Abstract

There have been several strategies developed to increase the diversified supply of energy so that it can meet all of the future demands for energy. As a result, to ensure a healthy and sustainable energy future, it is imperative to warrant reliable and diverse energy supply sources if the “green energy economy” is to be realized. The purpose of developing and deploying clean energy technologies is to improve our overall energy security, reduce our carbon footprint, and ensure that the generation of energy is secure and reliable in the future, making sure that we can spur economic growth in the future. In this paper, advancements in alternative sources of energy sustainability and strategies will be examined to ensure there will be enough fuel to supply all the future demands for energy. Several emerging clean energy technologies rely heavily on the availability of materials that exhibit unique properties that are necessary for their development. This paper examines the roles that rare earth and other energy-critical materials play in securing a clean energy economy and the development of clean energy economies in general. For the development of these technologies to be successful and sustainable, a number of these energy-critical materials are at risk of becoming unavailable. This is due to their limited availability, disruptions in supply, and a lack of suitable resources for their development. An action plan focusing on producing energy-critical materials in energy-efficient ways is discussed as part of an initiative to advance the development of clean and sustainable energy.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The 27th Conference of the Parties (COP27) to the United Nations Framework Convention on Climate Change indeed plays a crucial role in shaping and implementing international climate agreements, including the Paris Agreement. The primary objective of the COP meetings is to bring together representatives from member countries to discuss, negotiate, and make decisions on global climate change issues. At the COP meetings, member countries share their progress in reducing greenhouse gas emissions, discuss adaptation strategies, address financing for climate action, and explore ways to enhance international cooperation on climate change. The COP serves as a platform for countries to collaborate, exchange knowledge, and make commitments towards a sustainable and low-carbon future (Zielinski 2023). The Paris Agreement, which was adopted at COP21 in 2015, is one of the key international agreements aimed at combatting climate change. It sets the goal of limiting global temperature rise to well below 2 °C above pre-industrial levels and pursuing efforts to limit it to 1.5 °C. COP27 will continue the efforts to advance the implementation of the Paris Agreement and drive global actions to address the urgent challenges of climate change (Das and Ghosh 2023).

A decarbonization of the energy sector is now a prerequisite for reducing global warming to 1.5 °C and achieving net zero carbon emissions by the year 2050 (Waisman et al. 2019). This is an essential measure that must be implemented to achieve the Paris Agreement’s objective of reducing the global average temperature (Schleussner et al. 2016). In recent years, with the increasing demand for energy and the requirement to reduce our dependence on fossil fuels, there has been an increase in the amount of research being done into new sources of renewable energy and better ways of producing, storing, transmitting, and conserving energy for a variety of uses. With technological advancement, the transition from fossil fuels to renewable energy sources has been significantly accelerated over the past decade (Golroudbary et al. 2022). Several technological advances have allowed researchers to identify energy-critical elements that can be tailored precisely to their specific needs, and then employ them in novel energy technologies to meet energy demands. To scale up the use of modern green technologies and advanced technologies, there is an increase in demand for energy-critical materials. Because of their crucial role in preserving the environment, there are essential factors that must be considered for their applications and uses (Molina-Calderón et al. 2022).

Green technology is being put into research to develop advanced renewable energy sources and reduce the carbon footprint of our planet in an efficient way. It is likely that recycling technology would be one of the most promising aspects of addressing both economic and environmental issues, given their economic importance in comparison to environmental issues (Jyothi 2020). Further, recycling energy-critical materials from scrap has recently attracted a lot of attention. This is because of increased concern about the risks associated with the supply chain for energy-critical materials. There have been several monographs published regarding the use of energy-critical recycling methods from the viewpoints of physical separation, hydrometallurgy, and pyrometallurgy, as well as their applications to magnets, phosphors, batteries, polishing powders, and so forth (Tanaka et al. 2013; Rademaker et al. 2013; Swain and Mishra 2019; Molina-Calderón et al. 2022).

There are many rare earth metals and other materials, categorized under energy-critical elements, that are valued due to their unique properties, like their magnetic and catalyst properties, as well as their optical, electrical, physical, and chemical properties, which are used in many types of clean energy technologies, such as energy generation, transmission, and storage (Balaram 2019). Several energy-critical elements, including rare earth metals and other materials, are currently being developed and deployed in the evolving clean energy economy in a bid to support the transition from fossil fuels to renewable energy sources (Laznicka 2010). These materials are of significant value due to their unique properties. To realize the full potential of clean energy technologies for the circular economy, such as energy generation, transmission, and storage, their potential applications are expected to grow at a faster rate than anticipated (Pell et al. 2021).

As shown in Table 1, many clean energy production technologies require several energy-critical elements, which are listed with their extensive uses in the table (Price 2011; Hurd et al. 2012; Dutta et al. 2016). Nevertheless, it should be noted that this list of energy-critical elements for a truly green future is not exhaustive. The use of these elements is essential to the development of many high-tech devices today.

Several potential resources for the energy-critical elements are available in the form of discarded electronic devices, catalysts, magnets, tailings from mines, Bayer red mud, coal fly ash, and other types of industrial waste (Borra et al. 2015; Sishi et al. 2017; Rivera et al. 2018). This would allow for a more diverse and secure supply chain, enabling the development of a circular economy by recycling end-of-life consumer products and reprocessing industrial waste tailings in a sustainable way, helping to minimize the environmental impacts arising from the mining of energy-critical elements (Golev et al. 2014).

Many of these energy-critical elements are being produced from their own resources, while others, which are primarily by-products or co-products of minerals and ores, are often being produced from other sources through the processing of materials (Zocco et al. 2022). In recent years, there has been a significant increase in the use of these materials in magnets that are used in electric vehicles, wind turbines, and similar devices, as well as in their applications in producing energy efficient lighting and solar photovoltaic cell panels. They are also used in fuel cells, computer displays, gas turbines, cryogenics, and many other research applications (Fishman and Graedel 2019). Figure 1 reviews critical materials, including rare earth elements, and their application in clean technology.

Energy-critical materials including rare earth elements and their application in clean technologies (Jyothi et al. 2020)

The supply of many of these metals may be limited due to their limited availability. The reason for this is that these essential energy-critical elements are not currently being mined, processed, or traded in large quantities, which makes them scarce (Jyothi 2020). Thus, there is, however, a limit to their resources, which in turn disrupts their supply chain as a result.

Alternatively, some potential energy-critical elements cannot be extracted currently because their primary sources of minerals do not have the concentration to make extraction viable. As a result, energy-critical elements have to be obtained through other methods (Nieto and Zhang 2013). The development of sustainable and environmentally friendly processes and the sourcing of materials like used products after their end of life are of utmost importance. Especially when it comes to sourcing bulk raw materials and processing them into end-use applications to get to net carbon zero. As a result, the processes should work effectively and efficiently (Herrington 2021). In order to achieve net zero during the production stages of mining, processing, manufacturing, and recycling, a number of measures need to be taken. It is important to reduce the amount of carbon emissions produced during the above stages to reduce their environmental impact as much as possible (Wilson et al. 2014).

Rare earth and energy-critical elements are important components in a wide range of technologies, including renewable energy systems, electric vehicles, and electronics. However, traditional mining and processing of these elements can have significant environmental impacts, including soil and water contamination, air pollution, and the generation of large amounts of waste materials. To address these concerns, this study focusses on developing more environmentally sound methodologies for rare earth and energy-critical element extraction. Several processes can be used to extract energy-critical materials. These processes include pyrometallurgical routes, hydrometallurgical routes, electrometallurgical routes, and bio-metallurgical routes, as well as a combination of these routes (Martins et al. 2021).

One promising methodology is the use of bioleaching, a process that uses microbes to break down minerals that contain rare earth and energy-critical elements. This approach has been shown to be more environmentally friendly than traditional methods because it generates fewer waste materials and consumes less energy. In addition, some studies have suggested that bioleaching could be used to extract rare earths and energy-critical elements from discarded electronic devices, which would reduce the need for mining and extraction operations (Debnath et al. 2018).

