Abstract

Purpose

Feed production is responsible for the majority of the environmental impact of livestock production, especially for monogastric animals, such as pigs. Some feeding strategies demonstrated that replacing one ingredient with a high impact, e.g. soybean meal (SBM), with an alternative protein source, e.g. locally produced peas or rapeseed meal, has potential to reduce the environmental impact. These studies, however, used an attributional life cycle assessment (ALCA), which solely addresses the direct environmental impact of a product. A replacement of SBM with alternative protein sources, however, can also have indirect environmental consequences, which might change environmental benefits of using alternative protein sources. This study aims to explore differences in results when performing an ALCA and a CLCA to reduce the environmental impact of pig production. We illustrated this for two case studies: replacing SBM with rapeseed meal (RSM), and replacing SBM with waste-fed larvae meal in diets of finishing-pigs.

Methods

We used an ALCA and CLCA to assess global warming potential (GWP), energy use (EU) and land use (LU) of replacing SBM with RSM and waste-fed larvae meal, for finishing-pigs. The functional unit was 1 kg of body weight gain.

Results and discussion

Based on an ALCA, replacing SBM with RSM showed that GWP (3%) and EU (1%) were not changed, but LU was decreased (14%). ALCA results for replacing SBM with waste-fed larvae meal showed that EU did not change (1%), but GWP (10%) and LU (56%) were decreased. Based on a CLCA, replacing SBM with RSM showed an increased GWP (15%), EU (12%) and LU (10%). Replacing SBM with waste-fed larvae meal showed an increased GWP (60%) and EU (89%), but LU (70%) was decreased. Furthermore, the results of the sensitivity analysis showed that assumptions required to perform a CLCA, such as definition of the marginal product, have a large impact on final results but did not affect the final conclusions.

Conclusions

The CLCA results seem to contradict the ALCA results. CLCA results for both case studies showed that using co-products and waste-fed larvae meal currently not reduces the net environmental impact of pork production. This would have been overlooked when results were only based on ALCA. To gain insight into the environmental impact of feed, animal nutritionists can use an ALCA. If policy makers or the feed industry, however, want to assess the net environmental impact of a potential feeding strategy, it is recommended to perform a CLCA. Feed and food markets are, however, highly dynamic. Pig feed optimization is based on least cost optimization and a wide range of ingredients are available; diet compositions can, therefore, change easily, resulting in different environmental impacts. Ideally, therefore, a CLCA should include a sensitivity analysis (e.g. different feed prices or different marginal products) to provide a range of possible outcomes to make the results more robust.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

The global demand for animal source food is expected to increase (Alexandratos and Bruinsma 2012). Simultaneously, livestock production causes severe environmental pressure via emissions to air, water and soil (Steinfeld et al. 2006). The global livestock sector is responsible for about 15% of the total anthropogenic emissions of greenhouse gases (Gerber et al. 2013). The sector also increasingly competes for scarce resources, such as land, water and fossil-energy.

Feed production is responsible for the largest part of the environmental impact of livestock production, especially for monogastric production systems (De Vries and De Boer 2010; Gerber et al. 2013). Several studies, therefore, assessed the potential benefits of using different feeding strategies to reduce the environmental impact. An often applied strategy is to replace feed ingredients with a high environmental impact for ingredients with a lower environmental impact. Studies exploring the environmental impact of different feed ingredients demonstrated, for example, that diets containing soybean meal (SBM) often result in a large environmental impact (Cederberg and Flysjo 2004; Eriksson et al. 2005; Van der Werf et al. 2005; Weightman et al. 2011). Currently, SBM is the main protein source in pig diets (Vellinga et al. 2009). Cultivation of SBM has a high environmental impact due to large transport distances, due to a high economic allocation as SBM nowadays drives the production process (Cederberg and Flysjo 2004; Van der Werf et al. 2005; Vellinga et al. 2009) and due to emissions related to land use change (LUC), such as deforestation in South America (Foley et al. 2007; Prudêncio da Silva et al. 2010).

Replacing SBM with alternative protein sources such as locally produced protein sources or co-products from the bio-diesel or food industry, therefore, might be a potential mitigation strategy. Replacing SBM with locally produced protein sources resulted in a reduction of global warming potential (GWP) up to 13% and of land use (LU) up to 11% (Eriksson et al. 2005; Meul et al. 2012; Sasu-Boakye et al. 2014). Replacing SBM with rapeseed meal (RSM) resulted in a reduction of LU up to 12%, but did not change GWP and energy use (EU) (Van Zanten et al. 2015a). Although the results of those studies seem to be promising, one should consider the fact that feed ingredients such as locally produced protein sources and co-products are limited available. Those studies, however, were based on an attributional life cycle assessment (ALCA), implying they addressed the direct environmental impact of a product in a status quo situation. The direct environmental impacts result from the use of resources and emissions of pollutants directly related to the production of 1 kg of pig meat, such as feed use, diesel for transport and electricity for heating, at a specific moment in time. Although commonly used in pig production (McAuliffe et al. 2016), an ALCA does not include consequences of a change in diet composition, outside the production chain of pork. It, therefore, does not consider that co-products or the land needed to produce locally produced protein sources might already have applications. An increase in demand of co-products or locally produced protein sources might, therefore, result in shifting of the application of the co-product or shifting local land sources from one sector to another sector. To assess such indirect consequences, a consequential LCA (CLCA) can be used. A CLCA describes how environmental flows/processes change within and outside the production cycle of a product, in response to a change in the system (Ekvall and Weidema 2004). Applying a CLCA might, therefore, result in different outcomes compared to the results of an ALCA. Van Zanten et al. (2015b), for example, explored the environmental consequences of using waste-fed larvae meal as feed ingredient. These larvae were partly fed on food-waste, which was originally used for production of bio-energy. Accounting for these indirect consequences implied including the environmental impact of production of energy needed to replace the original bio-energy function of food-waste in the analysis. The results of Van Zanten et al. (2015b) showed that the impact increased significantly when consequences where considered, showing the importance of considering those consequences. This study of Van Zanten et al. (2015b), however, was applied at the level of an individual feed ingredient, and not at the level of the entire pig diet. Van Zanten et al. (2015b) assumed that larvae meal could be replaced with SBM or fishmeal. In reality, if one feed ingredient is replaced with another feed ingredient, the whole diet composition will change to meet the nutritional requirements of the animal. If, for example, SBM is replaced with RSM based on crude protein content, the net energy content per kilogramme of feed will decrease. Meaning that if one aims to maintain the same growth performance of the animal, an increase in an energy-rich ingredient such as animals fat (having a high GWP and EU) is required.

