Abstract

The design of reactors based on high performance photocatalysts is an important research in catalytic hydrogenation. In this work, modification of titanium dioxide nanoparticles (TiO2 NPs) was achieved by preparation of Pt/TiO2 nanocomposites (NCs) through photo-deposition method. Both nanocatalysts were used for the photocatalytic removal of SOx from the flue gas at room temperature in the presence of hydrogen peroxide, water, and nitroacetanilide derivatives under visible light irradiation. In this approach, chemical deSOx was achieved along with protection of the nanocatalyst from sulfur poising through the interaction of the released SOx from SOx-Pt/TiO2 surface with p-nitroacetanilide derivatives to produce simultaneous aromatic sulfonic acids. Pt/TiO2 NCs have a bandgap of 2.64 eV in visible light range, which is lower than the bandgap of TiO2 NPs, whereas TiO2 NPs have a mean size of 4 nm and a high specific surface area of 226 m2/g. Pt/TiO2 NCs showed high photocatalytic sulfonation of some phenolic compounds using SO2 as a sulfonating agent along with the existence of p-nitroactanilide derivatives. The conversion of p-nitroacetanilide followed the combination processes of adsorption and catalytic oxidation–reduction reactions. Construction of an online continuous flow reactor–high-resolution time-of-flight mass spectrometry system had been investigated, realizing real-time and automatic monitoring of completion the reaction. 4-nitroacetanilide derivatives (1a-1e) was converted to its corresponding sulfamic acid derivatives (2a–2e) in 93–99% isolated yields of within 60 s. It is expected to offer a great opportunity for ultrafast detection of pharmacophores.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Air pollution has been identified as a major environmental health risk factor, causing an estimated 3.7 million early deaths globally (Abdelsalam et al. 2020; Khallaf 2011). Emissions of the air pollutants are mainly caused by agricultural activities and combustion of fuels in industrialized societies and are together and separately causing problems with human health, acidification, eutrophication, vegetation damages, and corrosion (Spix et al. 1998). Even though air pollution problems currently are more severe on other continents they still cause problems (Ayturan and Dursun 2018). Contaminated air, as is well known, comprises a wide range of chemical components, including dust, toxic gases, greenhouse gases, and metal salts. Sulfur dioxide (SO2) as one of polluted gas, the most frequent form of sulfur oxides (SOx) in the lower atmosphere, is a colorless gas with a pungent and disagreeable odor that can be detected by taste and smell in concentrations ranging from 1000 to 10,000 g/m3 (Krishnan et al. 2013; Nanayakkara et al. 2014; Flores et al. 2017). Sulfur trioxide (SO3), a sulfur oxide that is immediately discharged into the atmosphere or generated from sulfur dioxide, is swiftly converted to sulfuric acid (Ackermann et al. 1998; Cheremisinoff 2002). Sulfur oxide pollution has a negative impact on the ecosystem, especially forests and agricultural crops. Plants in close proximity to pollution sources are particularly sensitive. Even after a short exposure to high levels of sulfur dioxide, foliar necrosis can occur. The effects of forest ecosystems vary greatly depending on soil type, plant species, meteorological conditions, insect numbers, and other unknown factors (Pan 2019). As for critical levels of gaseous sulfur dioxide, it is not of practical importance that sulfur inputs in mist and rain may also contribute to indirect effects on vegetation (i.e., soil-mediated) and thus may also be included in critical load calculations. By reducing the pH of the water, acid depositions can affect freshwater lake and stream ecosystems. Lakes with low buffering capacity, which could assist in acid rain neutralization, are particularly vulnerable. Few fish species can withstand substantial pH fluctuations, and lakes that are affected may become completely barren of fish life. Acidification reduces the diversity and quantity of other animal and plant species (Chen et al. 2007). By scattering light, sulfate aerosols, which are formed from sulfur dioxide in the atmosphere, can affect visibility (Cheremisinoff 2001). The corrosion of iron, steel, and zinc is accelerated by sulfurous acid, which is generated when sulfur dioxide reacts with moisture. Sulfur oxides react with copper to form a green patina of copper sulfate on the metal’s surface (Clarelli et al. 2014).

