Abstract

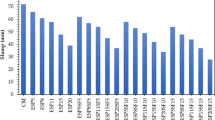

Global concrete demand is causing depletion of natural resources at an alarming rate. Self-compacting concrete (SCC) is an innovative solution as it uses less aggregates; however, the drawback of SCC is that high cement content is required compared to conventional concrete. Considering that cement production emits 7% of carbon dioxide (CO2) gas emissions, the use of high content of cement in SCC production is concerning. Though the high powder content of SCC may be of a concern, however, it allows the opportunity to substitute the cement content with supplementary cementitious materials. This experimental work was therefore conducted to reduce the cement content by substituting it with waste materials, such as eggshell powder (ESP) and palm oil fuel ash (POFA), and develop an eco-efficient SCC. The cement content was partially substituted by 0 to 5% ESP and 0 to 15% POFA by weight of total binder. A total of 90 cubes of 100 mm and 60 cylinders of 100 × 200 mm dimension were prepared to evaluate the compressive and splitting tensile strengths, modulus of elasticity, and Poisson’s ratio. Furthermore, the environmental impact assessment was conducted to assess the embodied CO2 and eco-strength efficiency of the developed eco-efficient SCC. It was found that the combination of POFA and ESP increased pozzolanic reactivity, developing additional calcium silicate hydrate gels, thus increasing strength. The combination of 2.5% ESP and 5% POFA (a total of 7.5% cement substitution) was deemed to be the optimal combination as it provided better strength in SCC after 28 days of curing, which leads to 9.66% higher compressive strength than the control SCC. Furthermore, the developed SCC was observed to be eco-friendly as it reduced embodied carbon ranging from 3.86 to 15.33% and eco-efficiency ranging from 2.38 to 15.48% on 28 days compared to the control SCC.

Similar content being viewed by others

References

Kamaruddin, S.; Goh, W.I.; Jhatial, A.A.; Mohd Zuki, S.S.; Faiz, A.: Self-compacting concrete with incorporation of recycled concrete aggregates. Int. J. Integr. Eng. 11(9), 164–173 (2019)

Bradu, A.; Cazacu, N.; Florea, N.; Mihai, P.: Compressive strength of self compacting concrete. Bul. Ina. Politeh. Din Iasi 62(66), 59–68 (2016)

Muhammad, A.; Usman, N.; Gambo, N.: Effect of binary blended pozzolanic materials on properties of self-compacting concrete. Int. J. Constr. Manag. (2020). https://doi.org/10.1080/15623599.2019.1707500

Memon, M.J.; Jhatial, A.A.; Murtaza, A.; Raza, M.S.; Phulpoto, K.B.: Production of eco-friendly concrete incorporating rice husk ash and polypropylene fibres. Environ. Sci. Pollut. Res. (2021). https://doi.org/10.1007/s11356-021-13418-3

Zhang, J.; Liu, G.; Chen, B.; Song, D.; Qi, J.; Liu, X.: Analysis of CO2 emission for the cement manufacturing with alternative raw materials: a LCA-based framework. Energy Procedia 61, 2541–2545 (2014). https://doi.org/10.1016/j.egypro.2014.12.041

Benhelal, E.; Zahedi, G.; Shamsaei, E.; Bahadori, A.: Global strategies and potentials to curb CO2 emissions in cement industry. J. Clean. Prod. 51, 142–161 (2013). https://doi.org/10.1016/j.jclepro.2012.10.049

Hanein, T.; Galvez-Martos, J.-L.; Bannerman, M.N.: Carbon footprint of calcium sulfoaluminate clinker production. J. Clean. Prod. 172, 2278–2287 (2018). https://doi.org/10.1016/j.jclepro.2017.11.183

Aljoumaily, Z.S.; Noordin, N.; Awang, H.; Almulali, M.Z.: The effect of blast furnace slag on foam concrete in terms of compressive strength, Adv. Mater. Res., 587, 81–87, 2012, https://doi.org/10.4028/www.scientific.net/AMR.587.81

Hasanbeigi, A.; Menke, C.; Price, L.: The CO2 abatement cost curve for the Thailand cement industry. J. Clean. Prod. 18(15), 1509–1518 (2010). https://doi.org/10.1016/j.jclepro.2010.06.005

