Abstract

Freshwater is one of the most essential needs of society. Due to the limited amount of potable water on Earth, guaranteeing the supply of clean water to society is a major challenge. By utilizing abundant sunshine, solar still could be utilized to provide the necessary amount of drinking water in remote locations. The issue of restricted daily production inspires researchers to investigate novel ways for enhancing the thermal performance of desalination techniques while lowering expenses. In this work, the scholars improved a unique distillation method related to solar stills. The authors presented a novel improvement to the vertical distiller design to enhance the exposure area while decreasing the thickness of the water layer as much as possible. Thus, two rotational discs (flat type) covered with wick were integrated into the vertical distiller basin at 1.5 rpm and 5 cm water depth. Furthermore, providing vacuum via a fan with an external condenser. Besides, various rotating speeds (from 400 to 2000 rpm) were tested to determine the perfect fan speed that provides the maximum yield. The experimental findings revealed that the modified vertical distiller produced more pure water than the conventional distiller. Moreover, the rotation of wick discs and vacuum fan enhanced the yield of distillers enormously. Besides, the highest distiller performance was obtained at 1.5 rpm (wick disc speed) and 1600 rpm (fan speed, 10 min ON, and 10 min OFF). Moreover, the daily freshwater output was 19.1 L/m2 day for MDSVD without the fan and 23.65 L/m2 day for MDSVD with the fan. So, the yield of MSSVD without/with vacuum fan was improved by 548.65% and 660.45%, respectively, over that of CTD. The best thermal efficacy for MDSVD without/with vacuum fan was 77.47% and 84.05%, respectively. Lastly, the average cost of freshwater was 0.021, 0.0177, and 0.0164 $/L for CTD, MDSVD without/with vacuum fan, respectively.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The ability to obtain potable water or drinking water is one of the four major human birthrights (clean air, drinking water, healthy food, and clean energy) (Essa 2022; Saini et al. 2019). The major concern in many nations (both developed and developing) is the scarcity of drinkable water. This issue is becoming more pressing as the world’s population continues to grow, the industrial revolution continues, and agriculture progresses (Essa et al. 2020b). It is predicted that freshwater supplies would be 40% depleted by 2030 (Rijsberman 2006). Desalination of saline, brackish, or even contaminated water is an effective solution to this issue (Panchal et al. 2020). Solar energy is a renewable energy source that may be gathered and used to run thermal desalination systems utilizing simple, inexpensive, and readily accessible equipment (Essa et al. 2020c).

The academics were encouraged to develop novel desalination concepts and technologies to solve the arid region’s potable water dilemma, particularly in Africa (Abdullah et al. 2021a). As a result, scholars proposed different techniques of obtaining drinkable water from saline water as the only way out of the globe’s freshwater crisis. Because it is the most inexpensive, simple, and generally accessible equipment in the thermal desalination group (Bouchekima 2003), solar still was presented as a popular method for water purification (Omara et al. 2021). Nevertheless, solar distillers have a fundamental drawback (Abdullah et al. 2020b; Kabeel et al. 2016): they produce a little amount of drinkable water per day.

In order to improve distiller efficacy and thermal performance, the researchers focus on improving previous designs and implementing new models according to the effective parameters of solar still which include increasing evaporation surface area, studying heat transfer mechanisms, and reducing the depth of water in distillers (Nafey et al. 2000, Tiwari and Tiwari 2006). Consequently, the researchers studied the performance of distiller with fins (Omara et al. 2011), solar still with condensation unit (Kabeel et al. 2014b), distiller with corrugated absorbers (Omara et al. 2015), solar still with reflectors (Omara et al. 2016), distiller with nanoparticles (Kabeel et al. 2014a; Panchal et al. 2021), solar distiller with rotating wick (Abdullah et al. 2019a; Gad et al. 2011; Haddad et al. 2017), tubular solar still (Essa et al. 2021a), drum distiller (Abdullah et al. 2019b, 2021a), trays solar still (Abdullah et al. 2020a; Essa et al. 2021c), disc solar still (Essa et al. 2020d), hemispherical solar still (Attia et al. 2021), pyramid solar still (Alawee et al. 2021a; Essa et al. 2021e), and stepped solar still (Essa et al. 2020a; Gandhi et al. 2021).

The free surface area of evaporation and condensation is one of the most important elements in determining the amount of freshwater produced by the solar still. Many designs and improvements were proposed to improve the solar distillers’ evaporative surface area to enhance yield. Solar distillers with rotating parts (Diab et al. 2021; Essa et al. 2021d) were recommended as a means of achieving this target. The rotating components cause the molecules of water on the surface to break their bonds (surface tension) and decrease the water film as much as possible. Many academics studied the effect of rotational elements on distiller performance such as rotating shaft (Abdel-Rehim and Lasheen 2005, Kumar et al. 2016), fan (Eltawil and Zhengming 2009, Omara et al. 2017), disc (Essa et al. 2020d, 2021d), drum (Abdullah et al. 2019b, 2021a; Alawee et al. 2021b; Essa et al. 2021b; Malaeb et al. 2016), and rotating wick (Abdullah et al. 2019a, 2019b, 2021b; Gad et al. 2011; Haddad et al. 2017; Omara et al. 2021), and these amendments have been more productive than conventional distillers. The surface tension is broken due to the rotation of the elements and the natural mechanism for heat transfer is changed to the forced. These conducts may accelerate the rate of evaporation.

