Abstract

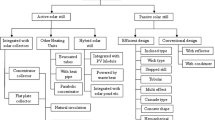

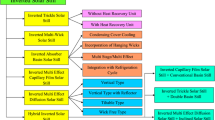

Solar distillation is one of the most promising solutions to provide freshwater in limited-population communities with high availability of solar radiation and poor accessibility to safe and clean water. Until now, several types of solar stills have been developed including wick-type stills, stepped stills, inclined and double-slope stills, tubular stills, and pyramid stills. Among them, vertical diffusion solar stills (VDSSs) have been newly developed, offering several priorities over conventional types. This study presents a detailed review of VDSSs by investigating effective parameters and employed techniques to enhance the productivity of these solar stills. For this purpose, design factors along with operational parameters including heat energy input, type of carrier gas, basin water depth, and feedwater flow rate are studied and profoundly discussed. Additionally, enhancement techniques including feedwater preheating, shape modifications, waste heat utilization, and integration with reflectors are studied. According to the literature, the productivity of VDSSs is enhanced by a reduction of the diffusion gap and a decrease in the number of effects. In some studies, the use of waste heat and electricity as energy inputs has led to higher productivity in comparison with solar energy. Moreover, considering design factors, a modified configuration can increase productivity by 44%. In this review, the environmental and economic aspects of VDSSs are also discussed. Numerical analyses have predicted that a passive VDSS with a multiple-chamber configuration and 13.85% exergy efficiency could cut 67.93 tons (average) of CO2 emission during its 20-year lifetime, while its financial payback time is 0.63 years. The studies have also demonstrated that an optimized VDSS can reach the water price of 6.1 USD/m3 which makes this technology more attractive than other low-capacity stills from economic aspects.

Similar content being viewed by others

Availability of data and material

Not applicable.

Code availability

Not applicable.

Notes

SCP is defined as the ratio of heat demanded by the still to the solar energy received by the system.

Abbreviations

- A col :

-

Collector area (m2)

- A eva :

-

Evaporation area (m2)

- A HW :

-

Heating section area (m2)

- CCF:

-

CO2 conversion factor (kg/kW h)

- C col :

-

Capital cost of the solar collector ($/m2)

- C m :

-

Capital cost of the miscellaneous components

- COP:

-

Coefficient of performance

- C p :

-

Specific heat of water (J/kg K)

- CPL:

-

Cost of distillate per liter (USD/L)

- CS:

-

Carbon saving (kg)

- C T :

-

Total annual cost per glass area (USD/m2)

- C VS :

-

Capital cost of the vertical still (USD/m2)

- EP:

-

Energy produced by the solar system (kWh)

- EPBT:

-

Energy payback time (year)

- Exeva :

-

Exergy of evaporation

- Exin :

-

Input exergy

- Exout :

-

Output exergy

- Exsun :

-

Exergy of sun

- F :

-

Sinking fund factor

- f cr :

-

Capital recovery factor

- g 1 :

-

First glass cover

- g 2 :

-

Second glass cover

- GOR:

-

Gain output ratio

- G S :

-

Total solar incident (W/m2)

- h c :

-

Convective heat transfer coefficient (W/m2 K)

- h CH :

-

Convective heat transfer coefficient of the fluid inside the heating unit (W/m2k)

- h fg :

-

Latent heat of condensation (J/kg)

- H V :

-

Water latent heat of evaporation (J/kg)

- \(I_{t}\) :

-

Solar radiation intensity (W/m2)

- IR:

-

Interest rate

- LHV :

-

Annual average latent heat of evaporation (J/kg)

- LT:

-

Life time (yr)

- M a :

-

The molecular weight of air (kg/kmol)

- M col :

-

Annual operation and maintenance cost of the solar collector (%C)

- mC p :

-

Heat capacity (J/k)

- m d( i ) :

-

Distillate yield ith each cell (kg)

- m d, daily :

-

Daily productivity of the still (kg/d)

- m e :

-

Evaporation rate (kg/s)

- m p :

-

Water production rate (kg/h)

- m f :

-

Feedwater flow rate (kg/s)

- m f(P) :

-

Mass flow rate of saline water on the plate (kg/s)

- M m :

-

Annual operation and maintenance cost of the miscellaneous components (%C)

- M V :

-

Molecular weight of water vapor

- M VS :

-

Annual operation and maintenance cost of the vertical still (%C)

- n :

-

Number of effects/cells

- P i :

-

\(i{\text{th}}\) Evaporating/condensing plate

- PBP:

-

Payback period (year)

- PPD:

-

Productivity per USD invested (kg/USD)

- PR:

-

Performance ratio

- Pr:

-

Prandtl number

- P s :

-

Saturated water vapor pressure corresponding to the plat temperature (Pa)

- P t :

-

Total pressure (Pa)

- P T (P i ) :

-

Partial vapor pressure in the temperature of the ith plate (Pa)

- Q c :

-

Convection heat (W)

- Q col :

-

Total energy produced by the solar collector (W)

- Q d :

-

Conduction heat (W)

- Q e :

-

Heat flux of evaporation–condensation (W)

- Q f :

-

Heat energy used for heating the saline water (W)

- Q in :

-

Heat flow supply into the system (W)

- Q L :

-

Total loss of energy (W)

- Q r :

-

Radiation heat transfer (W)

- S col :

-

Salvage value of the solar collector (%C)

- SCP:

-

Solar energy coefficient of performance

- S m :

-

Salvage value of the miscellaneous components (%C)

- S p :

-

Selling price of product water (USD/L)

- SVS :

-

Salvage value of the vertical still (%C)

- T :

-

Temperature (K)

- T sun :

-

Temperature of the sun (6000 K)

- T W :

-

Water temperature (°C)

- T amb :

-

Ambient temperature (K)

- T f :

-

Feedwater temperature (K)

- T fc :

-

Fluid temperature inside the heating unit (K)

- T mean :

-

Mean temperature between evaporating and condensing surfaces (K)

- u w :

-

Wind speed (m/s)

- β g :

-

Coefficient of glass volume expansion (1/K)

- δ g :

-

Glazing gap (m)

- δ g –P :

-

Distance between the glass and the plate (m)

- δ H :

-

Thickness of the heating unit (m)

- δ P :

-

Gap between the plates (m)

- η col :

-

Thermal efficiency of the solar collector

- \(\eta_{{{\text{exergy}}}}\) :

-

Exergy efficiency

- \(\eta_{{{\text{th}}}}\) :

-

Thermal efficiency of solar still

- λ a :

-

Air thermal conductivity (W/m K)

- λ f :

-

Thermal conductivity of the fluid (W/m Ksss)

- λ h :

-

Thermal conductivity of humid air (W/m K)

- λ HW :

-

Thermal conductivity of the heating wall (W/m K)

- \(A\) :

-

Aperture area (m2)

- \(D\) :

-

Diffusivity of water vapor in the air (m2/s)

- \({\text{EP}}\) :

-

Amount of energy produced annually (kWh)

- \({\text{Gr}}\) :

-

Grashof number

- \(R\) :

-

Gas constant of water (J/kg K)

- \(g\) :

-

Gravitational acceleration (m2/s)

- \(l\) :

-

Characteristic length (m)

- \(v\) :

-

Kinematic viscosity of air (m2/s)

- \(\alpha\) :

-

Absorbance

- \(\varepsilon\) :

-

Emissivity

- \(\sigma\) :

-

Stefan–Boltzmann constant

- \(\tau\) :

-

Transmittance

References

Adhikari RS, Kumar A, Sodha MS (1991) Thermal performance of a multi-effect diffusion solar still. Int J Energy Res 15:769–779. https://doi.org/10.1002/er.4440150908

Al-Ameri KA, Mahmud S, Dutta A (2019) Optimum conditions for high distillation partition performance: comparative studies. Appl Therm Eng 162:114279. https://doi.org/10.1016/j.applthermaleng.2019.114279

Arkian AH, Najafi G, Gorjian S, Loni R, Bellos E, Yusaf T (2019) Performance assessment of a solar dryer system using small parabolic dish and alumina/oil nanofluid: simulation and experimental study. Energies 12:4747. https://doi.org/10.3390/en12244747

Badran AA, Hamdan MA (1995) Inverted trickle solar still. Int J Sol Energy 17:51–60. https://doi.org/10.1080/01425919508914288

Badran AA, Assaf LM, Kayed KS, Ghaith FA, Hammash MI (2004) Simulation and experimental study for an inverted trickle solar still. Desalination 164:77–85. https://doi.org/10.1016/S0011-9164(04)00158-4

Belessiotis V, Kalogirou S, Delyannis E (2016) Solar distillation—solar stills. Therm Sol Desalin. https://doi.org/10.1016/b978-0-12-809656-7.00003-9