Ranjbar, N.; Mehrali, M.; Alengaram, U.J.; Metselaar, H.S.C.; Jumaat, M.Z.: Compressive strength and microstructural analysis of fly ash/palm oil fuel ash based geopolymer mortar under elevated temperatures. Constr. Build. Mater. 65, 114–121 (2014). https://doi.org/10.1016/j.conbuildmat.2014.04.064

Assi, L.; Carter, K.; Deaver, E.E.; Anay, R.; Ziehl, P.: Sustainable concrete: building a greener future. J. Clean. Prod. 198, 1641–1651 (2018). https://doi.org/10.1016/j.jclepro.2018.07.123

Raza, M.S.; Rai, K.; Kumar, D.; Ali, M.: Experimental study of physical, fresh-state and strength parameters of concrete incorporating wood waste ash as a cementitious material. J. Mater. Eng. Struct. 7(2), 267–276 (2020)

Liew, K.M.; Sojobi, A.O.; Zhang, L.W.: Green concrete: prospects and challenges. Constr. Build. Mater. 156, 1063–1095 (2017). https://doi.org/10.1016/j.conbuildmat.2017.09.008

Voora V.; Larrea C.; Bermudez S.; Baliño S.: Global Market Report: Palm Oil, (2020). https://www.iisd.org/publications/global-market-report-palm-oil (Accessed Dec. 25, 2020)

Malaysian Palm Oil Council: Monthly Palm Oil Trade Statistics : January–December 2019, (2020). http://mpoc.org.my/monthly-palm-oil-trade-statistics-2019/ (Accessed Dec. 25, 2020)

Ahmadi, R.; Zainudin, N.; Ismail, I.; Mannan, M.A.; Abidin, A.S.Z.: Micro fine sized palm oil fuel ash produced using a wind tunnel production system. Adv. Mater. Sci. Eng. 2016, 1–6 (2016). https://doi.org/10.1155/2016/6792731

Tangchirapat, W.; Jaturapitakkul, C.; Chindaprasirt, P.: Use of palm oil fuel ash as a supplementary cementitious material for producing high-strength concrete. Constr. Build. Mater. 23(7), 2641–2646 (2009). https://doi.org/10.1016/j.conbuildmat.2009.01.008

Palm Oil Analytics: Essential Palm Oil Statistics 2017, (2020). http://www.palmoilanalytics.com/files/epos-final-59.pdf (Accessed Oct. 13, 2020)

Yu, T.Y.; Ing, D.S.; Choo, C.S.: The effect of different curing methods on the compressive strength of eggshell concrete. Indian J. Sci. Technol. 10(6), 1–4 (2017). https://doi.org/10.17485/ijst/2017/v10i6/111210

Jhatial, A.A.; Goh, W.I.; Sohu, S.; Mangi, S.A.; Mastoi, A.K.: Preliminary investigation of thermal behavior of lightweight foamed concrete incorporating palm oil fuel ash and eggshell powder. Period. Polytech. Civ. Eng. 65(1), 168–180 (2021). https://doi.org/10.3311/PPci.16498

Shafigh, P.; Bin Mahmud, H.; Jumaat, M.Z.; Zargar, M.: Agricultural wastes as aggregate in concrete mixtures—a review. Constr. Build. Mater. 53, 110–117 (2014). https://doi.org/10.1016/j.conbuildmat.2013.11.074

Madurwar, M.V.; Ralegaonkar, R.V.; Mandavgane, S.A.: Application of agro-waste for sustainable construction materials: a review. Constr. Build. Mater. 38, 872–878 (2013). https://doi.org/10.1016/j.conbuildmat.2012.09.011

Tay, J.: Ash from oil-palm waste as a concrete material. J. Mater. Civ. Eng. 2(2), 94–105 (1990). https://doi.org/10.1061/(ASCE)0899-1561(1990)2:2(94)

Jaturapitakkul, C.; Tangpagasit, J.; Songmue, S.; Kiattikomol, K.: Filler effect and pozzolanic reaction of ground palm oil fuel ash. Constr. Build. Mater. 25(11), 4287–4293 (2011). https://doi.org/10.1016/j.conbuildmat.2011.04.073