As concluded in a recent review, Diab et al. (2021) discussed the impact of rotating parts inside the different solar distillers. The rotating disc technique was investigated to enhance solar distiller performance. The impact of utilizing a rotating disc inside the basin of a conventional distiller was tested by Essa et al. (2020d). The researchers reported that the disc solar still produced more potable water than the conventional still. Therefore, the corrugated disc distiller with wick was able to produce 124% more distilled water than conventional still at 0.05 rpm. Besides, the corrugated and flat disc distillers covered with wick had an overall efficiency of 54.5% and 50%, respectively. In a recent study, Essa et al. (2021d) investigated experimentally the incorporation of rotating discs inside the vertical distiller at various rotational speeds. The findings indicated that integrating discs within the vertical distiller significantly increased clean water yield as compared to a traditional distiller. Furthermore, the rotary discs’ effective speed was 1.5 rpm at 5 cm saltwater depth which enhanced the yield of modified vertical still by 617.4% over the conventional still.

Moreover, many scholars tested another rotating part (drum) to improve the distiller performance. To enhance the evaporation surface area and reduce the water thickness, Malaeb et al. (2016) proposed a revolving drum inside of the solar distiller. Solar still freshwater production was increased by 250% as a result of this improvement. According to another research by Ayoub et al. (2013), drum speed, basin water depth, and cover cooling are all factors that impact the efficiency of drum solar still. A low drum speed without generating dry spots on the drum’s surface was determined by the authors. In another study, incorporating a rotary fan within the solar still, Kabeel et al. (2012) enhanced potable water output by 25%. Also, Omara et al. (2017) mounted a rotary fan within the solar desalination system and evaluated its effectiveness at different water levels. Scholars indicated that at low fan speeds, the depth of basin water should be as minimal as possible. The drinking water output of the modified distiller combined with a rotating fan was increased by 17%. Furthermore, Essa et al. (2021b) reported observational and analytical research that used a moving drum with two different ends to enhance the productivity of a tubular distiller (closed and opened ends) by 175% at 0.05 rpm with open ends drum and wick.

On another parameter, the capillary effect of wick materials that utilized to cover the moving element made scientifically enhancement the performance of the solar distiller. Haddad et al. (2017) vertically incorporated rotating wick inside the basin of conventional distiller for enhancing the exposed area, evaporating rate, and condensation rate due to water-thin film and wick effect which led to increasing the distiller yield by 14.72% and 51.1% in summer and winter, respectively. In a similar study, installing wick belt on still basin but the belt was horizontal, by Gad et al. (2011), improving the still efficacy up to 43%. Abdullah et al. (2019a, 2021b) tried to maximize the amount of evaporation and exposure area of solar still by utilizing a rotary belt horizontally and vertically at the same time. Controlling the belt speed and its ON–OFF time enhanced the still productivity by 315% at 5 min belt ON and 30 min OFF. Besides, the distillate yield progressed from 4.35 to 7.25 L/m2/day via utilizing manual tracking for vertical rotating wick still (Omara et al. 2021) with jute cloth at 0.1 rpm (CCW). Moreover, installing a rotary shaft within the still to increase potable water output by Zeinab and Ashraf (Abdel-Rehim and Lasheen 2005). The best efficacy was enhanced by 5.5% in July.

Considering the impact of vapor withdrawal on still efficacy, Kabeel et al. (2014a) sought to improve the purified water amount through the use of various sorts of nanoparticles with different percentages of the weight fraction. They deduced that the performance was enhanced by 133.64% and 93.87% above traditional still with and without fan by using cuprous oxide–water nanofluid. In another investigation, El-Samadony et al. (2015) investigated experimentally the efficacy of the stepped distiller containing reflector(s) and external condenser. A vacuum fan is attached from the upper back end to the distiller to extract water vapor and transfer it to a condenser. It was shown that a modified distiller with a condenser increased profitability by 165% compared to traditional still if both reflectors and the external condenser were mounted. Moreover, Omara et al. (2015) analyzed the efficacy of the corrugated wick distiller using inner reflectors, combined with external condensers while using various kinds of nanoparticles. Experiments showed that the use of the nanomaterials cuprous and aluminum oxides raises the modified distiller efficiency by around 285.10% and 254.88%, respectively. Also, Kumar et al. (2016) used a stirrer for agitating water in the basin and an external condenser was mounted for withdrawal of some vapor and condensing it.

Regarding the previous concise literature, our recently published review (Diab et al. 2021), and our previous work (Essa et al. 2021d), incorporating rotating discs in vertical distiller augmented extremely the distillate yield of still. However, there was a problem that appeared during experiments on modified double-stage vertical distiller (MDSVD). That problem was the formation of a large amount of vapor in the lower stage, unable to condense due to the hot saltwater in the upper stage. So, the authors installed a vacuum fan with an external condenser for extracting vapor as a step for improving the distiller performance.

Hence, the major aims of this work are to lessen the saltwater layer on rotating discs, capture solar energy as much as possible due to stationary tracking of the sun, eliminate surface tension because of movement, enhance evaporation rate via wick covering discs, and increase the rate of condensation by vapor withdrawal via rotating fan with a condenser. Therefore, the innovation of this study can be summarized as follows:

-

1.