The most possible solutions for of SOx emissions (Godish 1991; Carey et al. 2006; Mills et al. 2007) are the following: (i) the use of low sulfur fuel oil; (ii) exhaust gas scrubber technology. In this technology, a scrubbing liquid is prepared from fresh water and sodium hydroxide which reduces the SOx to 95%. Then, the effluent water tends to treatment processes before it can be discharged overboard; (iii) Cylinder lubrication for engines along with efficient control systems to neutralize the sulfur in the fuel and reduce SOx emissions from the engine. It was worthy to note that each solution is expensive. Hence, an innovative approach is required (Moors et al. 2017; Wang et al. 2017; Rabiee and Mahanpoor 2018). Today, the catalysts possessing large surface area have been progressed to become one of the most important branches of advanced materials, organic chemistry, and nanotechnology. These catalysts have certain unique characteristics, such as stability in air and water, ease of handling, and even reusability (Shang et al. 2002; Wang and You 2018; Su et al. 2013). In addition, sulfonation of aromatic compounds is a very important chemical reaction. Along with nitration, halogenation, acylation, and alkylation, it belongs to the well-known class of electrophilic aromatic substitution (SEAr) reactions. In large industrial applications such as medicines, detergents, surfactants, dyes, and pesticides, sulfonation is a significant chemical step. Sulfur trioxide (SO3), oleum, sulfuric acid, and chlorosulfuric acid are the most regularly utilized sulfonating agents (Smith and Tatchell 1969; Roberts 1998; Chen et al. 2012). Acute SO2 exposure (single exposures) causes rapid bronchial constriction, airway narrowing, increased pulmonary resistance, and enhanced airway responsiveness (Baltrusaitis et al. 2011). As a result, eliminating SOx is very important, especially if it can be used in eco-friendly synthesis of organo-sulfonic acid derivatives. Various methods may convert SO2 to other compounds and/or remove it from the atmosphere once it is released into the atmosphere (Wang et al. 2016; Amini et al. 2019). The removal of SO2 from the atmosphere is aided by processes such as oxidation, wet deposition, dry deposition, absorption by vegetation and soil, solubility into water, and others. Today, the development of green techniques in chemical transformations (Attia and Mohamed 2022; Attia and Abdel-Hafez 2022) using recyclable nanocatalyst to afford high selectivity and catalytic performance has attracted great attentions (Taha et al. 2022; Attia and Abdel-Hafez 2021; Al-Musawi et al. 2022a; Attia 2016). Moreover, the regeneration/recovery of the initial photocatalytic activity through combining photocatalysis and nonthermal plasma was explored in several studies (Hassani et al. 2017; Abou Saoud et al. 2017). Titanium dioxide is among the most prevalent photo-nanocatalysts (TiO2) (Li et al. 2011; Liu et al. 2014; Bellardita et al. 2017; Eltohamy et al. 2022; Al-Musawi et al. 2023) due to its wide bandgap (3.2 eV), long-term photostability, low cost, low operational temperature, strong oxidation capability, non-toxic nature, and strong resistance to chemical and photocorrosion (Tada-Oikawa et al. 2016; Tsuneyasu et al. 2016). However, TiO2 NPs have some drawbacks, including a maximum wavelength in the ultraviolet, a tiny surface area, and rapid recombination of photogenerated electrons and holes (Attia and Altalhi 2017). By shifting its light absorption to the visible region and narrowing its bandgap energy, doping Titania with metal and nonmetal elements is one of the most active ways to improve its efficiency and overcome the shortcomings. Recently, noble metal doping TiO2 NPs were used for the NOx conversion into nitric acid (HNO3) under visible light irradiation (Abdelsalam et al. 2020) and TiO2 nanoparticles were used for dye photodegradation and H2 production (Attia and Altalhi 2017). Currently, the combination between nanocatalysis field and continuous flow technology has attracted the attentions of scientists (Liu et al. 2012; El Kadib et al. 2009; Al-Musawi et al. 2022b). Therefore, efforts shall be made with the design of novel reactors to push forward the application of photocatalysts based on TiO2 nanoparticles in organic transformations (Mohamed et al. 2021). Today, the Z-scheme photocatalysts showed high performance for contaminants elimination due to their visible light response and their strong redox ability (Hassani et al. 2021). Herein, we report the first trial to design a continuous flow reactor using Pt/TiO2 NCs for ultrafast conversion of 4-nitroacetanilide derivatives to sulfamic acids through catalytic reduction reaction. These methods open the access to use the Pt/TiO2 nanocatalyst as dual function material in which the use of SOx gas in design high-valued pharmaceutical products in spontaneous reaction process. In addition, the synthesized products had been characterized using different analytical tools. The main objective of this research proposal is to use new advanced techniques for the production of pharmaceutical products included: (i) Design new synthetic routes by using safe reagents and solvents; (ii) Improve the yield of the products and selectivity of the reactions in place of traditional industrial process.

Materials and methods

TiCl4, PtCl2, and 4-nitroaniline derivatives and ethanol were purchased from Sigma-Aldrich Company and were used without further purification. The N-acylation of 4-nitroaniline is a fundamental organic reaction that was used for the production of p-nitroacetanilide derivatives (Greene and Wuts 2007). Pt/TiO2 NCs and TiO2 NPs as photocatalysts were also according to literature procedures, respectively (Attia and Altalhi 2017; Bellardita et al. 2017). These synthesized nanoparticles were characterized by XRD, TEM, DRS, FTIR, BET, and UV–VIS spectrometer. Then the prepared photocatalysts were used in ecofriendly sulfonation of organic materials to synthesize organo-sulfonic acid derivatives as fine and pharmaceutical products. 1H and 13C NMR spectra for the sulfamic derivatives were recorded on Bruker Avance DPX (300 MHz for 1H and 75 MHz for and 13C, respectively). The chemical shift (δ) data were determined in parts per million (ppm) downfield from tetramethylsilane using DMSO-d6 as a partially deuterated NMR solvent. High-resolution mass spectrometry (HRMS) analysis was measured by 6230 Series Accurate-Mass Time-Of-Flight (TOF) liquid chromatography (LC)/MS system.

Preparation of TiO2 NPs

TiCl4 was mixed with deionized water (1:10) under vacuum condition with stirring for 30 min at 80 °C. The solution was left overnight to precipitate, and then the prepared precipitate was filtrated. TiO2 NPs were obtained after calcination for 4 h at 550 °C (Attia and Altalhi 2017).