Idris, M.H.M., Khairunisa, M., Rokiah, O.: Effect of palm oil fuel ash as partial cement replacement on strength of foamed palm oil clinker concrete. Natl. Conf. Postgrad. Res. 2016, Univ. Malaysia Pahang, no. October 2016, pp. 115–119, (2016)

Ranjbar, N.; Behnia, A.; Alsubari, B.; Moradi Birgani, P.; Jumaat, M.Z.: Durability and mechanical properties of self-compacting concrete incorporating palm oil fuel ash. J. Clean. Prod. 112, 723–730 (2016). https://doi.org/10.1016/j.jclepro.2015.07.033

Islam, M.M.U.; Mo, K.H.; Alengaram, U.J.; Jumaat, M.Z.: Mechanical and fresh properties of sustainable oil palm shell lightweight concrete incorporating palm oil fuel ash. J. Clean. Prod. 115, 307–314 (2016). https://doi.org/10.1016/j.jclepro.2015.12.051

Chindaprasirt, P.; Jaturapitakkul, C.; Sinsiri, T.: Effect of fly ash fineness on microstructure of blended cement paste. Constr. Build. Mater. 21(7), 1534–1541 (2007). https://doi.org/10.1016/j.conbuildmat.2005.12.024

Jain, N.; Garg, M.; Minocha, A.K.: Green concrete from sustainable recycled coarse aggregates: mechanical and durability properties. J. Waste Manag. 2015, 1–8 (2015). https://doi.org/10.1155/2015/281043

Khalid, N.H.A., et al.: Palm oil fuel ash as potential green micro-filler in polymer concrete. Constr. Build. Mater. 102, 950–960 (2016). https://doi.org/10.1016/j.conbuildmat.2015.11.038

Jhatial, A.A.; Goh, W.I.; Mohamad, N.; Mo, K.H.; Sohu, S.: Incorporation of palm oil fuel ash and egg shell powder as supplementary cementitious materials in sustainable foamed concrete. Teh. Vjesn. (2020). https://doi.org/10.17559/TV-20190326112511

Freire, M.N.; Holanda, J.N.F.: Characterization of avian eggshell waste aiming its use in a ceramic wall tile paste. Cerâmica 52, 240–244 (2006)

Afolayan, J.O.; Oriola, F.O.P.; Moses, G.; Sani, J.E.: Investigating the effect of eggshell ash on the properties of sandcrete block, Int. J. Civ. Eng. Constr. Estate Manag., 5(3), 43–54, 2017, [Online]. Available: https://www.researchgate.net/publication/319493954

Yerramala, A.: Properties of concrete with eggshell powder as cement replacement. Indian Concr. J. 88(10), 94–102 (2014)

Department Veterinary Service Report: Consumption of Livestock Products, 2013–2019, http://www.dvs.gov.my/dvs/resources/user_1/2019/BP/Perangkaan%20Ternakan%2020182019/1)_Malaysia_Perangkaan_Ternakan.pdf, (2020)

Altuntas, E.; Sekeroglu, A.: Mechanical behavior and physical properties of chicken egg as affected by different egg weights. J. Food Process Eng. 33(1), 115–127 (2010). https://doi.org/10.1111/j.1745-4530.2008.00263.x

Murakami, F.S.; Rodrigues, P.O.; de Campos, C.M.T.; Silva, M.A.S.: Physicochemical study of CaCO3 from egg shells. Ciência e Tecnol. Aliment. 27(3), 658–662 (2007). https://doi.org/10.1590/S0101-20612007000300035

Gowsika, D.; Kokila, S.S.; Sargunan, K.: Experimental investigation of egg shell powder as partial replacement with cement in concrete. Int. J. Eng. Trends Technol. 14(1), 65–68 (2014). https://doi.org/10.14445/22315381/IJETT-V14P214

Raji, S.A.; Samuel, A.T.: Egg shell as a fine aggregate in concrete for sustainable construction. Int. J. Sci. Technol. Res. 4(8), 8–13 (2015)

Parthasarathi, N.; Prakash, M.; Satyanarayanan, K.S.: Experimental study on partial replacement of cement with egg shell powder and silica fume. Rasayan J. Chem. 10(2), 442–449 (2017). https://doi.org/10.7324/RJC.2017.1021689

