Abstract

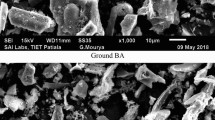

Concrete is widely used as a building material all over the world, and its use is increasing the demand of cement and sand in the construction industry. However, the limited resources and environmental degradation are driving scientists to develop alternative materials from vast volumes of agro-industrial wastes as a partial replacement for conventional cement. In the manufacture of concrete, cement is a major binding resource. This study looked into recycling agro-industrial wastes into cement, such as sugarcane bagasse ash (SCBA), coal bottom ash (CBA), and others, to create sustainable and environmentally friendly concrete. This study aims to see how the combined effects of agricultural by-product wastes affected the characteristics of concrete. SCBA is used to replace fine aggregate (FA) ranging from 0 to 40% by weight of FA, while CBA is used to replace cement content ranging from 0 to 20% by weight of the total binder. In this case, a total of 204 concrete samples (cubes and cylinders) are made using a mixed proportion of 1:1.5:3 and a water-cement ratio of 0.54. Workability, density, water absorption, and mechanical characteristics in terms of compressive and splitting tensile strengths were examined in this study. In addition, for each mix percentage, the total embodied carbon was determined. Workability, density, and water absorption were found to be considerably decreased when CBA and SCBA concentration increased. Due to the pozzolanic nature of CBA and SCBA, an increase in compressive and splitting tensile strengths were seen for specific concrete mixtures, and further addition of CBA and SCBA, the decrease in strength. The embodied carbon of SCBA has augmented the total embodied carbon of concrete, though it can be seen that C15S40, which comprises of 15% CBA and 40% SCBA, is the optimum mix that attained tensile and compressive strength by 3.05 MPa and 28.75 MPa correspondingly, with a 4% reduction in total embodied carbon.

Similar content being viewed by others

Data availability

Not applicable.

References

Abubakar AU, Baharudin KS (2012) Potential use of Malaysian thermal power plants coal bottom ash in construction. Int J Sustain Constr Eng Technol 3(2):25–37

Alex J, Dhanalakshmi J, Ambedkar B (2016) Experimental investigation on rice husk ash as cement replacement on concrete production. Constr Build Mater 127:353–362. https://doi.org/10.1016/j.conbuildmat.2016.09.150

Amin NU (2011) Use of bagasse ash in concrete and its impact on the strength and chloride resistivity. J Mater Civ Eng 23(5):717–720

Aprianti E, Shafigh P, Bahri S, Farahani JN (2015) Supplementary cementitious materials origin from agricultural wastes–a review. Constr Build Mater 74:176–187. https://doi.org/10.1016/j.conbuildmat.2014.10.010

Assefa S, Dessalegn M (2019) Production of lightweight concrete using corncob ash as replacement of cement in concrete. Am J Civ Eng 7(1):17–20

ASTM C 150/ C150M-20 (2020) Standard specification for Portland cement. Annu B ASTM Stand (April 2017):1–9.

ASTM C192/C192M–19 Standard Practice for Making and Curing Concrete Test Specimens in the Laboratory 2019 ASTM International West Conshohocken, PA.

Bakar B, Jaya R, Johari M, Ibrahim M (2011) Engineering properties of normal concrete grade 40 containing rice husk ash at different grinding time. Adv Mater Sci 11(1):5. https://doi.org/10.2478/v10077-011-0001-0

Bheel N, Abbasi RA, Sohu S, Abbasi SA, Abro AW, Shaikh ZH (2019) Effect of tile powder used as a cementitious material on the mechanical properties of concrete. Eng Technol Appl Sci Res 9(5):4596–4599

Bheel N, Awoyera P, Aluko O, Mahro S, Viloria A, Sierra CAS (2020) Sustainable composite development: novel use of human hair as fiber in concrete. Case Stud Constr Mater 13:e00412. https://doi.org/10.1016/j.cscm.2020.e00412

Bheel N, Ali MOA, Liu Y, Tafsirojjaman T, Awoyera P, Sor NH, Bendezu Romero LM (2021) Utilization of corn cob ash as fine aggregate and ground granulated blast furnace slag as cementitious material in concrete. Buildings 11(9):422

Bheel N.D. Meghwar S.K. Abbasi R.A. Ghunio I.A. and Shaikh Z.H. 2019a, December. Use of sugarcane bagasse ash as cement replacement materials in concrete. In International Conference on Sustainable Development in Civil Engineering, Jamshoro, Pakistan (pp. 1–4).

Bheel N.D. Meghwar S.K. Abbasi R.A. Ghunio I.A. and Shaikh Z.H. 2019c, December. Use of sugarcane bagasse ash as cement replacement materials in concrete. In International Conference on Sustainable Development in Civil Engineering, Jamshoro, Pakistan (pp. 1–4).

