Abstract

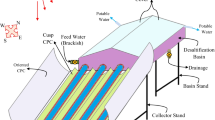

In this paper, an eco-design criterion for a novel solar desaltification setup (SDS) with evacuated annular tube collector (EATC) and a specific set of modified combination of parabolic concentrator has been examined for maximum performance with environmental and economic circumstances. This technique approaches to rectify the irregular utilization of EATC for optimum performance with environ-economic viabilities, which evidently satisfies the eco-design requirements and boosts the solar absorption capabilities uniformly along the periphery of vacuum tubes, and results improved thermo-syphon loom significantly more than in typical applications. The suggested unit is being refined and improved water temperature by 11.4% while keeping the basin lid and annular tubes at the same direction (30°). An incremental improvement in thermo-syphon circulation of 28.1% obtained through the present study. The average solar intensity of the respective clear day has been found as 401.8 kW and the overall energy and exergy efficiency on a daily basis are 50.8%, and 3.8%, correspondingly. At a minimal retail price of 0.07 $/l, and improved daily output by 12.3 kg per day than the typical SDS-EATC system taken for comparison into consideration are determined to be more satisfactory. 131.97 and 67.44 tons alleviates for $1318.36 and $673.77 from environmental generated money based on energy-exergy are there for CO2, respectfully. The setup cost is noticeably reduced by 9.15% to the comparative system, and its productivity is determined to be 940.8% (> 100%), and this indicates that the present system is highly viable and appreciable for the feasible adaptation with the positive environ-economic possibilities.

Similar content being viewed by others

Abbreviations

- \(A_{a}\) :

-

MCPC aperture area (m2)

- \(A_{g}\) :

-

Glass area (m2)

- \(A_{b}\) :

-

Liner area (m2)

- \(A_{rc}\) :

-

Collector area of EATC (m2)

- \(C_{w} , C_{f}\) :

-

Water heat capacity (J/kg K)

- \(d\) :

-

EATC interior diameter (m)

- \(E_{e}\) :

-

Energy get (kWh)

- \(E_{x}\) :

-

Exergy get (kWh)

- \(F^{^{\prime}}\) :

-

Tube collector efficiency aspect

- \(G_{r}\) :

-

Grashof No.

- \(h_{ba}\) :

-

Net heat transport coefficient (liner-atmosphere) (W/m2 K)

- \(h_{bw}\) :

-

Convective heat transport coefficient (liner-water) (W/m2 K)

- \(h_{t - g} , h_{o}\) :

-

Thermal thrashing coefficient (glaze-atmosphere) (W/m2 K)

- \(h_{t - wg}\) :

-

Net heat transport coefficient (water-top glass) (W/m2 K)

- \(h_{c - wg}\) :

-

Convection heat transport coefficient (water-top glass) (W/m2 K)

- \(h_{e - wg}\) :

-

Evaporation heat transport coefficient (water-top glass) (W/m2 K)

- \(h_{r - wg}\) :

-

Radiation heat transport coefficient (water-top glass) (W/m2 K)

- \(h_{r - ev}\) :

-

Radiation thermal thrashing coefficient of EATC (W/m2 K)

- \(h_{{{\text{saf}}}}\) :

-

Net heat transport coefficient from EATC absorber to water (W/m2 K)

- \(I_{d} \left( t \right)\) :

-

Imitated radiation of ground (W/m2)

- \(I_{s} \left( a \right)\) :

-

Absorbed sun’s ray energy (W/m2)

- \(I_{s} \left( t \right)\) :

-

Sun’s ray energy of instance (W/m2)

- \(I_{b} \left( t \right)\) :

-

Irradiated solar beam radiation (W/m2)

- \(K_{g}\) :

-

Glaze conductivity (thermal) (W/m K)

- \(K_{b}\) :

-

Lining conductivity (thermal) (W/m K)

- \(K_{w}\) :

-

Medium (water) conductivity (thermal) (W/m K)

- L:

-

Heat latent (vaporization) (J/kg)

- \(L_{{{\text{EATC}}}}\) :

-

Tube length (m)

- \(\dot{m}_{{{\text{ewg}}}}\) :

-

Hour yielding (kg/h)

- \(\dot{m}_{f}\) :

-

Water circulation rate (kg/s)

- \(m_{w}\) :

-

Basin water amount (kg)

- \(m_{f}\) :

-

EATC water amount (kg)

- \(n_{o}\) :

-

Air index (refractive)

- \(n_{g}\) :

-

Glass index (refractive)

- \(n_{w}\) :

-

Water index(refractive)

- \(N_{u}\) :

-

Nusselt No.