To our knowledge, there are only a few studies that assessed the difference in results between an ALCA and a CLCA, when assessing the environmental impact of changing livestock diets (Mogensen et al. 2010; Nguyen et al. 2013); none of them relates to pig production. This study, therefore, aims to explore the differences in results when performing an ALCA and a CLCA to reduce the environmental impact of pig production in the Netherlands. We assessed two feeding strategies replacing SBM with RSM, and replacing SBM with waste-fed larvae meal in diets of finishing-pigs. In this study, GWP, EU and LU were assessed per kilogramme of body weight gain.

2 Material and method

An ALCA and a CLCA will be used to assess the environmental impact of replacing SBM with RSM or with waste-fed larvae meal. RSM was chosen as an alternative protein source because co-products from bio-diesel production, such as rapeseed meal (RSM) became increasingly available during the last decade in Europe (Makkar et al. 2012). Consequently, the RSM content in pig diets more than doubled (Vellinga et al. 2009). Increasing the use of RSM might be interesting from an environmental perspective as feeding co-products has potential to lower the environmental impact (Elferink et al. 2008). RSM is a protein-rich feed ingredient and, therefore, can replace soybean meal (Thamsiriroj and Murphy 2010; Reinhard and Zah 2011). The aim of this case was, therefore, to assess the environmental consequences of replacing SBM with RSM in finishing-pig diets. Waste-fed larvae meal was chosen as an alternative protein source as recent developments indicate environmental benefits of rearing insects for livestock feed (Van Huis et al. 2013; Sánchez-Muros et al. 2014). The nutritional value of insects is high, especially as a protein source for livestock (Veldkamp et al. 2012). Insect-based feed products, therefore, can replace conventional feed ingredients, like fishmeal or soybean meal. Replacing SBM with waste-fed larvae meal at the level of the entire pig diet is not analysed so far, but preliminary results of Van Zanten et al. (2015b) on the individual feed ingredient level showed that waste-fed larvae meal has potential to reduce the environmental impact of feed production. The aim of this case was, therefore, to assess the environmental consequences of replacing SBM with waste-fed larvae meal in diets of growing pigs. To assess those two feeding strategies, we first describe the diet formulation and growth performance of finishing-pigs (2.1), and subsequently explain the environmental impact assessment methods used (2.2).

2.1 Diet composition and growth performance

All diets were designed to meet the requirements of a Dutch average standard diet for finishing-pigs, and contained 9.50 MJ net energy (NE) and 7.59 g standard ileal digestible (SID) lysine per kilogramme of feed, while pigs were fed ad libitum. Diets had to meet requirements for SID methionine and cystine 62%, SID threonine 65% and SID tryptophan 20%, relative to SID lysine. Furthermore, because of nutritional reasons and taste, the following dietary restrictions were applied in all scenarios: a diet contained a maximum of 30% maize, 40% wheat, 40% barley, 10% peas, 2% molasses, contained 500 FTU phytase per kilogramme and 0.4% premix to provide minerals and vitamins.

Given the above mentioned restrictions, the basic scenario (S1) was defined, using SBM as major protein source (see Table 1), based on Van Zanten et al. (2015a). In the second scenario (S2), SBM was replaced with RSM based on their crude protein (CP) content, as described in detail by Van Zanten et al. (2015a). In summary, the amount of CP in 15% SBM and 8% barley was replaced with the CP in 23% RSM. In the last diet (S3), 15% SBM was replaced with 15% waste-fed larvae meal also based on their CP content. The final diet was formulated by using a commercial linear programming tool (i.e. Bestmix®, Adifo, Maldegem, Belgium), with the nutritional value of feed ingredients from CVB database (CVB (Dutch feed tables) 2011). Linear programming was used to optimize the diet by minimizing the cost price of the diet. The same pricelist was used as in S1 and S2 (the price of ingredients was based on the average of a quarterly published pricelist of Nuscience 2012). The CVB database, however, does not contain information about the nutrient content and digestibility of waste-fed larvae meal. The digestibility coefficient is needed to assess the actual nutritional intake. Because the actual nutritional intake is based on the nutrient content multiplied with the digestibility coefficient. The nutrient content of waste-fed larvae meal (Table 2) was adapted from Van Zanten et al. (2015b), but values were consistent with a literature review of Makkar et al. (2014). Information about the digestibility coefficient of waste-fed larvae meal for pigs is unknown. Information about the digestibility coefficient of waste-fed larvae meal for poultry is, however, available. As the digestibility coefficient for poultry and pigs is quite similar for other protein-rich ingredients, such as SBM and fishmeal, calculation on the digestibility coefficient of waste-fed larvae meal were based on the digestibility coefficient for poultry (Appendix Table A.1 and Table A.2, Electronic Supplementary Material). By using the following equation (CVB 2011), the net energy (NE) value of waste-fed larvae meal was calculated resulting in 13.01 MJ per kg waste-fed larvae meal:

As the nutrient content of the diet in each scenario was identical (9.50 MJ NE/kg feed and 7.59 g lysine/kg feed), and no adverse effect of pig performance were found by including RSM (McDonnell et al. 2010) or waste-fed larvae meal (Makkar et al. 2014) in finishing-pig diets, a similar growth performance was assumed between the three scenarios. Growth performance was based on Van Zanten et al. (2015a), who calculated the growth performance of finishing-pigs for S1 and S2. Scenarios started with 100 days, weight at start 45 kg, final age 180 days and total feed use 183 kg. The final body weight of the growing pigs was 116.4 kg (Van Zanten et al. 2015a).