Another potential method is the use of ionic liquids, which are salts that are liquid at room temperature. These liquids can be used to extract rare earth and energy-critical elements from ores and tailings without the use of harsh chemicals or high temperatures, which can reduce the environmental impact of the extraction process. However, ionic liquids are still a relatively new technology, and more research is needed to determine their effectiveness and potential environmental risks (Abbott et al. 2011; Wang et al. 2017).

Numerous vital energy-critical elements are derived from the refining of other important metals and minerals (Qi 2018). However, each route has to decide which is the most effective process or combination of processes, it is essential to examine each carefully. These stages need to be carefully designed to make the extraction process efficient utilizing the processes of recovery and recycling (Rao 2011). Many critical metals are extracted using secondary methods, so the environment doesn't get polluted (Xu et al. 2020). There is a lot of concern about raw materials and primary resources when it comes to recycling and recovery technology. Additionally, processing primary resources is getting more expensive. India, for example, has a wide variety of minerals and ores. Although these minerals and ores are low grade, they can contribute significantly to the supply of energy-critical metals we need for alternative clean energy sources (Balaram 2019).

To ensure that these methodologies are truly sustainable and environmentally sound, there are several environmental concerns that should be addressed. One major concern is the potential for unintended environmental consequences, such as the introduction of non-native microorganisms or the spread of pollutants. Additionally, the long-term environmental impact of these new methodologies needs to be carefully considered, including their effects on local ecosystems, water quality, and soil health. Finally, the social and economic impacts of rare earth and energy-critical element mining and processing need to be addressed to ensure that communities are not adversely affected by these activities. Altogether, while there are promising new technologies for environmentally sound rare earth and energy-critical element extraction, it is important that these methods are developed and implemented with careful consideration of their potential environmental impacts and long-term sustainability.

Several strategies can be employed to mitigate the effect of supply disruptions on valuable energy-critical elements evaluated in this monograph that have been shown to be effective in mitigating the impact of disruptions in supply chains. Since the supply chain is a closed loop system, scraps and waste materials can be redesigned, repurposed, recycled, and refabricated so that they are able to be reused and recycled in the reverse supply chain and circular economy strategy. There are many stages involved in the lifecycle of a rare earth’s products, for both primary and secondary sources, as shown in Fig. 2.

The use of recycling and circular economies as a means of reducing supply chain risks is considered to be a sustainable solution when it comes to supply chain risk reduction (Miao et al. 2022). This paper provides a brief analysis of advancements in the development of more sustainable sources of energy as well as strategies for ensuring their sustainability in the future. These strategies have been reviewed to ensure that they keep pace with emerging technologies. This is in order to ensure that they can be adapted in a sustainable manner to meet future energy needs. Also, it outlines recommendations from groups and governments around the world. There have been many studies undertaken in recent years that have looked into how to ensure that the use of clean energy technologies is used as a means of driving circular economies in the future (Habib and Wenzel 2014; Wang et al. 2020).

A literature gap has been identified in the assessment of energy strategies for the sustainable development of sources. As part of this research gap, we focus on generating novel insights into recycling potential based on geopolitical considerations. Comprehensive studies that provide detailed information on effective strategies are rare. It could be hard to develop sustainable solutions that consider the full life cycle of these elements, including extraction, processing, use, and disposal. It also hinders the development of policies and regulations that promote responsible sourcing and sustainable management. Similarly, there has not been much study of alternative materials and technologies that can act as substitutes or reduce reliance on energy-critical elements. In sustainable resource development, this gap could limit strategy identification and evaluation. By leveraging the existing knowledge base, we developed more robust strategies for the efficient use and management of energy-critical elements in this study. This is in the context of the development of sustainable energy sources.

The research problem of this article revolves around addressing the challenges and ensuring the availability and sustainable supply of critical elements essential for the development of sustainable energy sources. It encompasses the need to address the availability, potential scarcity, geopolitical risks, sustainability, supply chain resilience, environmental impacts, and social and economic implications associated with these rare earths and energy-critical elements. It also involves investigating substitute materials, developing recycling technologies, and exploring innovative approaches to reduce the reliance on energy-critical elements while maintaining the performance and viability of renewable energy technologies with sustainable energy sources. It aims to identify solutions and strategies to overcome challenges and ensure the long-term viability of sustainable energy sources.

To successfully manage the circular economy, a theoretical framework is based on a number of essential components, including assessment of the development and deployment of sustainable energy technologies, transition to sustainable and low-carbon energy sources, resource availability, and constraints, as well as developing strategies to deal with energy-critical elements. It would provide a comprehensive and interdisciplinary approach to understanding and evaluating the complex challenges and opportunities associated with the transition to sustainable energy sources.

The framework would draw on theories and concepts related to energy sustainability, renewable energy technologies, energy policy, and the environmental impacts of energy systems, and it would explore the availability, accessibility, and potential limitations of these elements for sustainable energy development. Further, the framework would address issues of policy coherence, international cooperation, stakeholder engagement, and the role of government, industry, and civil society in ensuring the sustainable supply of energy-critical elements, and it would examine how the strategies for energy-critical elements contribute to achieving these goals, considering aspects such as environmental sustainability, social equity, and economic viability.

The analysis in the assessment of the strategies necessary for the development of sustainable energy sources for the energy-critical and rare earth elements typically follows a logical flow, which can be organized into several key steps. Figure 3 shows the flow of analysis for the assessment of strategies for the development of sustainable energy sources for energy-critical and rare earth elements, which provides valuable insights and informs decision-making processes to ensure a sustainable and secure supply of these elements for the energy transition.

The sustainability of proposed methodologies depends on a variety of factors, including the specific technology being used, the local environment, and the social and economic impacts of the process; and must be evaluated on a case-by-case basis, taking into consideration environmental impact, long-term sustainability, and social and economic considerations. Sustainable methodologies should prioritize the reduction of environmental impacts, including greenhouse gas emissions, water and soil contamination, and waste generation. The proposed methodologies, such as bioleaching and the use of ionic liquids, have shown promise in reducing environmental impact compared to traditional processes. The other proposed methodologies, such as close-loop extraction systems, would allow for the recycling and reuse of extracted chemicals and minimize waste generation. Finally, the proposed methodologies should consider the social and economic impacts of the extraction process on local communities, including impacts on local economies, human health, and cultural heritage. It requires engagement and participation from local communities and stockholders in the development and implementation of new extraction methodologies.

The objective of this manuscript is to provide a comprehensive assessment of the challenges and opportunities related to rare earths and energy-critical elements for sustainable development of energy sources, assess the technological feasibility of recycling these elements from end-of-life products, and provide strategies to reduce the dependence on primary extraction and minimize waste. The novelty of the manuscript lies in its comprehensive and holistic approach by considering the entire life cycle of energy-critical elements, with an emphasis on exploring technological alternatives and strategies to reduce dependence on energy-critical elements. It goes beyond traditional approaches by investigating substitute materials, innovative technologies, and recycling methods. In this article, we examined the use of energy materials in developing clean energy sources to secure a clean energy economy. We also analyzed sustainable energy sources and initiatives to ensure their sustainability.

In this study, one of our aims was to study on rare earth element processing and alternative energy sources with a sustainable future. We focused on efforts that have been made in the last decades to find more environmentally friendly and sustainable means of extracting materials, including hydrometallurgy, to make the extraction and refining of these materials more sustainable in the long run. We also included the potential of using a bio-hydrometallurgy route involving bacteria to extract rare earth elements, which may provide a more sustainable alternative to traditional methods that involve the use of chemicals. The recycling of rare earths from discarded electronic waste and other products has also been a focus of this study to reduce the need for new mining operations to extract rare earths from them. These are the main achievements in this study, along with challenges and future directions.