- \(N_{sh}\) :

-

Sunshine hours

- \(P_{r}\) :

-

Prandtl No.

- \(p_{w}\) :

-

Fractional vapor pressure (water surface) (Pa, N/m2)

- \(p_{gi}\) :

-

Fractional vapor pressure (top glaze) (Pa, N/m2)

- \(\dot{Q}_{{N - {\text{EATC}}}}\) :

-

Heat gain rate from EATC (kJ/s)

- \(R_{a}\) :

-

Rayleigh No.

- \(R_{e}\) :

-

Reynold No.

- \(R_{g}\) :

-

Glass reflectivity

- \(R_{i1}\) :

-

Internal tube ID (m)

- \(R_{i2}\) :

-

Internal tube OD (m)

- \(R_{o2}\) :

-

External tube OD (m)

- \(R_{sc}\) :

-

Absorber reflectivity

- \(T_{a}\) :

-

Air temperature (°C)

- \(T_{b}\) :

-

Lining temperature (°C)

- \(t_{b}\) :

-

Lining thickness (m)

- \(t\) :

-

Time (s)

- \(t_{g}\) :

-

Glass thickness (m)

- \(T_{sa}\) :

-

Temperature of EATC absorber (°C)

- \(T_{f}\) :

-

EATC fluid temperature (°C)

- \(T_{fo1}\) :

-

EATC outlet water (brackish) temperature (°C)

- \(T_{w}\) :

-

Still water (brackish) temperature (°C)

- \(T_{go}\) :

-

Outer glass facade temperature (°C)

- \(T_{gi}\) :

-

Inner glaze facade temperature (°C)

- \(U_{saa}\) :

-

EATC tube overall heat transmit coefficient

- V:

-

Averaged air speed (m/s)

- SDS:

-

Solar desaltification scheme

- EATC:

-

Evacuated annulled tube collector

- CPC:

-

Combination of parabolic concentrator

- OCPC:

-

Orient combination of parabolic concentrator

- MCPC:

-

Modified combination of parabolic concentrator

- CCPC:

-

Cusp combination of parabolic collector

- \(\nu\) :

-

Viscosity (kinematic) (m2/s)

- \(\beta^{^{\prime}}\) :

-

Volumetric expansion (thermal) (K−1)

- \(\alpha\) :

-

Absorptivity (absorber)

- \(\mu\) :

-

Viscosity (dynamic) (N.s/m2)

- \(\alpha_{g}\) :

-

Glass absorptivity

- \(\alpha_{w}\) :

-

Water absorptivity

- \(\alpha_{b}\) :

-

Liner absorptivity

- \(\eta_{i}\) :

-

Instantaneous efficiency (%)

- \(\eta_{e}\) :

-

Energy efficiency (%)

- \(\eta_{x}\) :

-

Exergy efficiency (%)

- \(\tau\) :

-

Transmissivity

- \(\sigma\) :

-

Stefan–Boltzmann constant (W/m2 K4)

- \(\rho\) :

-

Density (kg/m3)

- \(\varepsilon_{{{\text{eff}}}}\) :

-

Effective emissivity

- \(\varepsilon_{g}\) :

-

Glass emissivity

- \(\varepsilon_{w}\) :

-

Water emissivity

References

Alayi, R., Khalilpoor, N., Heshmati, S., Najafi, A., & Issakhov, A. (2021). Thermal and environmental analysis solar water heater system for residential buildings. International Journal of Photoenergy, 6838138, 1–9.

Bait, O. (2019). Exergy, environeeconomic and economic analyses of a tubular solar water heater assisted solar still. Journal of Cleaner Production, 212, 630–646.

Benson, F. (1952). Further notes on the productivity of machines requiring attention at random intervals. Journal of the Royal Statistical Society: Series B (Methodological), XIV, 200–210.

Budihardjo, I., & Morrison, G. L. (2009). Performance of water-in-glass evacuated tube solar water heaters. Solar Energy, 83, 49–56.

Budihardjo, I., Morrison, G. L., & Behnia, M. (2007). Natural circulation flow through water-in- lass evacuated tube solar collectors. Solar Energy, 81, 1460–1472.

Cengel, X. A., & Boles, M. A. (2013). Thermodynamics, an engineering approach. McGraw-Hill Education Pvt. Ltd.

Cooper, P. I. (1973). The maximum efficiency of single-effect solar stills. Solar Energy, 15, 205–217.

