Abstract

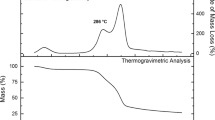

Microwave pyrolysis of oil palm fiber (OPF) with three types of Na-based catalysts was experimentally investigated to produce biochar. Sodium hydroxide (NaOH), sodium chloride (NaCl), and sodium carbonate (Na2CO3) with purity 99.9% were selected for this investigation. Microwave muffle reactor (Model: HAMiab-C1500) with a microwave power controller including a microwave generator was used to perform the microwave pyrolysis. OPF particles were used after removing foreign materials, impurities, and dust. Microwave power ranges from 400 to 900 W, temperature ranges from 450 to 700 °C, and N2 flow rates ranges from 200 to -1200 cm3/min were used along with all three Na-based catalysts for this investigation. Lower microwave power, temperature, and N2 flow rate have been found favorable for higher yield of biochar. NaOH is to be found as the more suitable catalyst than NaCl and Na2CO3 to produce biochar. A maximum biochar yield (51.42 wt%) has been found by using the catalysts NaOH at N2 flow rate of 200 cm3/min. One sample of the biochar (maximum yield without catalysts) was selected for further characterization via thermo gravimetric analysis (TGA), scanning electron microscopy (SEM), BET surface area, Fourier transform infrared spectroscopy (FTIR), and ultimate and proximate analysis. SEM and BET surface area analysis showed the presence of some pores in the biochar. High percentage of carbon (60.24 wt%) was also recorded in the sample biochar. The pores and high percentage of carbon of biochar have significant impact on soil fertilization by increasing the carbon sequestration in the soil. It assists to slow down the decomposition rate of nutrients from soil and therefore enhances the soil quality.

Similar content being viewed by others

References

Abnisa F, Daud WMAW, Husin WNW, Sahu JN (2011) Utilization possibilities of palm shell as a source of biomass energy in Malaysia by producing bio-oil in pyrolysis process. Biomass Bioenergy 35:1863–1872

Abnisa F, Arami-Niya A, Daud WW, Sahu J (2013) Characterization of bio-oil and bio-char from pyrolysis of palm oil wastes. Bio Energy Res 6:830–840

Arregi A, Lopez G, Amutio M, Barbarias I, Bilbao J, Olazar M (2016) Hydrogen production from biomass by continuous fast pyrolysis and in-line steam reforming. RSC Adv 6:25975–25985

Ateş F, Pütün E, Pütün AE (2004) Fast pyrolysis of sesame stalk: yields and structural analysis of bio-oil. J Anal Appl Pyrolysis 71:779–790

Aunkor M, Mahbubul I, Saidur R, Metselaar HSC (2015) Deoxygenation of graphene oxide using household baking soda as a reducing agent: a green approach. RSC Adv 5:70461–70472

Bouraoui Z, Dupont C, Jeguirim M, Limousy L, Gadiou R (2016) CO2 gasification of woody biomass chars: the influence of K and Si on char reactivity. C R Chimie 19:457–465

Brewer CE, Schmidt-Rohr K, Satrio JA, Brown RC (2009) Characterization of biochar from fast pyrolysis and gasification systems. Environ Prog Sustain Energy 28:386–396

Carrier M, Hardie AG, Uras Ü, Görgens J, Knoetze JH (2012) Production of char from vacuum pyrolysis of South-African sugar cane bagasse and its characterization as activated carbon and biochar. J Anal Appl Pyrolysis 96:24–32

Cetin E, Gupta R, Moghtaderi B (2005) Effect of pyrolysis pressure and heating rate on radiata pine char structure and apparent gasification reactivity. Fuel 84:1328–1334

Chen G, Andries J, Spliethoff H (2003) Catalytic pyrolysis of biomass for hydrogen rich fuel gas production. Energy Convers Manag 44:2289–2296