Designing and developing supply chain risk mitigation strategies based on a rational approach

A supply chain for energy-critical elements is comprised of mining, liberation, separation, refining, alloying, and manufacturing processes, ultimately leading to the point where devices and component parts are manufactured. Global and local geopolitical events are causing current and future supply shortages of energy-critical elements, which pose a high risk of interruptions (Rademaker et al. 2013). The shortage of energy-critical metals can have a significant impact on entire supply chains as well as efforts to meet nations’ emission targets (Khatib 2012). As the use of these metals has many strategic applications, such as generators used in wind turbines, hard disc drives used in computer servers, permanent magnets in high-performance electric motors used in hybrid electric vehicles, and fluorescent lamps, for example (Habib and Wenzel 2014). Several applications are adversely affected by the supply risks of energy-critical metals (Ponomarov and Holcomb 2009; Sun 2022). Therefore, renewable energy sectors will be impacted by the availability of energy-critical materials, which will determine their growth. As of now, there are not many alternatives available to us (Gielen et al. 2019).

There are methods of obtaining valuable energy-critical metals from primary and secondary sources. Pyrometallurgy and hydrometallurgy are the most common techniques for extracting precious metals, among others. On the other hand, hydrometallurgical technologies are more controllable, precise, predictable, and environmentally friendly than pyrometallurgy. Hydrometallurgical processes involve the use of chemical leaching to extract valuable metals or minerals from the ore.

Various techniques are used to purify the leached solution. Several hydrometallurgical methods have been employed in order to separate, purify, and pre-concentrate the energy-critical metals from the aqueous solution. These methods include chemical precipitation, solvent extraction, adsorption, ion exchange, and the use of liquid membranes for the separation process (Jyothi et al. 2020). The fact that energy-critical materials play an important role in many technologies and have comparable properties makes it extremely difficult to distinguish them from each other as a result of their similarities (Bogart et al. 2015).

Hydrometallurgical routes offer several advantages over traditional pyrometallurgical processes. Following are the few advantages of hydrometallurgical routes: (1) Hydrometallurgical processes typically operate at lower temperatures and pressures than pyrometallurgical processes, resulting in lower energy consumption and operating costs. (2) Hydrometallurgical processes generate fewer emissions of greenhouse gases and other pollutants, making them more environmentally friendly. (3) Hydrometallurgical processes are often designed to selectively extract metals from ores and minerals, resulting in higher metal recoveries and purities. (4) Hydrometallurgical processes allow for greater control of process parameters, such as temperature, pressure, and chemical composition, resulting in more consistent product quality and better process control. (5) Hydrometallurgical processes generally involve fewer hazards than pyrometallurgical processes, making them safer for workers and the environment. (6) Hydrometallurgical processes can be used to treat complex ores that are difficult or impossible to process using pyrometallurgical methods. Thus, hydrometallurgical routes offer significant advantages in terms of energy efficiency, environmental impact, control, safety, making them an attractive option for metal extraction and refining.

Among the secondary sources of rare earths elements, spent permanent magnets are the most common type. Dysprosium (Dy) and neodymium (Nd) are two of the heavy rare earth elements that can be found in high-performance permanent magnets and in most electrical devices. Membrane-assisted liquid–liquid extraction has been demonstrated, and it has also been shown that neodymium, dysprosium, and praseodymium (Pr) can be selectively extracted from permanent magnets using membranes (Kim et al. 2015; Jyothi et al. 2020). Figure 4 illustrates (a) a typical hydrometallurgical route and (b) a hydrometallurgical method developed for recovering rare earth elements from NdFeB magnet scraps.

Industrial mass production of energy-critical materials is a remarkable example of how chemical precipitation and solvent extraction techniques have been widely used. In terms of its operation, the process can be characterized as being simple and economical to operate (Pereao et al. 2018). However, in spite of these advantages, chemical precipitation requires a lot of chemical-based products. It is not very selective, and often requires extra treatment to get rid of excess sludge. This increases the cost of treatment. Moreover, these sludges have a significant impact on the environment over a long period of time. Consequently, before a technological process can be implemented, there has to be a cost barrier that must be overcome, as well as environmental protection measures that need to be taken (Anastopoulos et al. 2016). Solvent extraction has also been shown to be a highly effective technique for the separation of energy-critical elements. This is due to their high degree of selectivity and extractability, which makes them an ideal method for separating these elements. Even though solvent extraction has been used for many decades to recover energy-critical metal ions from water, it does have a number of disadvantages, including the aqueous solubility of extractants, solvents, and modifiers (Pereao et al. 2018). There is also no economic rationale for solvent extraction to be applied in the case of dilute solutions containing metal ions. It is generally considered that this method of extraction is inefficient because the procedures are usually slow, require several equilibrium extractions steps, and require a large amount of solvent. It is imperative to note that these procedures require a significant amount of labor. This is one of the main reasons why extraction plants cost a lot to operate (Das and Das 2013).

Adsorption is an alternative method of recovering valuable metals from aqueous media, even from diluted solutions of these media. In this process, the target metal ion (adsorbate) is transferred from an aqueous phase to a solid phase (adsorbent) by mass transfer of the metal ion. Specifically, adsorption occurs at the interface between solids and liquids because of physical or chemical interactions. The regeneration of adsorbents plays an instrumental role in the cyclic process, especially in the case of expensive adsorbents used in cyclic processes.

As one of the most promising and widely applied processes within the hydrometallurgy industry, adsorption has become widely adopted due to its flexibility in design and operation, ease of use, high efficiency, low cost, wide applicability, insignificant secondary waste generation, and excellent performance when it comes to removing and recovering energy-critical metal ions. A significant advantage of using adsorbed metal ions is that it reduces or eliminates the need to use toxic and flammable solvents. In addition, it allows the solution to be applied to metal solutions with a wide range of pH and metal ion concentrations (Iftekhar et al. 2020; Chen et al. 2021). The majority of the adsorbent metal ions do have some disadvantages, such as low selectivity, a lower number of active surfaces for their mass, which results in a lower load capacity, slow kinetics, and difficulties in the regeneration of metals (Jyothi et al. 2020).

We should take note of the fact that tailings from rare earth mines are a valuable secondary source of rare earth elements. The fact that some industries produce higher amounts of tailings than others is well known due to the availability of poor-quality raw materials in some industries. Figure 5 illustrates the flowsheet for recovering energy-critical materials from the Bayan Obo tailings.

Diagram of the flowsheet for recovering critical materials from the Bayan Obo tailings (Zhang et al. 2014)

As a matter of fact, it can be predicted that nanotechnology will ultimately replace a number of critical materials, in many of the current applications. This is done by mimicking their properties and, in doing so, reducing the quantities of these critical materials that are currently required (Massari and Ruberti 2013). As an alternative to conventional methods of adsorption, nanotechnology could present a viable solution to overcome these drawbacks, as due to its nanometric size, nanomaterials can provide a larger surface area per unit mass, a significant number of active adsorption sites, a high capacity to adsorb, and a fast adsorption rate (Gómez-Pastora et al. 2014). It can be concluded that functionalization of these nanomaterials increases the performance and selectivity of species adsorption, which is a very positive development. The application of this technique has also been considerably challenging on a large scale; however, functionalization options have made it possible to synthesize different engineered nanoadsorbent materials that have potential application to various industrial sectors, including medical, environmental, and industrial fields (Mohammed et al. 2017). The synthesis, functionalization, and characterization of several synthetic and functionalized magnetic nanomaterials have been conducted recently to evaluate their potential as innovative adsorbents for recovering, separating, pre-concentrating, and removing energy-critical ions from aqueous media in order to evaluate their potential as adsorbents (Condomitti et al. 2012). Most of these studies have been conducted in laboratories using aqueous solutions in order to evaluate the adsorption performance of magnetic nanoadsorbents for energy-critical elements.

Most of these studies have been carried out in order to evaluate the adsorption performance of these nanoadsorbents in aqueous solutions (Condomitti et al. 2012; Toma 2015). This revolutionary concept is being implemented using magnetic nano-hydrometallurgy technology, which is used to extract and recover strategic metal ions in a cost-effective and effective manner (Condomitti et al. 2012, 2018; Almeida and Toma 2016). The magnetic properties of nanoadsorbent, the colloidal stability, and the chemical composition of nanoabsorbent all contribute to the optimal performance of the adsorption process. This is the reason why state-of-the-art technology is necessary to design such a significant magnetic nanoadsorbent with superior characteristics.

