood system has an evacuation period of 90 min [45].

-

2.

The number of buildings at the national level by construction system according to the Population and Housing Census in El Salvador, a more significant number of buildings is considered favorable since it reflects greater acceptance of the construction system in the nation; therefore, the 2-NZEB-BH version obtains 3 points, while the 1-NZEB-LB version and the 4-NZEB-MLC version obtain 1 point.

5 Sustainability analysis

5.1 Weighted criteria scoring results

Each group of factors is shown in Table 12, where the highest score for the economic factor was obtained by version 2-NZEB-BH; in the technical factor, the highest score was obtained by version 2-NZEB-BH; in the environmental factor, version 1-NZEB-LB is the one with the highest score, while in the socio-cultural factor the same score was obtained in versions 2-NZEB-BH and 4-NZEB-MLC. It is interesting to note that the best-evaluated result was 2-NZEB-BH with a total of 22 points, corresponding to the system with the highest number of buildings constructed according to the Population and Housing Censusn El Salvador. In contrast, the system with the lowest score was 4-NZEB-MLC, with a total of 17 points. Figure 12 shows the score obtained for each indicator.

Figure 13 shows the total sum of weighted criteria, where it can be seen that version 1-NZEB-LB has little difference in score when compared to the system with the highest score due to the superior properties of the wood in the environmental factor.

6 Conclusions

Regarding the energy issue:

-

This work shows that the NZEB concept is adaptable to different construction practices, either by adapting existing systems to provide the required energy performance or by introducing new systems and materials that have a lower life cycle impact. However, continued assessment and analysis are encouraged to find new alternatives and optimize the overall life cycle impacts.

-

Although solar radiation in the tropics favors energy generation, energy efficiency is compromised given the significant solar heat gain and thermal conduction gain in the construction systems studied in this work. Therefore it has been proven that when complying with structural regulations, masonry systems do not allow thermal performances that ensure the NZEB standard, so it is necessary to consider thermal insulation that at the same time tends to increase the embodied carbon of the building.

Regarding life cycle assessment:

-

The results show that with respect to the baseline, the value of the embodied carbon when using mineral wool insulation increases up to 27%. In comparison, the glass fiber insulation contemplates an increase of 75%, even though the glass fiber thickness of 11.7 cm is less than the mineral wool thickness of 25 cm, which shows that the impact of the insulation is significant and depends not only on the weight or thickness but also on the raw material. This reinforces the idea of optimizing the envelope and evaluating materials with a history of recycling.

-

According According to the proportional ratio of embodied carbon between the proposals, there is not much difference between the results of the proposed systems, but compared to the baseline, the proposals represent a significant increase of more than 50%. Therefore, it may be inferred that, in the manufacture of the materials of the masonry systems, there is more energy of transformation of raw materials. This result highlights the importance of evaluating the carbon impact of the construction industry in manufacturing its materials and the possible search for more sustainable alternatives or processes.

-

In the life cycle analysis, the same foundation and the same type of finish on walls and roof as the baseline were assumed for the proposals, but it should be noted that in the case of the vertical structure, they obtained the third highest value. This is due to the fact that the proposed construction systems of load-bearing walls have a greater environmental impact than the wood system of the baseline, since they are not prefabricated systems, generate a greater amount of waste and have a low circularity factor at the end of their life cycle, obtaining almost no benefits beyond the limits of the system (stage D).

Data availability

The data in this research cannot be shared openly to protect the intellectual property of the authors as it contains open data and executive project calculation models. The data are property of Universidad Centroamericana UCA. But any person can consult with the corresponding author lrrodriguez@uca.edu.sv.

References

UNEP-UN Environment programme. Climate Change 2023: Synthesis Report. 2023.

U. N. E. Programme and G. A. for B. and Construction. 2020 Global Status Report for Buildings and Construction: Towards a Zero-emissions, Efficient and Resilient Buildings and Construction Sector - Executive Summary. 2020.

“IEA – International Energy Agency. 2023. https://www.iea.org/. Accessed 17 Sept 2023.