Belhadj MM, Bouguettaia H, Marif Y, Zerrouki M, Bechki D, Benhammou M, De L, Lenreza A (2014) Theoretical and experimental study of the solar still coupled to a vertical still with water film. Int J Eng Res Appl 3:547–552

Boukar M, Harmim A (2004) Parametric study of a vertical solar still under desert climatic conditions. Desalination 168:21–28. https://doi.org/10.1016/j.desal.2004.06.165

Boukar M, Harmim A (2005) Performance evaluation of a one-sided vertical solar still tested in the Desert of Algeria. Desalination 183:113–126. https://doi.org/10.1016/j.desal.2005.02.045

Boukar M, Harmim A (2007) Design parameters and preliminary experimental investigation of an indirect vertical solar still. Desalination 203:444–454. https://doi.org/10.1016/j.desal.2006.02.026

Boukar M, Harmim A, Amar M, De Recherche U, Saharien M (2011) Thermal behaviour of a novel vertical solar still under desert climatic conditions. Int J Water Resour Arid Environ 1:123–128

Chang Z, Zheng Y, Chen Z, Zheng H, Zhao M, Su Y, Mao J (2015) Performance analysis and experimental comparison of three operational modes of a triple-effect vertical concentric tubular solar desalination device. Desalination 375:10–20. https://doi.org/10.1016/j.desal.2015.07.020

Chong TL, Huang BJ, Wu PH, Kao YC (2014) Multiple-effect diffusion solar still coupled with a vacuum-tube collector and heat pipe. Desalination 347:66–76. https://doi.org/10.1016/j.desal.2014.05.023

Coffey JP (1975) Vertical solar distillation. Sol Energy 17:375–378. https://doi.org/10.1016/0038-092X(75)90041-9

Cooper PI (1973) The maximum efficiency of single-effect solar stills. Sol Energy 15:205–217. https://doi.org/10.1016/0038-092X(73)90085-6

Dhindsa GS, Mittal MK (2018) Experimental study of basin type vertical multiple effect diffusion solar still integrated with mini solar pond to generate nocturnal distillate. Energy Convers Manag 165:669–680. https://doi.org/10.1016/j.enconman.2018.03.100

Dhindsa GS, Mittal MK, Sokhal GS, Sokhal KS, Khalilpoor N, Emani S (2021) Performance analysis of basin-type vertical multiple-effect diffusion solar still integrated with solar pond: energy, exergy and economical analysis. Int J Low-Carbon Technol. https://doi.org/10.1093/ijlct/ctab004

Dsilva Winfred Rufuss D, Iniyan S, Suganthi L, Davies PA (2016) Solar stills: a comprehensive review of designs, performance and material advances. Renew Sustain Energy Rev 63:464–496. https://doi.org/10.1016/j.rser.2016.05.068

Duffie JA, Beckman WA (2013) Solar engineering of thermal processes, 4th edn. Wiley, London. https://doi.org/10.1002/9781118671603

Dunkle RV (1961) Solar water distillation, the roof top still multiple effect diffusion. In: ASME international heat transfer, pp 895–902. https://trove.nla.gov.au/work/34968478?selectedversion=NBD9189687. Accessed 10 Mar 2020

Durkaieswaran P, Murugavel KK (2015) Various special designs of single basin passive solar still: a review. Renew Sustain Energy Rev 49:1048–1060. https://doi.org/10.1016/j.rser.2015.04.111

Elimelech M, Phillip WA (2011) The future of seawater desalination: energy, technology, and the environment. Science (80- ) 333:712–717

Elsayed MM (1986) Effects of parametric conditions on the performance of an ideal diffusion still. Appl Energy 22:187–203. https://doi.org/10.1016/0306-2619(86)90002-4

El-Sebaii AA (1998) Parametric study of a vertical solar still. Energy Convers Manag 39:1303–1315. https://doi.org/10.1016/S0196-8904(98)00011-9

Elsherbiny SM, Fath HES (1995) Performance of diffusion stills under egyptian climatic conditions. Int J Sol Energy 16:277–288. https://doi.org/10.1080/01425919508914282

Gorjian S, Ghobadian B (2015a) Solar desalination: a sustainable solution to water crisis in Iran. Renew Sustain Energy Rev 48:571–584. https://doi.org/10.1016/j.rser.2015.04.009

Gorjian S, Ghobadian B (2015b) Solar thermal power plants: progress and prospects in Iran. Energy Procedia 75:533–539. https://doi.org/10.1016/j.egypro.2015.07.447

