Abstract

Purpose

Meeting the demands of a growing and increasingly affluent population necessitates a deeper understanding of the environmental and economic implications of production. This implication is most relevant in key production sectors including agriculture and livestock. This article is intended to provide an understanding of the influence of methods of assessing land-use change (LUC) with respect to minimizing both the global warming potential (GWP) and the monetary costs of pig feed formulation.

Methods

Feed mixtures intended for slaughter pigs were generated for minimal cost and GWP impacts by applying four differing LUC assessment methods. The objective function was the Danish slaughter pig feed unit, minimized for cost in Danish crowns (DKK), with GWP impacts constrained in multiple steps. Attributional LCA methodology was applied using the Agri-footprint 6.3 database, with GWP impacts calculated excluding land use changes, including direct land-use changes and including the carbon opportunity cost. Analyses of the functional relationship between the optimal cost and the GWP impact were conducted, followed by a comparative LCA of the cost of comparable feed mixture by applying two sets of functional units: 100 slaughter pig feed units and 1 kg of pig live weight.

Results and discussion

A similar relationship between cost and GWP impact was observed across all methods, although variability of GWP impact magnitude depending on method was observed. Reducing at an equivalent cost, GWP reduction ranged from 5.6 to 27% based on the pig feed functional unit, and 2.4 to 13% based on the pig live weight functional unit. Optimizing feed mixtures for GWP impacts resulted in significantly increased contributions to other impact categories, including a 56% increase in terrestrial ecotoxicity. Despite the increased contributions to other impact categories, all optimized feed mixtures achieved a reduction in endpoint indicators and single score. Endpoint reductions to the feed unit were 2.3–25% for ecosystem damage, 7.4–15% for human health, and 6.0–16% based on a single score value.

Conclusions

The findings emphasize the key importance of addressing LUC when optimizing the GWP of agri-food production. Suggestions are provided for areas of improvement in future optimization studies applying a dietary unit as the objective function, including additional midpoint impact categories and/or extended optimization covering whole areas of protection. The findings suggest that GWP impacts may be reduced at no additional cost if included or embedded in the pig feed formulation procedure.

Similar content being viewed by others

Explore related subjects

Find the latest articles, discoveries, and news in related topics.Avoid common mistakes on your manuscript.

1 Introduction

Recent statistics on global dietary patterns suggest that nearly 40% of human protein consumption is sourced from animal proteins originating from livestock, including eggs, dairy, and meat (FAO 2023a).

Livestock feed, and in particular pig feed, consists primarily of plant-based ingredients like grains and sources of dietary protein, including oilseed “meals” originating from vegetable oil production, and to a lesser extent dietary protein sources of animal origin, including blood plasma, fish meal, and milk protein (Lewis and Southern 2001, Sauber and Owens 2001). Dietary fat sources in pig feed are primarily plant-based, although this energy source may also be of animal origin (Azain 2001). Although consumption patterns differ globally, pork (i.e., pig meat) is on average the most highly consumed meat in China and the European Union, providing a substantial share of protein to the global food supply (FAO 2023c).

Presently, the Danish agricultural sector contributes to about 26.2% of the sectoral anthropogenic GHG emissions, primarily in the form of nitrous oxide (N2O), methane (CH4), and carbon dioxide (CO2) (Nielsen et al. 2023). These GHG emissions contribute to a rise in global temperatures at different magnitudes referred to as the “global warming potential” (GWP), an impact category expressed in the mass of CO2 equivalents (CO2-eq), usually over a 100-year time horizon (GWP-100). The European Union has set ambitious targets to reduce greenhouse gas (GHG) emissions by 70% (relative to 1990) by the year 2030 (European Commission 2020). The Danish government has also set a climate neutrality target for 2050, requiring major changes in national production across all sectors (Energistyrelsen 2020). Despite the urgency caused by rising mean global temperatures, multiple other environmental impact categories are highly relevant to the agri-food sector, including eutrophication, acidification, human toxicity, ecotoxicity, and excessive and unsustainable water and land use (Knudsen et al. 2019; Gislason et al. 2023). The relevance of global land and water use is exemplified by 70% of freshwater extraction and 44% of habitable land occupation directly attributable to the agri-food sector (FAO 2023b; FAO 2024). The application of pesticides to croplands may result in the leaching of toxic substances into groundwater, posing an additional risk to local water supplies (Mateo-Sagasta et al. 2017). Application of fertilizers, containing nitrogen, phosphorus, and potassium, is a common practice in conventional crop production, resulting in multiple emission pathways, including air, leaching, and run-off (Hutchings et al. 2023). Most GWP impacts attributable to crop cultivation are N2O emissions traced to fertilizer applications and emissions attributable to transformations of land cover (Bennetzen et al. 2016).

Life cycle assessments (LCAs) enable GWP impacts to be calculated from all production activities, including upstream and downstream activities in the supply chain (Bjørn et al. 2018). Additionally, the LCA methodology enables the substance characterization of multiple impact categories (e.g., ecotoxicity and eutrophication), enabling comprehensive environmental impact reporting (Hauschild and Huijbregts 2015). The attributional and consequential LCA approaches are the two main assessment classifications in LCA methodology (Weidema 2014). The attributional LCA approach is mostly used in environmental accounting, product declarations, and minor systematic decisions, while the consequential approach is intended for large-scale systematic changes and policy decisions (European Commission 2010). Land cover transformations are major drivers of GHG emissions and biodiversity loss, and contribute substantially to the agricultural sector’s GWP impact (Rosa et al. 2014). The GHG emissions from these transformation activities are often the result of the clearing of forests and the conversion and degradation of land systems, which leads to atmospheric releases of carbon stored in above- and below-ground biomass and soil (Andreson-Teixeira and DeLucia 2011). Practitioners of LCA refer to these transformations as land-use changes (LUC), although inclusion in LCA is usually limited to the GHG emissions attributable to a specific transformation activity (BSI 2012). The importance of including LUC within agricultural systems has been emphasized in previous LCA studies, most notably in respect of decisions regarding biofuels (Cherubini and Jungmeier 2010; Woltjer et al. 2017). The importance of LUC in the context of pig feed has also been emphasized, as the inclusion of LUC may increase the GWP impact severalfold (Meul et al. 2012; Kebreab et al. 2016).

Common LUC classifications methods are the direct (dLUC), indirect (iLUC), and “carbon opportunity cost” (COC) classifications (Persson et al. 2014; Searchinger et al. 2018). The dLUC assessment methodology enables accounting of past land transformation carbon losses that are attributed to production over a specific time horizon (usually the last 20 years) (BSI 2012). The iLUC assessment methodology provides an estimate of GHG emissions as the consequences of production choices in a systematic supply-capacity context relative to static demand imposed by global consumption (Schmidt et al. 2015). The COC assessment methodology is based on the opportunity cost principle originating from economics, which provides an estimate of lost carbon sequestration by choosing to continue current production as opposed to abandoning land. The COC method calculates the relative difference in current and natural carbon stocks of soil and vegetation that are attributed to production over a specified time horizon (Searchinger et al. 2018). Although land-management practices (e.g., crop rotation and tillage) may result in changes to the carbon stocks of cropland, LCAs generally do not include these stock changes (BSI 2012). These LUC assessment methods are all recognized within LCA applications, which are included in the latest draft of the greenhouse gas protocol (GHG Protocol 2022). The dLUC assessment method is best suited in attributional LCAs based on the attribution of recent carbon losses to current production (e.g., environmental accounting). A majority of existing dLUC studies and assessment methods statistically attribute carbon losses through deforestation to commodities relying on aggregated LUC data (Carter et al. 2018; De Sy et al. 2019; Pendrill et al. 2019). This approach introduces uncertainties regarding the precise locations of deforestation events and the resulting carbon losses (Bontinck et al. 2020). However, the integration of remote-sensing datasets with finer spatio-temporal resolutions significantly enhances the accuracy of the carbon losses attributed to commodity production, offering improvements over traditional statistical methods (Singh and Persson 2024). The iLUC assessment method is, on the other hand, best suited for consequential LCAs, providing an estimate of the GWP impacts through the indirect consequences of production choices. The COC assessment method is aligned with the attributional LCA methodology in the context of accounting, although it may also align with consequential LCA methodology in the decision context for climate action (Searchinger et al. 2018). These LUC assessment methods are valuable tools within agricultural LCAs, and their inclusion (or exclusion) should be carefully considered based on the specific LCA’s goal and scope.