Chen WY, Mattern DL, Okinedo E, Senter JC, Mattei AA, Redwine CW (2014) Photochemical and acoustic interactions of biochar with CO2 and H2O: applications in power generation and CO2 capture. AICHE J 60:1054–1065

Demiral I, Kul ŞÇ (2014) Pyrolysis of apricot kernel shell in a fixed-bed reactor: characterization of bio-oil and char. J Anal Appl Pyrolysis 107:17–24

Edreis EM, Yao H (2016) Kinetic thermal behaviour and evaluation of physical structure of sugar cane bagasse char during non-isothermal steam gasification. J Mater Res Technol 5:317–326

El Naggar AMA, Gobara HM, El Sayed HA, Soliman FS (2015) New advances in hydrogen production via the catalytic decomposition of wax by-products using nanoparticles of SBA frame-worked MoO3. Energy Convers Manag 106:615–624

Encinar JM, Beltrán FJ, Ramiro A, González JF (1997) Catalyzed pyrolysis of grape and olive bagasse. Influence of catalyst type and chemical treatment. Ind Eng Chem Res 36:4176–4183

Guo L, Cao C, Lu Y (2010) Supercritical water gasification of biomass and organic wastes. Biomass 165

Gusiatin ZM, Kurkowski R, Brym S, Wiśniewski D (2016) Properties of biochars from conventional and alternative feedstocks and their suitability for metal immobilization in industrial soil. Environ Sci Pollut Res 23:21249–21261

Hossain MA, Jewaratnam J, Ganesan P, Sahu JN, Ramesh S, Poh SC (2016) Microwave pyrolysis of oil palm fiber (OPF) for hydrogen production: parametric investigation. Energy Convers Manag 115:232–243

Hosseini SE, Wahid MA, Ganjehkaviri A (2015) An overview of renewable hydrogen production from thermochemical process of oil palm solid waste in Malaysia. Energy Convers Manag 94:415–429

Huang YF, Kuan WH, Lo SL, Lin CF (2008) Total recovery of resources and energy from rice straw using microwave-induced pyrolysis. Bioresour Technol 99:8252–8258

Idris SS, Rahman NA, Ismail K, Alias AB, Rashid ZA, Aris MJ (2010) Investigation on thermochemical behaviour of low rank Malaysian coal, oil palm biomass and their blends during pyrolysis via thermogravimetric analysis (TGA). Bioresour Technol 101:4584–4592

Ji S, Wang Q, Xia B (2002) Handbook of seismic properties of minerals, rocks and ores. Polytechnique International Press. Mineralogy, p 630

Jindo K, Mizumoto H, Sawada Y, Sanchez-Monedero MA, Sonoki T (2014) Physical and chemical characterization of biochars derived from different agricultural residues. Biogeosciences 11:6613–6621

Kalderis D, Kotti M, Méndez A, Gascó G (2014) Characterization of hydrochars produced by hydrothermal carbonization of rice husk. Solid Earth 5:477–483

Konsolakis M, Kaklidis N, Marnellos GE, Zaharaki D, Komnitsas K (2015) Assessment of biochar as feedstock in a direct carbon solid oxide fuel cell. RSC Adv 5:73399–73409

Lehmann J, Kuzyakov Y, Pan G, Ok YS (2015) Biochars and the plant-soil interface. Springer 395:1–5

Li J, Yin Y, Zhang X, Liu J, Yan R (2009) Hydrogen-rich gas production by steam gasification of palm oil wastes over supported tri-metallic catalyst. Int J Hydrog Energy 34:9108–9115

Mamaeva A, Tahmasebi A, Tian L, Yu J (2016) Microwave-assisted catalytic pyrolysis of lignocellulosic biomass for production of phenolic-rich bio-oil. Bioresour Technol 211:382–389

Mardoyan A, Braun P (2015) Analysis of Czech subsidies for solid biofuels. Int J Green Energy 12:405–408

Maroušek J (2014) Significant breakthrough in biochar cost reduction. Clean Techn Environ Policy 16:1821–1825