In recent years, there have been a variety of organizations that have emerged. These organizations have moved forward with strategies that are centered on separation, recycling, recovery, and reusing the resources that we have at our disposal (Fujita et al. 2022). Designing and developing sustainable processes for recycling and reusing energy-critical materials, such as rare earth metals, that come from the use of used products has become a long-term challenge. A systematic approach to experimentation is required at all stages of the process in order to achieve this goal (Binnemans et al. 2013).

In the process of developing environmentally friendly and economically feasible processes and technologies, a number of studies have been carried out which have focused on the recycling and reusing of specific resources that need to be addressed in order to develop environmentally friendly and economically viable solutions. Using an innovative recycling process, valuable elements from scrap or unused end products can be recovered without requiring any mining operations (Rademaker et al. 2013; Fujita et al. 2022). A detailed investigation carried out by Pradip and Fuerstenau (2013) with the use of Hallimond tube microflotation experiments, bench scale flotation experiments with a laboratory Denver flotation cell, and predesigned plant campaigns was conducted in order to differentiate the surface chemistry involved in bastnaesite from the gangue minerals that are present in the ore (Pradip and Fuerstenau 2013). There are several processes that have been developed over the course of the past few decades to separate rare earths and transition metals from secondary resources. Those processes were summarized by Swain and Mishra (Swain and Mishra 2019). Therefore, a compelling need exists to ensure that access to energy-critical elements is ensured in order to develop resilient, indigenous supply chains of energy and clean energy technologies for strategic purposes in order to meet the needs of the global population and ensure a sustainable future.

Materials substitution as a secondary source

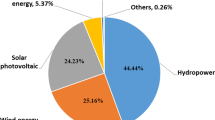

Among a variety of green energy technologies, there are automatic transmission systems for electric vehicles, as well as permanent magnets used in wind farms that are used to generate electricity. It is widely accepted that the most prevalent and widespread forms of renewable energy include hydropower, wind power, and other forms of information and communication. In order to develop these technologies, strong magnets with high coercivity are needed. This, in turn, requires materials with a high degree of magnetic anisotropy. It is due to the fact that rare earth elements exhibit high anisotropy that they are in high demand, so their supply is limited. In addition, new material selections that include cheaper elements such as iron and cobalt alloys are also increasing in popularity. Such selections are in high demand because they are available at an affordable price. Increasing power output and size reductions in electronic devices have created novel challenges for material selection. Under the stringent requirements of the environment and the circular economy, creating low-cost and high-performance materials with desirable properties is the need of the hour. The purpose of this section is to discuss topics related to the understanding of thermal resistance in materials, including nanophotonic materials for use in power generation, as well as novel opportunities for the management and conversion of thermal energy (McSherry et al. 2022).

Polymeric materials’ low cost and superior processability have led to their rise in prominence in recent years (Can-Ortiz et al. 2021). However, thermal insulation is not a strength of polymers, as their thermal conductivity is only 0.1 to 0.5 Wm−1 K−1. It is possible to increase the thermal conductivity of a polymer by introducing fillers with a high thermal conductivity, such as aluminum oxide, aluminum nitride, boron nitride, silicon nitride, beryllium oxide, or diamond (Enlow et al. 1999; Tanaka et al. 2012).

When making composites with high thermal conductivity, using hybrid fillers with a variety of shapes, sizes, and size distributions is beneficial, since it helps to achieve a low percolation threshold and increases filler packing density. The thermal conductivity of a composite cannot be attributed to a single factor without considering all of its other properties. Filler size has been discovered to have a surprising effect on the heat conductivity of polymer composites at a given loading. Thermal interface materials, often made of polymers, play an important role in the current electronic industry as composite materials. Interfacial thermal transfer between the fillers and the polymer phase is critical to the thermal transport performance of composites, regardless of whether the fillers are metals, ceramics, or carbon-based materials.

Thermal contact resistance (TCR) is frequently neglected during the production and quality assurance of thermally conductive composites. It is unclear which of the several factors at interfaces—such as interfacial bonding strength and vibration mismatch between materials—has the greatest impact on TCR (Hung et al. 2016; Sun et al. 2019). The development of heat-resistant shielding for the fastest-ever hypersonic space vehicles is made possible by the discovery that tantalum carbide (TaC) and hafnium carbide (HfC) materials can tolerate temperatures of approximately 4000 °C.

It was determined that the melting point of the combined compound (TaO.8HfO.20C) was 3905 °C. Temperatures of 3768 °C were required for the melting of the TaC compound, while those of 3958 °C were necessary for the melting of HfC. Incorporating thermal resistance material into the pavement design is a key part of the thermal resistance recommendation for cooling the surface. Ceramics, pottery sand, diatomite, bauxite, and refractory stone are all examples of materials with high thermal resistance. The ceramic material blend has the potential to bring the temperature down by 2–4 °C. As the amount of thermal material added to an asphalt mixture grows, the mixture's thermal conductivity drops. Ceramic (CE) mixtures have lower heat conductivity than floating beads (FB) combinations at the same admixture level, given that both mixtures have the same total volume. The beam bending test was used to determine the effectiveness of various CE and FB additions in preventing cracking at low temperatures, as shown in Fig. 6. There should be less than a one-to-one ratio of materials with different thermal resistances in the mixture (Wang et al. 2021).

High-temperature performance and durability can be improved with the use of in-situ and ex-situ synthesized zeolites that are thermally stable. Figure 7 the illustrates high-temperature behavior of geopolymer derived from coal fly ash. Materials with zeolite-like product contents between 2.5 and 10% wt.% exhibited favorable fire resistance. Increases in aluminum content improve zeolites' thermodynamic stability, which is in turn dependent on the strength of the Si–O (Si-silicon) and Al-O (Al-aluminum), bonds present in the material. Zeolites lose their Si–O-Si bonds when heated, and this is especially possible in the porous and channelled regions. The high-temperature exposure is beneficial because it shortens the bond length of Si–O-Si and Si–O-Al, thereby increasing van der Waals forces (Klima et al. 2022). Almost all the fly ash consists of a similar composition of rare earth elements, with light rare earth elements dominating the composition. It appears, however, that it has attracted ever-increasing attention in recent years. The process of extracting rare earth elements from fly ash is less intensive than the process of mining rare earth materials. Further, coal fly ash consists of a full spectrum of rare earth elements, which are very rare to be found in most mines. In addition, coal fly ash is an excellent source of phosphorus, iron, and nickel. In order to reduce the environmental impact of rare earth mining methods, it is necessary to explore methods that can be used for the extraction of rare earth from coal fly ash, so as to provide an economic and environmentally friendly alternative to traditional mining methods and reduce the environmental impact (Franus et al. 2014; Taggart et al. 2016).

Schematic depicting the high-temperature behavior of geopolymers derived from fly ash. Each parameter’s optimal operating temperature is indicated by the direction of the arrows (Klima et al. 2022)

Energy security, sustainable development, and environment

Energy security is becoming a more significant issue at a time when the energy transition is gathering more and more momentum (Humphries 2010). In order to keep pace with the rapid rate at which demand is growing, it is imperative to continue to invest in energy-critical mineral supplies. This will enable us to satisfy the growing demand. In this way, a rapid and orderly transition to new energy sources will be ensured. This puts the security of energy-critical materials at the center of the energy transition (Humphries 2010; Kiggins 2015). To achieve energy security and sustainable development, there is a need to ensure that energy-critical materials are available from new and diversified resources. The development of economically viable methods for their processing, however, remains the major challenge that faces these energy-critical industries. This is due to the requirement for permanent infrastructure, which is expensive and difficult to construct. A significant aspect of the processing and mining of rare earth metals is that they present serious environmental concerns. This is because such processing involves hazardous radioactive products, toxic chemical compounds, and water pollution. It is also very significant when it comes to environmental protection that the issues of energy-critical element substitutes, and recycling should be addressed in a timely manner. In the long run, the environmental protection practices associated with the processing and use of energy will bring substantial long-term financial benefits to the economy. Therefore, to realize the vision of clean energy and a circular economy, these critical resources are crucial to the ecosystem (Humphries 2010; Hurd et al. 2012). Several countries are intensifying their efforts to recover energy-critical elements to meet domestic demands and recycle high-tech waste, especially used electronics like cell phones and computers (Binnemans et al. 2013). Many countries are working on improving resource efficiency to achieve carbon neutrality targets. For example, Finland has set ambitious goals to become carbon neutral by 2035, and these technologies are essential for reducing greenhouse gas emissions and promoting sustainable practices across various sectors. Finland has been a pioneer in promoting circular economy principles (Alola and Adebayo 2023). Many European countries, including Spain, are achieving a decarbonized economy using renewable energy sources with technological innovation, which leads to a decrease in carbon emissions and a reduction in environmental degradation (Zang et al. 2023).