The majority of environmental impacts in pig production is attributable to the production of feed, the housing of animals, and manure management, with minimal contribution from capital goods (e.g., onsite energy use, machinery, and buildings) (Gislason et al. 2023). Although multiple mitigation areas have been discussed in existing LCA literature on pig production, changes in feeding practices are among the most promising mitigation areas (Gislason et al. 2023). As the GWP impact of feed mixtures for pigs is mainly influenced by its feed ingredients, including ingredient GWP impacts in the diet formulation may enable cost-effective impact reductions. Feed mixtures for pigs differ in their requirements depending on the developmental stage, which are usually split into three stages for slaughter pig production. The stages are as follows: (1) sow management and nursing of piglets until they reach weaning weight, (2) weaning of piglets from sows until attaining fattening weight, and (3) the fattening of pigs until slaughter weight. In Denmark, after giving birth to a litter of piglets, the sow will typically nurse these piglets for close to 28 days until weaning weight of approximately 7.0 kg. When piglets are weaned, they enter the nursery stage, where they will be housed in temperature-controlled stables until they reach a weight of about 30 kg. Throughout this period, piglets will typically consume two or three different diets that gradually adapt the piglet to consuming vegetable protein and grains. The final stage is the grower-finisher phase, where pigs are fattened from 30 kg to their slaughter weight, which ranges from 110 to 140 kg depending on the system in question. In this period, pigs consume dry feed dispensed in automatic feeders or using a liquid feeding system. The slaughter pig diets primarily consist of plant feed as a mixture of grains (primarily wheat and barley) in addition to the meal by-product of oil-pressing beans or seeds (primarily soybean meal).

Studies that formulate pig’s diet are based on multiple-linear programming, taking into account the individual ingredient cost and nutrient content (van Zanten et al. 2018). In multiple-linear programming, an objective function defines the output variable (e.g., the unit of feed), while the decision variables are input variables (e.g., the cost) that are subjected to minimization or maximization (Stark 2012). In diet formulation for pigs, the objective function is defined as a feed unit that includes specific nutritional requirements based on constraints, while the decision variable is typically cost.

The nutrient constraints are typically retrieved from nutrient standards at a national level, i.e., the American “Nutrient Requirements of Swine,” the Dutch “Booklet of Feeding Tables for Pigs,” or the Danish Nutrient Standards (National Research Council 2012; Tybirk. 2022; CVB 2023). Formulation of pig feed mixtures require the combined knowledge of nutritional requirements and ideal ingredient compositions in pig feed mixtures, since certain ingredients may only be introduced in minimal quantities without risking digestive issues resulting in reduced growth performance (Landbrug & Fødevarer 2019). In modern pig production, the feed conversion ratio and average daily gain and mortality rates are typically monitored to utilize the feed as efficiently as possible. The primary source of non-feed-related GWP impacts consists of emissions of CH4, which occur during manure storage and animal housing through enteric (gut) fermentation. Various nitrogen-based emissions (e.g., N2O, NH3) originate from pig excretions during housing and manure storage, contributing to multiple environmental impact categories (Sørensen et al. 2023). Other emissions of stated significance include non-methane volatile organic compounds (NMVOCs) and particulate matter formation (Amon et al. 2019).

This study aims to provide an analysis of the optimal cost and GWP impact of feed mixtures fed to slaughter pigs by applying multiple common LUC assessment methods in calculation of the GWP impact. The analysis results will be used to investigate the potential reduction in the GWP impacts of Danish pig production by means of an LCA comparison of optimized feed mixtures at a cost equal to the average feed mixture used in Denmark.

2 Methodology

This study investigates the optimization of slaughter pig feed mixtures through the minimization of cost and the constraining of GWP impacts based on four separately applied LUC assessment methods. Each LUC assessment method was individually analyzed in terms of changes in cost and ingredient composition based on constraining the GWP impact in multiple steps. Thereafter, cost-equivalent and GWP-minimized feed mixtures were then generated for each applied LUC assessment method and subjected to an LCA comparison with an average feed mixture (baseline) used in Denmark. Two functional units were defined, the first comparing the slaughter pig feed mixtures directly as a slaughter pig feed unit and the second comparing the average Danish pig production system using the optimized feed mixtures. Animal performance and life cycle inventory data were based on published statistics that are representative of Danish production in 2021. Feed ingredients were subjected to sensitivity analyses of the ingredient’s production origins and ingredient constraints applied during feed optimization and formulation. Methodological sensitivity analysis included the addition of iLUC and an investigation of the correlations across the applied LUC assessment methods.

2.1 LCA methodology

All environmental impacts were calculated using attributional LCA methodology, following the ISO 14040 and 14,044 standards (ISO 2006a, b). Cost-equivalent slaughter pig feed mixtures were compared in two LCAs, the first comparing the slaughter pig feed directly and the second comparing slaughter pig production systems differing only in slaughter pig feed mixtures. The functional unit directly assessing the slaughter pig feed was defined as 100 Danish feed units for slaughter pigs (FUpig), a comparable unit fulfilling the nutrient requirements of slaughter pigs comparable to 1 kg of barley when completely oxidized (Tybirk et al. 2006). The functional unit assessing the slaughter pig production systems is defined as the mass of pig live weight in kilograms (kg*LW) exiting the farm gate, hence excluding all slaughterhouse activities. The system boundary assessing the functional unit of pig live weight does not account for changes in animal performance resulting from the different feed mixtures and is only included to provide a reference of reduction potential towards the entire pig production system. The product system applying the functional unit of FUpig is commonly referred to as “cradle to feed-gate,” including all activities required in the production of a ready-to-eat feed mixture. The product system for assessing slaughter pigs is commonly referred to as “cradle to farm-gate,” including all growth stages and activities from sow to slaughter weight (0–115 kg). The defined baseline slaughter pig feed mixture and the feed mixtures for sows and weaners were based on estimated feed mixtures typically used in Denmark (Tybirk. 2022). Feed ingredients are purchased with no crop production as part of the foreground system; therefore, a minimal contribution is expected from capital goods (stable construction, electricity, farming equipment) resulting in the exclusion of these activities from the foreground system. Feed ingredient life cycle inventories were retrieved from the Agri-footprint 6.3 economically allocated database, using Danish market mix processes (Mérieux NutriSciences | Blonk 2024). Statistical data on housing types and manure management systems were collected from the Danish national inventory reports for 2022 and 2023, verified by specialists at SEGES Innovation P/S (Nielsen et al. 2022, Nielsen et al. 2023). Productivity data on feed conversion ratios, litter sizes, and growth and mortality rates for Danish pig production in 2021 was retrieved from a SEGES Innovation P/S report (Hansen 2021).