A wick-covered aluminum disc was incorporated into the vertical solar still. A portion of the disc’s lower surface is immersed in saltwater that led to improve the exposed surface of solar radiation and evaporative area in the still basin.

-

2.

The authors evaluated the MDSVD performance compared to conventional tilted distiller (CTD).

-

3.

The impact of utilizing wick was tested at 1.5 rpm for discs and 5 cm water depth.

-

4.

The MDSVD performance incorporated with a rotating vacuum fan with a separate condenser was investigated at numerous fan speeds (400, 800, 1200, 1600, and 2000 rpm) at the same previous conditions for disc and saltwater depth.

-

5.

Controlling the ON–OFF times for rotary fan was tested at two conditions (10 min ON–10 min OFF and 10 min ON–20 min OFF) at the optimum fan speed.

Design and experimentation of system

Solar still description

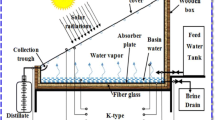

As illustrated in Fig. 1 and Fig. 2, the observational tests consisted of two kinds of solar desalination units and a saltwater reservoir feeding both stills. The first distiller was conventional tilted distiller (CTD) that was utilized as a reference for our measurements, and the inclination angle of glass cover was 31°. The second distiller was modified double-stage vertical distiller (MDSVD) that was incorporated with four rotating discs covered with wick and fitted with a vacuum fan. Both distillers were at the same atmospheric conditions to get a fair comparison between their performance.

The detailed description of CTD, as seen in Fig. 3, was 1 m long and 0.5 m wide. Besides, the heights were 0.15 m for the lower side and 0.45 m for the upper side. So, the still projected area was 0.5 m2. The authors used 1.5-mm galvanized steel for the distiller basin and aimed to capture more solar radiation, so they coated it by matt black paint. Also, the distiller was insulated by 5 cm fiberglass to prevent heat loss from gaps between the still basin and the wooden frame. Subsequently, they covered the solar still by 3-mm glass sheet. Moreover, a sloping trough was used to collect the condensed droplets, which were then sent out of the basin and gathered in graded flasks. On the bottom of the distiller, there was a pipe and a valve that regulated the extra outflow.

According to the layout of MDSVD as shown in Fig. 3, the authors reduced the projected area of the modified distiller to 0.1 m2. Additionally, they used different types of solar desalination units (vertical distiller). Moreover, the construction of MDSVD was as follows:

-

1.

Double stages of vertical solar still and the dimensions of each stage were 1 m long, 0.1 m wide, and 0.5 high. Besides, the still basin was made of 2-mm galvanized steel and also coated with matt black paint. Furthermore, a 4-mm glass sheet covered the still from four sides as indicated in Fig. 1 for sun tracking. The inclination to the upper base was enough small (tanα = 1/10) to benefit from the condensing water on it. If it was bigger, the amount of vapor would be less due to the reduction in the inner distiller volume and the cover would be very close to the rotating discs. So, the scholars preferred to make this tilt angle of glass cover as tanα = 1/10 to benefit from the condensing water and avoid the demerits of enlarging it as mentioned above. Also, the authors used 4-mm glass sheet for MDSVD to withstand loads (glass weight of four sides and vibration due to rotation). However, the authors used 3-mm glass sheet for CTD still because it has better transparency and the CTD design was simple compared to MDSVD. Finally, the same insulation, feeding, and L-shape wooden frame were used in this distiller.

-

2.

Two rotating discs in each stage were installed on the south side of the still and made of 3-mm black-painted aluminum. The flat discs were 0.45 m in diameter and covered with black jute cotton from all sides. In addition, a stepper motor (6 W—DC) was used to rotate the circular discs via pulley and belt arrangement at 1.5 rpm by the control unit (Fig. 4).

-

3.

The lower stage of MDSVD was integrated with an air suction fan (axial-flow type) that drawled water vapor into the condenser coil which consisted of copper pipe (2 m length and 2 cm diameter) was enclosed in a tank filled with cold water. The condensate water is collected in a graded bottle at the end of the pipe. The blade diameter of the fan was 10 cm, and the authors controlled the fan speed by speed controller from 400 to 2000 rpm (400, 800, 1200, 1600, and 2000 rpm). Besides, the scholars controlled the ON–OFF times for the rotary fan via a timer at two conditions (10 min ON–10 min OFF and 10 min ON–20 min OFF) at the optimum fan speed.

Experimental tests

Experiments were carried out in the Faculty of Engineering, Kafrelsheikh University, Egypt (latitude = 31.1107° N and longitude = 30.9388° E). The trials were carried out in August and September 2021. All the distillers under consideration were oriented east–west to catch as much of the sun’s energy as feasible. At the same time, factors impacting distiller productivity such as water temperature, ambient temperature, solar radiation, glass temperature, and air speed were measured. In addition, the distilled water production was recorded hourly. Two stills were set on a fair foundation for the operating and environmental standards. The saline water depth within the vertical distiller was 5 cm to cover a larger area of the two rotating discs that are responsible for increasing production in this experiment. The second reason was that the authors utilized 5 cm vertical still to contain the same amount of water as a traditional distiller. The bottom of the discs was immersed in the water basin.

Initially, the bottom disc part was immersed in the disc basin. Hence, the discs started to rotate at the set speed. As a result of movement, the top section of the discs has become a lower portion, and vice versa. Therefore, a thin layer of water formed on the surfaces of the discs. Because it does not take long to warm up, this layer evaporated quickly. In addition, potable water was gathered and recorded daily.