Marszal AJ, et al. Zero energy building–a review of definitions and calculation methodologies. Energy Build. 2011;43(4):971–9.

Satori I, Hestnes A. Energy use in the life cycle of conventional and low-energy buildings: a review article. Energy Build. 2007;39(3):249–57.

Pless S, Torcellini P. Net-zero energy buildings: a classification system based on renewable energy supply options,” United States. 2010.

I. O. for Standardization. ISO 14044:2006 (traducción oficial) Gestión ambiental Análisis del ciclo de vida Requisitos y directrices. 2006.

Fong KF, Lee CK. Towards net zero energy design for low-rise residential buildings in subtropical Hong Kong. Appl Energy. 2012;93:686–94.

Heydari MH, Heravi G. A BIM-based framework for optimization and assessment of buildings’ cost and carbon emissions. J Build Eng. 2023;79:107762.

Martinez L. Passive House Design Guidelines for Residential Buildings in El Salvador. 2010ASME. 2010; 985–991.

Feist W, Schnieders J, Dorer V, Haas A. Re-inventing air heating: convenient and comfortable within the frame of the Passive House concept. Energy Build. 2005;37(11):1186–203.

European Union. “Union Europea,” documents-publications. Energy Performance of Buildings Directive.” 2018. https://energy.ec.europa.eu/topics/energy-efficiency/energyefficient-buildings/energy-performance-buildings-directive_en. Accessed 14 May 2024.

“Energy Performance of Buildings Directive.” https://energy.ec.europa.eu/topics/energy-efficiency/energy-efficient-buildings/energy-performance-buildings-directive_en. Accessed 14 May 2024.

Martínez L, et al. On net zero energy building design methodology: a case study examining learning as measured by interdisciplinary knowledge acquisition. Adv Environ Eng Res. 2023;04(01):1–36.

Rodríguez L, et al. LCA of the NZEB El Salvador building, a model to estimate the carbon footprint in a tropical country. J Clean Prod. 2023;408:137137.

Chau CK, Leung TM, Ng WY. A review on life cycle assessment, life cycle energy assessment and life cycle carbon emissions assessment on buildings. Appl Energy. 2015;143(1):395–413.

Chang CC, Shi W, Mehta P, Dauwels J. Life cycle energy assessment of university buildings in tropical climate. J Clean Prod. 2019;239:117930.

Hammond G, Jones C. Embodied energy and carbon in construction materials. Proc Inst Civ Eng - Energy. 2008;161(2):87–98.

Circular Ecology. Embodied Carbon - The ICE Database. 2019.

ASHRAE. Standard 90.1–2013, Energy standard for buildings except low rise residential buildings. 2013.

Sesana MM, Salvalai G. Overview on life cycle methodologies and economic feasibility for nZEBs. Build Environ. 2013;67:211–6.

Röck M et al. Towards embodied carbon benchmarks for buildings in Europe - #2 Setting the baseline: A bottom-up approach. 2022.

Ministerio de Obras Públicas, Norma técnica para diseño por sismo. El Salvador. 1997.

Rodríguez L, Cisneros A. Estrategia de economía circular para El Salvador: Soluciones habitacionales sostenibles,” CEPAL ONU, Dec. 2022.

Ministerio de Obras Públicas, Norma especial para diseño y construcción de viviendas. El Salvador. 1997.

Taishin P. Mampostería de suelo cemento confinada: informe de resultados. San Salvador. 2007.

Ministerio de Obras Públicas, Reglamento para la seguridad estructural de las construcciones. El Salvador. 1996.

Ministerio de Obras Públicas, Norma para el Diseño y Construcción Estructural de Mampostería. El Salvador. 1994.

Ministerio de Obras Públicas, Vivienda Social de un nivel (mampostería de bloque de concreto y mampostería confinada). El Salvador. 2014.

ASTM International. Standard specification for loadbearing concrete masonry units. ASTM C90-22. 2022.

ASTM International. Standard Test Methods for Sampling and Testing Brick and Structural Clay Tile. ASTM C67/C67M-21. 2021.