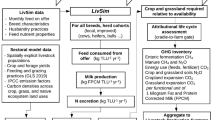

Figure 1 illustrates the product systems, including the emissions modelled as part of the foreground system for animal housing and manure storage, all based on IPCC and EMEP calculation models (Amon et al. 2019; Gavrilova et al. 2019). Sow multifunctionality (culled sows and piglets) is treated by economic allocations based on previous 5-year average prices, while manure is treated as a waste flow (cutoff) in alignment with the Agri-footprint 6.3 methodology (Landbrug & Fødevarer 2024, Blonk et al. 2022). OpenLCA 2.0.3 software was used for inventory modelling and impact assessments using a modified version of the ReCiPe 2016 (H) midpoints and endpoints (Huijbregts et al. 2016, Green Delta 2023). The modification of the ReCiPe 2016 (H) methods included the implementation of multiple GWP impact (sub-)categories for characterizing GWP impacts depending on the LUC assessment method in question. Additionally, as regionalized characterization factors for Danish NH3 flows were missing for acidification impacts, they were included manually to provide representative acidification impacts. Details of inventory data, emission models, applied emission factors, and the characterization factors applied in modifications to the impact assessment method are available in the supplementary information (Online resource 1 & 2).

2.2 Methods assessing land-use change

Four LUC assessment methods were defined and included in this study as specified in Table 1, resulting in four separate feed optimization analyses and LCA results. Feed ingredient inventories were based on Danish market mix processes for the Agri-footprint 6.3 feed database, which provide disaggregated elementary flows (e.g., emissions), including separated dLUC flows. These elementary flows were utilized in addition to newly added LUC flows generated for the additional LUC assessment methods, all expressed as CO2 emissions. The differences between the LUC assessment methods were only the characterization values applied to the GWP impact for the existing or newly generated LUC flows. The additions of new LUC flows were limited to crop ingredient inventory processes, with no additional LUC flows provided for supplements (minerals and free amino acids). Applying the modifications of ReCiPe 2016 (H) midpoint in the various LUC flows enabled the environmental impacts of all LUC methods for ingredients, feed mixtures, and the entire pig production system to be calculated. The “noLUC” assessment method included no characterization of LUC flows on the GWP impact, while including the standard characterization values of all other elementary flows, including peat-soil drainage emissions. All subsequent LUC assessment methods include the characterization of flows described for “noLUC,” in addition to their unique LUC flows characterized towards the GWP impact. The “dLUCa” assessment method included characterization of the default land transformation flows provided by the Agri-footprint 6.3 database. The “dLUCb” assessment method characterized a newly added flow based on a model that combined geospatial datasets with agricultural statistics (i.e., a combination of direct and statistical land attribution approaches) for assessing the carbon losses through land transformation (Singh and Persson 2024). To ensure homogeneity and fair comparability of the two dLUC assessment methods, carbon losses attributable to crop land (in hectares) were attributed to individual crop products (in kg) for the dLUCb assessment method using the PAS2050 guideline and FAO statistics data (BSI 2012; FAO 2022). The LUC assessment method “COC” characterized a newly added flow that was calculated using the LPJmL model to estimate current and native carbon stocks (Searchinger et al. 2018). Calculation of COC requires the difference in carbon stock to be attributed over a specific time horizon by discounting or amortization over a period of 80 and 30 years, respectively. Details of the newly added flows and value per kg of ingredient are available in the supplementary information (Online resource 2)

2.3 Feed optimization

The steps needed to enable feed optimization, including the cost and GWP impacts, are presented visually in Fig. 2. The first steps were development of the life cycle inventory for ingredients including LUC (Sect. 2.2), and was followed by a calculation of the resulting GWP impacts for all ingredients and LUC assessment methods. Data on the ingredient’s nutrients, cost, and GWP impacts were then uploaded to the software WinOpti (v2023.1.8628.14970), where optimized feed mixtures were generated and analyzed (AgroVision 2024). Verification of successful implementation was performed by comparing feed mixture GWP impacts reported by WinOpti to those reported by OpenLCA. After verification that optimization had been successful, analysis was performed and followed by an LCA comparison of cost-equivalent and GWP impact-optimized slaughter pig feed mixtures using the two different functional units. Table 2 displays the feed ingredients used in this study, which consist of 15 crop products as feed ingredients, in addition to five essential free amino acid supplements and three mineral supplements. Free amino acids only balance the amino acid profile of the feed mix, being limited to this purpose within the feed mixture formulation. The analysis and changes were limited to slaughter pig feed to avoid increasing the study’s complexity, but were substantiated by majority of feed-related environmental impacts attributed to slaughter pig feed (Gislason et al. 2023). Data sources of ingredient nutrient contents were based on a combination of primary data and proprietary and/or confidential data (AgroVision 2024). Data on average feed ingredient prices for 2021 were acquired through correspondence with the Danish feed distributor Vestjyllands Andel A.m.b.a. (Ehmsen 2023).

The objective function was defined as 100 slaughter pig feed units (FUpig), a unit that typically ranges between 1.0 and 1.1 FUpig per kg of total ingredient mass (wet weight). As a technical limitation of WinOpti required constraining the GWP impacts relative to the ingredients’ dry matter (DM) content, an additional constraint was applied at precisely 1.20 FUpig/kg*DM to ensure accuracy. The allowable ingredient limits within the feed mixtures were based on nutritional guidelines published by SEGES innovation P/S and the specialists participating in this study (Online resource 1). These include a minimum mass constraint of 15% barley and 1% vegetable oil content, representing local feeding practices (barley) and ensuring that feed pellets can be produced from the feed mixtures (oil). The analysis began by formulating an “economic-optimum” feed mixture, which represents the lowest cost feed mixture that can be achieved while still satisfying all nutritional and ingredient constraints. The economic-optimum feed mixture is identical for all LUC assessment methods since no maximum constraints are placed on GWP impacts. The economic-optimum feed mixtures resulting in a GWP impact were then gradually constrained for each LUC assessment method until arriving at each LUC assessment method’s “GWP-optimum,” representing the lowest GWP impact achievable for a feed mixture while still satisfying all nutritional and ingredient constraints. These two “optimum” feed mixtures provided two key pieces of information about all optimized feed mixtures. The first is the lowest cost achievable and its resulting GWP impact, and the second is the lowest GWP impact achievable and its resulting cost. This means that all possible combinations of optimal feed mixtures are within these GWP impact values, providing valuable information of the relationship of minimal cost and GWP impact. Multiple feed mixtures were generated for each LUC assessment method at GWP impact constraints between the two optimum values, followed by collecting data on feed mixture costs, GWP impacts, and ingredient compositions. The data collected on the feed mixtures were then analyzed to identity relationships, followed by formulation of the cost-equivalent and GWP-minimized slaughter pig feed mixtures used in the LCA comparison.