The experimental investigations were performed in some stages. Firstly, the distiller’s performance was examined at constant water depth (5 cm). Besides, flat discs covered with wick were tested at the optimum disc speed (1.5 rpm) from the previous trials. Secondly, flat discs covered with wick and installing a fan with an external condenser were investigated at numerous fan speeds (400, 800, 1200, 1600, and 2000 rpm). Thirdly, the running time of the rotary fan was tested at two conditions (10 ON–10 OFF and 10 ON–20 OFF). Every single modification was examined through an experiment in one complete day.

Measuring instruments

The instruments used to estimate the factors affecting the output yield of the solar still are K-type thermocouples, van type anemometer, Datalogging solar power meter, and graded flasks. The Datalogging solar power meter was used to measure solar radiation. Temperature analysis at various distiller points was performed by the K-type thermocouples. In addition, the speed of air was measured by a van anemometer. Moreover, a calibrated small bottle was used to record the distillate.

The uncertainty in the measured data was estimated using the method proposed by Holman (2012). The result errors can be estimated by:

where WR is the resultant uncertainty, and W1, W2, W3, …, Wn are the uncertainties in the independent parameters. The measuring devices’ specifications are listed in Table 1. Furthermore, the hourly yield may be expressed as a function of basin water depth, m = f (h). As a result, the uncertainty for productivity is as follows:

Additionally, the uncertainty in thermal efficacy (\({\eta }_{th}\)) is:

As a consequence, the errors in daily productivity and efficacy of distillers are approximately ± 1.4% and ± 2.5%, respectively.

Results and discussion

Considering various operating scenarios, the implications of rotational wick disc and fan for vapor suction adjustments on the thermal behavior of the still were investigated. Temperature variations, radiation from the sun factors, and daily clean water yield were employed to evaluate the thermal performance of the current still. The thermal efficiency and potable water production output of the current modified and traditional solar stills were analyzed under identical conditions.

Performance of MDSVD with rotating discs covered with wick at 1.5 rpm

The authors tested the performance of MDSVD incorporated with rotating wick discs at 1.5 rpm and 5 cm water depth in 14/08/2021 and the measurements for solar radiation and temperature were recorded hourly from 9:00 to 17:00, as shown in Fig. 5. During the measuring period, the sun radiation grew steadily until noon, when it reached its maximum (935 w/m2) on the inclined surface. Then, as seen in Fig. 5, its value gradually dropped until it reached its lowest point at sunset. There was a difference between CTD and MDSVD in the amount of solar radiation from one side to another due to the design of the glass cover. Accordingly, solar radiation was measured from inclined, front, east, and west sides (Fig. 5).

Furthermore, the variations of ambient, water basin, and outside glass cover temperatures were affected by the solar radiation and took the same trend, as illustrated in Fig. 6. The analysis of temperature variations showed that CTD had a higher temperature than MDSVD by about 1.6–13.3 °C due to the angle of receiving direct incident radiation that was responsible for basin water heating. However, MDSVD captured more radiation because of tracking the sun due to its glass design and installing aluminum discs, the wick materials absorbed much solar energy and caused the reduction of water temperatures. Also, the heat loss from MDSVD was higher than CTD because MDSVD was only insulated from the back and bottom sides.

Furthermore, there was a difference between basin water temperatures on the double stages of MDSVD because the water of the upper stage was heated by the vapor of the lower stage due to the glass sheet between them. On the other hand, the glass temperatures of two distillers took the same trend. Besides, CTD glass temperature was higher than that of MDSVD. That is related to basin water temperature and the glass cover area which is exposed to the air. Briefly, the difference between CTD and MDSVD outside glass temperature was about 0.5–3.5 °C.

Comparing hourly distillate yield per 1 m2 between CTD and MDSVD with wick, Fig. 7 presents the variation of hourly freshwater output for CTD, lower stage of MDSVD, and upper stage of MDSVD. Nevertheless, as a result of wick discs and saltwater had not yet been heated, there was not enough potable water output in the morning. Henceforth, CTD, 1st stage of MDSVD, and 2nd stage of MDSVD reached their supreme levels of 0.62, 1, and 1.5 L/m2 h at 14:00, respectively, as sun radiation increased.

The authors observed that the modifications done on the vertical distiller massively increased the freshwater yield compared to that of CTD. Also, according to solar radiation and temperatures variations (Fig. 5 and Fig. 6), the hourly productivity increased from morning until reached peak as mentioned before. After that, it began to decrease gradually till sunset. Leading reasons for this enhancement include the following: first, the discs played an important role in reducing the water film (main effective parameter of distiller performance) as much as possible. So, the evaporation process happened faster compared to CTD. Also, covering the rotating discs enlarges the wet area of discs taking advantage of the capillary effect property for wick. Second, MDSVD had a huge accessible surface area (0.5 m2 for CTD and 1.48 m2 for MDSVD, 196% rise) that could capture more radiation from the sun. That led to an enormous rate of evaporation inside MDSVD more than CTD. Third, the surface tension of the water surface was broken due to the movement of discs inside MDSVD basin. Related to turbulence, the water evaporation happened more easily and heightened its rate on MDSVD more than CTD. Forth, the stationary sun tracking of MDSVD increased the absorbed amount of solar radiation (6276 W/m2 for CTD, 0.5 m2 exposure area vs 16,109 W/m2 for MDSVD, 1.48 m2 exposure area). Fifth, due to the greater condensation area of MDSVD compared to the conventional still, this milestone was achieved. A condensation process on traditional still happened just on the single-slope glass cover, but on MDSVD occurred on four sides of the glass cover. Besides, the little vibration of the motor helped the condensate droplets to be collected.

