Abstract

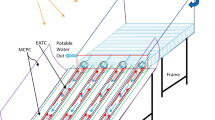

This work presents a novel approach for a double-slope solar desaltification system having parallel array of evacuated annular tube collectors with compound parabolic modified concentrators (DS-SDS-EATC-MCPC) that are observed for eco-design requisites for the optimum performance with environ-economic viabilities. The proposed scheme has been configured to obtain the utmost probable basin’s medium hotness as 99.6 °C of having greater depth of water (0.16 m) for the East–West-faced direction of basin peak cover (30°) along with South-oriented evacuated annular tube (30°). The highest circulation pace (thermo syphon) is obtained ~ 55 kg/h. The generalized efficiencies (energy-exergy) of the system are 46.53% and 3.62%, correspondingly. The everyday distillate (16.94 kg) and its production cost (energy $0.007/kWh; exergy $0.013/kWh) at a titular selling cost ($0.07/l) maintains its goodness. The CO2 mitigates (energy-exergy) and green earned credits are 139.74 and 77.30 tons, and $1396 and $772.24, in that order. The framework outlay of the scheme is quite stumpy at $200.79, and productivity of the model is set up > 100% that shows the scheme as appreciably realistic. The evident distillate at little operating cost, ecological returns, elevated alleviation, and short payoff period makes the arrangement sustainable, viable for reasonable collector areas, and optimum EATC with MCPC as eco-design requisites for the projected scheme.

Similar content being viewed by others

Data availability

The datasets used and analyzed during the current study are available from the corresponding author on reasonable request.

Abbreviations

- \({A}_{a}\) :

-

Accumulative opening area for MCPC

- \({A}_{g}\) :

-

Top glaze area (m2)

- \({A}_{b}\) :

-

Basin liner area (m2)

- \({A}_{rc}\) :

-

Annular tube receiver area

- \({C}_{w}, {C}_{f}\) :

-

Water mass specific heat capacity (J/kg K)

- \(d\) :

-

Interior dia of inner annular tube (m)

- \({E}_{e}\) :

-

Energetic growth (kWh)

- \({E}_{x}\) :

-

Exergetic growth (kWh)

- \({F}^{^{\prime}}\) :

-

Annular tube efficiency aspect

- \({G}_{r}\) :

-

Grashof number

- \({h}_{ba}\) :

-

Net heat transmission factor from liner to ambiance (W/m2 K)

- \({h}_{bw}\) :

-

Heat transmission factor (convective) from liner to water (W/m2 K)

- \({h}_{t-g}, {h}_{o}\) :

-

Heat loss factor (convention) from top glass to ambiance (W/m2 K)

- \({h}_{t-wg}\) :

-

Net heat transmission factor from water surface to top glaze cover (W/m2 K)

- \({h}_{c-wg}\) :

-

Heat transmission coefficient (convective) of brackish water to top glass cover (W/m2 K)

- \({h}_{e-wg}\) :

-

Heat transmission factor (evaporative) of brackish water to top glass cover (W/m2 K)

- \({h}_{r-wg}\) :

-

Heat transmission factor (radiative) from brackish water to top glass cover (W/m2 K)

- \({h}_{r-ev}\) :

-

Thermal loss factor (radiative) of annular tube along vacuum region (W/m2 K)

- \({h}_{saf}\) :

-

Overall heat transmission factor from absorber to annular tube water (W/m2 K)

- \({I}_{d}(t)\) :

-

Solar irradiance (diffused and reflected) (W/m2)

- \({I}_{s}(a)\) :

-

Solar energy engrossed at annular tube receiver (W/m2)

- \({I}_{s}(t)\) :

-

Radiative astral energy (instantaneous) at SDS unit (W/m2)

- \({I}_{b}(t)\) :

-

Irradiated solar beam radiation over EATC collectors (W/m2)

- \({K}_{g}\) :

-

Glass thermal conductivity (W/m K)

- \({K}_{b}\) :

-

Basin liner thermal conductivity (W/m K)

- \({K}_{w}\) :

-

Water thermal conductivity (W/m K)

- L:

-

Latent heat (water) for vaporization (J/kg)