Preparation of Pt/TiO2 NCs

To a suspension solution of TiO2 NPs (0.5 g) in 100 mL of distilled water and ethanol (50 mL), appropriate PtCl2 (corresponding to 0.5 wt% metal loading) were added. Then, the mixture was placed in a 1.5-L cylindrical photoreactor equipped with a medium pressure Hg lamp (500 W, 400–790 nm. 47–63 HZ). The suspensions were irradiated for 6 h (Bellardita et al. 2017).

Photocatalytic activity assessment toward SO2 removal and synthesis of organo-sulfonic acid derivatives

An amount equal of the selected photo-nanocatalysts, i.e., Pt/TiO2 NCs or TiO2 NPs (5 mg or 7.5 mg) was loaded in a mixture of (25 mL deionized water and 25 mL ethanol) and 0.15 g of the organic material (p-nitroacetanilide derivatives) within a ratio (1/3 or 1/2, w/w), and then 10 ppm concentration of SOx gas was passed through the reaction solution with 1.0 L/min flow rate for 10 min at room temperature. Then, the output data of SO2 outflow concentration was recorded. The setup included a SOx gas supply, a reactor, and analytical system. The reaction was carried out at room temperature (25 °C) under visible light irradiation. SO2 was analyzed with a gas analyzer (Thermo Scientific SO2 analyzer 43i).

Experimental setup

The scope of the test setup is to determine the air-purification performance of the photocatalyst, titanium dioxide, or titanium dioxide nanocluster, by continuous exposure of a specimen to the model air pollutant under illumination with visible light. A Thermo Scientific Company Model 1160 zero air generator was used to supply air. A SO2 primary cylinder (100 ppm) and zero air stream were mixed to a specific concentration by a Thermo Environmental Instruments Inc. Model 146 i dynamic gas calibration system. The gas flow and inlet concentration were calibrated by a gas blender of the calibrator. Flow rate of the gas stream was 1.0 L min−1 and SO2 concentration 10 ppm. The prepared catalyst was loaded into a 500-mL cylindrical glass filled with 25 mL of de-ionized water, 25 mL of ethanol, and 0.5 mL of H2O2 with stirring in addition to 0.15 g of the starting organic material (Fig. 1). The reaction mixture was irradiated with Vis-lamp (20 W, SANKYO DENKI, Japan) located outside the reactor. SO2 were analyzed with a SO2 analyzer (Thermo Scientific, Model 43i-SO2 analyzer).

In addition, for online continuous reduction of 4-nitroacetanilide, an online catalytic reactor–high-resolution time-of-flight mass spectrometry system was implemented. Firstly, the direct injection method was used to detect the molecular mass of 4-nitroacetanilide in the reaction solution by HR-TOF–Ms.

Characterization of dioxadithiine-6-sulfonic acid derivatives

(4-acetamidophenyl)sulfamic acid (2a): 1H NMR: δ (ppm) 2.03 (s, 3H, CH3), 5.06 (s, br, 1H, SO3H), 6.78 (d, 2H, J = 8.4 Hz, 2H), 7.34 (d, 2H, J = 8.4 Hz, 2H), 9.02 (br, s, 1H, NH), 10.63 (br, s, 1H, NH); 13C NMR (75 MHz, DMSO-d6): 22.5, 23.8, 26.8, 129.6, 132.4, 135.1, 138.0, 155.9. m/z (HRMS): calcd. for C8H10N2O4S: 230.0361, found 231.0741 for [M + H]+.

(4-(2,2,2-trifluoroacetamido)phenyl)sulfamic acid (2b): 1H NMR: δ (ppm) 5.12 (s, br, 1H, SO3H), 6.82 (d, J = 8.4 Hz, 1H), 7.36 (d, J = 8.4 Hz, 1H), 9.08 (s, br, 1H), 10.61 (s, br, 1H); 13C NMR (75 MHz, DMSO-d6): 23.8, 116.2 (2xC), 122.1 (2xC), 128.1, 133.5, 138.0, 167.2. m/z (HRMS): calcd. for C8H7F3N2O4S: 284.0079, found 285.0103 for [M + H]+.

(4-acetamido-3-methoxyphenyl)sulfamic acid (2c): 1H NMR: δ (ppm) 2.11 (s, 3H, CH3), 3.64 (s, 3H, OCH3), 5.11 (s, br, 1H, SO3H), 6.84–6.88 (m, 1H), 7.31 (s, 1H), 7.42–7.46 (m, 1H), 9.08 (s, br, 1H), 10.32 (s, br, 1H); 13C NMR (75 MHz, DMSO-d6): 24.1, 55.2, 101.8, 108.9, 116.3, 122.9, 128.1, 134.6, 152.1, 168.6. m/z (HRMS): calcd. for C9H12N2O5S: 260.0467, found 261.1008 for [M + H]+.

(4-acetamido-3-acetylphenyl)sulfamic acid (2d): 1H NMR: δ (ppm) 2.02 (s, 3H, CH3), 2.53 (s, 3H, CH3), 2.02 (s, 3H), 2.53 (s, 3H), 5.09 (s, br, 1H, SO3H), 7.09–7.16 (m, 1H), 7.33 (s, 1H), 7.48–7.51 (m,1H), 9.64 (s, br, 1H), 10.56 (s, br, 1H); 13C NMR (75 MHz, DMSO-d6): 24.2, 29.1, 113.1, 121.9, 122.7, 128.3, 133.8, 168.1, 199.7. m/z (HRMS): calcd. for C10H12N2O5S: 272.0467, found 273.0692 for [M + H]+.