Maroušek J, Hašková S, Zeman R, Váchal J, Vaníčková R (2015) Processing of residues from biogas plants for energy purposes. Clean Techn Environ Policy 17:797–801

Maroušková A, Braun P (2014) Holistic approach to improve the energy utilization of Jatropha curcas L. Rev Téc Ing Univ Zulia 37:1–7

Mašek O, Budarin V, Gronnow M, Crombie K, Brownsort P, Fitzpatrick E, Hurst P (2013) Microwave and slow pyrolysis biochar—comparison of physical and functional properties. J Anal Appl Pyrolysis 100:41–48

McHenry MP (2009) Agricultural bio-char production, renewable energy generation and farm carbon sequestration in Western Australia: certainty, uncertainty and risk. Agric Ecosyst Environ 129:1–7

Menéndez JA, Domngíuez A, Inguanzo M, Pis JJ (2004) Microwave pyrolysis of sewage sludge: analysis of the gas fraction. J Anal Appl Pyrolysis 71:657–667

Mohammed MAA, Salmiaton A, Wan Azlina WAKG, Mohammad Amran MS, Fakhru’l-Razi A, Taufiq-Yap YH (2011) Hydrogen rich gas from oil palm biomass as a potential source of renewable energy in Malaysia. Renew Sust Energ Rev 15:1258–1270

Mollinedo J, Schumacher TE, Chintala R (2016) Biochar effects on phenotypic characteristics of “wild” and “sickle” Medicago truncatula genotypes. Plant Soil 400:1–14

Mushtaq F, Mat R, Ani FN (2016) Fuel production from microwave assisted pyrolysis of coal with carbon surfaces. Energy Convers Manag 110:142–153

Nasir Uddin M, Daud WMAW, Abbas HF (2013) Potential hydrogen and non-condensable gases production from biomass pyrolysis: insights into the process variables. Renew Sust Energ Rev 27:204–224

Nizamuddin S, Mubarak N, Tiripathi M, Jayakumar N, Sahu J, Ganesan P (2016) Chemical, dielectric and structural characterization of optimized hydrochar produced from hydrothermal carbonization of palm shell. Fuel 163:88–97

Peng L, Ren Y, Gu J, Qin P, Zeng Q, Shao J, Lei M, Chai L (2014) Iron improving bio-char derived from microalgae on removal of tetracycline from aqueous system. Environ Sci Pollut Res 21:7631–7640

Rahman AA, Abdullah N, Sulaiman F (2014) Temperature effect on the characterization of pyrolysis products from oil palm fronds. Advances in Energy Engineering 2:14–21

Saldarriaga JF, Aguado R, Pablos A, Amutio M, Olazar M, Bilbao J (2015) Fast characterization of biomass fuels by thermogravimetric analysis (TGA). Fuel 140:744–751

Şensöz S, Demiral İ, Gerçel HF (2006) Olive bagasse (Olea europea L.) pyrolysis. Bioresour Technol 97:429–436

Shinoj S, Visvanathan R, Panigrahi S, Kochubabu M (2011) Oil palm fiber (OPF) and its composites: a review. Ind Crop Prod 33:7–22

Smets K, Roukaerts A, Czech J, Reggers G, Schreurs S, Carleer R, Yperman J (2013) Slow catalytic pyrolysis of rapeseed cake: product yield and characterization of the pyrolysis liquid. Biomass Bioenergy 57:180–190

Suriapparao DV, Vinu R (2015) Bio-oil production via catalytic microwave pyrolysis of model municipal solid waste component mixtures. RSC Adv 5:57619–57631

Tian Y, Zuo W, Ren Z, Chen D (2011) Estimation of a novel method to produce bio-oil from sewage sludge by microwave pyrolysis with the consideration of efficiency and safety. Bioresour Technol 102:2053–2061