Bheel N. Kumar A. Shahzaib J. Ali Z. and Ali M. 2021a. An investigation on fresh and hardened properties of concrete blended with rice husk ash as cementitious ingredient and coal bottom ash as sand replacement material. Silicon, pp.1–12.

Bheel N. Ali M.O.A. Khahro S.H. and Keerio M.A. 2021c. Experimental study on fresh, mechanical properties and embodied carbon of concrete blended with sugarcane bagasse ash, metakaolin, and millet husk ash as ternary cementitious material. Environmental Sci Pollut Res, pp.1–16.

Bheel N. Sohu S. Jhatial A.A. Memon N.A. and Kumar A. 2021d. Combined effect of coconut shell and sugarcane bagasse ashes on the workability, mechanical properties and embodied carbon of concrete. Environ Sci Pollut Res, pp.1–17.

Bheel, N., Aluko, O.G. and Khoso, A.R., 2022. Synergistic and sustainable utilization of coconut shell ash and groundnut shell ash in ternary blended concrete. Environ Sci Pollut Res, pp.1–12.

Broomfield J (2003) Corrosion of steel in concrete: understanding, investigation and repair. CRC Press

BS 1881: part 122, ‘Method, for determination of water absorption’ (British Standards Institution, London, 1983).

Channa SH, Mangi SA, Bheel N, Soomro FA, Khahro SH (2022) Short-term analysis on the combined use of sugarcane bagasse ash and rice husk ash as supplementary cementitious material in concrete production. Environ Sci Pollut Res 29(3):3555–3564

Dayo AA, Kumar A, Raja A, Bheel N, Shaikh ZH (2019) Use of sugarcane bagasse ash as a fine aggregate in cement concrete. Eng Sci Technol Int Res J 3(3):8–11

BS EN 12350–2. Testing fresh concrete, Part 2: Slump-test. BSI; 2009a.

BS EN 12390–3. Testing harden concrete. Compressive strength of test specimens. BSI; 2009b.

BS EN 12390–6. Testing hardened concrete. Tensile splitting strength of test specimens. BSI; 2009c.

BS EN 12390–7 (2019) Testing hardened concrete. Density of hardened concrete [Internet]. British Standards Institution, London Available from: https://shop.bsigroup.com/ProductDetail?pid= 000000000030429702

Fairbairn EM, Americano BB, Cordeiro GC, Paula TP, Toledo Filho RD, Silvoso MM (2010) Cement replacement by sugar cane bagasse ash: CO2 emissions reduction and potential for carbon credits. J Environ Manage 91(9):1864–1871

Ghorbani S, Taji I, De Brito J, Negahban M, Ghorbani S, Tavakkolizadeh M, Davoodi A (2019) Mechanical and durability behaviour of concrete with granite waste dust as partial cement replacement under adverse exposure conditions. Constr Build Mater 194:143–152. https://doi.org/10.1016/j.conbuildmat.2018.11.023

Hussain RR, Ishida T (2009) Critical carbonation depth for initiation of steel corrosion in fully carbonated concrete and development of electrochemical carbonation induced corrosion model. Int J Electrochem Sci 4(8):1178–1195

Ismail ZZ, Al-Hashmi EA (2008) Reuse of waste iron as a partial replacement of sand in concrete. Waste Manage 28(11):2048–2053

Jhatial, A.A., 2021. Thermomechanical evaluation of sustainable foamed concrete incorporating palm oil fuel ash and eggshell powder. J Eng Res, 9(3A). https://doi.org/10.36909/jer.v9i3A.8290

Jhatial AA, Goh WI, Mastoi AK, Traore AF, Oad M (2022) Environmental assessment and mechanical properties of polypropylene fibres reinforced ternary binder foamed concrete. Environ Sci Pollut Res 29(2):2985–3007

Jhatial, A.A., Goh, W.I., Kamaruddin, S., Rahman, A.F., Kumar, R. and Siddiqui, F.H., 2021. Behaviour of green foamed concrete incorporating palm oil fuel ash (POFA) and eggshells powder (ESP). J Eng Res. https://doi.org/10.36909/jer.10723

R. Jones, M. Mccarthy, and M. Newlands, “Fly ash route to low embodied CO2 and implications for concrete construction,” in World of Coal Ash (WOCA) Conference, 2011.