2.2 Life cycle assessment

To assess the environmental impact of each scenario, a life cycle assessment (LCA) was used. LCA is an internationally accepted and standardized method (ISO 14044 and 14040 2006) to evaluate the environmental impact of a product during its entire life cycle (Guinée et al. 2002; Bauman and Tillman, 2004). During the life cycle of a product, two types of environmental impacts are considered: emissions of pollutants and use of resources, such as land or fossil-fuels (Guinée et al. 2002). We assessed GHG emissions EU, and LU. These impacts were chosen because the livestock sector contributes significantly to both LU and climate change worldwide (Steinfeld et al. 2006a). Furthermore, EU was used as it influences GWP considerably and plays an important role in the rearing of insects (Van Zanten et al. 2015b). LU was recalculated to square meters and expressed in square meter per year per kilogramme of body weight gain, whereas EU to megajoules of primary energy and expressed in MJ. The major GHGs related to livestock production (Steinfeld et al. 2006) were included in this study: carbon dioxide (CO2), methane (CH4) and nitrous oxide (N2O). These GHGs were summed up based on their equivalence factors in terms of CO2 (100 years’ time horizon) per kilogramme of body weight gain, i.e. carbon dioxide (CO2), biogenic methane (CH4, bio) 28 kg CO2-eq/kg, fossil methane (CH4, fossil) 30 kg CO2-eq/kg and nitrous oxide (N2O) 265 kg CO2-eq/kg (Myhre et al. 2013). In this study, only the environmental impact related to feed production is assessed because no changes are expected on related emissions of piglet production (rearing), enteric fermentation from pigs and from pig housing. Changes from manure management can be expected but no data is available on related emissions of manure management when insects are used as feed.

As stated in the introduction two types of LCA exist: ALCA and CLCA. Both methods are explained below.

2.2.1 Attributional LCA

An ALCA describes the environmentally relevant physical flows to and from all processes, in the life cycle of a product, at one specific moment in time. During the life cycle of a product, like pork, multifunctional processes occur. A multifunctional process is an activity that fulfils more than one function (Ekvall and Weidema 2004), yielding two or more products: the determining product, which determines the production volume of that process (e.g. rapeseed oil), and a co-product (e.g. rapeseed meal; Weidema et al. 2009). In case of a multifunctional process, most ALCA studies of livestock products partition the environmental impact of the process to the various products based on their relative economic values, a method called economic allocation (De Vries and De Boer, 2010). In our ALCA, we used economic allocation to divide the environmental impact between the determining product and the co-product.

2.2.2 Environmental impact of feed ingredients

To assess the environmental impact of the three scenarios, the environmental impact of each ingredient must be known. GWP, EU and LU of most feed ingredient were based on Vellinga et al. (2013). Production of feed ingredients included impacts from cultivation (e.g. impacts related to the production and use of fertilizers, pesticides, machinery and energy), impacts from drying/processing and impacts from transport to the farm. GWP, EU and LU related to waste-fed larvae meal were based on Van Zanten et al. (2015b). Production of 1 ton dry matter of waste-fed larvae meal based on ALCA resulted in a GWP of 770 kg CO2-eq, an energy use of 9329 MJ and a land use of 32 m2. Production of larvae meal, however, also has environmental consequences. The food-waste to feed the larvae, for example, was originally used for production of bio-energy. Accounting for these consequences implies, e.g. including the environmental impact of production of energy needed to replace the original bio-energy function of food-waste. Based on the CLCA, the production of 1 ton larvae meal reduced LU (1713 m2), but increased EU (21,342 MJ) and consequently GWP (1959 kg CO2-eq). LU and EU values of feed additives (salt, chalk, vitamins and minerals, phytase, monocalcium phosphate and amino acids) were based on Garcia-Launay et al. (2014) (GWP was based on Vellinga et al. (2013)). Appendix Table A.3 (Electronic Supplementary Material) provides an overview of GWP, LU and EU per kilogramme of feed ingredient. To assess the average impact of 1 kg feed, the environmental impact per kilogramme feed ingredient was multiplied with its relative use in the diet. Next, for each scenario, the average environmental impact per kilogramme feed was multiplied with the total feed intake during the finishing period and divided by the growth performance during the finishing period (116.4 kg − 45 kg = 71.4 kg). The functional unit was 1 kg weight gain.

2.2.3 Consequential LCA

A CLCA describes how environmental flows change in response to a change in the system (Ekvall and Weidema 2004). Only those processes (within and outside the system) that respond to the change are considered. Considering changes is especially important when a mitigation strategy includes the use of co-products or food-waste. This is because the production volume is restricted for co-products and food-waste. For co-products, for example, a change in demand of the determining product (e.g. sugar) directly affects the production volume of the co-product (e.g. beet pulp) (Weidema et al. 2009), whereas a change in demand of co-product does not. Due to this, co-products are limited available. Increasing the use of co-products in animal feed, therefore, results in a reduction of co-product use in another sector necessitating substitution (see Appendix 1 for more information). We define the sector which was using the co-product before, as the previous user.