(4-acetamido-3-fluorophenyl)sulfamic acid (2e): 1H NMR: δ (ppm) 2.15 (s, 3H, CH3), 5.02 (s, br, 1H, SO3H), 6.72–6.75 (m, 1H), 7.05 (s, 1H), 7.46–7.49 (m, 1H), 9.88 (s, br, 1H), 10.64 (s, br, 1H); 13C NMR (75 MHz, DMSO-d6): 24.1, 105.1, 110.5, 111.8, 112.6, 123.9, 134.1, 163.8, 169.3. m/z (HRMS): calcd. for C8H9FN2O4S: 248.0267, found 249.1102 for [M + H]+.

Results

Characterization of the prepared TiO2 NPs and Pt/TiO2 NCs

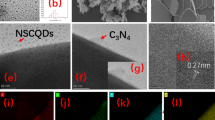

TEM images were used to examine the morphology of the anatase Pt/TiO2 NCs and TiO2 NPs samples, as shown in Fig. 2. TiO2 NPs are found to have a mean size of 4 ± 0.12 nm (Fig. 2a). However, Pt/TiO2 NCs with a mean size of 7 ± 1.27 nm were formed (Fig. 1b). An energy dispersive spectrometer (EDS) spectrum was used to examine the chemical compositions of TiO2 NPs and Pt/TiO2 NCs, which revealed the presence of (Ti and O) with (56.34 wt% and 43.66 wt%) and for Pt/TiO2 NCs (Ti, Pt, and O) with (52.61 wt%, 0.57 wt%, and 47.18 wt%), respectively. These findings show that the TiO2 in the as-prepared samples is of high purity and homogeneously produced.

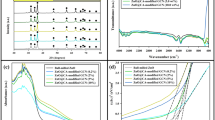

The crystal structure of TiO2 NPs was pure anatase, as revealed by the X-ray diffraction (XRD) patterns in Fig. 3. The optimal peaks for the plane of tetragonal anatase TiO2 (JCPDS 21–1272) were found to be 25.50°, 37.92°, 48.00°, 53.71°, 54.88°, 62.72°, 68.88°, 70.33°, and 75.12°, corresponding to crystallographic planes (101), (004), (200), (105), (211), (204), (116), and (220), respectively while Pt NPs were detected at 2θ angles of 47.6° and 54.6° corresponding to (111) and (200), respectively (Attia and Altalhi 2017). The absence of impurity peaks in the XRD pattern indicates that the TiO2 nanostructures are pure and well crystalline. Using the Scherer’s equation of the XRD pattern and in agreement with the determination of the average size from TEM images, average crystallite sizes of 7.51 nm for Pt/TiO2 NCs and 4.25 nm for NPs were found (Table 1) (Eghbali et al. 2019; Abdelhamid et al. 2020; Attia et al. 2020). Pt/TiO2 NCs have a specific surface area of 186.37 m2/g, while TiO2 NPs have a specific surface area of 225.57 m2/g (Table 1).

In the region of 200–900 nm, UV–Vis-diffuse reflectance spectra (DRS) were measured (Fig. 4a). The bandgap of the samples was calculated using Regan and Gratzel’s equation (Eg = 1239.8/λ), where Eg is the bandgap energy (eV) and (nm) is the wavelength of the absorption edges in the spectra. TiO2 NPs have a bandgap of 3.198 eV, while Pt/TiO2 NCs have a bandgap of 2.642 eV (Bellardita et al. 2017). Tauc curve of the DRS (Fig. 4b) confirmed the Regan and Gratzel’s calculations.

Photoluminescence (PL) spectra of the TiO2 containing Pt-doping in Fig. 5 show that the maximum emission located at 428 nm. TiO2 without Pt exhibits about a 45% decrease in luminescence intensity compared with Pt/TiO2 NCs. This decrease in PL can confirm the reduction in e–h recombination (Eun et al.2021).

The FT-IR spectra of Pt/TiO2 NCs and TiO2 NPs were shown in Fig. 6. It revealed characteristic peaks at 1628 cm−1 and 1386 cm−1, which correspond to the vibration of the hydroxyl group of TiO2 NPs and the bending mode of water Ti–OH for TiO2 NPs. The peaks around 100–1000 cm−1 attributed the presence of Pt dopant (Fig. 6) (Wang et al. 2005; Sadeaka et al. 2022).

Photo-oxidative/transformation of SOx to high valued products

In our protocol we aimed to investigate the utility of TiO2 NPs and Pt/TiO2 NCs as detoxification/transformation agents in photocatalytic SOx removal reaction besides the sulfonation of p-nitroacetanilide derivatives 1a under dark and visible light irradiation conditions. Scheme 1 depicted the reaction between SOx gas at atmospheric pressure with TiO2 NPs or Pt/TiO2 NCs in the presence of p-nitroacetanilide 1a under dark and visible light irradiation conditions at room temperature.