Adebayo et al. (2023) analyzed the co-movement between CO2 emissions and disaggregated non-renewable and renewable energy consumption in the BRICS (Brazil, Russia, India, China, and South Africa) using wavelet coherence, which involves applying a specific methodology to examine the relationship between these variables across different time scales. The insights into their relationship at different time scales are needed to enhance the understanding of the co-movements between CO2 emissions and energy consumption variables (Adebayo et al. 2023).

Technologies like recycling, waste-to-energy conversion, and industrial symbiosis enable the efficient use of resources and minimize environmental impacts. These technologies contribute to reducing greenhouse gas emissions associated with resource extraction, production, and disposal. Using digital technologies and innovation plays a significant role in enhancing resource efficiency and reducing carbon emissions. Advanced data analytics, Internet of Things (IoT) devices, and artificial intelligence (AI) enable the optimization of energy systems, smart grids, and industrial processes. These technologies help identify energy-saving opportunities, reduce waste, and improve overall efficiency. By embracing these technologies, Finland can transition towards a more sustainable and low-carbon economy while minimizing environmental impacts and promoting a greener future (Alola and Onifade 2022).

It is estimated that only a small percentage of energy-critical materials are recycled at present in a formal way, and therefore, many of these resources are not being exploited to their full potential (Pradhan et al. 2022). According to data from several studies, it was found that the recovery of energy-critical elements from nickel-metal (Ni-MH) hydride spent batteries was not at all difficult (Rodrigues and Mansur 2010). It is difficult to economically recover energy-critical materials by existing processes. Li et al. (2009) and Gasser and Aly (2013) (Li et al. 2009; Gasser and Aly 2013) used unique methods to separate and recover rare earth elements from spent nickel metal hydride batteries by hydrometallurgical processes, as illustrated in Fig. 8. Researchers have developed a procedure that uses 2.25 kg/m3 of RECl3 (60% Nd and 40% La) to separate and recover Nd2O3 and LaCl3 with a considerable amount of efficiency. As the main step in this process, 0.1 g of LDH-Cyanex 272 is used for 10 mL of RECl3 solution, which represents a key part of the process. It is then processed by diluting HCl (0.01 mol/L) in the aliquot to separate out the LaCl3 from the resulting aliquot. The filtrate solution is then treated with oxalic acid so that Nd2O3 can be recovered from the filtrate solution (Gasser and Aly 2013).

It is also reported that hydrometallurgical methods can be used to recover base metals (nickel, cobalt, and rare earth elements) from spent NiMH batteries. As the first method for the recovery of rare earth elements after the sulfuric acid leaching process was investigated in this study, the extraction process involved two stages. Leaching of spent batteries involves the treatment of spent batteries with NaOH followed by an acid solution (1 mol/L HCl) in order to obtain the RECl3 concentrate. Second, the leached solution is processed using Cyanex 272 for base-metal separation in the second stage of the process. There is a second stage operation where enriched rare-earth liquor is looped with the first stage operation in order to enrich the concentration of rare-earth elements (Li et al. 2009). During the last few years, there have been a number of scientific contributions, primarily from Japan, that suggest methods of obtaining energy-critical metals efficiently from wastes and sludges.

Hydrometallurgical processes for recovering rare earth elements from spent fluorescent lamps are being investigated. In Rabah’s (2008) study, he recovered europium, yttrium metals, oxides, or some salts of value from the powder coating of the inner surface of the glass tubes used in fluorescent lamps. The economic analysis of the proposed method revealed that it was likely to be feasible for industrial applications (Rabah 2008). Figure 9 illustrates the hydrometallurgical recovery method of rare earth elements from fluorescent lamp waste.

Using sulfuric acid digestion to extract rare earth metals from xenotime concentrate, Vijayalakshmi et al. (2001) outlined a technique that can be used to recover rare earth metals from xenotime concentrate. It was estimated that over 98% of the metal values had been dissolved. As a result of ammonia precipitation, it was possible to precipitate lighter rare earths, while thorium was precipitated preferentially (Vijayalakshmi et al. 2001). As a result of hydrometallurgical methods, it is possible to recover two rare earth elements from spent fluorescent lamps. These elements are europium and yttrium. An overview of the flowsheet developed in this study can be found in Fig. 9. Rabah (2008) found that the spent fluorescent lamps (SFLs) contained 61.52 wt.% orthophosphate and 34.48 wt.% calcium sulphate, as well as other calcium products, which are included in the composition of these lamps (Rabah 2008).

The COVID-19 pandemic had a profound impact on global industrial activity, including in the USA. Lockdown measures, supply chain disruptions, and reduced economic activity resulted in a significant decline in industrial production. This decline in industrial activity led to a temporary reduction in CO2 emissions, including industrial emissions. However, as economies recover and industrial production resumes, emissions are likely to rebound unless there are long-term structural changes in industrial practices and policies that prioritize sustainability and decarbonization (Adebayo and Kartal 2023).

The SFL leaching process involves the use of a mixture of sulfuric acid and nitric acid with testing times of 0–12 h at 60 °C and an acidity ranging from 1 to 4 mol/L. Due to the low leaching efficiency of less than 18.5%, in order to improve the efficiency of the leaching process, 5 MPa of pressure was applied along with an increase in temperature up to 125 °C. The result is an enhanced leaching efficiency of more than 90% for both yttrium, and europium as a result of this process. An alternative method included the treatment of pregnant leached liquor with thiocyanate, followed by solvent extraction with tri-methyl-benzyl-ammonium chloride, followed by thiocyanate treatment after the solvent extraction. The use of nitric acid as a stripping agent for the loaded organic (LO) phase resulted in a successful recovery rate of rare earths after scraping (Rabah 2008; Jyothi et al. 2020).

A hydrometallurgical process is used to process energy-critical elements from secondary sources such as permanent magnets, electric arc furnace residue, industrial residue types (phosphogypsum and red mud), plasma screens, cathode ray tubes, computer hard drives, LEDs, fluorescent lamps, etc. It involves using hydrometallurgical techniques, as illustrated in Fig. 10.

a Illustration of rare earth elements recovery from end of life of computer hard discs by hydro- and pyrometallurgy (Abrahami et al. 2015). b Flowsheet shows rare earth elements recovery from CRT phosphor waste (Xingmei et al. 2015). c Schematic flowsheet shows rare earth elements recovery from waste of oil shale ash by using hydrometallurgical techniques (Yang et al. 2010)

There is no doubt that the next generation of energy sources will come from clean energy technologies such as electric vehicles, wind turbines, and phosphors. The recovery of energy-critical materials from waste is becoming a potential source of rare earth elements in the future. There are a number of aspects that contribute to the development of recycling strategies that can meet the nation’s needs in terms of energy. As a result of the integration of hydrometallurgical operations with leaching, solvent extraction, and precipitation, there have been several routes adopted for the recovery of energy-critical materials that have several advantages, such as low emissions, zero water generation, low operation costs, and high purity (Jyothi et al. 2020).

