Abstract

The shear strength properties of rock materials, cohesion and internal friction angle, are determined by carrying out tri-axial strength test on cylindrical core specimens in laboratory. But determination of these parameters by triaxial tests in accordance with standards and suggested methods, particularly for weak, fractured and weathered rocks is exteremely difficult and/or impossible due to difficulties related to preparation of test specimens suitable for this test. In addition, the tri-axial test requires high cost equipment and too much time for sample preparation and testing. In such cases, there is a need to precisely estimate the friction angle and estimation of rock shear strength properties using some indirect methods, as they are economical and easy to carry out. In this study, the traditional method, which is recommended to be used for the prediction of internal friction angle (ϕ) when triaxial test data is not available, was briefly assessed with its some limitations and an alternative method using theoretical tensile strength and uniaxial compressive strength to predict ϕ was proposed. Then the prediction performances of traditional and proposed methods were compared using a very large data set collected from published literature. The statistical reliability of the derived equations was assessed using F- and t-tests and according to the test results the prediction equations were found to be statistically reliable. The results indicated that the method proposed in this study using the theoretical tensile strength yields best predictions of ϕ when compared to those estimated from the traditional methods based on direct and Brazilian tensile strength values.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

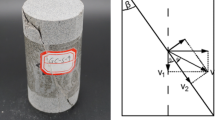

The internal friction angle is one of the two main shear strength parameters of rock materials, determines the rate of increase in shear strength depending on normal stress and is used in many rock engineering applications. Shear strength of rock materials is often determined by Mohr-Coulomb (MC) failure criterion. The shear strength properties of rock materials, cohesion and internal friction angle, are determined by carrying out tri-axial strength test on cylindrical core specimens in laboratory and the test results are represented by Mohr Circles. The friction angles of rock specimens tested are obtained from the slopes of the Mohr–Coulomb envelopes drawn as a tangent to the Mohr circles.

The theory of graphical representation of stresses in the form of Mohr circles is available in most standard textbooks on rock mechanics (i.e. Jaeger and Cook 1979) and the testing method for tri-axial test is given in standards (i.e. ASTM 2023) and suggested methods (ISRM 1981, 2007).

However, it is not always possible to determine this parameter by triaxial tests in accordance with standards and suggested methods, particularly for weak, fractured and weathered rocks from which preparation of cylindrical core specimens suitable for tri-axial test is exteremely difficult and/or impossible. In addition, the tri-axial test requires high cost equipment and too much time for sample preparation and testing.

In such cases, there is a need to precisely estimate the friction angle and estimation of rock shear strength properties using some indirect methods, as they are economical and easy to carry out. For this purpose, there are two approaches. The first approach is the traditional method using Mohr circles, while the second approach is to obtain the internal friction angle from different parameters of rock materials such as strength, deformability or index properties.

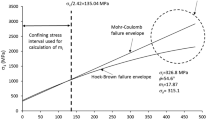

In the first approach, the shear strength properties (cindr and ϕindr) of rock materials are indirectly determined with the help of tangents drawn to the Mohr circles of the strength properties by considering the stress states effective at failure (σ1 = σc and σ3 = 0 for uniaxial compressive strength -UCS- test, σ1 = 0 and σ3 = − σt for direct tensile test and σ1 = 3σt and σ3 = − σt for Brazilian tensile test) for tensile and uniaxial compression tests as illustrated in Figs. 1a and b, respectively.

The magnitude of compressive stress is three times of the tensile stress at failure in Brazilian tensile test (Goodman 1989; Piratheepan et al. 2012; Serati et al. 2014). However, Serati et al. (2014) also stated that this ratio is valid for centre of the disc and stress tensor becomes almost negligible at relatively large distance from the load contact area. Therefore, the value of tensile strength determined from the Brazilian test is generally higher than the actual value (Li and Wong 2013). On the other hand, direct tensile test is not widely used due to difficulty of preparing test specimens and pure one-dimensional direct tensile loading (Gong et al. 2019).

The formulation of traditional method summarized above was derived by Piratheepan et al. (2012) and Sivakugan et al. (2014). Piratheepan et al. (2012) used BTS and UCS to determine the cohesion and internal friction angle, which are traditionally used and obtained by drawing tangents to Mohr circles. These researchers have formulated the theoretical equations (Eqs. 1 and 2), which allow the calculation of shear strength parameters of rock material using UCS and BTS test data, taking into account the stress state effective at the time of failure for the Brazilian tensile (Indirect Diametrical Tensile-IDT) and uniaxial compression tests. The values of cohesion and internal friction angle obtained from these equations are the same as the values found from the traditional method, in which shear strength properties (c and ϕ) are determined by drawing tangents to Mohr circles. However, the proposed theoretical equations provide a more practical determination of the shear strength properties and the limitations of the traditional method are also valid for these equations, where σc is the UCS, σIDT is the tensile strength obained from IDT test.