2.2.4 Changes in the use of feed ingredients

First, we had to define the changes in diet composition when we replace SBM with RSM or waste-fed insects. By subtracting all feed ingredients used in S1, from those in S2 and in S3, differences in use of feed ingredients becomes clear (see Table 3). Table 3 shows which feed ingredients changed compared with the basic scenario containing SBM, for example, replacing SMB with RSM, i.e. resulted in an increase in RSM of 23%, a decrease of 15% SBM, etcetera. As a consequential LCA only considers the changes, only the consequences related to those feeding ingredients of which the use changed were considered. In case a feed ingredient is used in the same amount, such as maize, it is, therefore, not considered as it does not result in an environmental change.

2.2.5 Environmental impact of feed ingredients

After we identified the changes in diet composition, the second step was to identify the environmental consequences for each feed ingredient (Table 3). The environmental consequences for each feed ingredient are largely determined whether or not a feed ingredient is a determining product without a co-product, or a determining product with a co-product, or a co-product (Table 4).

The following feed ingredients are determining products without a co-product: peas, maize, wheat, barley, limestone, salt, monocalcium-posphate, bicarbonate, lysine, threonine and methionine. For those ingredients, the environmental impact of cultivation can be fully ascribed to this single product. The environmental impact of the cultivation of peas, for instance, is fully allocated to one product, namely peas. The environmental impact of determining products without a co-product, therefore, could be based on ALCA data of Vellinga et al. (2013). This is reasonable because when a product is not part of a multifunctional process, the environmental impact related to cultivation does not have to be allocated between products. Similar to an ALCA, therefore, the environmental impact related to cultivation is fully ascribed to this single product. We, therefore, assumed no differences in environmental impact between the ALCA and the CLCA for a determining product without a co-product.

Of all the feed ingredients in the pig diets, SBM is the only determining products with a co-product. Furthermore, RSM, waste-fed larvae meal, wheat middlings and animal fat were the co-products used in the pig diets. An increase or decrease of the determining product (SBM) will also result in an increase or decrease of the co-product (soy oil). Co-products can already have applications, resulting in shifting the application of the co-product from one sector to another sector. To assess the environmental consequences of using co-products in livestock feed, we used a framework developed by Van Zanten et al. (2014). Based on this framework, the net environmental impact can be calculated. The net environmental impact depends on the environmental benefits minus the environmental costs. The environmental benefits are determined by the decrease in environmental impact related to the product that was replaced with co-products or food-waste. The environmental costs are determined by the increased environmental impact related to the marginal product which is replacing the co-product used by the previous user (the product that replaces the ‘old’ application of the co-product or food-waste). Whether or not this results in an improved net environmental impact depends on the environmental benefits of using the product in its new application minus the environmental cost of replacing the product in its old application.

2.2.6 Zoom in: the assessment of RSM

Figure 1 gives an example, based on RSM, on how the environmental consequences of the co-products are assessed. RSM is a co-product from the bio-diesel industry, and does not drive the production process. An increased use of RSM in diets of finishing-pigs, therefore, results in a reduction of the original applications of RSM. We assumed that RSM was originally used in diets of dairy cows (the previous user). Increasing the use of RSM in pig diets, therefore, resulted in a decreased use of RSM in diets of dairy cow. RSM in diets of dairy cows, therefore, was replaced (or also often called displaced) with the marginal product, which we assumed to be SBM (Weidema 2003). Replacing RSM with SBM in diets of dairy cows was based on net energy for lactation, as this was the limiting nutritional factor of SBM. An increased production of SBM also results in an increased production of soy oil, the depended co-product. The increased production of soy-oil was assumed to replace the marginal oil, being palm oil (Dalgaard et al. 2008; Schmidt 2015). A reduction in production of palm oil, however, also implies a reduction in production of palm kernel meal. A reduction of palm kernel meal resulted in an increased use of the marginal meal SBM. Replacing palm kernel meal with SBM was based on their energy and protein content, as suggested by Dalgaard et al. (2008). The reduction of 19 g of palm kernel meal, therefore, was replaced with 3 g SBM and 15 g barley. Barley is assumed to be the marginal feed grain (Weidema, 2003). Thus, the amount of CP and energy in palm kernel meal is equal to the total amount of CP and energy in SBM and barley. In the Appendix, the calculations related to animal fat, wheat middlings and SBM are also explained.

Principle to assess the environmental consequences of rapeseed meal (RSM) based on Van Zanten et al. (2014)

2.3 Sensitivity analysis

For assessing the indirect environmental impact of RSM, animal fat, wheat middlings and SBM, we made assumptions based on current situations of feed and food. World food and feed markets, however, are highly complex and dynamic. To what extend did these assumptions affect our final results? Our main assumptions were related to (1) previous user, (2) the limiting nutritional factor and (3) the marginal product. To determine how sensitive our results are to changes in these assumptions, we varied our assumptions. Related to livestock species, for example, we first assumed that RSM was used as feed for cattle and changed this to broilers. The assumption related to the limiting nutritional factor changed from net energy for lactation to true protein digested in the small intestine. Last, the assumption related the marginal oil changed from palm oil to sunflower oil. For a more detailed description about the sensitivity analysis, please see Appendix 3 (Electronic Supplementary Material).

3 Results and discussion

Using an ALCA approach, S1 resulted in 1.62 kg CO2-eq, 14.01 MJ and 4.81 m2.year per kg weight gain; S2 in 1.67 kg CO2-eq, 14.11 MJ and 4.12 m2.year per kg weight gain and S3 in 1.45 kg CO2-eq, 14.17 MJ and 2.14 m2.year per kg weight gain.

