Abstract

Objective

Validate and assess the limitations of the Shear Compression 0 Specimen (SCS0) as a simple shear specimen for quasi-static and dynamic large strain loading conditions. Propose a simple data reduction procedure, using a simple, back of the envelope method, as a first approximation for the strain, as opposed to cumbersome numerical simulations and avoid the use of ad-hoc data reduction factors.

Methods

Static and dynamic finite elements simulations were performed in which the large deformation options was turned on and off. Assessment of the Lode parameter in each case and evaluation of the accuracy of the specimen’s strains and stresses as determined through simple data reduction and full numerical simulations.

Results

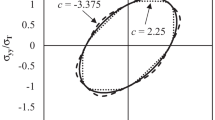

The SCS0 was shown to undergo simple shear, both statically and dynamically, as evidenced from the very low values of the Lode parameter. The calculated stress is in excellent agreement with the measured one, determined using simple strength of materials definitions. When assuming the corresponding kinematics, it is observed that the calculated and the measured strain diverge to an extent of about 25%. This discrepancy is shown to result from the assumption of large geometrical deformations in the numerical model as opposed to the simple analytical kinematics.

Conclusion

The conclusion is that the SCS0 is now fully validated, and the experimentalist will decide which strain approximation is suitable, between analytical and numerical.

Similar content being viewed by others

Data Availability

All relevant data is within the manuscript and its appendices, any additional material will be provided upon reasonable request.

References

Miyauchi K (1984) Proposal of a Planar Simple Shear Test in Sheet Metals. Sci Pap Inst Phys Chem Res 78:27–40

An YG, Vegter H, Heijne J (2009) Development of simple shear test for the measurement of work hardening. J Mater Process Technol 209:4248–4254. https://doi.org/10.1016/j.jmatprotec.2008.11.007

Klopp RW, Clifton RJ, Shawki TG (1985) Pressure-shear impact and the dynamic viscoplastic response of metals. Mech Mater 4:375–385. https://doi.org/10.1016/0167-6636(85)90033-X

Meyer LW, Manwaring S (1986) Critical Adiabatic Shear Strength of Low Alloyed Steel Under Compressive Loading pp 657–674

Meyer LW, Staskewitsch E, Burblies A (1994) Adiabatic shear failure under biaxial dynamic compression/ shear loading. Mech Mater 17:203–214. https://doi.org/10.1016/0167-6636(94)90060-4

Mcnelley TR (2003) Microstructural evolution in adiabatic shear localization in stainless steel. 51:1307–1325. https://doi.org/10.1016/S1359-6454(02)00526-8

Peirs J, Tirry W, Amin-Ahmadi B et al (2013) Microstructure of adiabatic shear bands in Ti6Al4V. Mater Charact 75:79–92. https://doi.org/10.1016/J.MATCHAR.2012.10.009

Bronkhorst CA, Hansen BL, Cerreta EK, Bingert JF (2007) Modeling the microstructural evolution of metallic polycrystalline materials under localization conditions. J Mech Phys Solids 55:2351–2383. https://doi.org/10.1016/J.JMPS.2007.03.019

Bronkhorst CA, Cerreta EK, Xue Q et al (2006) An experimental and numerical study of the localization behavior of tantalum and stainless steel. Int J Plast 22:1304–1335. https://doi.org/10.1016/j.ijplas.2005.10.002

Mourad HM, Bronkhorst CA, Livescu V et al (2017) Modeling and simulation framework for dynamic strain localization in elasto-viscoplastic metallic materials subject to large deformations. Int J Plast 88:1–26. https://doi.org/10.1016/J.IJPLAS.2016.09.009

Budiwantoro B, Kariem MA, Febrinawarta B (2021) The Influence of Shear Angles on the Split Hopkinson Shear Bar Testing. Int J Impact Eng 149:103787. https://doi.org/10.1016/j.ijimpeng.2020.103787

Peirs J, Verleysen P, Degrieck J, Coghe F (2010) The use of hat-shaped specimens to study the high strain rate shear behaviour of Ti-6Al-4V. Int J Impact Eng 37:703–714. https://doi.org/10.1016/j.ijimpeng.2009.08.002

Mohr D, Henn S (2007) Calibration of stress-triaxiality dependent crack formation criteria: A new hybrid experimental-numerical method. Exp Mech 47:805–820. https://doi.org/10.1007/s11340-007-9039-7

Dunand M, Mohr D (2011) Optimized butterfly specimen for the fracture testing of sheet materials under combined normal and shear loading. Eng Fract Mech 78:2919–2934. https://doi.org/10.1016/J.ENGFRACMECH.2011.08.008

Peirs J, Verleysen P, Van Paepegem W, Degrieck J (2011) Determining the stress-strain behaviour at large strains from high strain rate tensile and shear experiments. Int J Impact Eng 38:406–415. https://doi.org/10.1016/j.ijimpeng.2011.01.004

Peirs J, Verleysen P, Degrieck J (2012) Novel Technique for Static and Dynamic Shear Testing of Ti6Al4V Sheet. Exp Mech 52:729–741. https://doi.org/10.1007/s11340-011-9541-9