Tripathi M, Sahu JN, Ganesan P, Dey TK (2015) Effect of temperature on dielectric properties and penetration depth of oil palm shell (OPS) and OPS char synthesized by microwave pyrolysis of OPS. Fuel 153:257–266

Tripathi M, Sahu J, Ganesan P, Jewaratnam J (2016a) Thermophysical characterization of oil palm shell (OPS) and OPS char synthesized by the microwave pyrolysis of OPS. Appl Therm Eng 105:605-612

Tripathi M, Sahu JN, Ganesan P (2016b) Effect of process parameters on production of biochar from biomass waste through pyrolysis: a review. Renew Sust Energ Rev 55:467–481

Tushar MSHK, Mahinpey N, Khan A, Ibrahim H, Kumar P, Idem R (2012) Production, characterization and reactivity studies of chars produced by the isothermal pyrolysis of flax straw. Biomass and Bioenergy 37:97–105

Wang J, Zhang M, Chen M, Min F, Zhang S, Ren Z, Yan Y (2006) Catalytic effects of six inorganic compounds on pyrolysis of three kinds of biomass. Thermochim Acta 444:110–114

Wang X-H, Chen H-P, Ding X-J, Yang H-P, Zhang S-H, Shen Y-Q (2009) Properties of gas and char from microwave pyrolysis of pine sawdust. Bioresources 4:946–959

Wang N, Tahmasebi A, Yu J, Xu J, Huang F, Mamaeva A (2015) A comparative study of microwave-induced pyrolysis of lignocellulosic and algal biomass. Bioresour Technol 190:89–96

Wilson L, Yang W, Blasiak W, John GR, Mhilu CF (2011) Thermal characterization of tropical biomass feedstocks. Energy Convers Manag 52:191–198

Wu C, Budarin VL, Gronnow MJ, De Bruyn M, Onwudili JA, Clark JH, Williams PT (2014) Conventional and microwave-assisted pyrolysis of biomass under different heating rates. J Anal Appl Pyrolysis 107:276–283

Yang H, Yan R, Chen H, Lee DH, Liang DT, Zheng C (2006) Pyrolysis of palm oil wastes for enhanced production of hydrogen rich gases. Fuel Process Technol 87:935–942

Yargicoglu EN, Reddy KR (2015) Characterization and surface analysis of commercially available biochars for geoenvironmental applications, IFCEE 2015. Am Soc Civil Eng 2637–2646

Yorgun S, Şensöz S, Koçkar ÖM (2001) Characterization of the pyrolysis oil produced in the slow pyrolysis of sunflower-extracted bagasse. Biomass Bioenergy 20:141–148

Zanzi R, Sjöström K, Björnbom E (2002) Rapid pyrolysis of agricultural residues at high temperature. Biomass Bioenergy 23:357–366

Zhang H, Xiao R, Huang H, Xiao G (2009) Comparison of non-catalytic and catalytic fast pyrolysis of corncob in a fluidized bed reactor. Bioresour Technol 100:1428–1434

Zhao X, Wang M, Liu H, Zhao C, Ma C, Song Z (2013) Effect of temperature and additives on the yields of products and microwave pyrolysis behaviors of wheat straw. J Anal Appl Pyrolysis 100:49–55

Zhong M, Gao S, Zhou Q, Yue J, Ma F, Xu G (2015) Characterization of char from high temperature fluidized bed coal pyrolysis in complex atmospheres. Particuology 25:59–67

Funding information

This research is financially supported by the University Malaya High Impact Research Chancellery grant (UM.C/625/1/HIR/237) and the Fundamental Research Grant Scheme (FRGS-FP052-2015A).

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Suresh Pillai

Rights and permissions

About this article

Cite this article

Hossain, M.A., Ganesan, P.B., Sandaran, S.C. et al. Catalytic microwave pyrolysis of oil palm fiber (OPF) for the biochar production. Environ Sci Pollut Res 24, 26521–26533 (2017). https://doi.org/10.1007/s11356-017-0241-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-017-0241-6