- \({L}_{EATC}\) :

-

Annular tube length (m)

- \({\dot{m}}_{ewg}\) :

-

Yield hourly distillation (kg/h)

- \({\dot{m}}_{f}\) :

-

Thermo syphon flow rate in annular tube (kg/s)

- \({m}_{w}\) :

-

Quantity of brackish medium in still (kg)

- \({m}_{f}\) :

-

Quantity of water in EATC (kg)

- \({n}_{o}\) :

-

Air refractive index

- \({n}_{g}\) :

-

Glaze refractive index

- \({n}_{w}\) :

-

Water refractive index

- \({N}_{u}\) :

-

Nusselt no.

- \({N}_{sh}\) :

-

Sunshine hour numbers

- \({P}_{r}\) :

-

Prandtl number

- \({p}_{w}\) :

-

Vapor pressure (partial) at the surface of still’s water (Pa, N/m2)

- \({p}_{gi}\) :

-

Vapor pressure (partial) at of top glaze interior face (Pa, N/m2)

- \({\dot{Q}}_{N-EATC}\) :

-

Rate of heat grow in SDS through paralleled N-EATC-MCPC arrangement (kJ/s)

- \({\dot{q}}_{ewg}\) :

-

Heat transmission rate of evaporation from brackish water to glass cover up (kJ/s)

- \({R}_{a}\) :

-

Rayleigh no.

- \({R}_{e}\) :

-

Reynold no.

- \({R}_{g}\) :

-

Glaze reflectivity

- \({R}_{i1}\) :

-

Internal tube interior radius (m)

- \({R}_{i2}\) :

-

External tube interior radius (m)

- \({R}_{o2}\) :

-

External tube exterior radius (m)

- \({R}_{sc}\) :

-

Selective absorber reflectivity

- \({T}_{a}\) :

-

Atmosphere temperature (°C)

- \({T}_{b}\) :

-

Temperature of basin liner (°C)

- \({t}_{b}\) :

-

Liner depth (m)

- \(t\) :

-

Time (s)

- \({t}_{g}\) :

-

Glaze thickness (m)

- \({T}_{sa}\) :

-

Selective absorber temperature (°C)

- \({T}_{f}\) :

-

Annular tube fluid (water medium) temperature (°C)

- \({T}_{fo1}\) :

-

Exit water temperature from independent EATC (°C)

- \({T}_{N-fo}\) :

-

Exit temperature of associative water medium impending through N-EATC (°C)

- \({T}_{w}\) :

-

SDS basin water mass temperature (°C)

- \({T}_{go}\) :

-

Top glaze temperature of external face (°C)

- \({T}_{gi}\) :

-

Top glaze temperature of interior face (°C)

- \({U}_{saa}\) :

-

Net heat transmission (loss) factor from external annular tube

- V :

-

Air velocity (average) (m/s

- ALN:

-

Aluminum nitride

- CCPC:

-

Combined parabolic collector

- CPC:

-

Parabolic collector

- DS:

-

Slope

- EATC:

-

(Vacuum) annular tube collector

- FP:

-

Plate

- MCPC:

-

Combined parabolic collector (modified)

- OCPC:

-

Combined parabolic collector (oriented)

- SDS:

-

Solar desaltification system

- \(\nu\) :

-

Kinematic viscosity water (m2/s)

- \({\beta }^{^{\prime}}\) :

-

Water volumetric thermal expansion coefficient (K−1)

- \(\alpha\) :

-

Absorber absorptivity

- \(\mu\) :

-

Dynamic viscosity of water (N·s/m2)

- \({\alpha }_{g}\) :

-

Glass absorptivity

- \({\alpha }_{w}\) :

-

Water absorptivity

- \({\alpha }_{b}\) :

-

Liner absorptivity

- \({\eta }_{i}\) :

-

Instantaneous efficiency (%)

- \({\eta }_{e}\) :

-

Energy efficiency (%)

- \({\eta }_{x}\) :

-

Exergy efficiency (%)

- \(\tau\) :

-

Transmissivity

- \(\sigma\) :

-

Constant of Stefan-Boltzmann (W/m2 K4)

- \(\rho\) :