Kadam MP, Patil YD (2014) The effect of sieved coal bottom ash as a sand substitute on the properties of concrete with percentage variation in cement. Am J Civ Eng Archit 2(5):160–166

Kalaw ME, Culaba A, Hinode H, Kurniawan W, Gallardo S, Promentilla MA (2016) Optimizing and characterizing geopolymers from ternary blend of Philippine coal fly ash, coal bottom ash and rice hull ash. Materials 9(7):580

Kamaruddin S, Goh WI, Abdul Mutalib NAN, Jhatial AA, Mohamad N, Rahman AF (2021) Effect of combined supplementary cementitious materials on the fresh and mechanical properties of eco-efficient self-compacting concrete. Arab J Sci Eng 46(11):10953–10973

Keerio MA, Khoso S, Khan JS, Ansari AA, Bhatti NK (2017) The effect of waste glass as partial replacement of cement on properties of concrete. Eng Sci Technol Int Res J 1(1):59–63

Keerio M.A. Abbasi S.A. Kumar A. Bheel N. ur Rehaman K. and Tashfeen M. 2020. Effect of silica fume as cementitious material and waste glass as fine aggregate replacement constituent on selected properties of concrete. Silicon, pp.1–12.

Keerio M.A. Saand A. Kumar A. Bheel N. and Ali K. 2021. Effect of local metakaolin developed from natural material soorh and coal bottom ash on fresh, hardened properties and embodied carbon of self-compacting concrete. Environmental Science and Pollution Research, pp.1–19.

Khan RA, Ganesh A (2016) The effect of coal bottom ash (CBA) on mechanical and durability characteristics of concrete. J Build Mater Struct 3(1):31

Khan R, Jabbar A, Ahmad I, Khan W, Khan AN, Mirza J (2012) Reduction in environmental problems using rice-husk ash in concrete. Constr Build Mater 30:360–365. https://doi.org/10.1016/j.conbuildmat.2011.11.028

Khan MI, Mourad SM, Charif A (2017) Utilization of supplementary cementitious materials in HPC: from rheology to pore structure. KSCE J Civ Eng 21(3):889–899. https://doi.org/10.1007/s12205-016-1781-x

Khoso S, Shahzaib KJ, Aziz AA, Hussain KZ (2016) Experimental investigation on the properties of cement concrete partially replaced by silica fume and fly ash. J Appl Eng Sci 14(3):345–350

Kumar A. Bheel N. Ahmed I. Rizvi S.H. Kumar R. and Jhatial A.A. 2021. Effect of silica fume and fly ash as cementitious material on hardened properties and embodied carbon of roller compacted concrete. Environmental Sci Pollut Res, pp.1–13. https://doi.org/10.1007/s11356-021-15734-0

Mangi SA, Jamaluddin N, Ibrahim MW, Awal AA, Sohu S, Ali N (2017) Utilization of sugarcane bagasse ash in concrete as partial replacement of cement. In IOP conference series: materials science and engineering. IOP Publishing 271(1):012001

Mangi SA, Ibrahim MHW, Jamaluddin N, Arshad MF, Memon SA, Shahidan S (2019a) Effects of grinding process on the properties of the coal bottom ash and cement paste. J Eng Technol Sci 51(1):1–13

Mangi SA, Wan Ibrahim MH, Jamaluddin N, Arshad MF, Ramadhansyah PJ (2019b) Effects of ground coal bottom ash on the properties of concrete. Journal of Engineering Science and Technology 14(1):338–350

Mangi SA, Memon ZA, Khahro SH, Memon RA, Memon AH (2020) Potentiality of industrial waste as supplementary cementitious material in concrete production. Int Rev Civ Eng 11(5):214–221. https://doi.org/10.15866/irece.v11i5.18779

Mangi SA, Wan Ibrahim MH, Jamaluddin N, Arshad MF, Khahro SH, Putra Jaya R (2021) Influence of coal ash on the concrete properties and its performance under sulphate and chloride conditions. Environ Sci Pollut Res 28(43):60787–60797

Manimaran A, Somasundaram M, Ravichandran PT (2017) Experimental study on partial replacement of coarse aggregate by bamboo and fine aggregate by quarry dust in concrete. Int J Civ Eng Technol 8(8):1019–1027

Meddah MS Ismail MA El-Gamal S (2018) Fitriani H. Performances evaluation of binary concrete designed with silica fume and metakaolin. Constr Build Mater [Internet] 166:400–412 Available from: https://linkinghub.elsevier .c om/r etri eve/ pii/ S0950061818301624

Okoye FN, Prakash S, Singh NB (2017) Durability of fly ash based geopolymer concrete in the presence of silica fume. J Clean Prod 149:1062–1067. https://doi.org/10.1016/j.jclepro.2017.02.176

Olu OO, Aminu N, Sabo LN (2020) The effect of sugarcane bagasse ash on the properties of Portland limestone cement. Am J Constr Build Mater 4(2):77–87

Prakash K.E. Sangeetha D.M. and Bagwan S. 2019. An experimental study on partial replacement of fine aggregate by vermiculate and cement by marble powder. In Sustainable Construction and Building Materials (pp. 897–906). Springer, Singapore.