2.4 Sensitivity analyses

Feed ingredient constraints and production origins were subjected to sensitivity analyses to investigate their influence on the resulting cost and their GWP impacts. An important distinction among ingredient constraints is that they are not defined by the feed unit and therefore do not influence the nutritional requirements, since there are applied specifically to avoid potential digestive issues that result in reduced growth performance. This influence of the ingredient constraints was investigated by repeating the analysis with the complete removal of ingredient constraints, followed by a comparison with the main results. The removal of constraints is aimed at providing insights into the importance of nutritional research, and more specifically to its influence when minimizing the costs and GWP impacts of pig feed mixtures. Although these feed mixtures are currently unusable in practice, their analysis provides insights into the potential that future nutritional research may unlock. Since the individual feed ingredients may differ in production origins and exhibit substantial differences in nutritional composition and GWP impacts, the ingredient production origin was subjected to a sensitivity analysis performed by replacing Danish market mix ingredients with multiple macro-regional ingredient processes at continental scales and resolutions (e.g., European barley, South American maize). These macro-regional processes were modelled for ingredients originating from different regions, included if a specific region supplies a minimum of 1% of a specific ingredient global net supply, as further explained in the supplementary information (Online resource 1). Since the influence of LUC assessment methodologies on the results is an area of interest for this research, the iLUC assessment method was included, and a correlation investigation of all LUC assessment methods was performed. The iLUC assessment method was not combined with the consequential LCA methodology (as recommended) and applied the identical attributional system boundary as applied for the other LUC assessment methodologies. The decision to include iLUC for sensitivity analysis with attributional LCA methodology is due to the interest in comparison of results to the other LUC assessment methods through the correlation investigation. The correlation investigation was performed through comparing optimized feed mixtures for each LUC assessment method to the results when applying the other LUC assessment methods. The correlation investigation was performed to investigate the potential correlation between methods, as optimizing for one LUC assessment method may have positive, negative, or alternatively no influence towards another LUC assessment method.

3 Results and discussion

3.1 Feed analysis: GWP impacts and costs

Figure 3 provides a visual representation of the relationship between the cost and GWP impact for each LUC assessment method, based on collected data from the various feed mixtures. To reiterate, the economic-optimum feed mixture is indicated by the lowest cost, while the GWP-optimum feed mixture is indicated by the lowest GWP impact (see Sect. 2.3 for details). The economic-optimum feed mixture is identical across LUC assessment methods and resulted in a cost of 148.4 DKK per 100 FUpig. The noLUC assessment method resulted in the lowest GWP impacts, with respective GWP optima and economic optima at 50.4 and 54.6 kg CO2-eq per 100 FUpig, respectively. The dLUCa assessment method exhibited a higher GWP impact of both optima and their range compared to the noLUC assessment method, with the GWP optimum and economic optimum at 55.1 and 77.6 kg CO2-eq per 100 FUpig, respectively. The dLUCb assessment method showed somewhat lower GWP impacts compared to its dLUCa counterpart, with the GWP optimum and economic optimum at 53.1 and 56.5 kg CO2-eq per 100 FUpig, respectively. The GWP impacts applying the COC assessment method were substantially higher compared to the other LUC assessment methods, with the GWP optimum and economic optimum at 240 and 390 kg CO2-eq per 100 FUpig, respectively.

Plotted data collected from optimized feed mixtures, displaying the GWP impact (y-axis) and cost in DKK per 100 FUpig (x-axis). The datapoints represent the optimal diet composition with the lowest cost at differing ranges of maximally constrained GWP impact, with the baseline cost of 152.2 indicated by the dashed line. Note that GWP impact (y-axis) differs in scale between A and B

Figure 4 displays changes in compositions of optimal feed mixtures based on changes in GWP impacts. The economical optimum feed mixture is composed of 40% rye, 39% barley, 10% rapeseed meal, 7.7% soybean meal, 0.7% palm oil, and 0.3% soy oil. All feed mixtures contained precisely 1.0% vegetable oil and approximately 2.0% mineral supplements and roughly 0.5% of free amino acids. Reductions in GWP impacts applying the noLUC assessment method (Fig. 4A) are first attributed to changing the oil source from palm to soy (not visible on graph), followed by a reduction in barley content and increases in both triticale and soybean meal. Achieving maximum reductions by applying the noLUC assessment method required introducing wheat, broad beans, maize, and sunflower meal into the feed mix. Reductions in GWP impacts applying the dLUCa assessment method (Fig. 4B) begin with a shift from palm to soy oil and are then followed by replacing barley and soybean meal in exchange for triticale and sunflower meal, and later including broad beans and replacing the soy oil with rapeseed oil. Reductions in GWP impacts applying the dLUCb assessment method (Fig. 4C) follow a similar pattern to the noLUC assessment method, although including sunflower meal rather than broad beans. This similarity in ingredient changes in noLUC and dLUCb is primarily due to GWP impacts driven by non-LUC-related emissions for both methods. Reductions in GWP impacts applying the COC assessment method (Fig. 4D) are achieved by replacing rye content with barley, followed by the addition of triticale and wheat, and finally reductions of barley in favor of increased maize and sunflower meal.

The resulting cost of the baseline feed mixture (average in Denmark) was 152.2 DKK per 100 FUpig; therefore, optimized feed mixtures were generated at this cost for the LCA comparison. Feed mixtures generated for LCA at the baseline price are indicated in Figs. 3 and 4 by the dotted line and detailed in the supplementary data file (Online resource 2). In particular, all feed mixtures generated for LCA comparisons included the maximum content of rapeseed meal at 10%, with most preferring soybean oil to satisfy the oil requirements and often including a high rye content. The feed mixture generated by applying the noLUC assessment method included soybean oil and grains of rye, barley, and triticale, including a 21% meal content consisting primarily of rapeseed and soybean meal, in addition to minimal sunflower meal content. The feed mixture generated by applying the dLUCa assessment method consisted of a similar grain profile, although including rapeseed oil to satisfy oil requirements in addition to a 9% broad bean content. Additionally, this contained a 16% meal content consisting primarily of rapeseed and sunflower meal and a minimal soybean meal content. The feed mixture generated applying the dLUCb assessment method had a similar grain profile to noLUC, although including wheat instead of triticale with a 19% meal content that consisted of rapeseed, sunflower, and soybean meals. The feed mixture generated by applying the COC assessment method included a grain profile that differed from the other methods, including the maximum allowable barley content (70%) and a 16% meal content consisting of rapeseed and soybean meal.

3.2 LCA impact results

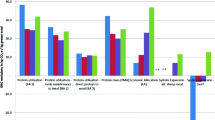

This section compares the costs of the LCA comparison slaughter pig feed mixtures (152.2 DKK per 100 FUpig). Impact results applying the ReCiPe 2016 (H) midpoint impact assessment method expressed per 100 FUpig and per 1 kg*LW are presented in Table 3. The reductions achieved by applying the noLUC and dLUCb assessment methods resulted in the lowest overall GWP impact reductions when compared to the baseline, respectively at 5.6% and 6.2% to the feed unit, and 2.4% and 2.7% to the pig live weight. The dLUCa assessment method resulted in the highest overall reduction to GWP impacts of all LUC assessment methods, at 27% to the feed unit and 13% to the pig live weight when compared to the baseline. The COC assessment method resulted in a GWP impact reduction of 15% by applying the feed unit and 10% by applying the pig live weight compared to the baseline. An interesting finding is that optimizing for one LUC assessment method did not necessarily provide a performance advantage for the GWP impact of another LUC assessment method. Furthermore, while the optimized feed mixtures lowered the GWP impact of a specific LUC assessment method, increases were observed for other impact categories at various magnitudes, notably in the ecotoxicity impact categories. The largest burden shift was observed for the dLUCa optimized feed mixture, where increases of 23%, 26%, and 56% in freshwater, marine, and terrestrial ecotoxicity impact categories were observed when compared to the baseline, respectively. On the other hand, lower impacts were observed in water use, land use, marine eutrophication, terrestrial acidification, and non-carcinogenic human toxicity in the GWP-optimized feed mixtures compared to the baseline. ReCiPe 2016 (H) endpoint indicators and weighted and normalized single scores are presented for 100 FUpig and 1 kg*LW in Table 4. Endpoint and single score results include the characterization, weighing, and normalization of LUC-induced elementary flows specific to the LUC assessment method. Despite the substantial increase in ecotoxicity impacts, an overall reduction to endpoint and single-score indicators was observable across the optimized feed mixtures, with exception of the resource depletion indicator. Applying the functional unit 100 FUpig resulted in a reduction of 2.8–24% to ecosystem damage, 7.4–15% to human health impact, and 7.4–15% applying the weighed and normalized single score when compared to the baseline. Applying the functional unit of 1 kg*LW resulted in a reduction of 1.4–11% to ecosystem damage, 4.2–8.4% to human health impact, and 4.1–8.5% applying the weighed and normalized single score when compared to the baseline. Figure 5 visualizes the contribution to GWP impacts for the baseline and optimized pig production systems for all LUC assessment methods when applying the functional unit of 1 kg*LW. The largest contributors to GWP impacts applying the noLUC and dLUCb assessment methods were feed production and manure management. Contributions from LUC-related activities were only substantial to GWP impacts when applying the dLUCa and COC assessment methods, contributing 26% of the baseline and 13% of the optimized systems when applying dLUCa, and contributing 74% to the baseline system and 64% to the optimized system when applying COC. Detailed results of the impact assessment are available in the supplementary information (Online resource 2).