By carrying out the reaction under dark conditions, there was no conversion observed, and the organic substance 1a was recovered without any change. Under the effect of visible light irradiation, the reaction between SOx gas and p-nitroacetanilide 1a was performed efficiently by using Pt/TiO2 NCs rather than the use of TiO2 NPs as photocatalyst (Scheme 1). By adding TiO2 or Pt/TiO2 nanocatalyst and p-nitroacetanilide derivative 1a (1/3 or 1/2, w/w) to the reaction, followed by interaction of SOx gas (concentration = 10 ppm) through its passing through the reaction solution with 1.0 L/min flow rate, the results showed that Pt/TiO2 NCs exhibited higher catalytic activity than TiO2 NPs and sulfonated compounds were obtained in high quantitative yields. It was observed that the SOx gas concentration was reduced from 10 ppm to 60 ppb under visible light irradiation which means that the concentration of sulfur dioxide is reduced to 0.6% of the original concentration. The formed sulfamic acid in the solution was analyzed using HR-TOF–MS to measure the % conversion of starting material 1a product 2a that was calculated according to the following equation:

where Ci is the initial concentration and Cf is obtained concentration after various time intervals.

It was determined that ultrafast conversion of 4-nitroacetanilide was completed for Pt/TiO2 within 60 s, while for TiO2, it required 200 s, respectively. The highly efficient activity of Pt/TiO2 in catalytic applications was attributed to the coexistence of Pt and TiO2 nanoparticles in the matrix, which accelerates the electron transfer rate in the catalytic reaction. In addition, smaller bandgap of Pt/TiO2 (2.642 eV) (see Fig. 4) was beneficial to improve the charge transfer efficiency in the catalytic process.

As a result, the effectiveness of the removal efficiency of SOx can be elucidated in Table 2 that illustrated the optimized conditions of chemical deSOx according to comparative study in the regard of the catalyst concentration of TiO2 NPs or Pt/TiO2 NCs as photocatalyst and the reaction time.

The results showed that Pt/TiO2 nanocomposite showed better catalytic performance than TiO2 by 3.09 times.

Recovery and reusability of TiO2 and Pt/TiO2 nanocatalysts

Pt/TiO2 NCs can be easily recovered from the reaction mixture. After completion of the SOx removal reactions by using the aforementioned catalysts, these catalysts were collected from the reaction mixture by flirtation and washed with ethyl acetate, ethanol, and water, and then dried under vacuum. As shown in Fig. 7, Pt/TiO2 NCs could be recovered and reused at least five times, without any obvious decrease in catalytic activity.

The limitation and the scope of the method for the removal of SOx as an effective way for recovery of the nanocatalyst from sulfur poising using green and efficient approach at room temperature, under visible light photo-oxidation/photo-reduction approach, were studied. A series of experiments using other p-nitroacetanilide derivatives 2a–2e was used in the presence of Pt/TiO2 NCs under the investigated optimized condition (Scheme 2 and Table 3).

As it was observed from Table 2, several p-nitroacetanilide possessing various functional groups were subjected to the deSOx method. It was investigated that the approach is effective for capturing of SOx by its reaction with p-nitroacetanilide through photo-oxidation/photo-reduction reaction to produce p-aminoacetanilide derivatives 2b–2e. From the results, it was noted that all the formed products 2a–2e were afforded in excellent yields 93–99%, respectively without any observable change on the functional groups, i.e., OCH3, COCH3, F.

Discussion

The photocatalytic removing rate of SOx gas with Pt/TiO2 NCs is higher than TiO2 NPs under visible light irradiation due to its high specific surface area and narrow bandgap (at visible range). It was indicated that the newly developed protocol has several advantages regarding the formation of series of aromatic sulfonic acids and mitigation of SO2 gas effects. From the results, it was demonstrated that Pt/TiO2 NCs are known as optical semiconductor which showed greater efficiency than TiO2 NPs in absorbing visible light. By subjecting the Pt/TiO2 NCs to the energy of visible light, it changes to efficient semiconductor. This happened because electrons in valence band are photoexcited to the conduction band, causing the formation of holes in the valence band (Abdelsalam et al. 2020). The following mechanism can be proposed for the capturing of SOx gases: The noble metal (Pt) absorbs energy from visible light irradiation, as illustrated in Fig. 8.

The electrons of Pt can be excited to its conduction band and then migrate to the conduction band of TiO2, followed by electrons can move from the valance band of TiO2 to the valance band of Pt due to generated holes in valance band of Pt. The above-mentioned processes can increase the charge carrier lifetime and reduce electron–hole recombination, consequently improving the photocatalytic activity (Alamelu and Ali 2018; Muhich et al. 2012). In the first step, the holes can react with SOx atmosphere producing SO3− anions. While in the second step, the excited electrons can react with p-nitroacetanilide derivatives 1 for fixation of the SO3− anions forming aromatic sulfonic acid derivatives 2. These are extremely high beneficial process in which capturing SOx occurred by low-cost aromatic substances and converting them to valued products (Shang et al. 2002).

Table 4 showed comparison between the previous studies and the present approach (Table 4). From these results, it was observed few protocols in literature for abetment SOx through photocatalysis technology using continuous flow reactor. In contrast with other previously reported approaches, the present method was performed under mild condition that assists on efficient deSOx with a facile the synthesis of sulfamic acid derivatives as high-valued pharmaceutical compounds in facile (Şentürk et al. 2012; Abdulrasheed et al. 2018; Berger et al. 2020).