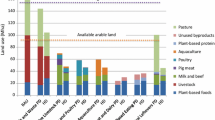

Replacing SBM (S1) with RSM (S2) based on an ALCA, therefore, hardly changed GWP and EU but it decreased LU per kilogramme weight gain, implying that this strategy has no potential to reduce GWP and EU but has potential to reduce LU of pork production. Using a CLCA approach, this strategy resulted in an increase of 0.25 kg CO2-eq, 1.61 MJ and 0.48 m2.year per kg weight gain, yielding even less unambiguous results. Relative differences between the ALCA and CLCA approach are presented in Fig. 2.

Replacing SBM (S1) with waste-fed larvae meal (S3) based on an ALCA approach resulted in a decreased GWP and LU and hardly changed EU, implying this strategy has potential to reduce GWP and LU but has no potential to reduce EU of pork production. Using a CLCA approach, this strategy resulted in an increase of 0.97 kg CO2-eq, 12.51 MJ and a reduction of 3.38 m2.year per kg weight gain, yielding less unambiguous results. Relative differences between the ALCA and CLCA approach are presented in Fig. 3.

3.1 Sensitivity analysis

Livestock species

We assumed, based on Dutch practice, that RSM and wheat middlings were used in diets of dairy cows, whereas animal fat was used in diets of broilers. Based on the nutritional value of SBM compared to RSM, however, dairy cows need more SBM compared to broilers to replace 1 kg of RSM. Dairy cows also need more barley to replace 1 kg of wheat middlings compared to broilers, while they need less palm oil to replace 1 kg animal fat. In case livestock species are, therefore, shifted (RSM and wheat middlings were used in broiler diets and animal fat in diets of dairy cows), results will change. If livestock species are shifted in S1-S2, GWP decreased from 15 to 14%, EU from 12 to 11% and LU from 10 to 5%. If livestock species are shifted in S1-S3, GWP decreased from 60 to 54%, EU from 89 to 87% and LU from −70 to −76%. So, GWP, EU and LU decreased in both scenarios (Fig. 4).

Limiting nutritional factor

Replacing RSM with SBM and wheat middlings with barley was based on their energy value, as energy was the limiting factor. It should, however, be noted that besides energy, those ingredients also provide protein. In case the replacement is based on protein, GWP, EU and LU will change (Fig. 4). If calculations were based on protein content instead of energy in S1-S2, GWP decreased from 15 to 13%, EU decreased from 12 to 9% and LU from 10 to −9%. If calculations were based on protein instead of energy in S1-S3, GWP decreased from 60 to 54%, EU from 89 to 86% and LU from −70 to −74%. Replacement based on the limiting factor (energy), therefore, will result in an overestimation, while replacement based on protein will result in an underestimation. Replacement based on either energy or protein is, therefore, restrictive.

Marginal product

RSM, wheat middlings, animal fat and bio-diesel were replaced by a marginal product. The marginal product is the product that responds to a change in demand. RSM was assumed to be replaced with SBM, wheat middlings with barley, animal fat with palm oil and bio-diesel with fossil-fuel. The marginal product is, however, subject to numerous socio- and economic aspects. The marginal product, for example, can change over time and can differ across space. Changing the assumption related to the marginal product affects the results. If the marginal oil is sunflower oil instead of palm oil, for example, GWP decrease from 15 to 12%, EU would increase from 12 to 14% and LU from 10 to 23% for S1-S2. In S1-S3, GWP would decrease from 60 to 50%, EU increased from 89 to 96% and LU increased from −70 to −33%. The results of a CLCA, therefore, largely depend on the assumptions made related to the marginal product (Schmidt and Weidema, 2008; Reinhard and Zah, 2011; Dalgaard et al. 2014; Schmidt et al. 2015). As a change in a system can result in different possible chain-of-event pathways, CLCA results are, therefore, rather uncertain (Thomassen et al. 2008; Nguyen et al. 2013; Plevin et al. 2014).

4 Discussion

Based on an ALCA, replacing SBM with RSM reduced LU, but hardly changed GWP and EU. Based on a CLCA, however, replacing SBM with RSM resulted in an increased GWP, EU and LU. Differences in results between ALCA and CLCA were caused because the net environmental impact was increased. In S1, 15% SBM and 8% barley was replaced with 23% RSM and 2% animal fat. As RSM and animal fat are both co-products, using them resulted in indirect environmental consequences. The increased impact (environmental costs) related to the consequences of using co-products (using RSM resulted in an increased use of SBM in diets of dairy cows, whereas using animal fat resulted in an increased use of palm oil in broiler diets) was higher compared to the reduction in impact (environmental benefits) due to decreasing SBM and barley in pig diets.

Based on an ALCA, replacing SBM with waste-fed larvae meal reduced GWP and LU, but hardly affected EU. Based on a CLCA replacing SBM with waste-fed larvae meal resulted in an increased GWP and EU but LU were still decreased. The difference in results between ALCA and CLCA were mainly caused by the high environmental impact of the waste-fed larvae meal. The environmental impact of waste-fed larvae meal was based on Van Zanten et al. (2015b). Larvae were fed partly on food-waste. Food-waste was originally used for anaerobic digestion in the Netherlands. Using food-waste for waste-fed larvae meal production decreased its availability for anaerobic digestion, as the amount of food-waste was limited by the amount of food spilled by humans. The decreased production of electricity, heat and digestate, therefore, was substituted by fossil-fuels and synthetic fertilizer, resulting in an increased environmental impact. Although waste-fed larvae meal can be a feed ingredient with a high nutritional value, changing the application of food-waste, from bio-fuel production to waste-fed larvae meal production, does not reduce the overall environmental impact.