Gorjian S, Ghobadian B, Tavakkoli Hashjin T, Banakar A (2014) Experimental performance evaluation of a stand-alone point-focus parabolic solar still. Desalination 352:1–17. https://doi.org/10.1016/j.desal.2014.08.005

Gorjian S, Jamshidian FJ, Hosseinqolilou B (2019a) Feasible solar applications for brines disposal in desalination plants. In: Kumar A, Prakash O (eds) Solar desalination technology. Springer, Singapore, pp 25–48. https://doi.org/10.1007/978-981-13-6887-5_2

Gorjian S, Zadeh BN, Eltrop L, Shamshiri RR, Amanlou Y (2019b) Solar photovoltaic power generation in Iran: development, policies, and barriers. Renew Sustain Energy Rev 106:110–123. https://doi.org/10.1016/j.rser.2019.02.025

Gorjian S, Ghobadian B, Ebadi H, Ketabchi F, Khanmohammadi S (2020a) Applications of solar PV systems in desalination technologies. In: Gorjian S, Shukla A (eds) Photovoltaic solar energy conversion, 1st edn. Elsevier, London, pp 237–274. https://doi.org/10.1016/B978-0-12-819610-6.00008-9

Gorjian S, Ebadi H, Calise F, Shukla A, Ingrao C (2020b) A review on recent advancements in performance enhancement techniques for low-temperature solar collectors. Energy Convers Manag 222:113246. https://doi.org/10.1016/j.enconman.2020.113246

Gorjian S, Singh R, Shukla A, Mazhar AR (2020c) On-farm applications of solar PV systems. In: Gorjian S, Shukla A (eds) Photovoltaic solar energy conversion, 1st edn. Elsevier, London, pp 147–190. https://doi.org/10.1016/B978-0-12-819610-6.00006-5

Gorjian S, Sharon H, Ebadi H, Kant K, Scavo FB, Tina GM (2021) Recent technical advancements, economics and environmental impacts of floating photovoltaic solar energy conversion systems. J Clean Prod 278:124285. https://doi.org/10.1016/j.jclepro.2020.124285

Gräter F, Dürrbeck M, Rheinländer J (2001) Multi-effect still for hybrid solar/fossil desalination of sea- and brackish water. Desalination 138:111–119. https://doi.org/10.1016/S0011-9164(01)00252-1

Gude VG (2018) Exergy evaluation of desalination processes. ChemEngineering 2:1–27. https://doi.org/10.3390/chemengineering2020028

Gude VG, Nirmalakhandan N, Deng S (2010) Renewable and sustainable approaches for desalination. Renew Sustain Energy Rev 14:2641–2654. https://doi.org/10.1016/j.rser.2010.06.008

Hanjra MA, Qureshi ME (2010) Global water crisis and future food security in an era of climate change. Food Policy 35:365–377. https://doi.org/10.1016/j.foodpol.2010.05.006

Hosseini A, Banakar A, Gorjian S (2018) Development and performance evaluation of an active solar distillation system integrated with a vacuum-type heat exchanger. Desalination 435:45–59. https://doi.org/10.1016/j.desal.2017.12.031

Hou J, Yang J, Chang Z, Zheng H, Su Y (2018) Effect of different carrier gases on productivity enhancement of a novel multi-effect vertical concentric tubular solar brackish water desalination device. Desalination 432:72–80. https://doi.org/10.1016/j.desal.2018.01.011

Huang BJ, Chong TL, Chang HS, Wu PH, Kao YC (2014) Solar distillation system based on multiple-effect diffusion type still. J Sustain Dev Energy Water Environ Syst 2:41–50. https://doi.org/10.13044/j.sdewes.2014.02.0004

Huang BJ, Chong TL, Wu PH, Dai HY, Kao YC (2015) Spiral multiple-effect diffusion solar still coupled with vacuum-tube collector and heat pipe. Desalination 362:74–83. https://doi.org/10.1016/j.desal.2015.02.011

Huang L, Jiang H, Wang Y, Ouyang Z, Wang W, Yang B, Liu H, Hu X (2020) Enhanced water yield of solar desalination by thermal concentrated multistage distiller. Desalination 477:114260. https://doi.org/10.1016/j.desal.2019.114260

Hunkyun P (2017) Low-cost multi-effect solar still: alternative appropriate technology for personal desalination. In: Yonar T (ed) Desalination. InTech, Rijeka. https://doi.org/10.5772/intechopen.68365