Peirs J, Verleysen P, Van Paepegem W, Degrieck J (2009) Novel pure-shear sheet specimen geometry for dynamic material characterisation pp 35–41. https://doi.org/10.1051/dymat/2009005

Roth CC, Mohr D (2018) Determining the strain to fracture for simple shear for a wide range of sheet metals. Int J Mech Sci 149:224–240. https://doi.org/10.1016/j.ijmecsci.2018.10.007

Dorogoy A, Rittel D (2005) Numerical validation of the shear compression specimen. Part I: Quasi-static large strain testing. Exp Mech 45:167–177. https://doi.org/10.1177/0014485105052325

Dorogoy A, Rittel D (2005) Numerical validation of the shear compression specimen. Part II: Dynamic large strain testing. Exp Mech 45:178–185. https://doi.org/10.1177/0014485105052324

Dorogoy A, Rittel D, Godinger A (2015) Modification of the Shear-Compression Specimen for Large Strain Testing. Exp Mech 55:1627–1639. https://doi.org/10.1007/S11340-015-0057-6/FIGURES/26

Dorogoy A, Rittel D, Godinger A (2016) A Shear-Tension Specimen for Large Strain Testing. Exp Mech 56:437–449. https://doi.org/10.1007/s11340-015-0106-1

Dorogoy A, Rittel D (2017) Dynamic large strain characterization of tantalum using shear-compression and shear-tension testing. Mech Mater 112:143–153. https://doi.org/10.1016/j.mechmat.2017.06.003

Rittel D, Ravichandran G, Lee S (2002) Large strain constitutive behavior of OFHC copper over a wide range of strain rates using the shear compression specimen. Mech Mater 34:627–642. https://doi.org/10.1016/S0167-6636(02)00164-3

Rittel D, Lee S, Ravichandran G (2002) A shear-compression specimen for large strain testing 42:58–64

Daly S, Rittel D, Bhattacharya K, Ravichandran G (2009) Large deformation of nitinol under shear dominant loading. Exp Mech 49:225–233. https://doi.org/10.1007/s11340-008-9178-5

Zhu S, Guo Y, Chen H, et al (2019) Formation of adiabatic shear band within Ti-6Al-4V: Effects of stress state. Mech Mater 137. https://doi.org/10.1016/j.mechmat.2019.103102

Zhou T, Wu J, Che J et al (2017) Dynamic shear characteristics of titanium alloy Ti-6Al-4V at large strain rates by the split Hopkinson pressure bar test. Int J Impact Eng 109:167–177. https://doi.org/10.1016/j.ijimpeng.2017.06.007

Nizolek TJ, Mourad HM, Liu C et al (2021) Compact forced simple shear specimen: Design improvement based on quasi-static experiments and finite element simulations. Int J Solids Struct 233:111195. https://doi.org/10.1016/j.ijsolstr.2021.111195

Dolinski M, Rittel D, Dorogoy A (2010) Modeling Adiabatic Shear Failure from Energy Considerations. J Mech Phys Solids 58:1759–1775. https://doi.org/10.1016/J.JMPS.2010.08.007

Dorogoy A, Rittel D (2006) A numerical study of the applicability of the shear compression specimen to parabolic hardening materials. Exp Mech 46:355–366. https://doi.org/10.1007/s11340-006-6414-8

Vural M, Molinari A, Bhattacharyya N (2011) Analysis of Slot Orientation in Shear-Compression Specimen (SCS). Exp Mech 51:263–273. https://doi.org/10.1007/s11340-010-9363-1

Klepaczko JR (1994) An experimental technique for shear testing at high and very high strain rates. The case of a mild steel. Int J Impact Eng 15:25–39. https://doi.org/10.1016/S0734-743X(05)80005-3

Jia B, Rusinek A, Pesci R, et al (2021) Simple shear behavior and constitutive modeling of 304 stainless steel over a wide range of strain rates and temperatures. Int J Impact Eng 154:103896. https://doi.org/10.1016/j.ijimpeng.2021.103896

Guo Y, Li Y (2012) A novel approach to testing the dynamic shear response of Ti-6Al-4V. Acta Mech Solida Sin 25:299–311. https://doi.org/10.1016/S0894-9166(12)60027-5

Bonnet-Lebouvier, A. S., & Klepaczko, J. R. (2002). Numerical study of shear deformation in Ti–6Al–4V at medium and high strain rates, critical impact velocity in shear. International Journal of Impact Engineering, 27(7), 755–769. https://doi.org/10.1016/S0734-743X(02)00010-6

Ruiz DJ, Harding J, Ruiz C (1991) High strain rate testing of materials - a fully validated test calibration by a hybrid numerical/experimental technique. 1 Journal de Physique IV Proceedings, 1991, 01 (C3), pp.C3-465-C3-470. https://doi.org/10.1051/jp4:1991366. https://doi.org/10.1051/jpa-00250510