Results of both case studies, therefore, showed that using co-products and food-waste not necessarily results in a reduction of the environmental impact. Based on the CLCA results, a comparative assessment can be made between possible application of a co-product or food-waste. This comparative assessment can provide building blocks to make a hierarchy. Such a hierarchy provides information about which type of application of a co-product or food-waste should be used to optimally reduce the environmental impact. Based on the results of this study, for example, one can conclude that from an environmental perspective it is better to feed RSM and wheat middlings to cows, feed animal fat to chickens and use food-waste for the production of bio-energy. The building blocks of a hierarchy, however, depend on the current situation which determines the related consequences, e.g. currently fossil-energy is the marginal energy source but this can shift to solar- or wind-energy overtime. Each co-product or type of food-waste, therefore, needs its own hierarchy, and the hierarchy is time specific.

To gain insight into the full environmental impact of replacing SBM with RSM or with waste-fed larvae meal, and to prevent burden shifting, other environmental impact categories such as eutrophication and acidification should be assessed as well. One other important point which should be considered before a feeding strategy is implemented are consequences from land use change (LUC). As the results of this study indicated, feeding strategies (mainly) affect land use. An increase in crop demand, e.g. barley, however, leads to increased production and, if production cannot be increased it leads to the displacement of another crop product which may be compensated by production somewhere else (Kloverpris 2008). Increased production of a specific crop, therefore, can be achieved by displacement of another product. Displacement will, however, lead to replacement and, ultimately, the marginal response will be a combination between expansion (e.g. deforestation) and intensification (e.g. increasing yields). Assessing LUC is due to feed-food-fuel competition for arable land, an important topic which is often addressed in studies assessing the environmental consequences related to bio-diesel production.

4.1 Feed optimisation, which method should we use, ALCA versus CLCA

Assessing the status quo of a pig system by performing an ALCA can create understanding about the environmental impact of the current situation, and can yield hotspots (i.e. processes with a major impact), and potential improvement options. By performing an ALCA, we identified that replacing SBM with RSM or waste-fed larvae meal can (partly) reduce the environmental impact. Results of this study, however, also showed that an ALCA does not grasp the full complexity of the consequences of implementing an innovation. Based on the results of an ALCA study, one can easily conclude that feeding more co-products or waste products to livestock results in an improved environmental impact, while this is not necessarily the case.

To assess the environmental impact of implementing an innovation, a CLCA is suitable, especially in combination with a sensitivity analysis to underpin uncertainty (Zamagni et al. 2012; Plevin et al. 2014; Meier et al., 2015). By performing a CLCA, information will be provided on the environmental change in comparison with the current situation. CLCA studies can be highly relevant especially in case we assess the environmental impact of a novel feed ingredient. Such studies provide information about interactions outside the production chain, resulting in environmental consequences when the innovation will be implemented and providing support to policy makers during decision making (Zamagni et al. 2012; Plevin et al. 2014; Meier et al. 2015).

The difficulty of performing a CLCA-related feed optimization, however, is that it requires insight into world food and feed markets. Especially in pig feed, where feed optimization is based on least cost optimization and a wide range of ingredients are available, diet formulations can change from day to day, resulting each in different environmental impacts. Currently, we see developments as precision farming in which each finishing-pig is fed based on its individual needs. It is hard to fully grasp such a complex and dynamic system with an LCA (Plevin et al. 2014). Some researcher as in the report of Dalgaard et al. (2007), therefore, assume that at the end, an increased demand for pork always results in an increased demand for the marginal protein source, SBM, and the marginal energy source, barley, although different feed ingredients are used. We can, however, wonder if this is correct? The starting point of a CLCA is the point where the stone hits the water, resulting in waves, the so called cause-and-affect chain (Ekvall and Weidema 2004). The first waves, or first consequences, have the most impact. Ekvall and Weidema (2004), therefore, advise to include only the environmental relevant waves and not to estimate consequences far down the cause-and-effect chain. Results of this study, however, showed that diet formulations are complex. Each feed ingredient has its own nutritional value, and are not solely energy- or protein rich. For example, the study of Van Zanten et al. (2015b) assumed based on CP content, that waste-fed larvae meal will replace SBM or fishmeal. We found, however, based on feed optimization, that waste-fed larvae meal replaces protein sources (SBM) and energy sources (barley) and consequently more co-products, e.g. wheat middlings were used in feed optimization of pig diets, multiple feed ingredients have to be used to meet the nutritional requirements of the pigs to ensure optimal growth performance. The results of our study showed, due to this complexity of feed optimization, a single substitution of one ingredient with another ingredient based on energy and/or protein not always results in a change in demand for the marginal product.

Related to feed optimization, we recommend farmers and animal nutritionist to use an ALCA to get insight in the environmental impact of their feed. In case, however, a policy maker or the feed industry wants to apply a mitigation strategy, it is recommended to perform a CLCA. Such a CLCA should be based on several scenarios (e.g. including different marginal products) to provide insight into different pathways.

5 Conclusions

Based on an ALCA, replacing SBM with RSM reduced LU, but did not affect GWP and EU. Whereas replacing SBM by waste-fed larvae meal decreased GWP and LU, but increased EU. Based on a CLCA, replacing SBM with RSM increased impacts on the environment. Replacing SBM with waste-fed larvae meal resulted in an increased GWP and EU but still reduced LU. The CLCA results were, therefore, contradictory with the standard ALCA results. Environmental benefits from an ALCA appeared more promising than from a CLCA. CLCA results for both case studies showed that using co-products and food-waste not necessarily reduces the environmental impact of pork production. For both cases, replacing SBM with RSM or waste-fed larvae meal resulted in an increased net environmental impact. This would have been overlooked when results were only based on ALCA.

Furthermore, the results of the sensitivity analysis showed that assumptions required to perform a CLCA, such as definition of the marginal product, have a large impact on final results. Results of a CLCA, therefore, seem to be relatively more uncertain compared to results of the ALCA, but more exact. Although the assumption made did affect the results, they did not have an effect on the final conclusions.