Sivakugan et al. (2014), conducted a theoretical study similar to that of Piratheepan et al. (2012) and derived Eqs. 3 and 4 for theoretical shear strength properties by considering the loading conditions applied in UCS (σc) and BTS (σt) tests.

Sivakugan et al. (2014) compared the c and ϕ values determined from Eqs. 3 and 4 with the results of laboratory experiments using 35 rock specimens. These researchers stated that the cohesion values determined from these equations are more realistic than the internal friction angle values determined from the laboratory tests. Sivakugan et al. (2014) also obtained a few negative and very low internal friction angles using the traditional method. This situation revealed an important limitation of the traditional approach.

In the second approach, the shear strength properties are predicted by other parameters (such as UCS, point load strength index (Is50), Poisson’s ratio etc.). In several studies (Turk and Dearman 1986; Esterhuizen et al. 2013; Armaghani et al. 2014), which were carried out to date, the issue of estimation of shear strength properties has been considered. Armaghani et al. (2014) carried out a research on predicting the shear strength properties of shales using some index properties, artificial neural networks and multivariate regression analyses. The index properties used by these researchers for predicting the shear strength properties (c, ϕ) were dry density (ρd), point load strength index (Is(50)), Schmidt rebound value (SHn), Brazilian tensile strength (σt(Brazilian)) and P-wave velocity (Vp). The multivariate prediction equations derived by Armaghani et al. (2014) are given in Eqs. 5 and 6. Although these researchers obtained a high coefficient of determination in their study, the results are valid only for the shale rock unit used in their investigation. The necessity of determining a large number of index features to estimate the friction angle is another limitation of this study.

Turk and Dearman (1986) stated that internal frictional angle of rock materials can be predicted from strain properties measured under uniaxial loading and recommended the following relationship between internal friction angle and Poisson’s ratio (ν). However, in order to use this relationship, strain measurements should be carried out.

Esterhuizen et al. (2013) proposed the empirical equations given in Table 1 for predicting the internal friction angle using UCS depending on rock types and ranges of UCS.

Without any order implied by the principal stresses, the Mohr–Coulomb criterion can be expressed as given in Eq. 8 (Labuz and Zang 2012).

where, \(a=\frac{m-1}{m+1}, \,m=\frac{{C}_{o}}{{T}_{o}}=\frac{1+sin\phi }{1-sin\phi }\), \(b=\frac{1}{m+1}\), \({C}_{o}=\frac{m}{m+1}\), \({T}_{o}=\frac{{C}_{o}}{2} (1-sin\phi )\) ve 0 ≤ a < 1.

To is the theoretical Mohr–Coulomb uniaxial tensile strength, and experimentally, a much lower tensile strength value is generally obtained when the failure plane is perpendicular to the direction of σ3 (σ1 = 0, σ3 = − T). Co is the theoretical MC UCS that is generally close to the experimental value, therefore, another symbol is not used (Labuz and Zang 2012).

The actual internal friction of rock materials can be determined by drawing the MC failure envelope obtained under compressive confining stresses (σ3 > 0). However, if there is no data for confining stress of σ3 > 0, the failure envelope can be drawn by the indirect method, which consider the Mohr circles of UCS and tensile strength. As given in Fig. 2, the failure envelope is tangent to the Mohr circle of the theoretical tensile strength test according to MC criterion. Therefore, in order to calculate the actual internal friction angle, the theoretical tensile strength (To) should be determined as well as the UCS. However, for this purpose, Mohr circles of direct or Brazilian tensile strength tests are generally used.