-

Density (kg/m3)

- \({\varepsilon }_{eff}\) :

-

Emissivity (effective)

- \({\varepsilon }_{g}\) :

-

Glaze emissivity

- \({\varepsilon }_{w}\) :

-

Water emissivity

References

Badran OO, Abu-Khader MM (2007) Evaluating thermal performance of a single slope solar still. Heat Mass Transfer 43:985–995

Bait O (2019) Exergy, environeeconomic and economic analyses of a tubular solar water heater assisted solar still. J Cleaner Production 212:630–646

Barbosa EG, Martins MA, Araujo MEV, Renato NS, Zolnier S, Pereira EG, Resende MO (2020) Experimental evaluation of a stationary parabolic trough solar collector: influence of the concentrator and heat transfer fluid. Journal of Cleaner Production 276:124174

Benson, F., 1952. Further notes on the productivity of machines requiring attention at random intervals. J. Roy. Stat. Soc. B XIV, 200–210.

Budihardjo I, Morrison GL (2009) Performance of water-in-glass evacuated tube solar water heaters. Sol Energy 83:49–56

Budihardjo I, Morrison GL, Behnia M (2007) Natural circulation flow through water-in- lass evacuated tube solar collectors. Sol Energy 81:1460–1472

Cengel XA, Boles MA (2013) Thermodynamics, an engineering approach. McGraw-Hill Education Pvt. Ltd., New York

Cooper PI (1973) The maximum efficiency of single-effect solar stills. Sol Energy 15:205–217

Cooper PI (1969) The absorption of solar energy radiation in solar stills. Sol Energy 12:133

Cox DR (1951) The productivity of machines requiring attention at random intervals. J. Roy. Stat. Soc. B XIII, 65–82

Dev R, Tiwari GN (2012) Annual performance of evacuated tubular collector integrated solar still. Desalination Water Treatment 41:204–223

Dubey A, Kumar S, Arora A (2021) Enviro-energy-exergo-economic analysis of ETC augmented double slope solar still with ‘n’ parallel tubes under forced mode: environmental and economic feasibility. J Clean Prod. https://doi.org/10.1016/j.jclepro.2020.123859

Duffie JA, Beckman WA (2006) Solar engineering of thermal processes. Hoboken- Wiley, New Jersey

Dunkle RV (1961) Solar water distillation: the roof type solar still and a multiple effect diffusion still, International Developments in Heat Transfer ASME 895–902

Dwivedi VK, Tiwari GN (2008) Energy and exergy analysis of single and double slope passive solar still. Trends in Applied Sciences and Research 3(3):225–241

IAPWS (1996) International association for the properties of water and steam, for the thermodynamic properties of ordinary water substance for general and scientific use, 1996

IAPWS (2008) International association for the properties of water and steam, the viscosity of ordinary water substance, 2008

Issa RJ, Chang B (2017) Performance study on evacuated tubular collector coupled solar stillin west texas climate. Int J Green Energy. https://doi.org/10.1080/15435075.2017.1328422

Kalogirou S (2003) The potential of solar industrial process heat applications. Appl Energy 76:337–361

Kalshian R (2008) Energy versus emissions: the big challenge of the new millennium. Info Change News and Features, www.infochangeindia.org/agenda5_01.jsp, accessed 21 March 2008

Koffi PME, Andoh HY, Gbaha P, Toure S, Ado G (2008) Theoretical and experimental study of solar water heater with internal exchanger using thermosiphon system. Energy Convers Manage 49:2279–2290

Kumar S, Dubey A, Tiwari G (2014) A solar still augmented with an evacuated tube collector in forced mode. Desalination 347:15–24

Liu BYH, Jordan RC (1960) The interrelationship and characteristic distribution of direct, diffuse and total solar radiation, Solar Energy 4(3)

Liu BYH, Jordan RC (1962) Daily insolation on surfaces tilted towards equator. ASHRAE J 3(10):53

Malik MAS, Tiwari GN, Kumar A, Sodha MS (1982) Solar distillation—a practical study of a wide range of stills and their optimum design, construction and performance. Pergamon Press, Oxford, U. K.