Cox, D. R. (1951). The productivity of machines requiring attention at random intervals. Journal of the Royal Statistical Society: Series B (Methodological) XIII, 65–82.

Dev, R., & Tiwari, G. N. (2012). Annual performance of evacuated tubular collector integrated solar still. Desalination Water Treatment, 41, 204–223.

Duffie, J. A., & Beckman, W. A. (2006). Solar engineering of thermal processes. Hoboken- Wiley.

Dunkle, R. V. (1961). Solar water distillation: the roof type solar still and a multiple effect diffusion still, International Developments in Heat Transfer ASME 895–902.

IAPWS (1996). International association for the properties of water and steam, for the thermodynamic properties of ordinary water substance for general and scientific use, 1996.

IAPWS (2008). International association for the properties of water and steam, the viscosity of ordinary water substance, 2008.

Issa, R. J., & Chang, B. (2017). Performance study on evacuated tubular collector coupled solar stillin west texas climate. International Journal of Green Energy. https://doi.org/10.1080/15435075.2017.1328422

Koffi, P. M. E., Andoh, H. Y., Gbaha, P., Toure, S., & Ado, G. (2008a). Theoretical and experimental study of solar water heater with internal exchanger using thermosiphon system. Energy Conversion and Management, 49, 2279–2290.

Koffi, P. M. E., Andoh, H. Y., Gbaha, P., Toure, S., & Ado, G. (2008b). Theoretical and experimental study of solar water heater with internal exchanger using thermosiphon system, Energy Convers. Manage, 49, 2279–2290.

Kumar, S., Dubey, A., & Tiwari, G. (2014). A solar still augmented with an evacuated tube collector in forced mode. Desalination, 347, 15–24.

Liu, B. Y. H., Jordan, R. C., (1960). The interrelationship and characteristic distribution of direct, diffuse and total solar radiation, Solar Energy, 4(3).

Malik, M. A. S., Tiwari, G. N., Kumar, A., & Sodha, M. S. (1982). Solar distillation—a practical study of a wide range of stills and their optimum design, construction and performance. Pergamon Press.

Mittal, M. L., Sharma, C., & Singh, R. (2014). Decadal emission estimates of carbon dioxide, sulphur dioxide and nitic oxide emissions from coal burning in electric power generation plants in India. Environmental Monitoring and Assessment, 186, 6857–6866.

Morrison, G. L., Budihardjoa, I., & Behnia, M. (2005). Measurement and simulation of flow rate in a water-in-glass evacuated tube solar water heater. Solar Energy, 78, 257–267.

Patel, J., Markam, B. K., & Maiti, S. (2019). Potable water by solar thermal distillation in solar salt works and performance enhancement by integrating with evacuated tubes. Solar Energy, 188, 561–572.

Pissavi, P. (1982). Modelling of the dynamic behavior of a tank for solar storage with internal exchanger. Rev´ Ge´n Thermique, 246–247, 521–35.

Reddy, K. S., & Sharon, H. (2017). Energy–environment–economic investigations on evacuated active multiple stage series flow solar distillation unit for potable water production. Energy Conversion and Management, 151, 259–285.

Reddy, K. S., Sharon, H., Krithika, D., & Philip, L. (2018). Performance, water quality and enviro-economic investigations on solar distillation treatment of reverse osmosis reject and sewage water. Solar Energy, 173, 160–172.

Roome, J. (2019). State and Trends of Carbon Pricing (2019). World Bank Group.

Sampathkumar, K., Arjunan, T., & Senthilkumar, P. (2013). The experimental investigation of a solar still coupled with an evacuated tube collector. Energy Sources, Part A433A: Recovery, Utilization, and Environmental Effects+A465, 35, 261–270.

Sato, A. I., Scalon, V. L., Padilha, A., (2012). Numerical analysis of a modified evacuated tubes solar collector. International Conference on Renewable Energies and Power Quality (ICREPQ'12).

Sharon, H., Reddy, K. S., Krithika, D., & Philip, L. (2017). Experimental performance investigation of tilted solar still with basin and wick for distillate quality and enviro-economic aspects. Desalination, 410, 30–54.

Singh, A. K., Samsher (2021c). Tech-en-econ-energy-exergy-matrix (T4EM) observations of evacuated solar tube collector augmented solar desaltification unit: A modified design loom, Materials Today: Proceedings. https://doi.org/10.1016/j.matpr.2021c.09.088

Singh, A. K. (2020). An inclusive study on new conceptual designs of passive solar desalting systems. Heliyon, 7, e05793.