Kabeel AE, Omara ZM, Younes MM (2015) Techniques used to improve the performance of the stepped solar still: a review. Renew Sustain Energy Rev 46:178–188. https://doi.org/10.1016/j.rser.2015.02.053

Kalogirou S (2009) Solar energy engineering: processes and systems. Academic Press, Cambridge

Kaur V, Mahajan R (2016) Water crisis: towards a way to improve the situation. Int J Eng Technol Sci Res 3:2394–3386

Kaushal AK, Mittal MK (2019) Performance study of an improved basin type vertical multiple effect diffusion solar still. Int J Green Energy 16:1343–1352. https://doi.org/10.1080/15435075.2019.1671409

Kaushal AK, Mittal MK, Gangacharyulu D (2016) Development and experimental study of an improved basin type vertical single distillation cell solar still. Desalination 398:121–132. https://doi.org/10.1016/j.desal.2016.07.017

Kaushal AK, Mittal MK, Gangacharyulu D (2017a) An experimental study of floating wick basin type vertical multiple effect diffusion solar still with waste heat recovery. Desalination 414:35–45. https://doi.org/10.1016/j.desal.2017.03.033

Kaushal AK, Mittal MK, Gangacharyulu D (2017b) Productivity correlation and economic analysis of floating wick basin type vertical multiple effect diffusion solar still with waste heat recovery. Desalination 423:95–103. https://doi.org/10.1016/j.desal.2017.09.016

Kaviti AK, Yadav A, Shukla A (2016) Inclined solar still designs: a review. Renew Sustain Energy Rev 54:429–451. https://doi.org/10.1016/j.rser.2015.10.027

Ketabchi F, Gorjian S, Sabzehparvar S, Shadram Z, Ghoreishi MS, Rahimzadeh H (2019) Experimental performance evaluation of a modified solar still integrated with a cooling system and external flat-plate reflectors. Sol Energy 187:137–146. https://doi.org/10.1016/j.solener.2019.05.032

Kiatsiriroat T, Bhattacharya SC, Wibulswas P (1987a) Performance analysis of multiple effect vertical still with a flat plate solar collector. Sol Wind Technol 4:451–457

Kiatsiriroat T, Bhattacharya SC, Wibulswas P (1987b) Transient simulation of vertical solar still. Energy Convers Manag 27:247–252. https://doi.org/10.1016/0196-8904(87)90081-1

Lim BJ, Yu SS, Chung KY, Park CD (2018) Numerical analysis of the performance of a tiltable multi-effect solar distiller. Desalination 435:23–34. https://doi.org/10.1016/j.desal.2017.12.035

Lim BJ, Lee GR, Choi SM, Chung KY, Park CD (2020) Model optimization and economic analysis of a multi-effect diffusion solar distiller. Desalination 485:114446. https://doi.org/10.1016/j.desal.2020.114446

Loni R, Askari Asli-ardeh E, Ghobadian B, Kasaeian AB, Gorjian S (2017) Thermodynamic analysis of a solar dish receiver using different nanofluids. Energy 133:749–760. https://doi.org/10.1016/j.energy.2017.05.016

Loni R, Askari Asli-Areh E, Ghobadian B, Kasaeian AB, Gorjian S, Najafi G, Bellos E (2020) Research and review study of solar dish concentrators with different nanofluids and different shapes of cavity receiver: experimental tests. Renew Energy 145:783–804. https://doi.org/10.1016/j.renene.2019.06.056

Malik MAS, Tran VV (1973) A simplified mathematical model for predicting the nocturnal output of a solar still. Sol Energy 14:371–385. https://doi.org/10.1016/0038-092X(73)90015-7

Manikandan V, Shanmugasundaram K, Shanmugan S, Janarthanan B, Chandrasekaran J (2013) Wick type solar stills: a review. Renew Sustain Energy Rev 20:322–335. https://doi.org/10.1016/j.rser.2012.11.046

Mayere A (2011) Solar powered desalination. University of Nottingham, Nottingham

McEvoy J (2014) Desalination and water security: the promise and perils of a technological fix to the water crisis in Baja California Sur, Mexico. Water Altern 7:518–541

Minasian AN, Al-Karaghouli AA (1992) Floating vertical solar still for desalination of marsh water. Renew Energy 2:631–635. https://doi.org/10.1016/0960-1481(92)90029-3

Mohammed AJ, Hashim AY (2013) Study the effect of the external reflector on the efficiency of one sided vertical solar still. Basrah J Sci 31:119–128