Mittal ML, Sharma C, Singh R (2014) Decadal emission estimates of carbon dioxide, sulphur dioxide and nitic oxide emissions from coal burning in electric power generation plants in India. Environ Monit Assess 186:6857–6866

Morrison G, Tran N, McKenzie D, Onley I, Harding G, Collins R (1984) Long term performance of evacuated tubular solar water heaters in Sydney, Australia. Sol Energy 32:785–791

Morrison GL, Budihardjoa I, Behnia M (2005) Measurement and simulation of flow rate in a water-in-glass evacuated tube solar water heater. Sol Energy 78:257–267

Patel J, Markam BK, Maiti S (2019) Potable water by solar thermal distillation in solar salt works and performance enhancement by integrating with evacuated tubes. Sol Energy 188:561–572

Petela R (1964) Exergy of heat radiation. Journal of Heat Transfer, ASME 2:187–192

Petela R (2003) Exergy of undiluted thermal radiation. Sol Energy 74:469–488

Petela R (2010a) 2010. McGraw Hill, Inc, Engineering thermodynamics of thermal radiation for solar power utilization

Petela R (2010b) Radiation spectra of surface. Int J Exergy 7:89–109

Pissavi P (1982) Modelling of the dynamic behavior of a tank for solar storage with internal exchanger. Re´v Ge´n Thermique 246–247, 521–35

Rashidi S, Karimi N, Mahian O, Esfahani JA (2018) A concise review on the role of nanoparticles upon the productivity of solar desalination systems. J Therm Anal Calorim 135:1145–1159

Reddy KS, Sharon H (2017) Energy–environment–economic investigations on evacuated active multiple stage series flow solar distillation unit for potable water production. Energy Convers Manage 151:259–285

Reddy KS, Sharon H, Krithika D, Philip L (2018) Performance, water quality and enviro-economic investigations on solar distillation treatment of reverse osmosis reject and sewage water. Sol Energy 173:160–172

Roome J (2019) State and Trends of Carbon Pricing (2019). World Bank Group, Washington DC

Sadeghi G, Pisello AL, Nazari S, Jowzi M, Shama F (2021) Empirical data-driven multi-layer perceptron and radial basis function techniques in predicting the performance of nanofluid-based modified tubular solar collectors. J Clean Prod 295:126409

Sampathkumar K, Arjunan T, Senthilkumar P (2013) The experimental investigation of a solar still coupled with an evacuated tube collector. Energy Sources, Part A 35:261–270

Sato AI, Scalon VL, Padilha A (2012) Numerical analysis of a modified evacuated tubes solar collector. International Conference on Renewable Energies and Power Quality (ICREPQ'12)

Sharon H, Reddy KS, Krithika D, Philip L (2017) Experimental performance investigation of tilted solar still with basin and wick for distillate quality and enviro-economic aspects. Desalination 410:30–54

Singh AK (2020) An inclusive study on new conceptual designs of passive solar desalting systems. Heliyon 7:e05793

Singh AK, Samsher, (2020) Analytical study of evacuated annulus tube collector assisted solar desaltification system: A review. Sol Energy 207:1404–1426

Singh AK, Samsher, (2021) A review study of solar desalting units with evacuated tube collectors. Journal of Cleaner Production 279:123542

Singh AK, Samsher, (2021b) Material conscious energy matrix and enviro-economic analysis of passive ETC solar still. Materials Today: Proceedings 38:1–5

Singh AK, Samsher (2021b) Tech-en-econ-energy-exergy-matrix (T4EM) observations of evacuated solar tube collector augmented solar desaltification unit: a modified design loom. Materials Today: Proceedings, https://doi.org/10.1016/j.matpr.2021.09.088

Singh AK, Yadav RK, Mishra D, Prasad R, Gupta LK, Kumar P (2020) Active solar distillation technology: a wide overview. Desalination 493:114652

Singh AK, Samsher, (2022) Techno-environ-economic-energy-exergy-matrices performance analysis of evacuated annulus tube with modified parabolic concentrator assisted single slope solar desalination system. Journal of Cleaner Production 332:129996

Singh RV, Kumar S, Hasan M, Khan ME, Tiwari G (2013) Performance of a solar still integrated with evacuated tube collector in natural mode. Desalination 318:25–33