Conclusions

In this study, Pt/TiO2 NCs and TiO2 NPs photocatalysts were prepared and used for ultrafast reduction of 4-nitroacetanilides using flow photocatalytic reactor. The reaction of SOx as sulfonating agent with 4-nitroacetanilide derivatives under visible light irradiation conditions for the formation of sulfamic acid derivatives was investigated. Full characterizations of the as-prepared nanocatalysts were also conducted to investigate the relationship between the physico-chemical properties and the photocatalytic activity. The study showed that online continuous flow reactor–HRMS-TOF system was constructed to realize real-time monitoring of the reaction time. In this system, nearly complete reaction of 4-nitroacetanilide was achieved in a short time (60 s). This approach of SOx photocatalytic conversion is characterized by high performance, no need for high temperature or pressure, and the catalytic removal carried out in a short reaction time.

Data availability

The dataset supporting the conclusions of this article is available in the [https://pubs.rsc.org/en/content/articlelanding/2017/sc/c6sc03500k] repository.

References

Abdelhamid M, Attia YA, Abdel Harith M (2020) Significance of the nano-shapes in nanoparticle-enhanced laser-induced breakdown spectroscopy. J Anal at Spectrom 35(12):2982–2989

Abdelsalam EM, Mohamed YMA, Abdelkhalik S, El Nazer H, Attia YA (2020) Photocatalytic oxidation of nitrogen oxides (NOx) using Ag- and Pt-doped TiO2 nanoparticles under visible light irradiation. Environ Sci Pollut Res 27:35828–35836

Abdulrasheed AA, Jalil AA, Triwahyono S, Zaini MAA, Gambo Y, Ibrahim M (2018) Surface modification of activated carbon for adsorption of SO2 and NOX: a review of existing and emerging technologies. Renew Sust Energ Rev 94:1067–1085

Abou Saoud W, Assadi AA, Guiza M, Bouzaza A, Aboussaoud W, Ouederni A, Soutrel I, Wolbert D, Rtimi S (2017) Study of synergetic effect, catalytic poisoning and regeneration using dielectric barrier discharge and photocatalysis in a continuous reactor: abatement of pollutants in air mixture system. Appl Catal B: Environ 213:53–61

Ackermann RO, Aggarwal S, Dixon JR, Fitzgerald AD, Hanrahan DC, Hughes GA, Kunte A, Lovei M, Lvovsky K, Somani AH (1998) Pollution prevention and abatement handbook 1998: toward cleaner production (English). World Bank Group, Washington, DC

Alamelu K, Ali BMJ (2018) TiO2-Pt composite photocatalyst for photodegradation and chemical reduction of recalcitrant organic pollutants. J Environ Chem Eng 6(5):5720–5731

Al-Musawi TJ, Rl A, Yilmaz M, Mengelizadeh N, Asghari A, Balarak D, Darvishmotevall M (2022a) Synthesis of a doped α-Fe2O3/g-C3N4 catalyst for high-efficiency degradation of diazinon contaminant from liquid wastes. Magnetochemistry 8(11):137

Al-Musawi TJ, Yilmaz M, Mohebi S, Balarak D (2022b) Ultraviolet radiation/persulfate/hydrogen peroxide treatment system for the degradation of acid blue 80 dye from a batch flow chemical reactor: effects of operational parameters, mineralization, energy consumption, and kinetic studies. Energ Ecol Environ 7:630–640

Al-Musawi TJ, Yilmaz M, Ramírez-Coronel AA, Al-Awsi GRL, Alwaily ER, Asghari A, Balarak D (2023) Degradation of amoxicillin under a UV or visible light photocatalytic treatment process using Fe2O3/bentonite/TiO2: performance, kinetic, degradation pathway, energy consumption, and toxicology studies. Optik 272:170230

Amini N, Soleimani M, Mirghaffari N (2019) Photocatalytic removal of SO2 using natural zeolite modified by TiO2 and polyoxypropylene surfactant. Environ Sci Pollut Res 26(17):16877–16886

Attia YA (2016) Ag/ZnO/graphene-TBSCl hybrid nanocomposite as highly efficient catalyst for hydrogen production. Mater Express 6(3):211–219

Attia YA, Abdel-Hafez SH (2021) Nano Co3O4 catalyzed microwave-assisted one-pot synthesis of some seleno[2,3-b] pyridine/quinoline derivatives. Res Chem Intermed 47(9):3719–3732

Attia YA, Abdel-Hafez SH (2022) Nano Cu2O catalyzed ultrasonic-assisted green synthesis of some seleno[2,3-b] quinoline derivatives. J Organomet Chem 960:122245

Attia YA, Altalhi TA (2017) Low-cost synthesis of titanium dioxide anatase nanoparticles as advanced materials for hydrogen photoproduction. Res Chem Intermed 43(7):4051–4062

Attia YA, Mohamed YMA (2022) Nano Ag/AgCl wires photocatalyzed hydrogen production and transfer hydrogenation of Knoevenagel-type products. New J Chem 46:1677–1686

Attia YA, Mohamed YMA, Awad MM, Alexeree S (2020) Ag doped ZnO nanorods catalyzed photo-triggered synthesis of some novel (1H-tetrazol-5-yl)-coumarin hybrids. J Organomet Chem 919:121320

Ayturan ZC, Dursun S (2018) Usage of photocatalytic oxidation for the removal of air pollutants. Int J Ecosyst Ecol Sci 8(4):711–716