Nayi KH, Modi KV (2018) Pyramid solar still: a comprehensive review. Renew Sustain Energy Rev 81:136–148. https://doi.org/10.1016/j.rser.2017.07.004

Nosoko T, Kinjo T, Park CD (2005) Theoretical analysis of a multiple-effect diffusion still producing highly concentrated seawater. Desalination 180:33–45. https://doi.org/10.1016/j.desal.2004.09.031

Omara ZM, Abdullah AS, Essa FA, Younes MM (2021) Performance evaluation of a vertical rotating wick solar still. Process Saf Environ Prot 148:796–804. https://doi.org/10.1016/j.psep.2021.02.004

Ouahes R, Ouahes C, Le Goff P, Le Goff J (1987) A hardy, high-yield solar distiller of brackish water. Desalination 67:43–52. https://doi.org/10.1016/0011-9164(87)90230-X

Panchal H, Sadasivuni KK, Israr M, Thakar N (2019) Various techniques to enhance distillate output of tubular solar still: a review. Groundw Sustain Dev 9:100268. https://doi.org/10.1016/j.gsd.2019.100268

Park CD, Lim BJ, Noh YD, Lee SS, Chung KY (2015) Parametric performance test of distiller utilizing solar and waste heat. Desalin Water Treat 55:3303–3309. https://doi.org/10.1080/19443994.2014.946712

Park C-D, Lim B-J, Chung K-Y, Lee S-S, Kim Y-M (2016) Experimental evaluation of hybrid solar still using waste heat. Desalination 379:1–9. https://doi.org/10.1016/j.desal.2015.10.004

Porter MG, Downie D, Scarborough H, Sahin O, Stewart RA (2014) Drought and desalination: Melbourne water supply and development choices in the twenty-first century. Desalin Water Treat 3994:1–18. https://doi.org/10.1080/19443994.2014.959743

Rajaseenivasan T, Murugavel KK, Elango T, Hansen RS (2013) A review of different methods to enhance the productivity of the multi-effect solar still. Renew Sustain Energy Rev 17:248–259. https://doi.org/10.1016/j.rser.2012.09.035

Ramli M (1984) Solar stills with vertical absorbing surfaces. Asian Institute of Technology, Bangkok

Ranjan KR, Kaushik SC (2013) Energy, exergy and thermo-economic analysis of solar distillation systems: a review. Renew Sustain Energy Rev 27:709–723. https://doi.org/10.1016/j.rser.2013.07.025

Reddy KS, Sharon H (2016) Active multi-effect vertical solar still: Mathematical modeling, performance investigation and enviro-economic analyses. Desalination 395:99–120. https://doi.org/10.1016/j.desal.2016.05.027

Reddy KS, Sharon H (2018) Energy and environmental analysis of multi-effect active vertical solar desalination unit for Indian conditions. In: Nižetić S, Papadopoulos A (eds) Green energy technology. Springer, Berlin, pp 339–350. https://doi.org/10.1007/978-3-319-89845-2_24

Rommerskirchen A, Gendel Y, Wessling M (2015) Single module flow-electrode capacitive deionization for continuous water desalination. Electrochem Commun 60:34–37. https://doi.org/10.1016/j.elecom.2015.07.018

Seleem A, Mortada M, El Morsi M, Younan M (2015) Parametric study of vertical diffusion still for water desalination. Int J Mech Aerosp Ind Mechatron Eng 9:319–324

Shakouri M, Ebadi H, Gorjian S (2020) Solar photovoltaic thermal (PVT) module technologies. In: Gorjian S, Shukla A (eds) Photovoltaic solar energy conversion, 1st edn. Elsevier, London, pp 79–116. https://doi.org/10.1016/B978-0-12-819610-6.00004-1

Shanmugan S, Essa FA, Gorjian S, Kabeel AE, Sathyamurthy R, Muthu Manokar A (2020) Experimental study on single slope single basin solar still using TiO2 nano layer for natural clean water invention. J Energy Storage 30:101522. https://doi.org/10.1016/j.est.2020.101522

Sharma VB, Mullick SC (1991) Estimation of heat-transfer coefficients, the upward heat flow, and evaporation in a solar still. J Sol Energy Eng 113:36–41. https://doi.org/10.1115/1.2929949

Sharon H, Reddy KS (2015) Performance investigation and enviro-economic analysis of active vertical solar distillation units. Energy 84:794–807. https://doi.org/10.1016/j.energy.2015.03.045