Mohr envelope obtained by using Mohr circles of theoretical uniaxial tensile and uniaxial compression strength test data (redrawn from Labuz and Zang 2012)

BTS is approximately 1.24 times greater than the direct tensile strength (AlAwad 2022), therefore, there is an order between these parameters as ϕ (σt (direct)) > ϕ (σt (Brazilian) > ϕ (To) = ϕ (actual) (Fig. 3). In other words, since the experimentally determined values of tensile strength are lower than the theoretical value, the indirectly obtained internal friction angle values are generally determined to be greater than the actual internal friction angle value of the rock material. The level of this difference is controlled by both Co/To and To/σt (exp). For this reason, in order to estimate the internal friction angle with a high precision, it is necessary to determine the theoretical tensile strength rather than directly using the experimental tensile strength. If the theoretical tensile strength can be predicted with a high precision, it will also be possible to estimate the internal friction angle with a high precision. By considering this, this study aims to estimate the theoretical tensile strength and internal friction angle using a great number of data of different rock types available in literature.

In this study, first the proposed method was described and a database was compiled from previous studies. The database consists of internal friction angle (or major and minor principal stress data from triaxial tests), tensile strength (obtained from direct or Brazilian tensile tests) and UCS of rock materials. In order to predict the theoretical tensile strength (To), cohesion and internal friction angle values (cindr and ϕindr) determined from the traditional method and UCS were used. In order to check the statistical reliability of the relationships found from the proposed method for predicting the theoretical tensile strength, statistical analyses (F- and t-tests) were carried out. Then, the values of internal friction angle were calculated using method proposed in this study and they were compared with experimental ϕ values in the database used. Finally, the main conclusions drawn from this study and the recommendations for further studies were given.

Proposed method

In order to calculate the actual internal friction angle using the traditional method, as shown in Fig. 2, the theoretical tensile strength (To) should be determined as well as the C0. According to the MC failure criterion, the theoretical tensile strength value is defined as given in Eq. 9 (Labuz and Zang 2012).

where, Co is the UCS (considering that it is equal to the experimental value, C0≈σc), ϕ is the internal friction angle, and To is the theoretical uniaxial tensile strength value.

As can be seen from Eq. 10, which is obtained by rearranging Eq. 9, the internal friction angle can be determined if the values of UCS (Co) and theoretical tensile strength (To) are known.

Alternatively, if the theoretical tensile strength is determined, the internal friction angle can be determined from the Mohr circles to be drawn (see Fig. 2). Therefore, accurate estimation of To is very important.

In this study, statistical analyses were carried out regarding the estimation of To using 153 UCS and tensile strength data pairs of different rock types which are given in the following section of this paper. The results of the statistical analyses indicated that the use of the values of cohesion (cindr) and internal friction angle (ϕindr) as independent variables improved the prediction performance of To.

The relationships with the highest prediction performance obtained using the independent variable [(C0−cindr)/ϕindr] are shown in Fig. 4 and given in Table 2. The statistical reliability and significance of these relationships were also examined using F- and t tests. As can be seen from Tables 3 and 4, all significance values for the 95% confidence level were determined less than 0.05. Therefore, the prediction equations derived for the estimation of To are considered as statistically reliable and significant.

The predicted values of To are obtained using the equations given in Table 2. The values of cohesion and internal friction angle used in these equations are determined by traditional method shown in Fig. 1, and the UCS is the experimentally determined value. In other words, the values of cohesion and internal friction angle are indirectly obtained using the traditional method given in Fig. 1 and are used as input variables for the prediction of To in the method proposed in this study.

The internal friction angle is calculated by substituting the predicted To values and experimental UCS values into Eq. 10. At the same time, the values of internal friction angle and cohesion can be determined by drawing Mohr circles of experimentally determined UCS and theoretical tensile strength test data. Since it allows the internal friction angle to be calculated more precisely and practically and for the purpose the use of Eq. 10 is recommended. The flow chart summarizing the calculation stages in the proposed method is depicted in Fig. 5.

Data collection

In this study, a total of 153 strength data sets (internal friction angle, UCS and tensile strength) were compiled from the published literature. The rock materials of which data were used in this study belong to different rock groups (sedimentary, igneous and metamorphic and volcano-sedimantary).

As emphasized in the Introduction section, Brazilian tensile strength is approximately 1.24 times greater than the direct tensile strength for various rock types (AlAwad 2022). The ratio between the values of theoretical tensile strength, which were calculated by taking into account the experimental values used in this study, and the direct and Brazilian tensile strength are 2.33 and 1.79, respectively. Therefore, the Brazilian tensile strength is 1.30 (2.33/1.79) times greater than the direct tensile strength considering the data used in this study.

Since the tensile strength values obtained from the Brazilian and direct tensile tests are different from each other, it is impossible to create an unique prediction equation. Therefore, two different groups were constructed considering the type of the tensile strength tests. In these data set, the number of the Brazilian and direct tensile strength tests are 82 and 71, respectively.