Related to feed optimization, we recommend animal nutritionists to use an ALCA to get insight in the environmental impact of their feed. If policy makers or the feed industry want to assess the environmental benefits of a mitigation strategy, however, it is recommended to perform a CLCA. One should, however, keep in mind that feed and food markets are highly dynamic. Pig feed optimization is based on least cost optimization and a wide range of ingredients are available; diet compositions can, therefore, change easily resulting in different environmental impacts. A CLCA should, therefore, include a sensitivity analysis to provide insight into different potential pathways and decrease uncertainty.

References

Alexandratos N, Bruinsma J (2012) World agriculture towards 2030/2050: the 2012 revision. Food and Agriculture Organisation of the United Nations (FAO), Rome

Bauman H, Tillman AM (2004) The hitchhiker’s guide to LCA. Chalmers University of Technology, Götenborg

Cederberg C, Flysjo A (2004) Environmental assesment of future pig farming systems. SIK report 728. Swedish Institute for Food and Biotechnology, Gothenburg

CVB (2010) Feed tables. (in Dutch: Tabellenboek veevoeding. CVB-reeks nr. 49.). Productschap Diervoeder, Centraal Veevoederbureau, The Hague

CVB (2011) Feed tables. (in Dutch: Veevoedertabel. CVB-reeks nr. 49.). Productschap Diervoeder, Centraal Veevoederbureau, Den Haag

Dalgaard R, Halberg N, Hermansen JE (2007) Danish pork production. An environmental assessment. University of Aarhus, Tjele

Dalgaard R, Schmidt J, Flysjö A (2014) Generic model for calculating carbon footprint of milk using four different life cycle assessment modelling approaches. J Clean Prod 73:146–153

Dalgaard R, Schmidt J, Halberg N, Christensen P, Thrane M, Pengue WA (2008) LCA of soybean meal. Int J Life Cycle Assess 13(3):240–254

De Vries M, De Boer IJM (2010) Comparing environmental impacts for livestock products: a review of life cycle assessments. Livest Sci 128(1):1–11

Ekvall T, Weidema B (2004) System boundaries and input data in consequential life cycle inventory analysis. Int J Life Cycle Assess 9(3):161–171

Elferink EV, Nonhebel S, Moll HC (2008) Feeding livestock food residue and the consequences for the environmental impact of meat. J Clean Prod 16:1227–1233

Eriksson IS, Elmquist H, Stern S, Nybrant T (2005) Environmental systems analysis of pig production—the impact of feed choice. Int J Life Cycle Assess 10(2):143–154

Foley JA, Asner GP, Costa MH, Coe MT, DeFries R, Gibbs HK, Howard EA, Olson S, Patz J, Ramankutty N, Snyder P (2007) Amazonia revealed: forest degradation and loss of ecosystem goods and services in the Amazon Basin. Front Ecol Environ 5(1):25–32

Garcia-Launay F, Van der Werf HMG, Nguyen TTH, Le Tutour L, Dourmad JY (2014) Evaluation of the environmental implications of the incorporation of feed-use amino acids in pig production using life cycle assessment. Livest Sci 161(0):158–175

Gerber PJ, Steinfeld H, Henderson B, Mottet A, Opio C, Dijkman J, Falcucci A, Tempio G (2013) Tackling climate change through livestock: a global assessment of emissions and mitigation opportunities. Food and Agriculture Organization of the United Nations (FAO), Rome

Guinée JB, Gorrée M, Heijungs R, Huppes G, Kleijn R, De Koning A, Van Oers L, Wegener Sleeswijk A, Suh S, Udo De Haes HA, De Bruijn H, Van Duin R, Huijbregts MAJ, Lindeijer E, Roorda AAH, Van der Ven BL, Weidema BP (2002) Life cycle assessment: an operational guide to the ISO standards. Centrum voor Milieukunde, Leiden University, Leiden

ISO 14044 and 14040 (2006) Environmental management—life cycle assessment: Life cycle interpretation. European Committee for Standardization (CEN), Brussels

Kløverpris JH (2008) Consequential life cycle inventory modelling of land use induced by crop consumption. Doctoral Dissertation Thesis, Technical University of Denmark, Copenhagen

Makkar HPS, Cooper G, Weber JA, Lywood W, Pinkney J (2012) Biofuel co-products as livestock feed. Opportunities and challenges. Food and Agriculture Organization of the United Nations, Rome

Makkar HPS, Tran G, Heuzé V, Ankers P (2014) State-of-the-art on use of insects as animal feed. Anim Feed Sci and Tech 197:1–33

McAuliffe GA, Chapman DV, Sage CL (2016) A thematic review of life cycle assessment (LCA) applied to pig production. Environ Impact Asses 56:12–22

McDonnell P, O'Shea C, Figat S, O'Doherty JV (2010) Influence of incrementally substituting dietary soya bean meal for rapeseed meal on nutrient digestibility, nitrogen excretion, growth performance and ammonia emissions from growing-finishing pigs. Arch Anim Nutr 64(5):412–424

Meier MS, Stoessel F, Jungbluth N, Juraske R, Schader C, Stolze M (2015) Environmental impacts of organic and conventional agricultural products—are the differences captured by life cycle assessment? J Environ Manag 149:193–208

Meul M, Ginneberge C, Van Middelaar CE, De Boer IJM, Fremaut D, Haesaert G (2012) Carbon footprint of five pig diets using three land use change accounting methods. Livest Sci 149(3):215–223

Mogensen L, Kristensen T, Nguyen T, Knudsen M (2010) Greenhouse gas emissions from production of imported and local cattle feed: 8th International Conference on LCA in the Agri-Food Sector, Rennes, France. Paper presented at the LCA food