Contribution analysis of sources to GWP impacts of the pig life cycle, applying all LUC assessment methods. A The contribution of the baseline pig production system for each LUC assessment method. B The pig production system including slaughter pig feed mixtures optimized for the applied LUC method, presented relative to the correspondent baseline scenario. GWP impacts are expressed in kg*CO2-eq per kg*LW, and they are provided on top of the bars, for each LUC assessment method, and for both A and B

3.3 Sensitivity analysis

3.3.1 Ingredient constraints and the origin of production

This section investigates the influence of feed ingredient constraints applied during feed formulation, and the influence of the ingredient origin of production by specifying source regions. For assessing the sensitivity of nutritional constraints, feed ingredient constraints were removed from the optimization entirely; therefore, no specific feed ingredients were defined in terms of their minimal or maximum contents. To reiterate, the removal of ingredient constraints only applied to specific feed ingredient minimum and maximum contents and does not influence any nutrients defined by the feed unit, since these constraints are only introduced to avoid potential digestive issues that reduce animal performance. For assessing the sensitivity of feed ingredients’ production origins, the Danish market mix was replaced by macro-regional ingredient processes on a continental scale (see Sect. 2.4, online resource 2). Figure 6 provides a visual representation of the resulting cost and GWP impacts of both ingredient changes in a side-by-side comparison of the original results, although at differing scales depending on the LUC assessment method.

Plotted data collected from optimized feed mixtures applying ingredient sensitivity parameters, displaying the GWP impact (y-axis) and cost in DKK per 100 FUpig (x-axis), although at differing scales. The four plots presented (A, B, C, and D) use different LUC assessment methods, as indicated by the figures’ titles. The baseline feed mixture cost is indicated by the dashed line crossing the y-axis at 152.2 DKK per 100 FUpig

Removing feed ingredient constraints resulted in an economically optimal feed mixture cost of 143.2 DKK per 100 FUpig, composed of approximately 80% rye and 17% meal content split between rapeseed and soybean meal, with the remaining ~ 3% consisting of mineral supplements and free amino acids. The preference for rye can be attributed to its nutritional content combined with the price data utilized for the optimization. Removal of ingredient constraints resulted in substantial changes to the cost and GWP impact for all applied LUC assessment methods. No feed mixture could be formulated at the baseline cost when applying the dLUCb assessment method, as the cost of the GWP optimal feed mixture was below this point. The economically optimal diet composition exhibited a greatly increased GWP impact when applying the COC assessment method, although a substantial reduction was observed when comparing GWP impacts relative to cost. Differences in feed mixtures were primarily observed through the complete absence of oils as ingredients, combined with rye and rapeseed meal content exceeding the original constraints. The low preference for oils and high preference for meal is likely to be influenced by sensitivities in applying economic allocations for calculation of the different ingredients’ GWP impacts, since prices of oils are considerably higher than the prices of meals. Therefore, applying economical allocation results in a twofold sensitivity depending on the cost ratio of the oil and meal of specific crops, resulting in both optimization objectives (GWP and cost) being determined by cost. This highlights the sensitivity of cost when applying economic allocations in optimization studies minimizing both cost and environmental impacts, since cost influences both optimization objectives that is highly relevant for oil crop ingredients.

Replacing the market mix datasets with macro-regional datasets of feed ingredients resulted in an economically optimal feed mixture cost of 148.6 DKK per 100 FUpig, composed of approximately 40% rye, 39% barley, 10% rapeseed meal, 7.5% soybean meal, and 1% soybean oil satisfying the oil requirement. The rye and soy products originated from Europe and South America, respectively, while the barley and rapeseed meal originated from a mix between North America and Denmark. Applying the noLUC and dLUCb assessment methods resulted in a higher GWP impact at the economic optimum, with relatively lower GWP impacts observed at higher cost ranges when compared to the main results. Applying the dLUCa assessment method resulted in a consistently lower GWP impact relative to cost when compared to the main results, although minimal differences are observed at approximately 155 DKK per 100 FUpig. Applying the COC assessment method provided a consistent reduction in the GWP impact relative to cost, with a 25% reduction to the economical-optimal GWP impact possible with a 1% increase in cost. This indicates that, for certain applied LUC methods, the selection of a feed ingredient’s origin may enable a greater overall reduction in GWP, although possibly at greater cost. Ingredient changes relative to GWP impact changes for both ingredient sensitivity analyses are provided in the supplementary information (Online resource 1 & 2).

3.3.2 LUC assessment methods

Inclusion of the iLUC assessment method was performed identically to the other methods (see Sect. 2.2), i.e., by applying iLUC data acquired from the Bonsai database currently in development at Aalborg University (Schmidt et al. 2015, Aalborg University 2024). Figure 7 displays the relationship of cost, GWP impact, and ingredient changes for iLUC. The baseline feed mixture GWP impact was 88.1 kg CO2-eq per 100 FUpig, while the optimized impact at the same price point was 85.3 kg CO2-eq per 100 FUpig. This results in a 3.2% reduction when compared to the baseline, the lowest reduction achievable for all included LUC assessment methods. The optimized feed mixture at the baseline cost (152.2 DKK) contained 34% rye, 23% wheat, 15% barley, 10% rapeseed meal, 7.4% soybean meal, 6.7% oats, and 1% soybean oil content.

A Potted data collected from the optimized iLUC feed mixtures, displaying the GWP impact (y-axis) and cost in DKK per 100 FUpig (x-axis). The datapoints represent the optimal diet composition with the lowest cost at different ranges of maximally constrained GWP impact. B Changes in the composition of optimal feed mixture for iLUC relative to changes in GWP impact

To investigate potential correlations between methods, we included a second data collection exercise of GWP impacts across LUC assessment methods to investigate potential similarities (e.g., correlations) in results optimization. Figure 8 displays the relative change in GWP impact to the economic optimum (at 0%) and the GWP optimum (at − 100%), where + 100% indicates that the GWP impact has increased equal to the difference between the economic optimum and the GWP optimum. Optimizing for GWP impacts applying the noLUC assessment method resulted in relative GWP impact reductions for dLUCb and iLUC, with increased GWP impacts for dLUCa at high cost ranges. Optimizing for GWP impacts applying the dLUCa assessment method resulted in variable results depending on the method in question, and exhibited a 100% relative increase to iLUC at approximately 153 DKK per 100 FUpig, followed by a 50% relative decrease at 161 DKK per 100 FUpig. Optimizing for GWP impacts applying the dLUCb assessment method resulted in relatively linear reductions of GWP impacts when applying the noLUC and iLUC methods. Additionally, optimizing for dLUCb had no influence on COC and a variable influence on dLUCb depending on cost range. Surprisingly, optimizing for GWP impacts applying COC assessment methods resulted in suboptimal formulations with all other methods, plus a relative increase of GWP impacts to all other methods of approximately 40% at the cost point of 151 DKK per 100 FUpig. Optimizing for GWP impacts applying the iLUC assessment method varied depending on cost, although this method appears to result in a relative reduction compared to all other methods regarding GWP impact, with the exception of dLUCa at high cost range. In some cases, a non-linear relationship was observed through a GWP impact reduction at one point followed by an increase at another, which is likely explained by the introduction of a specific feed ingredient providing a mutual reduction in GWP impacts. The non-linearity may provide some insight into the best performing feed ingredients at specific price points across multiple methods. A prime example of this is the reduction of palm oil in favor of soybean oil, a change that is apparently beneficial across all applied LUC assessment methods.