Challenges, expectation, and future directions

In recent years, the recovery of energy-critical elements from secondary resources has been viewed as a promising approach for mitigating the challenges associated with mining, processing, and supplying energy-critical metals and oxides within the supply chain (Dushyantha et al. 2020; Molina-Calderón et al. 2022). Furthermore, energy-critical industries face the challenge of developing and implementing innovative technologies to extract, separate, and recover energy-critical materials from various secondary resources, all with a focus on being environmentally friendly and economically viable.

The economic feasibility of energy-critical elements necessary for the development of sustainable energy sources is a crucial consideration in assessing the viability of renewable energy technologies. Some of the most important key elements include lithium, cobalt, nickel, and rare earth elements. There are several factors influencing their economic feasibility. It includes supply and demand dynamics, technological advancements, policy changes, economies of scale, research and development investments, environmental regulations, and social factors (Qiu and Suh 2019).

The availability and demand for energy-critical elements play a significant role in their economic feasibility. Growing demand for electric vehicles, energy storage systems, and renewable energy technologies has increased the need for elements like lithium, cobalt, nickel, and other rare earth elements. Supply constraints, geopolitical factors, and market fluctuations can impact their availability and price, affecting the overall economic feasibility of sustainable energy sources (Martins et al. 2021).

Advances in extraction, refining, and processing technologies can enhance the economic feasibility of energy-critical elements. More efficient extraction methods, such as improved lithium brine extraction techniques or innovative hydrometallurgical processes for rare earths and critical elements, can help reduce production costs. Additionally, technological advancements in recycling and recovery methods can enhance the availability and cost-effectiveness of these elements. Large-scale production and economies of scale can contribute to the economic feasibility of energy-critical and rare-earth elements. Scaling up production processes and establishing efficient supply chains can help reduce costs and increase profitability. As demand for sustainable energy technologies continues to grow, economies of scale can play a significant role in cost reduction and enhancing economic feasibility (Bailey et al. 2017).

Environmental regulations and social considerations can impact the economic feasibility of energy-critical elements. Stricter environmental regulations, such as responsible sourcing and environmental sustainability requirements, may increase production costs. Additionally, ethical and social considerations surrounding the supply chain, such as labor conditions and human rights, can affect the market dynamics and pricing of these elements (Ferron and Henry 2015).

Research and development investments aimed at improving extraction, processing, and recycling technologies can drive down costs and improve the economic feasibility of energy-critical and rare earth elements. Governments, industry players, and research institutions investing in research and development can contribute to technological advancements and cost reduction, making sustainable energy sources more economically viable. It is worth noting that the economic feasibility of energy-critical and rare earth elements can evolve over time due to various factors, including technological advancements, market dynamics, and policy changes. Continued efforts to enhance efficiency, develop alternative materials, and diversify supply chains can contribute to improving the economic feasibility of these elements as sustainable energy sources (Golev et al. 2014; Jowitt et al. 2018).

As a matter of fact, a major challenge facing the industry is how to scale-up innovative technologies and reduce harmful emissions to reach this goal. Since many of these elements are being used in clean energy technologies, it is imperative that the industry of energy-critical elements has a sustainable future. This is to reap maximum benefits and be able to remain competitive in the future. As mentioned earlier, in the energy-critical metal processing industry, it is widely accepted that pyrometallurgy is the most common method of treating energy-critical metals used in the industry. However, on the other hand, it has a negative impact from the perspective of the environment, since it generates dust, releases harmful gases, and has a high operational cost, thus having a negative impact on the environment (Hsu et al. 2019).

As an integral part of extractive metallurgy, hydrometallurgy techniques are utilized in a variety of metal refining activities throughout a wide range of industries. The process of treating raw materials for metal production involves the use of flexible and highly selective process technology (Thompson et al. 2018).

There are four main processes in hydrometallurgical treatment, which include leaching, solvent extraction, ion exchange, and precipitation. It is imperative to note that the processes to be used in these types of procedures vary depending on the type of material that is being recovered. In the separation process, it should be noted that there are four stages in the process. These stages are namely leaching, solvent extraction, ion exchange, and precipitation (Brierley and Brierley 2013).

In terms of metal recovery, the most prominent method is hydrometallurgy (the process of extracting metals from primary and secondary resources using aqueous solutions). There are several research areas within hydrometallurgy, and a general description of the activity has been provided in Fig. 11 (Habashi 1969; Mooiman et al. 2005). It is imperative that research be conducted on the recovery of energy-critical metals from a comprehensive and integrated viewpoint to develop more effective methods for recovering energy-critical metals and oxides. By pursuing in-depth and holistic studies in the field of energy-critical metals, we can better identify and assess potential recovery processes (Binnemans et al. 2013; Ambaye et al. 2020; Akcil et al. 2021; Dhawan and Tanvar 2022). For a potential recycling framework to be effective, it should be focused on the up-stream, middle-stream, and downstream aspects. There is an urgent need to take advantage of recycling schemes to recover critical elements from secondary resources to address supply issues and meet future demand. As part of their review, Dhawan and Tanvar (2022) presented a critical analysis of the current recycling processes and market value potential for recycling waste fluorescent lamps, as well as the recovery processes of energy-critical materials that are currently being employed (Dhawan and Tanvar 2022).

It is essential to tackle some of the key issues that arise in the recycling of scrap and used products. These issues need to be addressed to achieve sustainable recycling. It is especially pertinent that we concentrate on issues related to dismantling, demagnetizing, and separating the iron from the magnets. In addition, we need to concentrate on the separation of fine particles from the magnets and the terbium dissolution of the phosphors (Tanaka et al. 2013). It is imperative that the scientific community take prompt action to solve these issues so that cost-effectiveness, efficiency, and environmental sustainability solutions can be provided.

To address both short- and long-term recycling related frameworks, there are several potential tools that can help, including material flow analysis, multiregional input–output models, system dynamics, and complex network theory, to name a few (Sun 2022). To respond effectively to the challenges of the supply chain, studies should invest in diversification at every stage of the process. Due to the rapid clean energy transition and the fact that energy-critical metals are scarce, more quantitative models that incorporate the price factor, recycling, reuse, and technological breakthroughs are also worthy of attention. In the case of recycling critical metals, there have been few studies that have examined the costs associated with recycling and the factors that influence them. However, this deserves further research.

Mineral extraction involves the mining of the ore deposit, followed by leaching and cracking, refining, making alloys, compounds, and other products that can be marketed. These products include oxides, acetates, and carbonates, as well as alloys manufactured into commercial components (Paul and Campbell 2011; Navarro and Zhao 2014). Several other advancements in technologies have been identified in the study, including the automated separation of magnet, and the use of high gradient magnetic separation for the phosphors, as well as a new extractant for the phosphors (Ambaye et al. 2020).

In the mining and mineral industries, the use of blockchain algorithms to promote supply chain traceability, reduce waste, and recycle is highly recommended. This is to increase efficiency and productivity. The blockchain algorithm has many advantages, including decentralization, security, traceability, auditability, and time-stamped transactions, all of which contribute to increased productivity within the mining and mineral industries (Hastig and Sodhi 2020). It is for this reason that blockchain-based supply chain traceability tools have become a hot topic and have emerged as a promising emerging technology (Sun 2022). For such emerging technologies to be successful, however, critical factors for the mineral and mining industries need to be carefully studied to bring them to fruition.

Using artificial intelligence (AI) and machine learning (ML) techniques can improve the efficiency of the process and increase productivity. Every stage of the process can be better served with the use of these emerging techniques. A data-driven machine learning approach can potentially also speed up the discovery of new ligands for the separation of energy-critical metals and ions. It is possible to do high-throughput screening of an extended chemical space, and the machine learning algorithm-based model will continuously improve as more data is generated as well. As a result of the increasing popularity of this approach, it has been increasingly used in predicting key equilibrium properties of molecules such as solubility, binding affinity, pKa, adsorption capacities, and partition coefficients (Wang et al. 2019; Boobier et al. 2020; Chaube et al. 2020; Kanahashi et al. 2022). Earlier this year, Liu et al. published a study showing that deep neural networks, which have been trained on the available experimental data, can be applied to the prediction of accurate distribution coefficients of rare earth ions for solvent extraction, opening the door for high-throughput screening of ligands for rare earth separations (Liu et al. 2022). The machine learning approach may need further development for creating powerful magnets to use in wind turbines and computer hard drives by judicious use or by substitution of energy-critical materials.