Jhatial, A.A.; Goh, W.I.; Rind, T.A.; Kumar, A.: Thermal performance simulation of eco-friendly lightweight foamed concrete incorporating palm oil fuel ash and eggshell powder using ABAQUS. Silicon (2021). https://doi.org/10.1007/s12633-020-00907-2

Mohamad, M.E.; Mahmood, A.A.; Min, A.Y.Y.; AR, N.N.: Palm Oil Fuel Ash (POFA) and Eggshell Powder (ESP) as partial replacement for cement in concrete. E3S Web Conf 34, 01004 (2018). https://doi.org/10.1051/e3sconf/20183401004

Kamaruddin, S.; Goh, W.I.; Jhatial, A.A.; Lakhiar, M.T.: Chemical and fresh state properties of foamed concrete incorporating palm oil fuel ash and eggshell ash as cement replacement. Int. J. Eng. Technol. 7(4.30), 350 (2018). https://doi.org/10.14419/ijet.v7i4.30.22307

Rahman, A.F.; Goh, W.I.; Mohamad, N.; Kamarudin, M.S.; Jhatial, A.A.: Numerical analysis and experimental validation of reinforced foamed concrete beam containing partial cement replacement. Case Stud. Constr. Mater. (2019). https://doi.org/10.1016/j.cscm.2019.e00297

Rahman, A.F.; Goh, W.I.; Jhatial, A.A.: Flexural study of reinforced foamed concrete beam containing palm oil fuel ash (POFA) and eggshell powder (ESP) as partial cement replacement”. Int. J. Sustain. Constr. Eng. Technol. (2019). https://doi.org/10.30880/ijscet.2019.10.01.009

Khankhaje, E., et al.: On blended cement and geopolymer concretes containing palm oil fuel ash. Mater. Des. 89, 385–398 (2016). https://doi.org/10.1016/j.matdes.2015.09.140

Alsubari, B.; Shafigh, P.; Jumaat, M.: Development of self-consolidating high strength concrete incorporating treated palm oil fuel ash. Bul. INSTITUTULUI Politeh. DIN IAŞI 8(5), 2154–2173 (2015). https://doi.org/10.3390/ma8052154

Base Concrete: Different Types of Concrete Grades and Their Uses (2018)

EFNARC: Specification and Guidelines for Self-Compacting Concrete (2005)

Chopra, D.; Siddique, R.; Kunal: Strength, permeability and microstructure of self-compacting concrete containing rice husk ash, Biosyst. Eng., 130, 72–80, doi: https://doi.org/10.1016/j.biosystemseng.2014.12.005 (2015)

ASTM C114-18: Standard Test Methods for Chemical Analysis of Hydraulic Cement (2018)

BS EN 12390-3: Testing hardened concrete. Compressive strength of test specimens (2019)

BS EN 12390-6: Testing hardened concrete: Tensile splitting strength of test specimens (2009)

BS EN 12390-13: Testing hardened concrete. Determination of secant modulus of elasticity in compression, British Standards Institution, London, (2013)

Ramzi, N.I.R.; Shahidan, S.; Maarof, M.Z.; Ali, N.: Physical and chemical properties of coal bottom ash (CBA) from Tanjung Bin Power Plant. IOP Conf. Ser. Mater. Sci. Eng. 160, 012056 (2016). https://doi.org/10.1088/1757-899X/160/1/012056

Binici, H.; Kapur, S.; Rızaoğlu, T.; Kara, M.: Resistance to Thaumasite form of sulphate attack of blended cement mortars. Br. J. Appl. Sci. Technol. 4(31), 4356–4379 (2014). https://doi.org/10.9734/BJAST/2014/11948

Oyejobi, D.; Abdulkadir, T.S.; Ahmed, A.T.: A study of partial replacement of cement with palm oil fuel ash in concrete production. J. Agric. Technol. 12(4), 619–631 (2016)

Jhatial, A.A.; Goh, W.I.; Mastoi, A.K.; Rahman, A.F.; Kamaruddin, S.: Thermo-mechanical properties and sustainability analysis of newly developed eco-friendly structural foamed concrete by reusing palm oil fuel ash and eggshell powder as supplementary cementitious materials. Environ. Sci. Pollut. Res. (2021). https://doi.org/10.1007/s11356-021-13435-2