Sharon H, Reddy KS, Gorjian S (2020) Parametric investigation and year round performance of a novel passive multi-chamber vertical solar diffusion still: energy, exergy and enviro-economic aspects. Sol Energy 211:831–846. https://doi.org/10.1016/j.solener.2020.10.016

Sharqawy MHM, Lienhard JH, Zubair SM (2010) Thermophysical properties of seawater: a review of existing correlations and data. Desalin Water Treat 16:354–380. https://doi.org/10.5004/dwt.2010.1079

Sharshir SW, Elsheikh AH, Peng G, Yang N, El-Samadony MOA, Kabeel AE (2017) Thermal performance and exergy analysis of solar stills: a review. Renew Sustain Energy Rev 73:521–544. https://doi.org/10.1016/j.rser.2017.01.156

Tanak H, Nakatake Y, Watanabe K (2005) Parametric study on a vertical multiple-effect diffusion-typesolar still coupled with a heat-pipe solar collector. Desalination 171:243–255. https://doi.org/10.1016/j.desal.2004.04.006

Tanaka H (2009) Experimental study of vertical multiple-effect diffusion solar still coupled with a flat plate reflector. Desalination 249:34–40. https://doi.org/10.1016/j.desal.2008.10.022

Tanaka H (2016a) Thermal distillation system utilizing biomass energy burned in stove by means of heat pipe. Alex Eng J 55:2203–2208. https://doi.org/10.1016/j.aej.2016.06.008

Tanaka H (2016a) Theoretical analysis of a vertical multiple-effect diffusion solar still coupled with a tilted wick still. Desalination 377:65–72. https://doi.org/10.1016/j.desal.2015.09.013

Tanaka H (2017) Parametric investigation of a vertical multiple-effect diffusion solar still coupled with a tilted wick still. Desalination 408:119–126. https://doi.org/10.1016/j.desal.2017.01.019

Tanaka H (2018) Analyzing the effect of an enlarged flat plate reflector (FPR) on a vertical multiple-effect diffusion solar still’s (VMEDS) performance. Appl Therm Eng 142:138–147. https://doi.org/10.1016/j.applthermaleng.2018.06.054

Tanaka H, Iishi K (2017) Experimental study of a vertical single-effect diffusion solar still coupled with a tilted wick still. Desalination 402:19–24. https://doi.org/10.1016/j.desal.2016.09.031

Tanaka H, Nakatake Y (2004) A vertical multiple-effect diffusion-type solar still coupled with a heat-pipe solar collector. Desalination 160:195–205. https://doi.org/10.1016/S0011-9164(04)90009-4

Tanaka H, Nakatake Y (2005a) A simple and highly productive solar still: a vertical multiple-effect diffusion-type solar still coupled with a flat-plate mirror. Desalination 173:287–300. https://doi.org/10.1016/j.desal.2004.08.035

Tanaka H, Nakatake Y (2005b) Factors influencing the productivity of a multiple-effect diffusion-type solar still coupled with a flat plate reflector. Desalination 186:299–310. https://doi.org/10.1016/j.desal.2005.07.005

Tanaka H, Nakatake Y (2007a) Outdoor experiments of a vertical diffusion solar still coupled with a flat plate reflector. Desalination 214:70–82. https://doi.org/10.1016/j.desal.2006.08.016

Tanaka H, Nakatake Y (2007b) Numerical analysis of the vertical multiple-effect diffusion solar still coupled with a flat plate reflector: optimum reflector angle and optimum orientation of the still at various seasons and locations. Desalination 207:167–178. https://doi.org/10.1016/j.desal.2006.05.020

Tanaka H, Park C-D (2010) Distillation utilizing waste heat from a portable electric generator. Desalination 258:136–142. https://doi.org/10.1016/j.desal.2010.03.025

Tanaka H, Nosoko T, Nagata T (2000a) A highly productive basin-type-multiple-effect coupled solar still. Desalination 130:279–293

Tanaka H, Nosoko T, Nagata T (2000b) Parametric investigation of a basin-type-multiple-effect coupled solar still. Desalination 130:295–304

Tanaka H, Nosoko T, Nagata T (2002) Experimental study of basin-type, multiple-effect, diffusion-coupled solar still. Desalination 150:131–144. https://doi.org/10.1016/S0011-9164(02)00938-4

Tanaka H, Nakatake Y, Tanaka M (2005) Indoor experiments of the vertical multiple-effect diffusion-type solar still coupled with a heat-pipe solar collector. Desalination 177:291–302. https://doi.org/10.1016/j.desal.2004.12.012