The recycling rate and the possibility of substituting the most strategic and energy-critical elements are very limited. There is therefore a need to ensure stable supplies, as well as support the high-tech industry based on these energy-critical materials, which could be reached by different, but concurrent strategies. It is imperative to adopt eco-friendly and easy but efficient methods for the processing of energy-critical materials so as to reduce their environmental impact as well as their lifecycle footprint. There is an urgent need for research-enabling activities to be undertaken in order to discover ways in which scarce and strategic materials can be recycled and reused. It is imperative to implement emerging technologies such as machine learning and artificial intelligence in order to improve and promote statistical information in a judicious and effective manner. This will enable us to optimize their use. Moreover, it is imperative to promote activities at the national and international levels through the signing of bilateral and multilateral agreements that will facilitate cooperation between nations. Through this, the strategic mission will be enriched by investing in research and development to develop suitable substitutes (Massari and Ruberti 2013).

The assessment of the strategies for energy-critical and rare earth elements necessary for the development of sustainable energy sources depends on the specific rare earth and energy-critical elements, technologies, and strategies considered in the literature. The potential results obtained emerged from the comprehensive assessment of strategies conducted in this work and the specific findings are shown in Fig. 12, which are the outcomes from the methodology employed and the data available.

Conclusions

Due to the growing global shortage of rare earth elements and the associated supply risks in various sectors, rare earth element consumption has gained increased attention over the past two decades. Due to these concerns, research and development have been accelerated to address them. The purpose of this research is to identify and assess more effective or better approaches to obtaining rare earth elements. In addition, it is to identify new secondary sources to ensure a continuous, competitive supply of rare earth elements into the future. In order to develop sustainable energy sources, it is imperative that the energy-critical elements be evaluated in terms of strategies. In this manuscript, we take a critical look at current research and studies. We identify possible pathways and technologies based on hydrometallurgy to fill gaps in existing research. It will also allow us to provide a glimpse into what the future will hold in terms of the recycling and recovery of energy-critical materials, thereby allowing us to develop sustainable sources of energy in the future.

Data availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

Abbreviations

- TCR:

-

Thermal contact resistance

- TaC:

-

Tantalum carbide

- HfC:

-

Hafnium carbide

- FB:

-

Floating beads

- CE:

-

Ceramic

- Nd2O3 :

-

Neodymium(III) oxide

- LaCl3 :

-

Lanthanum(III) chloride

- ReCl3 :

-

Rhenium trichloride

- LDH-Cyanex 272:

-

Layered/lamellar double hydroxide-based sorbents

- NiMH battery:

-

Nickel metal hydride battery

- HCl:

-

Hydrochloric acid

- NaOH:

-

Sodium hydroxide

- SFLs:

-

Spent fluorescent lamps

- LO:

-

Loaded organic phase

- LEDs:

-

Light-emitting diodes

- Nd:

-

Neodymium

- Dy:

-

Dysprosium

- Pr:

-

Praseodymium

- NdFeB:

-

Neodymium iron boron/neodymium magnets

- AI:

-

Artificial intelligence

- ML:

-

Machine learning

References

Abbott AP, Frisch G, Hartley J, Ryder KS (2011) Processing of metals and metal oxides using ionic liquids. Green Chem 13:471–481

Abrahami ST, Xiao Y, Yang Y (2015) Rare-earth elements recovery from post-consumer hard-disc drives. Miner Process Extr Metall 124:106–115. https://doi.org/10.1179/1743285514Y.0000000084

Adebayo TS, Ağa M, Kartal MT (2023) Analyzing the co-movement between CO2 emissions and disaggregated nonrenewable and renewable energy consumption in BRICS: evidence through the lens of wavelet coherence. Environ Sci Pollut Res 30:38921–38938. https://doi.org/10.1007/s11356-022-24707-w

Adebayo TS, Kartal MT (2023) Effect of green bonds, oil prices, and COVID-19 on industrial CO2 emissions in the USA: Evidence from novel wavelet local multiple correlation approach. Energy Environ 0958305X231167463. https://doi.org/10.1177/0958305X231167463

Akcil A, Ibrahim YA, Meshram P et al (2021) Hydrometallurgical recycling strategies for recovery of rare earth elements from consumer electronic scraps: a review. J Chem Technol Biotechnol 96:1785–1797

Al-Khateeb GG, Haider SW, Rahman M, Nazzal M (2019) Innovative materials, new design methods, and advanced characterization techniques for sustainable asphalt pavements. Adv Mater Sci Eng 2019:8241071. https://doi.org/10.1155/2019/8241071

Alola AA, Adebayo TS (2023) The potency of resource efficiency and environmental technologies in carbon neutrality target for Finland. J Clean Prod 389:136127. https://doi.org/10.1016/j.jclepro.2023.136127

Alola AA, Onifade ST (2022) Energy innovations and pathway to carbon neutrality in Finland. Sustain Energy Technol Assess 52:102272

Ambaye TG, Vaccari M, Castro FD et al (2020) Emerging technologies for the recovery of rare earth elements (REEs) from the end-of-life electronic wastes: a review on progress, challenges, and perspectives. Environ Sci Pollut Res 27:36052–36074. https://doi.org/10.1007/s11356-020-09630-2

Anastopoulos I, Bhatnagar A, Lima EC (2016) Adsorption of rare earth metals: a review of recent literature. J Mol Liq 221:954–962

Bailey G, Mancheri N, Van Acker K (2017) Sustainability of permanent rare earth magnet motors in (H)EV industry. J Sustain Metall 3:611–626. https://doi.org/10.1007/s40831-017-0118-4

Balaram V (2019) Rare earth elements: a review of applications, occurrence, exploration, analysis, recycling, and environmental impact. Geosci Front 10:1285–1303. https://doi.org/10.1016/j.gsf.2018.12.005

Binnemans K, Jones PT, Blanpain B et al (2013) Recycling of rare earths: a critical review. J Clean Prod 51:1–22. https://doi.org/10.1016/j.jclepro.2012.12.037

Bogart JA, Lippincott CA, Carroll PJ, Schelter EJ (2015) An operationally simple method for separating the rare-earth elements neodymium and dysprosium. Angew Chem Int Ed 54:8222–8225. https://doi.org/10.1002/anie.201501659

Boobier S, Hose DRJ, Blacker AJ, Nguyen BN (2020) Machine learning with physicochemical relationships: solubility prediction in organic solvents and water. Nat Commun 11:5753. https://doi.org/10.1038/s41467-020-19594-z

Borra CR, Pontikes Y, Binnemans K, van Gerven T (2015) Leaching of rare earths from bauxite residue (red mud). Miner Eng 76:20–27

Brierley CL, Brierley JA (2013) Progress in bioleaching: part B: applications of microbial processes by the minerals industries. Appl Microbiol Biotechnol 97:7543–7552

Can-Ortiz A, Laudebat L, Valdez-Nava Z, Diaham S (2021) Nonlinear electrical conduction in polymer composites for field grading in high-voltage applications: a review. Polymers (Basel) 13. https://doi.org/10.3390/polym13091370

Chaube S, Goverapet Srinivasan S, Rai B (2020) Applied machine learning for predicting the lanthanide-ligand binding affinities. Sci Rep 10:14322. https://doi.org/10.1038/s41598-020-71255-9

Chen Z, Li Z, Chen J, Kallem P, Banat F, Qiu H (2022) Recent advances in selective separation technologies of rare earth elements: A review. J Environ Chem Eng 10(1):107104