Figure 8 presents the hourly accumulated yield for CTD, 1st stage of MDSVD, 2nd stage of MDSVD, and MDSVD. This figure showed that MDSVD had a large clean water output during the whole day compared to CTD. The daily freshwater of CTD, 1st stage of MDSVD, 2nd stage of MDSVD, and MDSVD was 2.96, 7.75, 11.45, and 19.2 L/m2 day, respectively. So, the enhancement percentage of MDSVD was 548.65% over CTD output. As discussed in the previous section, the milestones for this high increase could be concluded as follows: minimum water film on discs, the capillary effect of wick, large surface area, large evaporation and condensation rates, movement inside distiller, forced evaporation process, sun tracking, and breaking surface tension.

Performance of MDSVD with a rotating fan with an external condenser at various fan speeds

The scholars faced a problem that appeared during experiments on modified double-stage vertical distiller (MDSVD). That problem was the formation of a large amount of vapor in the lower stage, unable to condense due to the hot saltwater in the upper stage. So, the authors installed a vacuum fan with an external condenser for extracting vapor as a step for improving the distiller performance. During the investigation, the MDSVD performance with a constant water depth of 5 cm and rotating wick discs at 1.5 rpm was tested to a variety of rotating fan speeds (400, 800, 1200, 1600, and 2000 rpm) to determine the influence of vapor withdrawal on the performance of MDSVD.

According to the trials data, the MDSVD achieved the best performance at the best rotating fan speed (1600 rpm), as shown in Table 2. Additionally, the scholars chose to display the findings at a single speed to highlight the influence of fan adjustment and wick discs on MDSVD performance. Furthermore, Table 2 shows the atmospheric conditions and stills productivity during the testing days at various fan speeds.

As discussed in the previous section, there was another reason for the increase of MDSVD output. The non-condensable vapor from the lower stage of MDSVD is exhausted to the exterior condensation unit through the small power fan. Furthermore, the fan drawled non-condensable vapor from the basin and transported it to the condensation unit. The impact of non-condensable vapor, which reduced condensation ratio, is also eliminated. In addition, the fan circulated air within the MDSVD lower stage. Consequently, the evaporation rate was enhanced due to the air circulation and vapor withdrawal caused by the fan. Because of this difference in evaporation and condensation capabilities, MDSVD produced at a quicker and higher rate than the traditional one.

The impact of installing a fan was shown obviously on the hourly and accumulated productivity of MDSVD, as indicated in Fig. 9 and Fig. 10, respectively.

Comparing hourly distillate yield per 1 m2 between CTD and MDSVD with wick and continuous rotating fan with a condenser, Fig. 9 presents the variation of hourly freshwater output for CTD, lower stage of MDSVD, upper stage of MDSVD, and rotating fan. Nevertheless, as a result of wick discs, negative pressure due to the fan and saltwater had not yet been heated, there was not enough potable water output in the morning. Henceforth, CTD, 1st stage of MDSVD, 2nd stage of MDSVD, and rotating fan reached their supreme levels of 0.6, 1.15, 1.65, and 0.5 L/m2 h at 14:00, respectively, as sun radiation increased.

Figure 10 presents the hourly accumulated yield for CTD, 1st stage of MDSVD, 2nd stage of MDSVD, continuous rotating fan with a condenser, and MDSVD. This figure showed that MDSVD had a large clean water output during the whole day compared to CTD. The daily freshwater of CTD, 1st stage of MDSVD, 2nd stage of MDSVD, continuous rotating fan with a condenser, and MDSVD was 3.08, 8.95, 11.25, 2.9, and 23.1 L/m2 day, respectively. So, the enhancement percentage of MDSVD was 650% over CTD output and the consumed power of the fan was 44Wh. As discussed in the previous sections, the milestones for this high increase could be concluded as follows: minimum water film on discs, the capillary effect of wick, large surface area, large evaporation and condensation rates, movement inside distiller, forced evaporation process, sun tracking, vapor withdrawal, and breaking surface tension.

Performance of MDSVD at the best fan speed and controlling fan ON–OFF times

In order to increase the distiller efficacy, the authors aimed to control the ON–OFF times to decrease the consumed power of rotating fan. So, the study investigated the best fan speed (1600 rpm) at various conditions (continuous fan speed at 1600 rpm, 1600 rpm at 10 ON–10 OFF times, and 1600 rpm at 10 ON–20 OFF times), as presented in Table 3.

In the next sections, the best condition will be declared obviously by figures to avoid reputations.