Telkes M (1959) N.Y. University, U. States. Solar still construction. http://mirlyn.lib.umich.edu/Record/005890281. Accessed 10 Mar 2020

Tiwari GN, Sahota L (2017a) Review on the energy and economic efficiencies of passive and active solar distillation systems. Desalination 401:151–179. https://doi.org/10.1016/j.desal.2016.08.023

Tiwari GN, Sahota L (2017b) Economic analysis of solar-distillation systems. In: Tiwari GN, Sahota L (eds) Green energy and technology. Springer, Berlin, pp 361–401. https://doi.org/10.1007/978-981-10-4672-8_10

Toyama S, Aragaki T, Salah HM, Murase K (1987) Dynamic characteristics of a multistage thermal diffusion type solar distillator. Desalination 67:21–32. https://doi.org/10.1016/0011-9164(87)90228-1

UNWater (2016) World Water Development Report 2016 - Water and Jobs. UNESCO. Parsi, France.https://www.unwater.org/publications/world-water-development-report-2016/

Vishwanath Kumar P, Kumar A, Prakash O, Kaviti AK (2015) Solar stills system design: a review. Renew Sustain Energy Rev 51:153–181. https://doi.org/10.1016/j.rser.2015.04.103

Wilder MO, Aguilar-Barajas I, Pineda-Pablos N, Varady RG, Megdal SB, McEvoy J, Merideth R, Zúñiga-Terán AA, Scott CA (2016) Desalination and water security in the US–Mexico border region: assessing the social, environmental and political impacts. Water Int 8060:1–20. https://doi.org/10.1080/02508060.2016.1166416

Xie G, Xiong J, Liu H, Xu B, Zheng H, Yang Y (2015) Experimental and numerical investigation on a novel solar still with vertical ripple surface. Energy Convers Manag 98:151–160. https://doi.org/10.1016/j.enconman.2015.03.099

Xu Z, Zhang L, Zhao L, Li B, Bhatia B, Wang C, Wilke KL, Song Y, Labban O, Lienhard JH, Wang R, Wang EN (2020a) Ultrahigh-efficiency desalination via a thermally-localized multistage solar still. Energy Environ Sci 13:830–839. https://doi.org/10.1039/C9EE04122B

Xu Z, Zhang L, Zhao L, Li B, Bhatia B, Wang C, Wilke KL, Song Y, Labban O, Lienhard JH, Wang R, Wang EN (2020b) Ultrahigh-efficiency desalination: via a thermally-localized multistage solar still. Energy Environ Sci 13:830–839. https://doi.org/10.1039/c9ee04122b

Yadav S, Sudhakar K (2015) Different domestic designs of solar stills: a review. Renew Sustain Energy Rev 47:718–731. https://doi.org/10.1016/j.rser.2015.03.064

Yeo S-D, Lim B-J, Lee G-R, Park C-D (2019) Experimental study of effects of different heat sources on the performance of the hybrid multiple-effect diffusion solar still. Sol Energy 193:324–334. https://doi.org/10.1016/j.solener.2019.09.062

Zubair SM, Kadaba PV, Evans RB (1985) Design optimization of two-phase heat exchangers. American Society of Mechanical Engineers, United States. http://inis.iaea.org/search/search.aspx?orig_q=RN:19036430. Accessed 10 Mar 2020

Acknowledgements

This project was supported by Ministry of Science, Research and Technology of Islamic Republic of Iran and Department of Science and Technology of India as one of the selected proposals announced by India–Iran Joint call in 2018. The authors would also like to acknowledge Laxmikant D. Jathar because of his valuable advisory and contribution to this study.

Author information

Authors and Affiliations

Contributions

HE was involved in the conceptualization; methodology; resources; optional; and writing—original draft. SG contributed to the writing—original draft; conceptualization; methodology; supervision; and funding acquisition. HS contributed to the writing—original draft; review and editing. JB-G contributed to the conceptualization; writing—review and editing. AK was involved in the visualization; writing—review and editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper. The authors declare the following financial interests/personal relationships which may be considered as potential competing interests.

Additional information

Editorial responsibility: Samareh Mirkia.

Rights and permissions

About this article

Cite this article

Ebadi, H., Gorjian, S., Sharon, H. et al. Investigation of design configurations and effective parameters on productivity enhancement of vertical diffusion solar stills. Int. J. Environ. Sci. Technol. 19, 6889–6924 (2022). https://doi.org/10.1007/s13762-021-03823-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13762-021-03823-z