Condomitti U, Zuin A, Silveira AT et al (2012) Magnetic nanohydrometallurgy: a promising nanotechnological approach for metal production and recovery using functionalized superparamagnetic nanoparticles. Hydrometallurgy 125:148–151

Condomitti U, Almeida SN, Silveira AT Jr et al (2018) Green processing of strategic elements based on magnetic nanohydrometallurgy. J Braz Chem Soc 29:948–959

da Almeida SN, Toma HE (2016) Neodymium (III) and lanthanum (III) separation by magnetic nanohydrometallurgy using DTPA functionalized magnetite nanoparticles. Hydrometallurgy 161:22–28

Das N, Das D (2013) Recovery of rare earth metals through biosorption: an overview. J Rare Earths 31:933–943

Das A, Ghosh A (2023) Vision Net Zero: a review of decarbonisation strategies to minimise climate risks of developing countries. Environ Dev Sustain. https://doi.org/10.1007/s10668-023-03318-6

Debnath B, Chowdhury R, Ghosh SK (2018) Sustainability of metal recovery from E-waste. Front Environ Sci Eng 12:1–12

Dhawan N, Tanvar H (2022) A critical review of end-of-life fluorescent lamps recycling for recovery of rare earth values. Sustain Mater Technol 32:e00401. https://doi.org/10.1016/j.susmat.2022.e00401

Dushyantha N, Batapola N, Ilankoon I et al (2020) The story of rare earth elements (REEs): Occurrences, global distribution, genesis, geology, mineralogy and global production. Ore Geol Rev 122:103521

Dutta T, Kim K-H, Uchimiya M et al (2016) Global demand for rare earth resources and strategies for green mining. Environ Res 150:182–190. https://doi.org/10.1016/j.envres.2016.05.052

Enlow LR, Swanson DW, Naito CM (1999) Development of test vehicles for evaluating plastic-encapsulant reliability and improving thermal conductivity of encapsulant materials11© 1997 IMAPS—International Microelectronics and Packaging Society, formerly ISHM—The Microelectronics Society. Reprinted with permission from the Proceedings of the 1997 International Symposium on Microelectronics, pp. 314–321, October 14–16, 1997, Philadelphia, Pennsylvania. Microelectron Reliab 39:515–527. https://doi.org/10.1016/S0026-2714(98)00202-9

Ferron CJ, Henry P (2015) A review of the recycling of rare earth metals. Can Metall Q 54:388–394

Fishman T, Graedel TE (2019) Impact of the establishment of US offshore wind power on neodymium flows. Nat Sustain 2:332–338

Franus W, Wdowin M, Franus M (2014) Synthesis and characterization of zeolites prepared from industrial fly ash. Environ Monit Assess 186:5721–5729

Fujita Y, McCall SK, Ginosar D (2022) Recycling rare earths: perspectives and recent advances. MRS Bull 47:283–288. https://doi.org/10.1557/s43577-022-00301-w

Gasser MS, Aly MI (2013) Separation and recovery of rare earth elements from spent nickel–metal-hydride batteries using synthetic adsorbent. Int J Miner Process 121:31–38. https://doi.org/10.1016/j.minpro.2013.02.012

Gielen D, Boshell F, Saygin D et al (2019) The role of renewable energy in the global energy transformation. Energ Strat Rev 24:38–50. https://doi.org/10.1016/j.esr.2019.01.006

Golev A, Scott M, Erskine PD et al (2014) Rare earths supply chains: current status, constraints and opportunities. Resour Policy 41:52–59

Golroudbary SR, Makarava I, Kraslawski A, Repo E (2022) Global environmental cost of using rare earth elements in green energy technologies. Sci Total Environ 832:155022. https://doi.org/10.1016/j.scitotenv.2022.155022

Gómez-Pastora J, Bringas E, Ortiz I (2014) Recent progress and future challenges on the use of high performance magnetic nano-adsorbents in environmental applications. Chem Eng J 256:187–204

Habashi M (1969) Principles of Extractive Metallurgy. Vol 2. Hydrometallurgy. Gordon & Breach

Habib K, Wenzel H (2014) Exploring rare earths supply constraints for the emerging clean energy technologies and the role of recycling. J Clean Prod 84:348–359

Hastig GM, Sodhi MS (2020) Blockchain for supply chain traceability: business requirements and critical success factors. Prod Oper Manag 29:935–954

Herrington R (2021) Mining our green future. Nat Rev Mater 6:456–458

Hsu E, Barmak K, West AC, Park A-HA (2019) Advancements in the treatment and processing of electronic waste with sustainability: a review of metal extraction and recovery technologies. Green Chem 21:919–936

Humphries M (2010) Rare earth elements: the global supply chain. Diane Publishing

Hung S-W, Kikugawa G, Shiomi J (2016) Mechanism of temperature dependent thermal transport across the interface between self-assembled monolayer and water. J Phys Chem C 120:26678–26685. https://doi.org/10.1021/acs.jpcc.6b09516

Hurd AJ, Kelley RL, Eggert RG, Lee M-H (2012) Energy-critical elements for sustainable development. MRS Bull 37:405–410. https://doi.org/10.1557/mrs.2012.54

Iftekhar S, Srivastava V, Sillanpää M (2020) Synthesis of hybrid bionanocomposites and their application for the removal of rare-earth elements from synthetic wastewater. In: Advanced Water Treatment. Elsevier, pp 505–564

Jowitt SM, Werner TT, Weng Z, Mudd GM (2018) Recycling of the rare earth elements. Curr Opin Green Sustain Chem 13:1–7

Jyothi RK, Thenepalli T, Ahn JW et al (2020) Review of rare earth elements recovery from secondary resources for clean energy technologies: grand opportunities to create wealth from waste. J Clean Prod 267:122048

Jyothi RK (ed) (2020) Rare-earth metal recovery for green technologies: methods and applications. Springer Nature

Kanahashi K, Urushihara M, Yamaguchi K (2022) Machine learning-based analysis of overall stability constants of metal–ligand complexes. Sci Rep 12:11159. https://doi.org/10.1038/s41598-022-15300-9

Khatib H (2012) IEA world energy outlook 2011—a comment. Energy Policy 48:737–743

Kiggins RD (2015) The political economy of rare earth elements: rising powers and technological change. Springer

Kim D, Powell LE, Delmau LH et al (2015) Selective extraction of rare earth elements from permanent magnet scraps with membrane solvent extraction. Environ Sci Technol 49:9452–9459. https://doi.org/10.1021/acs.est.5b01306

Klima KM, Schollbach K, Brouwers HJH, Yu Q (2022) Enhancing the thermal performance of Class F fly ash-based geopolymer by sodalite. Constr Build Mater 314:125574. https://doi.org/10.1016/j.conbuildmat.2021.125574

Laznicka P (2010) Giant deposits: industry, economics, politics. In: Giant Metallic Deposits. Springer, pp 703–724

Li L, Xu S, Ju Z, Wu F (2009) Recovery of Ni, Co and rare earths from spent Ni–metal hydride batteries and preparation of spherical Ni(OH)2. Hydrometallurgy 100:41–46. https://doi.org/10.1016/j.hydromet.2009.09.012

Liu T, Johnson KR, Jansone-Popova S, Jiang D (2022) Advancing rare-earth separation by machine learning. JACS Au 2:1428–1434. https://doi.org/10.1021/jacsau.2c00122

Martins LS, Guimarães LF, Junior ABB et al (2021) Electric car battery: an overview on global demand, recycling and future approaches towards sustainability. J Environ Manag 295:113091

Massari S, Ruberti M (2013) Rare earth elements as critical raw materials: focus on international markets and future strategies. Resour Policy 38:36–43. https://doi.org/10.1016/j.resourpol.2012.07.001

McSherry S, Webb M, Kaufman J et al (2022) Nanophotonic control of thermal emission under extreme temperatures in air. Nat Nanotechnol 17:1104–1110. https://doi.org/10.1038/s41565-022-01205-1

Miao Y, Liu L, Zhang Y et al (2022) An overview of global power lithium-ion batteries and associated critical metal recycling. J Hazard Mater 425:127900