Rusinek A, Klepaczko JR (2001) Shear testing of a sheet steel at wide range of strain rates and a constitutive relation with strain-rate and temperature dependence of the flow stress. Int J Plast 17:87–115. https://doi.org/10.1016/S0749-6419(00)00020-6

Campbell JD, Ferguson WG (1970) The temperature and strain-rate dependence of the shear strength of mild steel. J Theor Exp Appl Phys 21:63–82. https://doi.org/10.1080/14786437008238397

Dorogoy A, Rittel D (2017) Quasi-Static and Dynamic Large Strain Shear-Tension Testing. Exp Mech 57:1509–1514. https://doi.org/10.1007/s11340-017-0315-x

Jia B, Rusinek A, Pesci R et al (2020) A novel technique for dynamic shear testing of bulk metals with application to 304 austenitic stainless steel. Int J Solids Struct 204–205:153–171. https://doi.org/10.1016/j.ijsolstr.2020.08.019

Lode W (1926) Versuche über den Einfluß der mittleren Hauptspannung auf das Fließen der Metalle Eisen, Kupfer und Nickel. Zeitschrift für Phys 36:913–939. https://doi.org/10.1007/BF01400222

Peng J, Zhou P, Wang Y et al (2021) Stress Triaxiality and Lode Angle Parameter Characterization of Flat Metal Specimen with Inclined Notch. https://doi.org/10.3390/met11101627

Danas K, Ponte Castañeda P (2012) Influence of the Lode parameter and the stress triaxiality on the failure of elasto-plastic porous materials. Int J Solids Struct 49:1325–1342. https://doi.org/10.1016/J.IJSOLSTR.2012.02.006

Bai Y, Wierzbicki T (2008) A new model of metal plasticity and fracture with pressure and Lode dependence. Int J Plast 24:1071–1096. https://doi.org/10.1016/J.IJPLAS.2007.09.004

Dunand M, Mohr D (2014) Effect of Lode parameter on plastic flow localization after proportional loading at low stress triaxialities. J Mech Phys Solids 66:133–153. https://doi.org/10.1016/J.JMPS.2014.01.008

Gershanik T, Levin I, Rittel D (2022) 2BarG—A program to process split Hopkinson (Kolsky) bar test results. SoftwareX 18:1–6. https://doi.org/10.1016/j.softx.2022.101093

User CAE (2014) Abaqus theory manual. Abaqus 613 Doc

Funding

The financial support of Israel Science Foundation (Grant 325/19) is greatly appreciated. The technical assistance of G. Goviazin (M.Sc.), Prof. S. Osovski and the staff from the Materials Mechanics Center, Ziv Keren and Andrey Garkun (both M.Sc.) and Mr. Yoseph Barazani is acknowledged.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of Interest

The authors declare no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

I. Levin and D. Rittel are members of SEM.

Appendix

Appendix

Appendix A Specimen Drawing

Appendix Figure A - Specimen drawing

Appendix Table A - Modified gauge length

Material | CP-Ti | Ti-6-Al-4-V | CP-Zr |

|---|---|---|---|

Gauge length \(\left[mm\right]\) | 7 | 10 | 7.6 |

Appendix B Analytical Considerations

The calculations that were carried for the strains in equation (6):

The invariant identities for \({I}_{1},{I}_{2},{I}_{3}\) that were used are:

The invariant identities for \({J}_{1},{J}_{2},{J}_{3}\) that were used are:

Appendix C Material Properties

Appendix Table C - Elastic properties

CP Ti | Ti6Al4V | CP Zr | Maraging Steel C300 | |

|---|---|---|---|---|

Density \([\frac{kg}{{m}^{3}}]\) | 4.51 \(\cdot \;{10}^{3}\) | 4.43 \(\cdot \;{10}^{3}\) | 6.53 \(\cdot\; {10}^{3}\) | 8 \(\cdot\; {10}^{3}\) |

Quasi-static yield stress \([MPa]\) | 230 | 890 | 420 | - |

Dynamic yield stress \([MPa]\) | 280 | 1170 | 490 | - |

Young’s Modulus \([MPa]\) | 105,000 | 114,000 | 94,500 | 190,000 |

Poisson’s Ratio | 0.37 | 0.33 | 0.34 | 0.3 |

For the plastic properties of our three materials, an overall bi-linear law was used, such that the plastic part is a linear extrapolation of our experimental data (both quasi-static and dynamic loading cases).

Appendix Figure B - Mechanical properties of all three materials in both quasi-static and dynamic loading. Top figure is for the quasi-static case and the bottom figure is for the dynamic case.

Appendix D Recorded Results of Dynamically Experimented SCS0

Appendix Figure D - Dynamically Fractured SCS0. (a) Ti6Al4V specimen; (b) CP Zr specimen

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Levin, I., Rittel, D. Making Shear Simple – Validation of the Shear Compression Specimen 0 (SCS0) for Shear Testing. Exp Mech 63, 1461–1477 (2023). https://doi.org/10.1007/s11340-023-00996-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-023-00996-1