Daily productivity rise

The rise in daily productivity for MDSVD at several speeds of the rotating fan and ON–OFF conditions is shown in Fig. 11. The daily improvement in productivity, as indicated in the figure, is dependent on the control parameters of the rotation speed of the fan, and also the adjustment performed on the vertical distiller such as rotating discs at 1.5 rpm and wick effect. The output of clean water will increase when the fan speed is increased from 400 rpm to the maximum productivity of 1600 rpm. Then, when the speed changes from 1600 to 2000 rpm, it begins to drop. Besides, the controlling of fan ON–OFF times improved the distillate yield of MDSVD. The authors compared the productivity of MDSVD to that of CTD under the same conditions in each experimental test to ensure a fair comparison even if the weather changed from one day to the next because it would change by the same value on both distillers.

The maximum daily productivity rise was obtained for MDSVD over CTD at 1.5 rpm rotating wick discs, as shown in Fig. 11. The greatest yield was gained at 1600 rpm fan running 10 ON–10 OFF times, where the output gain for MDSVD was approximately 660.45% (23.65 L/m2 day) compared to that of CTD (3.11 L/m2 day). Moreover, the freshwater was reduced at higher fan speeds compared to 1600 rpm as the quicker rotation of the fan provided high vapor flowrate and depleted more thermal energy from the distiller.

Daily thermal efficiency

The daily efficacy, \(\upeta\) d, of the solar still is calculated from the following equation (Essa et al. 2020d):

In this section, the daily efficacy of the investigated solar stills in the various investigated scenarios is explained in Fig. 12. The scholars observed that the efficacy of CTD varied from 30.89 to 32.15% during tests. Moreover, the MDSVD efficacy recorded its peak value (84.05%) at the same conditions following Fig. 10.

Relation of the current research to prior studies

Prior studies are compared to the present study’s results to identify how much growth can be made with the redesigned vertical distiller. As shown in Table 4, our results were compared to those of the prior publications. Using a traditional solar still as a reference, the efficacy of the incorporated modifications was assessed by comparing.

Evaluation of 1 L cost of distillate water

The economic study for the distillers under consideration mainly focuses on the distiller classification including its elements, presented in Table 5.

In order to approximate the cost of freshwater provided by CTD and MDSVD, the analytical formulas have been demonstrated as seen below (Abdullah et al. 2020b):

where N is the still lifetime (number of years), and (i) is the interest rate.

where F is the distiller capital cost ($).

where M is the average freshwater yield in year.

The considerations of the cost analysis are as follows: the interest rate is 15%, the number of working days per year is 340 days (sunny days in Egypt), and the distiller lifetime is 10 years. The daily productivity is approximately 3.11, 19.2, and 23.65 L/m2 day for CTD and MDSVD without/with fan, respectively. As a result, the cost of freshwater produced by CTD and MDSVD without/with fan was estimated to be 0.021, 0.0177, and 0.0164 $/L, respectively.

Conclusion

The performance of the vertical distiller incorporated with rotating discs covered with wick and a rotary fan with an external condenser was experimentally investigated and compared with a conventional still. The main parameter tested in this study was the rotational speed variations of fan. Mainly focused on the above-mentioned discussed findings, it is declared that:

-

1-

The integration of rotating fan within the lower stage of MDSVD increased dramatically the yield of purified water and thermal energy efficacy due to minimum water film on discs, the capillary effect of wick, large surface area, large evaporation and condensation rates, movement inside distiller, forced evaporation process, sun tracking, vapor withdrawal, and breaking surface tension.

-

2-

The daily accumulated freshwater output was 3.11, 19.2, and 23.65 L/m2 day for CTD and MDSVD without/with fan, respectively. In addition, for the modified distiller, the highest amount of yield was gained at 1600 rpm for fan and 10 ON–10 OFF times. As a result, the freshwater distillate of MDSVD without/with fan was improved by 548.65% and 660.45% compared to that of CTD, respectively.

-

3-

The supreme thermal efficacy for CTD and MDSVD without/with fan was 31.04%, 77.47%, and 84.05%, respectively.

-

4-

The costs of freshwater obtained from CTD and MDSVD without/with fan are found to be 0.021, 0.0177, and 0.0164 $/L, respectively.

Scope for further research

There are a variety of reasons why solar stills with rotating components should be studied in greater depth:

-

To improve the absorption and evaporation areas, different rotating disc geometries are indeed being investigated.

-

The solar still may be fitted with a solar tracking device to ensure that it receives consistent energy from the sun.

-

As a heat storage material in the still, sensible materials and nanoparticles can be utilized to store energy.

Data availability

Not applicable.

Abbreviations

- A:

-

Projected area of still (m2)

- AMC:

-

The annual maintenance and operating costs ($)

- ASV:

-

The annual salvage value ($)

- CPL:

-

The freshwater cost ($/L)

- CRF:

-

The capital recovery factor

- F:

-

The distiller capital cost ($)

- FAC:

-

The fixed annual cost ($)

- hfg :

-

Latent heat of vaporization (KJ/kg)

- i:

-

The interest rate (%)

- I(t):

-

Solar intensity (W/m2)

- \(\dot{\mathrm{m}}\) :

-

Hourly distillate yield (mL/m2 h)

- M:

-

The average freshwater yield in year (L/m2 year)

- N:

-

The still lifetime (years)

- S:

-

The salvage value ($)

- SFF:

-

The sinking fund factor

- TAC:

-

The total annual cost ($)

- Η:

-

Efficiency

- CTD:

-

Conventional tilted distiller

- MDSVD:

-

Modified double-stage vertical distiller

References

Abdel-Rehim ZS, Lasheen A (2005) Improving the performance of solar desalination systems. Renewable Energy 30:1955–1971