Singh, A. K., & Gautam, S. (2022). Optimum techno-eco performance requisites for vacuum annulus tube collector-assisted double-slope solar desaltification unit integrated modified parabolic concentrator. Environmental Science and Pollution Research. https://doi.org/10.1007/s11356-021-18426-x

Singh, A. K., Samsher (2020). Analytical study of evacuated annulus tube collector assisted solar desaltification system: A review, Solar Energy, 207: 1404–1426.

Singh, A. K., Samsher (2021a). A review study of solar desalting units with evacuated tube collectors. Journal of Cleaner Production 279: 123542.

Singh, A. K., Samsher (2021b). Material conscious energy matrix and enviro-economic analysis of passive ETC solar still. Materials Today: Proceedings, 38, 1–5.

Singh, A. K., Samsher (2022). Techno-environ-economic-energy-exergy-matrices performance analysis of evacuated annulus tube with modified parabolic concentrator assisted single slope solar desalination system. Journal of Cleaner Production, 332:129996.

Singh, A. K., Yadav, R. K., Mishra, D., Prasad, R., Gupta, L. K., & Kumar, P. (2020). Active solar distillation technology: A wide overview. Desalination, 493, 114652.

Singh, R. V., Kumar, S., Hasan, M., Khan, M. E., & Tiwari, G. (2013). Performance of a solar still integrated with evacuated tube collector in natural mode. Desalination, 318, 25–33.

Tiwari, G. N., Raj, K., Maheshwari, K. P., Sawhney, R. L. (1992). Recent advances in solar distillation. In: International Journal of Solar Energy and Energy Conversion. Wiley Eastern, New Delhi, pp. 32e149 (Chapter 2).

Tiwari, G., Shukla, S., & Singh, I. (2003). Computer modeling of passive/active solar stills by using inner glass temperature. Desalination, 154, 171e185.

Tiwari, G. N., Tiwari, A., Shyam (2016). Handbook of Solar Energy Theory Analysis and Applications, Springer Nature

Tiwari, A. K., & Tiwari, G. N. (2007). Annual performance analysis and thermal modelling of passive solar still for different inclination of condensing cover. International Journal of Energy Research, 31(4), 1358–1382.

Tiwari, G. N. (2014). Solar Energy: Fundamentals, Design. Narosa Publishing House.

Tiwari, G. N., Yadav, J. K., Singh, D. B., Al–Helal, I. M., Abdel–Ghany, A. M. (2015). Exergoeconomic and enviroeconomic analyses of partially covered photovoltaic flat plate collector active solar distillation system. Desalination, 367, 186–196.

Tsatsaronis, G., & Park, H. (2002). On avoidable and unavoidable exergy destructions and investment costs in thermal systems. Energy Conversion and Management, 43(9–12), 1259–1270.

Yari, M., Mazareh, A. E., & Mehr, A. S. (2016). A novel cogeneration system for sustainable water and power production by integration of a solar still and PV module. Desalination, 398, 1–11.

Yousef, Md. S., & Hassan, H. (2019). Assessment of different passive solar stills via exergoeconomic, exergoenvironmental, and exergoenviroeconomic approaches: A comparative study. Solar Energy, 182, 316–331.

Funding

This research received no specific grant from any funding agency in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Contributions

AKS: Conceptualization, Data curation, Formal analysis, Validation, Investigation, Methodology, Software, Writing—original draft. SG: Supervision, Resources, Visualization, Project administration.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Data availability

The datasets used and analyzed during the current study are available from the corresponding author on reasonable request.

Ethical approval

Not applicable.

Consent to participate

Not applicable.

Consent to publish

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

Relationships employed to resolve Eq. (1), (2) (Duffie & Beckman, 2006; Singh & Gautam, 2022)

Terminologies utilized in Eqs. (7), (10), and (17) as stated,

Relationships utilized for Eq. (18) as expressed (Cooper, 1973; Dunkle, 1961; Singh & Gautam, 2022; Singh & Samsher, 2020),

Equations used in Eq. (20) as,

Equations used in Eq. (22) as written (Tiwari, 2014),

Relationships involved in Eqs. (25), (28), and (34) as,

Rights and permissions

About this article

Cite this article

Singh, A.K., Samsher Eco-design requisites for solar desaltification still augmented evacuated annular tube collectors with parabolic concentrator: an optimum-environ-economic viability. Environ Dev Sustain 25, 11057–11094 (2023). https://doi.org/10.1007/s10668-022-02518-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10668-022-02518-w