Change in GWP impact across LUC assessment method optimizations. The title of each sub-figure indicates the chosen LUC assessment method for the calculation of GWP impacts that is subjected to maximization constraining. *The GWP impact of the economic-optimum feed mixture for the LUC assessment method of interest (i.e., that one reported in the titles of each sub-figure) is positioned at 0%, and the maximum reduction achieved indicated by the GWP optimum feed at − 100%

3.4 Implications of results and limitations

This study required handling multiple parameters that exhibit natural variations, many of which could not be investigated, mainly because of a lack of data combined with technical limitations. The feed ingredient cost is a key parameter with a substantial influence on the study’s results that could not be subjected to sensitivity analysis, a parameter well known to be a fluctuating variable. Inclusion of cost variations as a sensitivity scenario would have required the determination of local prices at a given time point and corrections for transport and storage. In practice, different feed mixtures can result in differences in growth rates for pigs (e.g., feed conversion ratios and growth rates), which requires large and expensive trials for performance validations that were not conducted to validate the performance of the hypothetical feed mixtures treated in this study. The LCA results and inventory data used for optimization are limited to average Danish production in 2021, and therefore represent a hypothetical improvement on the past. The results should not be used for any decision-support context, which would otherwise have required a consequential LCA. The findings provide further evidence that changes in pig feed may enable cost-effective reductions of the environmental impacts of pig production, although a key limitation of these results is that no evaluation was performed of the feed mixtures influence towards animal performance metrics (e.g., feed conversion ratios, growth rates). A key finding is the substantial influence of the applied LUC assessment method on the magnitude of reductions of GWP impacts, which are more pronounced when applying methods resulting in high LUC contributions. Applying the dLUCa assessment method resulted in the greatest reductions compared to the baseline of all the methods covered in this study, indicating that feed changes are likely to be a beneficial consideration when considering this assessment method. The achievable reduction may become apparent in future accounting studies through a growing awareness of feed suppliers, resulting in the avoidance of importing soybeans cultivated in recently deforested regions (DAKOFO 2021). It is important to consider the result differences between dLUCa and dLUCb should not influence the selection of one dLUC assessment method to another, but rather emphasize the need for further research and consensus of the specific dLUC assessment method to apply in agricultural LCAs. Although applying the COC assessment method resulted in lower-than-expected reductions when compared to the baseline, considering the broad range of the GWP impact for optimized feed mixtures for this LUC assessment method, the broad range of the COC assessment method indicates that greater reductions may be achievable for this method when considering a different baseline for comparison. However, we emphasize that the selection of LUC assessment methods should be aligned with the assessment’s goal and scope, as the inclusion of these methods provides additional answers in relation to a system’s GWP impact.

4 Conclusions

This study has provided an analysis of the environmental impacts of optimizing for cost and the GWP impacts of slaughter pig feed mixtures by applying multiple LUC assessment methods. Analysis of GWP and cost optima revealed that initial reductions of GWP impacts will be very cost-effective for non-optimized or cost-optimized feed mixtures, but costs will increase exponentially when approaching the lowest GWP impact feed mixtures (GWP-optima). The inclusion of GWP impacts in the cost optimizations of slaughter pig feed can provide a substantial GWP impact reduction at no additional cost, and we therefore encourage its inclusion in future feed formulation practices. Two LCAs were conducted for GWP optimized feed mixtures, generated at cost equal to the average feed mixture in Denmark that additionally served at the baseline for LCA comparison. The two LCAs compared the slaughter pig feed directly and the feed included in a pig’s life cycle. Depending on the LUC assessment method in question, GWP impacts ranged from 5.6 to 27% for the feed unit and 2.4 to 13% for the pig’s life cycle when compared to the baseline. Limiting the environmental impact optimization to GWP alone may result in increases in the impacts of other impact categories, demonstrated in this study to be up to 56%. Despite the increase in other impact categories, the optimization of GWP impacts resulted in a reduction in endpoints and single-score environmental indicators. Although the results of this study suggest that GWP impact is a promising decision variable in environmental feed optimization, future feed optimization studies should consider the inclusion of multiple impact categories, or alternatively apply endpoint indicators. In addition to the findings, we emphasize that the choice of LUC assessment method should be defined on the basis of the LCA’s goal and scope, and therefore of the intended use of the results.

Data availability

Additional data can be made available at request to the corresponding author, with exception of confidential data from WinOpti and the developing pig LCA model applied in this study.

References

AgroVision (2024) WinOpti (Software/program), Version. 2023.1.8628.14970. https://www.agrovision.com/about-agrovision. Accessed 6 Aug 2024

Amon B, Hutchings N, Dämmgen U, Sommer S, Webb J (2019) Manure management. EMEP/EEA air pollutant emission inventory guidebook 2019. European Environmental Agency 1–40. https://www.eea.europa.eu/ds_resolveuid/8e90ca718fd34d5786c12c331aa7a262. Accessed 6 Aug 2024

Andreson-Teixeira KJ, DeLucia EH (2011) The greenhouse gas value of ecosystems. GCB 17:425–438

Azain MJ (2001) Chapter 6: fat in swine nutrition. Swine nutrition. In: Lewis AJ, Southern LL (eds) Florida, pp 95–107

Bennetzen EH, Smith P, Porter JR (2016) Agricultural production and greenhouse gas emissions from world regions—the major trends over 40 years. GEC 37:43–55

Bjørn A, Owsianiak M, Molin C, Laurent A (2018) Main characteristics of LCA. In: Hauschild MZ, Rosenbaum RK, Olsen SI (eds) Life Cycle Assessment: Theory and Practice. Springer International Publishing, Cham, pp 9–16

Blonk H, Marcelo T, van Paassen M, Braconi N, Draijer N, van Rijn J (2022) Agri-footprint 6 Methodology Report. https://blonksustainability.nl/tools-and-databases/agri-footprint#methodology. Accessed 23 May 2024

Bontinck PA, Grant TF, Sevenster M, Eady S, Crawford D (2020) Improving direct land use change calculations: an Australian case study. tIJoLCA 25:998–1012. https://doi.org/10.1007/s11367-020-01751-7

BSI (2012) PAS 2050: 2012 (standard). PAS 2050–1:2012. Assessment of life cycle greenhouse gas emissions from horticultural products

Carter S, Herold M, Avitabile V, de Bruin S, De Sy V, Kooistra L, Rufino MC (2018) Agriculture-driven deforestation in the tropics from 1990–2015: emissions, trends and uncertainties. ERL 13:014002

Cherubini F, Jungmeier G (2010) LCA of a biorefinery concept producing bioethanol, bioenergy, and chemicals from switchgrass. tIJoLCA 15:53–66. https://doi.org/10.1007/s11367-009-0124-2