Abdullah AS, Alarjani A, Abou Al-sood MM, Omara ZM, Kabeel AE, Essa FA (2019a) Rotating-wick solar still with mended evaporation technics: experimental approach. Alex Eng J 58:1449–1459

Abdullah AS, Essa FA, Omara ZM, Rashid Y, Hadj-Taieb L, Abdelaziz GB, Kabeel AE (2019) Rotating-drum solar still with enhanced evaporation and condensation techniques: comprehensive study. Energy Convers Manag 199:112024

Abdullah AS, Essa FA, Bacha HB, Omara ZM (2020) Improving the trays solar still performance using reflectors and phase change material with nanoparticles. Journal of Energy Storage 31:101744

Abdullah AS, Younes MM, Omara ZM, Essa FA (2020b) New design of trays solar still with enhanced evaporation methods–comprehensive study. Sol Energy 203:164–174

Abdullah AS, Omara ZM, Alarjani A, Essa FA (2021) Experimental investigation of a new design of drum solar still with reflectors under different conditions. Case Studies in Thermal Engineering 24:100850

Abdullah AS, Omara ZM, Essa FA, Alarjani A, Mansir IB, Amro MI (2021) Enhancing the solar still performance using reflectors and sliding-wick belt. Sol Energy 214:268–279

Alawee WH, Essa FA, Mohammed SA, Dhahad HA, Abdullah AS, Omara ZM, Gamiel Y (2021) Improving the performance of pyramid solar distiller using dangled cords of various wick materials: novel working mechanism of wick. Case Studies in Thermal Engineering 28:101550

Alawee WH, Mohammed SA, Dhahad HA, Abdullah AS, Omara ZM, Essa FA (2021) Improving the performance of pyramid solar still using rotating four cylinders and three electric heaters. Process Saf Environ Prot 148:950–958

Attia MEH, Kabeel AE, Abdelgaied M, Essa FA, Omara ZM (2021) Enhancement of hemispherical solar still productivity using iron, zinc and copper trays. Sol Energy 216:295–302

Ayoub GM, Malaeb L, Saikaly PE (2013) Critical variables in the performance of a productivity-enhanced solar still. Sol Energy 98:472–484

Bouchekima B (2003) A solar desalination plant for domestic water needs in arid areas of South Algeria. Desalination 153:65–69

Diab MR, Essa FA, Abou-Taleb FS, Omara ZM (2021) Solar still with rotating parts: a review. Environ Sci Pollut Res 28:54260–54281

Eldalil KM (2009a): New concept for improving solar still performance by using vibratory harmonic effect experimental prediction, part-2, Thirteenth International Water Technology Conference, IWTC. Citeseer

Eldalil KM (2009b): New concept for improving solar still performance by using vibratory harmonic effect experimental prediction, part-1, Thirteenth International Water Technology Conference, IWTC. Citeseer, pp. 2009b

Eldalil KM (2010) Improving the performance of solar still using vibratory harmonic effect. Desalination 251:3–11

El-Samadony YAF, Abdullah AS, Omara ZM (2015) Experimental study of stepped solar still integrated with reflectors and external condenser. Experimental Heat Transfer 28:392–404

Eltawil MA, Zhengming Z (2009) Wind turbine-inclined still collector integration with solar still for brackish water desalination. Desalination 249:490–497

Essa FA (2022) Thermal desalination systems: from traditionality to modernity and development. Distillation Processes - From Conventional to Reactive Distillation Modeling, Simulation and Optimization. IntechOpen, London, p 23

Essa FA, Omara ZM, Abdullah AS, Shanmugan S, Panchal H, Kabeel AE, Sathyamurthy R, Alawee WH, Manokar AM, Elsheikh AH (2020) Wall-suspended trays inside stepped distiller with Al2O3/paraffin wax mixture and vapor suction: experimental implementation. Journal of Energy Storage 32:102008

Essa FA, AbdElaziz M, Elsheikh AH (2020) An enhanced productivity prediction model of active solar still using artificial neural network and Harris Hawks optimizer. Appl Therm Eng 170:115020

Essa FA, AbdElaziz M, Elsheikh AH (2020) Prediction of power consumption and water productivity of seawater greenhouse system using random vector functional link network integrated with artificial ecosystem-based optimization. Process Saf Environ Prot 144:322–329

Essa FA, Abdullah AS, Omara ZM (2020) Rotating discs solar still: new mechanism of desalination. J Clean Prod 275:123200

Essa FA, Abdullah AS, Omara ZM (2021) Improving the performance of tubular solar still using rotating drum – experimental and theoretical investigation. Process Saf Environ Prot 148:579–589

Essa FA, Abdullah AS, Omara ZM (2021) Improving the performance of tubular solar still using rotating drum–experimental and theoretical investigation. Process Saf Environ Prot 148:579–589

Essa FA, Abdullah AS, Omara ZM, Kabeel AE, Gamiel Y (2021) Experimental study on the performance of trays solar still with cracks and reflectors. Appl Therm Eng 188:116652

Essa FA, Alawee WH, Mohammed SA, Abdullah AS, Omara ZM (2021) Enhancement of pyramid solar distiller performance using reflectors, cooling cycle, and dangled cords of wicks. Desalination 506:115019