ASTM International. Standard Specification for Deformed and Plain Carbon-Steel Bars for Concrete Reinforcement. ASTM A615/A615M-22. 2022.

R. of Heating and I. (ASHRAE) Air-Conditioning Engineers, “26.1.1.1 Influencing Conditions,” 2021 ASHRAE® Handbook - Fudamentals (I-P Edition). American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc. (ASHRAE), 2021.

G. de E. Ministerio de Fomento. CTE Código Técnico de la Edificación, Catálogo de elementos constructivos del CTE. 2010.

Dodd N, Cordella M, Traverso M, Donatello S. Level(s), el marco común de la UE de indicadores básicos de sostenibilidad para edificios residenciales y de oficinas. Partes 1 y 2. Luxemburgo. 2021.

Cruz AS, Bastos LEG. Predicting climate change and occupants’ behaviour impact on thermal-energy performance of global south housing: case study in Brazil. Indoor Built Environ. 2023. https://doi.org/10.1177/1420326X231222157.

Cruz AS, da Cunha EG. The impact of climate change on the thermal-energy performance of the SCIP and ICF wall systems for social housing in Brazil. Indoor Built Environ. 2021;31(3):838–52.

A. Instituto Eduardo Torroja de ciencias de la construcción, CEPCO, Catálogo informático de elementos constructivos. España. 2010.

Rodríguez L, Muros A, Paris O. How to achieve balance in the life cycle equation of a building? Singapore: Springer Nature Singapore; 2023. p. 215–23.

Ingrao C, Messineo A, Beltramo R, Yigitcanlar T, Ioppolo G. How can life cycle thinking support sustainability of buildings? Investigating life cycle assessment applications for energy efficiency and environmental performance. J Clean Prod. 2018;201:556–69.

Muralikrishna IV, Manickam V. Chapter Five - life cycle assessment. In: Muralikrishna IV, Manickam V, editors. Environmental management. Oxford: Butterworth-Heinemann; 2017. p. 57–75.

Martínez L et al. Energy simulation of proposed net zero energy laboratory building in Central America. Proc. 2018 IEEE 38th Cent. Am. Panama Conv. CONCAPAN 2018, Dec. 2018.

Rodríguez L, González J, París-Viviana O, Muros A. Embodied energy and embodied carbon in different industrialized structural systems scenarios of a prototype building. ACE Archit City Environ. 2021. https://doi.org/10.5821/ace.16.47.10454.

Gustavsson L, Pingoud K, Sathre R. Carbon dioxide balance of wood substitution: comparing concrete- and wood-framed buildings. Mitig Adapt Strateg Glob Chang. 2006;11(3):667–91.

Giraldo P, Avellaneda A, Haurie L, Vilches M, Lacasta A. Experimental study of the effects of accelerated aging cycles on the fire reaction performance of five wood species. In World Conference on Timber Engineering, Oslo. 2023.

Acknowledgements

The authors thank the Central America University, the NZEB El Salvador project, and the professors who participated in the charrette sessions, especially Ricardo Ramos, Alexander Renderos, Carlos Grande, and Pilar Letona. The authors would like to thank the NZEB El Salvador project researchers, Carlos Flores, Arturo Cisneros, Mario Chávez.

Author information

Authors and Affiliations

Contributions

Lizeth Rodríguez: conceptualization, research, data curation, methodology, supervision, validation, writing, correction and editing. Luis Martínez: conceptualization, research, methodology, supervision, validation, project management, correction and editing, José Ramos: conceptualization, data curation, validation. René Ariza: conceptualization, data curation, validation, software. Oriol París, Adrián Muros: conceptualization, methodology, validation. Gabriel Morales, Andrea Palacios, Sofia Menjivar: formal analysis, research, visualization, software, writing original draft.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Rodríguez, L., Martínez, L., Ramos, J. et al. Life cycle assessment in net zero energy building scenarios in a tropical country. Discov Civ Eng 1, 18 (2024). https://doi.org/10.1007/s44290-024-00019-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s44290-024-00019-5