CVB (2023) Booklet of feeding tables for pigs - nutrient requirements and feed ingredient composition for pigs. CVB-series no. 68. https://www.cvbdiervoeding.nl/pagina/10081/downloads.aspx. Accessed 6 Aug 2024

DAKOFO (2021) DAKOFO's arbejde med ansvarlig soja (Website, In Danish). DAKOFO. https://www.dakofo.dk/ansvarlig-soja/. Accessed 1 May 2024

De Sy V, Herold M, Achard F, Avitabile V, Baccini A, Carter S, Clevers JGPW, Lindquist E, Pereira M, Verchot L (2019) Tropical deforestation drivers and associated carbon emission factors derived from remote sensing data. ERL 14:094022

Ehmsen SV (2023) Ingredient price list from Vestjyllands Andel for 2021. Personal correspondance with Styrmir Gislason and Thomas Sønderby Bruun

European Commission (2010) International reference life cycle data system (ILCD) handbook - general guide for life cycle assessment - detailed guidance. Publications Office of the European Union, Luxembourg

European Commission (2020) Impact assessment on the communication stepping up Europe’s 2030 climate ambition investing in a climate-neutral future for the benefit of our people. European Commission. Report number: EUR-lex 52020SC0177. https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:52020SC0177. Accessed 6 Aug 2024

Energistyrelsen (2020) Dansk klimapolitik. (Website) ENS. Law information (lov nr.965, 26/06/2020). https://ens.dk/ansvarsomraader/energi-klimapolitik/fakta-om-dansk-energi-klimapolitik/dansk-klimapolitik. Accessed 10 Mar 2024

FAO (2022) FAOSTAT (Database). Food and Agriculture Organization of the United Nations. Rome. https://www.fao.org/faostat/. Accessed 10 Nov 2023

FAO (2023a) Food and Agriculture Organization of the United Nations – with major processing by Our World in Data. Daily supply of protein from vegetal products. Food and Agriculture Organization of the United Nations, Food Balances: Food Balances (-2013, old methodology and population); Food and Agriculture Organization of the United Nations, Food Balances: Food Balances (2010-) [original data]. https://ourworldindata.org/grapher/per-capita-sources-of-protein?country=OWID_WRL~DNK. Accessed 5 Mar 2024

FAO (2023b) Food and Agriculture Organization of the United Nations (2024) – with major processing by Our World in Data. Food and Agriculture Organization of the United Nations, Land, Inputs and Sustainability: Land Cover [original data]. https://ourworldindata.org/grapher/agricultural-land. Accessed 6 Aug 2024

FAO (2023c) Food and Agriculture Organization of the United Nations (2023) – with major processing by Our World in Data. Daily supply of protein from fish and seafood – FAO . Food and Agriculture Organization of the United Nations, Food Balances: Food Balances (-2013, old methodology and population); Food and Agriculture Organization of the United Nations, Food Balances: Food Balances (2010-) [original data]. https://ourworldindata.org/grapher/animal-protein-consumption?country=CHN~OWID_EU27. Accessed 5 Mar 2024

FAO (2024) Food and Agriculture Organization of the United Nations – with major processing by Our World in Data. Food and Agriculture Organization, AQUASTAT data. [original data]. https://data.worldbank.org/indicator/ER.H2O.FWAG.ZS. Accessed 10 Feb 2024

Gavrilova O, Leip A, Dong H, MacDonald JD, Bravo AB, Rosales RB, Prado AD, de Lima MA, Oyhantçabal W, van der Weerden TJ, Widiawati Y (2019) Emissions from livestock and manure management. 2019 Refinement to the 2006 IPCC Guidelines for National Greenhouse Gas Inventories 10.11–10.168. https://www.ipcc-nggip.iges.or.jp/public/2019rf/pdf/4_Volume4/19R_V4_Ch10_Livestock.pdf. Accessed 6 Aug 2024

GHG Protocol (2022) Land sector and removals guidance - Part1: accounting and reporting requirements and guidance – draft for pilot testing and review (September 2022). Land sector and removals guidance. Greenhouse Gas Protocol. https://ghgprotocol.org/sites/default/files/2022-12/Land-Sector-and-Removals-Guidance-Pilot-Testing-and-Review-Draft-Part-1.pdf. Accessed 25 Mar 2024

Gislason S, Birkved M, Maresca A (2023) A systematic literature review of life-cycle assessments on primary pig production: impacts, comparisons, and mitigation areas. SPC 42:44–62

Green Delta (2023) OpenLCA (Software/program) Version 2.0.3. https://www.openlca.org/. Accessed 6 Aug 2024

Hansen C (2021) Notat 2115 - Landsgennemsnit for produktivet i produktionen af grise i 2020. 2115, SEGES Innovation P/S. https://svineproduktion.dk/-/media/PDF---Publikationer/Notater-2021/Notat_2115.pdf. Accessed 6 Aug 2024

Hauschild MZ, Huijbregts MAJ (2015) Introducing life cycle impact assessment. In: Hauschild MZ, Huijbregts MAJ (eds) Life Cycle Impact Assessment. Springer, Netherlands, Dordrecht, pp 1–16

Huijbregts MAJ, Steinmann ZJN, Elshout PMF, Stam G, Verones F, Vieira MDM, Hollander A, Zijp M, van Zelm R (2016) ReCiPe 2016 - a harmonized life cycle impact assessment method at midpoint and endpoint level Report I: Characterization. 2016–010, National Institute for Public Health and the Environment. https://www.rivm.nl/bibliotheek/rapporten/2016-0104.pdf. Accessed 6 Aug 2024

Hutchings N, Webb J, Amon B, Dämmgen U, Hinz T, Hoek KVD, Steinbrecher R, Dore C, Wiltshire J, Jiménez BS, Haenel H-D, Rösemann C, Misselbrook T, Hayashi K, Freibauer A, Cellier P, Butterbach-Bahl K, Sutton M, Skiba U, Kroeze C, Pain B, Winiwarter W, Bonazzi G, Svedinger I, Simpson D, Gyldenkærne S, Albrektsen R, Mikkelsen MH (2023) 3.D Agricultural soils 2023. Page 51 EMEP/EEA air pollutant emission inventory guidebook 2023. Euro Environ Agency

ISO (2006a) ISO 14040:2006 (Standard)- Environmental management life cycle assessment principles and framework. ICS: 13.020.10 13.020.60

ISO (2006b) ISO 14044:2006 (Standard)- Environmental management life cycle assessment requirements and guidelines. ICS: 13.020.10 13.020.60

Kebreab E, Liedke A, Caro D, Deimling S, Binder M, Finkbeiner M (2016) Environmental impact of using specialty feed ingredients in swine and poultry production: a life cycle assessment. JoAS 94:2664–2681

Knudsen MT, Dorca-Preda T, Djomo SN, Peña N, Padel S, Smith LG, Zollitsch W, Hörtenhuber S, Hermansen JE (2019) The importance of including soil carbon changes, ecotoxicity and biodiversity impacts in environmental life cycle assessments of organic and conventional milk in Western Europe. JoCP 215:433–443

Landbrug & Fødevarer (2024) Smågrispriser (Online database). https://svineproduktion.dk/Viden/Paa-kontoret/Oekonomi_ledelse/Beregningsvaerktoejer/Beregn_smaagrisepris. Accessed 18 Mar 2024

Landbrug & Fødevarer (2019) Råvarer (Webpage). https://svineproduktion.dk/viden/i-stalden/foder/indhold_foder/raavarer. Accessed 20 Nov 2023

Lewis AJ, Southern LL (2001) Protein supplements. Swine Nutrition. In: Lewis AJ, Southern LL (eds) Florida, pp 803–838