Essa FA, Abou-Taleb FS, Diab MR (2021d): Experimental investigation of vertical solar still with rotating discs. Energy Sources, Part A: Recovery, Utilization, and Environmental Effects, 1–21

Gad HE, El-Gayar S, Gad HE (2011): Performance of a solar still with clothes moving wick, 15th International Water Technology Conference, IWTC, pp. 28–30

Gandhi AM, Shanmugan S, Gorjian S, Pruncu CI, Sivakumar S, Elsheikh AH, Essa FA, Omara ZM, Panchal H (2021) Performance enhancement of stepped basin solar still based on OSELM with traversal tree for higher energy adaptive control. Desalination 502:114926

Haddad Z, Chaker A, Rahmani A (2017) Improving the basin type solar still performances using a vertical rotating wick. Desalination 418:71–78

Holman J (2012) Experimental methods for engineers. McGraw-Hill Companies, New York

Kabeel AE, Hamed MH, Omara ZM (2012) Augmentation of the basin type solar still using photovoltaic powered turbulence system. Desalin Water Treat 48:182–190

Kabeel AE, Omara ZM, Essa FA (2014) Improving the performance of solar still by using nanofluids and providing vacuum. Energy Convers Manage 86:268–274

Kabeel AE, Omara ZM, Essa FA (2014) Enhancement of modified solar still integrated with external condenser using nanofluids: an experimental approach. Energy Convers Manage 78:493–498

Kabeel AE, Omara ZM, Essa FA, Abdullah AS (2016) Solar still with condenser–a detailed review. Renewable Sustainable Energy Reviews 59:839–857

Kumar RA, Esakkimuthu G, Murugavel KK (2016) Performance enhancement of a single basin single slope solar still using agitation effect and external condenser. Desalination 399:198–202

Malaeb L, Aboughali K, Ayoub GM (2016) Modeling of a modified solar still system with enhanced productivity. Sol Energy 125:360–372

Nafey AS, Abdelkader M, Abdelmotalip A, Mabrouk AA (2000) Parameters affecting solar still productivity. Energy Convers Manage 41:1797–1809

Omara ZM, Hamed MH, Kabeel AE (2011) Performance of finned and corrugated absorbers solar stills under Egyptian conditions. Desalination 277:281–287

Omara ZM, Kabeel AE, Essa FA (2015) Effect of using nanofluids and providing vacuum on the yield of corrugated wick solar still. Energy Convers Manage 103:965–972

Omara ZM, Kabeel AE, Abdullah AS, Essa FA (2016) Experimental investigation of corrugated absorber solar still with wick and reflectors. Desalination 381:111–116

Omara ZM, Abdullah AS, Dakrory T (2017) Improving the productivity of solar still by using water fan and wind turbine. Sol Energy 147:181–188

Omara ZM, Abdullah AS, Essa FA, Younes MM (2021) Performance evaluation of a vertical rotating wick solar still. Process Saf Environ Prot 148:796–804

Panchal H, Sadasivuni KK, Prajapati C, Khalid M, Essa FA, Shanmugan S, Pandya N, Suresh M, Israr M, Dharaskar S, Khechekhouche A (2020) Productivity enhancement of solar still with thermoelectric modules from groundwater to produce potable water: a review. Groundwater for Sustainable Development 11:100429

Panchal H, Nurdiyanto H, Sadasivuni KK, Hishan SS, Essa FA, Khalid M, Dharaskar S, Shanmugan S (2021) Experimental investigation on the yield of solar still using manganese oxide nanoparticles coated absorber. Case Studies in Thermal Engineering 25:100905

Rijsberman FR (2006) Water scarcity: fact or fiction? Agric Water Manag 80:5–22

Saini V, Sahota L, Jain VK, Tiwari GN (2019) Performance and cost analysis of a modified built-in-passive condenser and semitransparent photovoltaic module integrated passive solar distillation system. Journal of Energy Storage 24:100809

Tiwari AK, Tiwari GN (2006) Effect of water depths on heat and mass transfer in a passive solar still: in summer climatic condition. Desalination 195:78–94

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB).

Author information

Authors and Affiliations

Contributions

Mohamed R. Diab: methodology, formal analysis, and investigation, writing—original draft preparation. Fawzy S. Abou-Taleb: conceptualization, editing. Fadl Abdelmonem Essa: methodology, conceptualization, formal analysis, review, explanation, and editing. Zakaria Mohamed Omara: conceptualization, editing, and explanation.

Corresponding author

Ethics declarations

Ethical approval

Not applicable.

Consent to participate

Not applicable.

Consent to publish

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Responsible Editor: Philippe Garrigues

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Research highlights

• Performance of vertical distiller with rotating wick discs with and without fan was investigated.

• Effect of different fan speeds from 400 to 2000 rpm was tested.

• Fan running time was conducted (10 ON-10 OFF and 10 ON-20 OFF).

• The best conditions were 1.5 rpm (disc), 5cm (water depth), 1600 rpm (fan), and 10 ON-10 OFF.

• Distillate of MDSVD was enhanced by 660.45% over CTD.

• Maximum thermal efficacy for MDSVD was 84.05%.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Diab, M.R., Abou-Taleb, F.S., Essa, F.A. et al. Improving the vertical solar distiller performance using rotating wick discs and integrated condenser. Environ Sci Pollut Res 29, 57946–57963 (2022). https://doi.org/10.1007/s11356-022-19873-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-022-19873-w