Baltrusaitis J, Jayaweera PM, Grassian VH (2011) Sulfur dioxide adsorption on TiO2 nanoparticles: influence of particle size, coadsorbates, sample pretreatment, and light on surface speciation and surface coverage. J Phys Chem C 115(2):492–500

Bellardita M, El Nazer HA, Loddo V, Parrino F, Venezia AM, Palmisano L (2017) Photoactivity under visible light of metal loaded TiO2 catalysts prepared by low frequency ultrasound treatment. Catal Today 284:92–99

Berger M, Brillard A, Dorge S, Habermacher D, Nouali H, Kerdoncuff P, Vierling M, Molière M, Patarin J, Brilh J-F (2020) Modeling SOx trapping on a copper-doped CuO/SBA-15 sorbent material. J Hazard Mater 385:121579

Carey JS, Laffan D, Thomson C, Williams MT (2006) Analysis of the reactions used for the preparation of drug candidate molecules. Org Biomol Chem 4(12):2337–2347

Chen TM, Gokhale J, Shofer S, Kuschner WG (2007) Outdoor air pollution: nitrogen dioxide, sulfur dioxide, and carbon monoxide health effects. Am J Med Sci 333(4):249–256

Chen Y, Su Y, Jiao F, Chen G (2012) A simple and efficient synthesis protocol for sulfonation of nitrobenzene under solvent-free conditions via a microreactor. RSC Adv 2(13):5637–5644

Cheremisinoff NP (2001) Handbook of Pollution Prevention Practices (1st ed.). CRC Press. https://doi.org/10.1201/9781482270877

Cheremisinoff NP (2002) Handbook of air pollution prevention and control (Elsevier)

Clarelli F, De Filippo B, Natalini R (2014) Mathematical model of copper corrosion. Appl Math Model 38(19–20):4804–4816

Eghbali P, Hassani A, Sündü B, Metin Ö (2019) Strontium titanate nanocubes assembled on mesoporous graphitic carbon nitride (SrTiO3/mpg-C3N4): preparation, characterization and catalytic performance. J Mol Liq 290:111208

El Kadib A, Chimenton R, Sachse A, Fajula F, Galarneau A, Coq B (2009) Functionalized inorganic monolithic microreactors for high productivity in fine chemicals catalytic synthesis. Angew Chem Int Edit 48:4969–4972

Eltohamy AM, Mohamed YMA, Abdelsalam EM, El Nazer H, Attia YA (2022) Photoactive TiO2/polyamide 11 (TiO2/PA-11) nanocomposite for degradation of methylene blue dye in wastewater. Egypt J Chem 13:753–758

Eun S-R, Mavengere S, Kim J-S (2021) Preparation of Ag-TiO2/Sr4Al14O25:Eu2+, Dy3+ photocatalyst on phosphor beads and its photoreaction characteristics. Catalysts 11:261

Flores LA, Murphy JG, Copeland WB, Dixon DA (2017) Reaction of SO2 with Group IV and VI transition metal oxide clusters. Comput Theor Chem 1120:46–55

Godish T (1991) Air quality. Chelsea, Mich : Lewis Publishers

Greene TW, Wuts PGM (2007) In Protective groups in organic synthesis, 3rd edn. Wiley & Sons, New York

Hassani A, Khataee A, Karaca S, Fathinia M (2017) Degradation of mixture of three pharmaceuticals by photocatalytic ozonation in the presence of TiO2/montmorillonite nanocomposite: Simultaneous determination and intermediates identification. J Environ Chem Eng 5(2):1964–1976

Hassani A, Krishnan S, Scaria J, Eghbali P, Nidheesh PV (2021) Z-scheme photocatalysts for visible-light-driven pollutants degradation: a review on recent advancements. Curr Opin Solid State Mater Sci 25(5):100941

Khallaf M, editor (2011) The Impact of Air Pollution on Health, Economy, Environment and Agricultural Sources. https://doi.org/10.5772/1000

Krishnan P, Zhang MH, Cheng Y, Riang DT, Yu LE (2013) Photocatalytic degradation of SO2 using TiO2-containing silicate as a building coating material. Constr Build Mater 43:197–202

Li X, Zou X, Qu Z, Zhao Q, Wang L (2011) Photocatalytic degradation of gaseous toluene over Ag-doping TiO2 nanotube powder prepared by anodization coupled with impregnation method. Chemosphere 83(5):674–679

Liu H, Zhang H, Yang H (2014) Photocatalytic removal of nitric oxide by multi-walled carbon nanotubes-supported TiO2. Chinese J Catal 35:66–77

Liu X, Ünal B, Jensen KF (2012) Heterogeneous catalysis with continuous flow microreactors. Catal Sci Technol 2:2134–2138

Mills A, Crow M, Wang J, Parkin IP, Boscher N (2007) Photocatalytic oxidation of deposited sulfur and gaseous sulfur dioxide by TiO2 films. J Phys Chem C 111(14):5520–5525

Mohamed YMA, Attia YA, El Nazer HA, Solum EJ (2021) An overview of recent development in visible light-mediated organic synthesis over heterogeneous photo-nanocatalysts. Curr Org Synth 18:23–36

Moors SLC, Deraet X, Van Assche G, Geerlings P, De Proft F (2017) Aromatic sulfonation with sulfur trioxide: mechanism and kinetic model. Chem Sci 8(1):680–688