Mateo-Sagasta J, Zadeh SM, Turral H (2017) Water pollution from agriculture: a global review - executive summary. FAO, Rome

Mérieux NutriSciences | Blonk (2023) Agri-footprint (Database), Version. 6.3. Single user educational for OpenLCA. https://blonksustainability.nl/tools-and-databases/agri-footprint. Accessed 25 Apr 2024

Mérieux NutriSciences | Blonk (2024) Agri-footprint information (Website). https://blonksustainability.nl/tools/agri-footprint. Accessed 25 Apr 2024

Meul M, Ginneberge C, Van Middelaar CE, de Boer IJM, Fremaut D, Haesaert G (2012) Carbon footprint of five pig diets using three land use change accounting methods. LS 149:215–223. https://doi.org/10.1016/j.livsci.2012.07.012

National Research Council (2012) Nutrient requirements of swine: eleventh, revised. The National Academies Press, Washington, DC

Nielsen O-K, Plejdrup MS, Winther M, Nielsen M, Gyldenkærne S, Mikkelsen MH, Albrektsen R, Hjelgaard K, Fauser P, Bruun HG, Levin L, Callisen LWA, Johannsen VK, Nord-Larsen T, Vesterdal L, Scott-Bentsen N, Rasmussen E, Petersen SB, Baunbæk L, Hansen MG (2023) Denmark’s national inventory report 2023: emission inventories 1990–2021 – submitted under the United Nations framework convention on climate change 541. https://dce2.au.dk/pub/SR541.pdf. Accessed 6 Aug 2024

Nielsen O-K, Plejdrup MS, Winther M, Nielsen M, Gyldenkærne S, Mikkelsen MH, Albrektsen R, Thomsen M, Hjelgaard K, Fauser P, Bruun HG, Johannsen VK, Nord-Larsen T, Vesterdal L, Stupak I, Scott-Bentsen N, Rasmussen E, Petersen SB, Baunbæk L, Hansen MG (2022) Denmark’s national inventory report: emission inventories 1990–2020 – submitted under the United Nations framework convention on climate change 494. http://dce2.au.dk/pub/SR494.pdf. Accessed 6 Aug 2024

Pendrill F, Persson UM, Godar J, Kastner T, Moran D, Schmidt S, Wood R (2019) Agricultural and forestry trade drives large share of tropical deforestation emissions. GEC 56:1–10. https://doi.org/10.1016/j.gloenvcha.2019.03.002

Persson UM, Henders S, Cederberg C (2014) A method for calculating a land-use change carbon footprint (LUC-CFP) for agricultural commodities – applications to Brazilian beef and soy, Indonesian palm oil. GCB 20:3482–3491

Rosa IMD, Ahmed SE, Ewers RM (2014) The transparency, reliability and utility of tropical rainforest land-use and land-cover change models. GCB 20:1707–1722

Sauber TE, Owens FN (2001) Cereal grains and by-products for swine. Swine Nutrition. In: Lewis AJ, Southern LL (eds) Florida

Schmidt JH, Weidema BP, Brandão M (2015) A framework for modelling indirect land use changes in life cycle assessment. JoCP 99:230–238

Searchinger TD, Wirsenius S, Beringer T, Dumas P (2018) Assessing the efficiency of changes in land use for mitigating climate change. Nature 564:249–253

Singh C, Persson M (2024) Global paterns of commodity-driven deforestation and associated carbon emissions. Submitted to EarthArXiv and under review (as of 23rd of May 2024). https://doi.org/10.31223/X5T69B

Sørensen MT, Tybirk P, Krogh UP, Hellwing ALFB (2023) Næringsstofudskillelse fra svin, ab dyr i gødningsåret 2023/2024. Aarhus University 1–35. https://anivet.au.dk/forskning/sektioner/husdyrernaering-og-fysiologi/normtal. Accessed 6 Aug 2024

Stark CR (2012) Feed processing to maximize feed efficiency. In: Patience JF (ed) Feed efficiency in swine. Wageningen Academic Publishers, Wageningen. https://doi.org/10.3920/978-90-8686-756-1_6

Tybirk P, Strathe NAB, Vils E, Sloth M (2006) Det danske fodervurderingssystem til svinefoder. Report number 30. Dansk Landbrugsrådgivning and Dansk Svineproduktion 1–78. https://svineproduktion.dk/publikationer/kilder/lu_rapporter/30. Accessed 6 Aug 2024

Tybirk P (2022) Notat 2213 - Klimaaftryk for typisk foder til søer, smågriser og slagtegriser. SEGES Innovation P/S

van Zanten HHE, Bikker P, Meerburg BG, de Boer IJM (2018) Attributional versus consequential life cycle assessment and feed optimization: alternative protein sources in pig diets. tIJoLCA 23:1–11. https://doi.org/10.1016/j.spc.2021.03.028

Weidema B (2014) Has ISO 14040/44 failed its role as a standard for life cycle assessment? JoIE 18:324–326. https://doi.org/10.1111/jiec.12139

Wirsenius S (2024) Unpublished dataset. Chalmers Institude of Technology

Woltjer G, Daioglou V, Elbersen B, Ibañez GB, Smeets E, González DSB (2017) Study report on reporting requirements on biofuels and bioliquids stemming from the directive (EU) 2015/1513. 2015/151. https://energy.ec.europa.eu/system/files/2017-10/20170816_iluc_finalstudyreport_0.pdf. Accessed 6 Aug 2024

Acknowledgements

The authors wish to express their sincere gratitude to the Innovation Fund Denmark, the Otto Mønsted Fund, and the Augustinus Fund for providing the support and funding that made this project and study a reality. In addition, we want to thank Dr. Robert Parkin for his valuable contribution to improve the written language of this paper.

Funding

Open access funding provided by University of Southern Denmark This research is part of an industrial PhD project funded by the SEGES Innovation and Innovation Fund Denmark (grant number: 1044-00035B). The University of Southern Denmark, SEGES Innovation, and Chalmers University of Technology have contributed to the study design, data collection and analysis, the decision to publish, and the preparation of the manuscript in accordance with the author list. Additional funding was obtained from the Otto Mønsted Fund (23–70-2013) and the Augustinus Fund (23–2575) to cover the expenses of the external research trip.

Author information

Authors and Affiliations

Contributions

Conceptualization: Styrmir Gislason, Alberto Maresca, Finn Udesen. Methodology: Styrmir Gislason, Alberto Maresca, Stefan Wirsenius, Morten Birkved, Finn Udesen. Data curation and software: Styrmir Gislason, Thomas Sønderby Bruun. Formal analysis and investigation: Styrmir Gislason, Thomas Sønderby Bruun, Stefan Wirsenius, Chandrakant Singh. Writing—original draft preparation: Styrmir Gislason, Alberto Maresca. Writing—review and editing: Alberto Maresca, Morten Birkved, Styrmir Gislason, Stefan Wirsenius, Thomas Sønderby Bruun, Chandrakant Singh, Finn Udesen. Funding acquisition: Styrmir Gislason, Finn Udesen, Morten Birkved, Alberto Maresca. Resources: Stefan Wirsenius, Chandrakant Singh, Thomas Sønderby Bruun, Finn Udesen. Supervision: Alberto Maresca, Stefan Wirsenius, Morten Birkved.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Communicated by Brad G. Ridoutt.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Gislason, S., Bruun, T.S., Wirsenius, S. et al. How methods to assess land-use changes influence the resulting global warming potential and cost of optimized diets: a case study on Danish pigs applying life cycle assessment methodology. Int J Life Cycle Assess (2024). https://doi.org/10.1007/s11367-024-02356-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11367-024-02356-0