Tiwari AK, Tiwari GN (2007) Annual performance analysis and thermal modelling of passive solar still for different inclination of condensing cover. Energy Res 31(4):1358–1382

Tiwari G, Shukla S, Singh I (2003) Computer modeling of passive/active solar stills by using inner glass temperature. Desalination 154:171–185

Tiwari GN (2014) Solar energy: fundamentals, design, modelling and applications. Narosa Publishing House, New Delhi

Tiwari GN, Mishra RK (2012) 2012. RSC Publishing Cambridge, UK, Advanced renewable energy sources

Tiwari GN, Raj K, Maheshwari KP, Sawhney RL (1992) Recent advances in solar distillation. In: International Journal of Solar Energy and Energy Conversion. Wiley Eastern, New Delhi, pp. 32e149 (Chapter 2)

Tiwari GN, Tiwari A, Shyam, (2016) Handbook of Solar Energy. Theory, Analysis and Applications, Springer Nature, Singapore

Tiwari GN, Yadav JK, Singh DB, Al–Helal, I.M., Abdel-Ghany, A.M., (2015) Exergoeconomic and enviroeconomic analyses of partially covered photovoltaic flat plate collector active solar distillation system. Desalination 367:186–196

Tsatsaronis G, Lin L, Pisa J (1993) Exergy costing in exergoeconomics. J. Energy Resour. – ASME 115, 9–16

Tsatsaronis G, Park H (2002) On avoidable and unavoidable exergy destructions and investment costs in thermal systems. Energy Convers Manage 43(9–12):1259–1270

Tsatsaronis G, Winhold M (1985) Exergoeconomic analysis and evaluation of energy conversion plants – a new general methodology. Energy 10:69–94

Watt M, Jonhnson A, Ellis M, Quthred N (1998) Prog Photovolt Res Appl 6(2):127–136

Xu L, Liu Z, Li S, Shao Z, Xia N (2019) Performance of solar mid-temperature evacuated tube collector for steam generation. Sol Energy 183:162–172

Yari M, Mazareh AE, Mehr AS (2016) A novel cogeneration system for sustainable water and power production by integration of a solar still and PV module. Desalination 398:1–11

Yousef MS, Hassan H, Sekiguchi H (2019) Energy, exergy, economic and enviro economic (4E) analyses of solar distillation system using different absorbing materials. Appl Therm Eng 150:30–41

Yousef MdS, Hassan H (2019) Assessment of different passive solar stills via exergoeconomic, exergoenvironmental, and exergoenviroeconomic approaches: a comparative study. Sol Energy 182:316–331

Author information

Authors and Affiliations

Contributions

Ashok Kumar Singh: conceptualization, data curation, formal analysis, validation, investigation, methodology, software, writing—original draft.

Samsher Gautam: supervision, resources, visualization, project administration.

Corresponding author

Ethics declarations

Ethical approval

Not applicable.

Consent to participate

Not applicable.

Consent to publish

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Responsible Editor: Philippe Garrigues

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

Relations were utilized to solve Eq. (1) following Singh and Samsher (2020), Duffie and Beckman (2006), and Dunkle (1961) as stated,

Expressions were utilized to solve Eqs. (7), (10), (17), and (19) as mentioned,

Relations were utilized to solve Eqs. (20)-(21) as mentioned (Cooper 1973; Dunkle 1961; Singh and Samsher 2021a, b, c; Singh and Samsher 2022),

Equations were utilized to solve Eq. (22) as mentioned (Tiwari 2014; Singh and Samsher 2021a, b, c),

Expressions were utilized to solve Eq. (25) as mentioned (Tiwari 2014),

Relations utilized to solve Eqs. (26)-(29), (31) as mentioned,

Rights and permissions

About this article

Cite this article

Singh, A.K., Gautam, S. Optimum techno-eco performance requisites for vacuum annulus tube collector–assisted double-slope solar desaltification unit integrated modified parabolic concentrator. Environ Sci Pollut Res 29, 34379–34405 (2022). https://doi.org/10.1007/s11356-021-18426-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-021-18426-x