Muhich CL, Zhou Y, Holder AM, Weimer AW, Musgrave CB (2012) Effect of surface deposited Pt on the photoactivity of TiO2. J Phys Chem C 116(18):10138–10149

Nanayakkara CE, Larish WA, Grassian VH (2014) Titanium dioxide nanoparticle surface reactivity with atmospheric gases, CO2, SO2, and NO2: roles of surface hydroxyl groups and adsorbed water in the formation and stability of adsorbed products. J Phys Chem C 118:23011–23021

Pan X (2019) Sulfur oxides. In: Nriagu JO (ed) Encyclopedia of environmental health. Elsevier, pp 823–829

Rabiee F, Mahanpoor K (2018) Experimental scale photocatalytic oxidation SO2 from simulated flue gas in the presence of Mn/copper slag as a novel nanocatalyst: optimizations by hybrid Box-Behnken experimental design and genetic algorithm. Russ J Appl Chem 91(4):687–700

Roberts DW (1998) Sulfonation technology for anionic surfactant manufacture. Org Process Res Dev 2(3):194–202

Sadeaka AA, Mahmoud EM, Abdellatif ES, Amr EA, Mohamed EAT, Attia Yasser A (2022) Heavy metal removal with nanoTiO2/chitosan modified poly(vinylidene chloride). Nanosci Nanotechnol-Asia 12(5):e190822207705

Şentürk GS, Vovk EI, Zaikovskii VI, Say Z, Soylu AM, Bukhtiyarov VI, Ozensoy E (2012) SOx uptake and release properties of TiO2/Al2O3 and BaO/TiO2/Al2O3 mixed oxide systems as NOx storage materials. Catal Today 184(1):54–71

Shang J, Zhu Y, Du Y, Xu Z (2002) Comparative studies on the deactivation and regeneration of TiO2 nanoparticles in three photocatalytic oxidation systems: C7H16, SO2, and C7H16-SO2. J Solid State Chem 166(2):395–399

Smith PWG, Tatchell AR (1969) Aromatic sulphonic acids. Aromat Chem 66–78. https://doi.org/10.1016/C2013-0-05520-X

Spix C, Anderson HR, Schwartz J, Vigotti MA, Letertre A, Vonk JM, Katsouyanni K (1998) Short-term effects of air pollution on hospital admissions of respiratory diseases in Europe: a quantitative summary of APHEA study results. Arch Environ Health Int J 53(1):54–64

Su C, Ran X, Hu J, Shao C (2013) Photocatalytic process of simultaneous desulfurization and denitrification of flue gas by TiO2-polyacrylonitrile nanofibers. Environ Sci Technol 47(20):11562–11568

Tada-Oikawa S, Ichihara G, Fukatsu H, Shimanuki Y, Tanaka N, Watanabe E, Suzuki Y, Murakami M, Izuoka K, Chang J, Wu W, Yamada Y, Ichihara S (2016) Titanium dioxide particle type and concentration influence the inflammatory response in Caco-2 cells. Int J Mol Sci 17:576

Taha M, Mohamed YMA, Medany SS, Attia YA (2022) Nano Ag/AgBr/g-C3 N4 catalyzed the production of hydrogen and reduction of D-glucose to sorbitol under visible light irradiation. New J Chem 46:17746–17754

Tsuneyasu S, Ichihara K, Nakamura K, Kobayashi N (2016) Why were alternating-current-driven electrochemiluminescence properties from Ru(bpy)32+ dramatically improved by the addition of titanium dioxide nanoparticles? Phys Chem Chem Phys 18:16317–16324

Wang H, Wu Y, Xu BQ (2005) Preparation and characterization of nanosized anatase TiO2 cuboids for photocatalysis. Appl Catal B 59:139–146

Wang H, Xie D, Chen Q, You C (2016) Kinetic modeling for the deactivation of TiO2 during the photocatalytic removal of low concentration SO2. Chem Eng J 303:425–432

Wang H, You C (2018) Photocatalytic oxidation of SO2 on TiO2 and the catalyst deactivation: a kinetic study. Chem Eng J 350:268–277

Wang L, Zhao Y, Zhang J (2017) Photochemical removal of SO2 over TiO2-based nanofibers by a dry photocatalytic oxidation process. Energy Fuels 31(9):9905–9914

Acknowledgements

The authors want to acknowledge the members of National Institute of Laser Enhanced Sciences (NILES), Cairo University and National Research Center (NRC) in Egypt for their support.

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB). The authors would like to acknowledge the Science and Technology Development Fund (STDF) of Egypt for funding this paper through research project number 43669.

Author information

Authors and Affiliations

Contributions

The hypothesis, as well as the conception and design of the experiments, was created by YAA and YMAM. Experiments were carried out by YMAM and YAA. The manuscript was written, reviewed, revised, and edited by YAA and YMAM. The final manuscript was read and approved by all authors.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Responsible Editor: Sami Rtimi

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Mohamed, Y.M.A., Attia, Y.A. Nano Pt/TiO2 photocatalyst for ultrafast production of sulfamic acid derivatives using 4-nitroacetanilides as nitrogen precursor in continuous flow reactors. Environ Sci Pollut Res 30, 51344–51355 (2023). https://doi.org/10.1007/s11356-023-25968-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-023-25968-9