Mujah, D.: Compressive strength and chloride resistance of grout containing ground palm oil fuel ash. J. Clean. Prod. 112, 712–722 (2016). https://doi.org/10.1016/j.jclepro.2015.07.066

Long, G.; Gao, Y.; Xie, Y.: Designing more sustainable and greener self-compacting concrete. Constr. Build. Mater. 84, 301–306 (2015). https://doi.org/10.1016/j.conbuildmat.2015.02.072

Alnahhal, M.F.; Alengaram, U.J.; Jumaat, M.Z.; Abutaha, F.; Alqedra, M.A.; Nayaka, R.R.: Assessment on engineering properties and CO2 emissions of recycled aggregate concrete incorporating waste products as supplements to Portland cement. J. Clean. Prod. 203, 822–835 (2018). https://doi.org/10.1016/j.jclepro.2018.08.292

Egg-machine.com, “Eggshell Grinding Machine,” 2021. https://www.egg-machine.com/product/eggshell-grinding-machine.html (Accessed Feb. 26, 2021)

DECC, “2011 Guidelines to Defra/DECC’s GHG. Conversion Factors for Company Reporting: Methodology Paper for Emission Factors,” 2011. [Online]. Available: https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/69314/pb13625-emission-factor-methodology-paper-110905.pdf

Flower, D.J.M.; Sanjayan, J.G.: Green house gas emissions due to concrete manufacture. Int. J. Life Cycle Assess. 12(5), 282–288 (2007). https://doi.org/10.1065/lca2007.05.327

Turner, L.K.; Collins, F.G.: Carbon dioxide equivalent (CO2-e) emissions: a comparison between geopolymer and OPC cement concrete. Constr. Build. Mater. 43, 125–130 (2013). https://doi.org/10.1016/j.conbuildmat.2013.01.023

Yang, K.-H.; Song, J.-K.; Song, K.-I.: Assessment of CO2 reduction of alkali-activated concrete. J. Clean. Prod. 39, 265–272 (2013). https://doi.org/10.1016/j.jclepro.2012.08.001

Jhatial, A.A.; Goh, W.I.; Mohamad, N.; Sohu, S.; Lakhiar, M.T.: Utilization of palm oil fuel ash and eggshell powder as partial cement replacement—a review. Civ. Eng. J. 4(8), 1977 (2018). https://doi.org/10.28991/cej-03091131

Zeyad, A.M.; Megat Johari, M.A.; Tayeh, B.A.; Yusuf, M.O.: Efficiency of treated and untreated palm oil fuel ash as a supplementary binder on engineering and fluid transport properties of high-strength concrete. Constr. Build. Mater. 125, 1066–1079 (2016). https://doi.org/10.1016/j.conbuildmat.2016.08.065

Shakiba, M.; Rahgozar, P.; Elahi, A.R.; Rahgozar, R.: Effect of activated pozzolan with Ca(OH) 2 and nano-SiO2 on microstructure and hydration of high-volume natural pozzolan paste. Civ. Eng. J. 4(10), 2437 (2018). https://doi.org/10.28991/cej-03091171

Uysal, M.; Yilmaz, K.: Effect of mineral admixtures on properties of self-compacting concrete. Cem. Concr. Compos. 33(7), 771–776 (2011). https://doi.org/10.1016/j.cemconcomp.2011.04.005

Funding

The authors would like to acknowledge financial support received by the Research Management Centre (RMC), Universiti Tun Hussein Onn Malaysia under grant GPPS-H684.

Author information

Authors and Affiliations

Contributions

SK done conceptualization, investigation, data analysis, writing—original draft, funding acquisition. WIG performed supervision, methodology, writing—original draft, funding acquisition. NANAM contributed to investigation, data analysis. AAJ performed data analysis, writing—review and editing. NM done supervision and methodology. AFR investigated and analysed the data.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interest.

Rights and permissions

About this article

Cite this article

Kamaruddin, S., Goh, W.I., Abdul Mutalib, N.A.N. et al. Effect of Combined Supplementary Cementitious Materials on the Fresh and Mechanical Properties of Eco-Efficient Self-Compacting Concrete. Arab J Sci Eng 46, 10953–10973 (2021). https://doi.org/10.1007/s13369-021-05656-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-021-05656-x