Rafieizonooz M, Mirza J, Salim MR, Hussin MW, Khankhaje E (2016) Investigation of coal bottom ash and fly ash in concrete as replacement for sand and cement. Constr Build Mater 116:15–24

Ramesh ST, Gandhimathi R, Nidheesh PV, Rajakumar S, Prateepkumar S (2013) Use of furnace slag and welding slag as replacement for sand in concrete. Int J Energy Environ Eng 4(1):1–6

Rid, Z.A., Shah, S.N.R., Memon, M.J., Jhatial, A.A., Keerio, M.A. and Goh, W.I., 2022. Evaluation of combined utilization of marble dust powder and fly ash on the properties and sustainability of high-strength concrete. Enviro Sci Pollut Res, pp.1–15.

Saand A, Manthar AK, Juj R, Khoso S, Bangwar DK (2017) Utilization of waste glass as partial replacement of fine aggregate in concrete. Eng Sci Technol Int Res J 1(1):28–32

Saand A, Ali K, Kumar A, Bheel N, Keerio MA (2021) Effect of metakaolin developed from natural material Soorh on fresh and hardened properties of self-compacting concrete. Innov Infrastruct Solutions 6(3):1–10

Sachdeva A, Sharma A (2019) Effective waste utilization in production of concrete. Procedia Environ Sci Eng Manag 6(3):501–511

Shirule PA, Rahman A, Gupta RD (2012) Partial replacement of cement with marble dust powder. Int J Adv Eng Res Stud 1(3):2249

Siddique R (2003) Effect of fine aggregate replacement with class F fly ash on the abrasion resistance of concrete. Cem Concr Res 33(11):1877–1881

Singh M, Siddique R (2013) Effect of coal bottom ash as partial replacement of sand on properties of concrete. Resour Conserv Recycl 72:20–32. https://doi.org/10.1016/j.resconrec.2012.12.006

Singh D, Singh J, Singh J (2017) Sustainable management of sugarcane bagasse ash and coal bottom ash in concrete. Nat Environ Pollut Technol 16(1):295

Thomas J. Thaickavil N.N. and Syamala T.N. 2019. Supplementary cement replacement materials for sustainable concrete. In Green buildings and sustainable engineering (pp. 387–403). Springer, Singapore. https://doi.org/10.1007/978-981-13-1202-1_33

L. K. Turner and F. G. Collins “Carbon dioxide equivalent (CO2-e) emissions: a comparison between geopolymer and OPC cement concrete,” Constr. Build. Mater., 2013.

Wongkeo W, Chaipanich A (2010) Compressive strength, microstructure and thermal analysis of autoclaved and air cured structural lightweight concrete made with coal bottom ash and silica fume. Mater Sci Eng, A 527(16–17):3676–3684. https://doi.org/10.1016/j.msea.2010.01.089

Xie Z, Xi Y (2001) Hardening mechanisms of an alkaline-activated class F fly ash. Cem Concr Res 31(9):1245–1249

Zhao J, Wang D, Wang X, Liao S, Lin H (2015) Ultrafine grinding of fly ash with grinding aids: impact on particle characteristics of ultrafine fly ash and properties of blended cement containing ultrafine fly ash. Constr Build Mater 78:250–259. https://doi.org/10.1016/j.conbuildmat.2015.01.025

Zhu Q (2011) CO2 abatement in the cement industry [Internet]. IEA Clean Coal Centre. Available from: https://usea.org/sites/default/ files/062011_CO2abatement in the cement_ccc184.pdf

Funding

This research was funded by Taif University, Researchers Supporting Project grant number (TURSP-2020/196).

Author information

Authors and Affiliations

Contributions

Naraindas Bheel: conceptualization, investigation, methodology, writing–original draft, validation, and writing–review and editing.

Salim Khoso: conceptualization, formal analysis, data analysis, methodology, validation, and writing–review and editing.

Mereen Hussain Baloch: data analysis, writing–original draft, writing–review and editing.

Omrane Benjeddou: formal analysis, software, validation, visualization, writing–review and editing.

Mamdooh Alwetaishi: supervision, resources, funding acquisition, visualization, validation.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

All authors consent for publication.

Conflict of interest

The authors declare no competing interests.

Additional information

Responsible Editor: Philippe Garrigues

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Bheel, N., Khoso, S., Baloch, M.H. et al. Use of waste recycling coal bottom ash and sugarcane bagasse ash as cement and sand replacement material to produce sustainable concrete. Environ Sci Pollut Res 29, 52399–52411 (2022). https://doi.org/10.1007/s11356-022-19478-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-022-19478-3