Myhre G, Shindell D, Bréon F-M, Collins W, Fuglestvedt J, Huang J, Koch D, Lamarque J-F, Lee D, Mendoza B, Nakajima T, Robock A, Stephens G, Takemura T, Zhang H (2013) Anthropogenic and natural radiative forcing. In: Stocker TF, Qin D, Plattner G-K et al (eds) Climate change 2013: the physical science basis. Contribution of working group I to the fifth assessment report of the intergovernmental panel on climate change. Cambridge University Press, Cambridge and New York, pp 659–740

Nguyen TTH, Corson MS, Doreau M, Eugène M, Van Der Werf HMG (2013) Consequential LCA of switching from maize silage-based to grass-based dairy systems. Int J Life Cycle Assess 18(8):1470–1484

Plevin RJ, Delucchi MA, Creutzig F (2014) Using attributional life cycle assessment to estimate climate-change mitigation benefits misleads policy makers. J Ind Ecol 18(1):73–83

Prudêncio da Silva V, Van der Werf HMG, Spies A, Soares SR (2010) Variability in environmental impacts of Brazilian soybean according to crop production and transport scenarios. J Environ Manag 91(9):1831–1839

Reinhard J, Zah R (2011) Consequential life cycle assessment of the environmental impacts of an increased rapemethylester (RME) production in Switzerland. Biomass Bioenergy 35(6):2361–2373

Sánchez-Muros MJ, Barroso FG, Manzano-Agugliaro F (2014) Insect meal as renewable source of food for animal feeding: a review. J Clean Prod 65:16–27

Sasu-Boakye Y, Cederberg C, Wirsenius S (2014) Localising livestock protein feed production and the impact on land use and greenhouse gas emissions. Animal 8(8):1339–1348

Schmidt JH (2015) Life cycle assessment of five vegetable oils. J Clean Prod 87:130–138

Schmidt JH, Weidema BP (2008) Shift in the marginal supply of vegetable oil. Int J Life Cycle Assess 13(3):235–239

Steinfeld H, Gerber P, Wassenaar T, Castel V, Rosales M, De Haan C (2006) Livestock's long shadow: environmental issues and options. Food and Agriculture Organization, Rome

Thamsiriroj T, Murphy JD (2010) Can rape seed biodiesel meet the European union sustainability criteria for biofuels? Energy and Fuels 24:1720–1730

Thomassen MA, Dalgaard R, Heijungs R, De Boer IJM (2008) Attributional and consequential LCA of milk production. Int J Life Cycle Assess 13(4):339–349

Van der Werf HMG, Petit J, Sanders J (2005) The environmental impacts of the production of concentrated feed: the case of pig feed in Bretagne. Agric Syst 83(2):153–177

Van Huis A, Van Itterbeeck J, Klunder H, Mertens E, Halloran A, Muir G, Vantomme P (2013) Edible insects. Future prospects for food and feed security. Food and Agriculture Organization of the United Nations (FAO), Rome

Van Zanten HHE, Bikker P, Mollenhorst H, Meerburg BG, De Boer IJM (2015a) Environmental impact of replacing soybean meal with rapeseed meal in diets of finishing pigs. Animal 9:1866–1874

Van Zanten HHE, Mollenhorst H, De Vries JW, Van Middelaar CE, Van Kernebeek HRJ, De Boer IJM (2014) Assessing environmental consequences of using co-products in animal feed. Int J Life Cycle Assess 19(1):79–88

Van Zanten HHE, Mollenhorst H, Oonincx DGAB, Bikker P, Meerburg BG, De Boer IJM (2015b) From environmental nuisance to environmental opportunity: housefly larvae convert waste to livestock feed. J Clean Prod 102:362–369

Veldkamp T, Van Duinkerken G, Van Huis A, Lakemond CMM, Ottevanger E, Bosch G, Van Boekel MAJS (2012) Insects as a sustainable feed ingredient in pig and poultry diets - a feasibility study. Livestock Research, Wageningen

Vellinga T, Van Laar H, Thomassen MA, De Boer IJM, Berkhout P, Aiking H (2009) Environmental impact of animal feed (Milieueffecten van diervoeders). Rapport 205, Wageningen UR, Wageningen

Vellinga TV, Blonk H, Marinussen M, Van Zeist WJ, De Boer IJM (2013) Methodology used in feedprint: a tool quantifying greenhouse gas emissions of feed production and utilization. Wageningen UR, Lelystad

Weidema BP (2003) Market information in life cycle assessment. Project no. 863. Danish Environmental Protection Agency, Copenhagen

Weidema BP, Ekvall T, Heijungs R (2009) Guidelines for application of deepened and broadened LCA. 2.-0 LCA consultants, Aalborg

Weightman RM, Cottrill BR, Wiltshire JJJ, Kindred DR, Sylvester-Bradley R (2011) Opportunities for avoidance of land-use change through substitution of soya bean meal and cereals in European livestock diets with bioethanol coproducts. GCB Bioenergy 3(2):158–170

Zamagni A, Guinée J, Heijungs R, Masoni P, Raggi A (2012) Lights and shadows in consequential LCA. Int J Life Cycle Assess 17(7):904–918

Acknowledgements

The authors thank Wageningen UR Livestock Research for funding this study.

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Greg Thoma

Electronic supplementary material

ESM 1

(DOCX 136 kb)

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

van Zanten, H.H.E., Bikker, P., Meerburg, B.G. et al. Attributional versus consequential life cycle assessment and feed optimization: alternative protein sources in pig diets. Int J Life Cycle Assess 23, 1–11 (2018). https://doi.org/10.1007/s11367-017-1299-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11367-017-1299-6