The availability of data for a large number of rock types belonging to sedimentary, igneous, metamorphic and volcano-sedimentary rock types in two different groups is an important advantage in terms of proving the validity of the proposed equations for different rock types.

Since the direct tensile test has not been widely used for a long time, except the data from Bell and Jermmy (2000), all direct tensile strength test data were collected from Shoerey (1997). The data set of Sheorey (1997) is available in his book entitled “Empirical Rock Failure Criteria” and the internal friction angle values (ϕexp) were calculated from the triaxial test data given in Appendix A of this book. Cohesion and internal friction angles (cindr and ϕindr) were calculated from the traditional method using UCS and direct tensile strength data as shown in Fig. 1a (UCS and Brazilian tensile strength data are as given in Fig. 1b), experimentally determined internal friction angle (ϕexp) were calculated using triaxial test data (ϕexp values are obtained directly from sources given in Appendix 2), theoretical tensile strength (To) were calculated using ϕexp and UCS based on Eq. 9, predicted theoretical tensile strength (To(pre)) was calculated from Equation given in Table 2, predicted internal friction angle ϕpre was calculated from Eq. 10 and error values are given in Appendices 1 and 2. Since the Brazilian test is a widely used and popular test method, it could be possible to provide Brazilian tensile strength data in many published studies.

Estimation of internal friction angle from the proposed method

In this study, the values of internal friction angle estimated from the traditional method shown in Fig. 1 and the experimentally determined internal friction angles were compared for all rock types in the Appendix given at the end of this paper. The statistical data obtained from this comparision is given in Table 5.

As can be seen from Table 5, the error margins obtained from the traditional methods are quite high. In particular, the values of internal friction angle obtained from the failure envelopes drawn using the data of direct tensile and UCS tests differ from the experimental values with an average of 21.32°. On the other hand, the mean absolute error obtained from the data of Brazilian tensile strength and UCS tests is 8.59° which is a significant deviation from the experimental values. If the standard deviations are taken into account, much higher prediction errors are obtained when compared to the values of average error given above. For this reason, the values of friction angle obtained from traditional approaches (see Fig. 1) are far from the experimental values and do not represent experimental values. The mean errors and standard deviations obtained from the method proposed in this study are given in Table 6. The low values of mean error and standard deviation indicate that it is possible to estimate internal friction angles with higher precision by the proposed method when compared to the other traditional indirect estimation approaches.

The frequency histograms for the error and absolute error values are given in Fig. 6. On these histograms, normal distribution curves and vertical lines corresponding to 1 and 2-standard deviation error levels are also shown by different colors. By considering the 1-standard deviation from the mean (corresponding to approximately 70% of the data obtained), the absolute error ranges obtained in the estimation of internal friction angle are 9.7–31.1° and 2.56–14.62° for the traditional method based on direct tensile and Brazilian tests, respectively, suggesting that a very high prediction error such as 31.1° is possible for the estimation of internal friction angle. On the other hand, the prediction error of 14.62° is possible for the estimation of internal friction angle by traditional method based on Brazilian test data within the interval of 1-standard deviation away from the mean. If the outlier values (absolute error values within 2-standard deviations from the mean) are taken into account, absolute prediction error values are 41.8° and 20.65° for the traditional method based on direct tensile and Brazilian tests, respectively. However, the values of mean absolute error are about 5° for the method proposed in this study. Moreover, the values of prediction errors can only reach to maximum values of 9.73° and 9.56° within the interval of 1-standard deviation for the proposed method based on direct tensile and Brazilian tests, respectively. For this reason, it is considered that the method proposed in this study has a higher performance for predicting the internal friction angle of rock materials when compared to the traditional methods.

On the other hand, if the error values given in Fig. 6c are carefully examined, it can be considered that the error values in traditional predictions using direct tensile tests (ϕprediction−ϕexperimental) are completely positive, with a few exceptions. It means that the values of overestimated internal friction angle are calculated by traditional method based on direct tensile tests. As can be seen from the error values obtained from the proposed method (Fig. 6a), there is an error distribution fitting to the normal distribution with a mean close to zero. The comparison of error values obtained for each rock type is also given in Fig. 7. As can be clearly seen from this figure, the errors obtained from the proposed method are generally close to zero, while the errors obtained from the traditional methods change in a much wider range. This range includes errors above 40° and 25° when direct tensile strength and Brazilian tensile strength data is used, respectively.

Conclusions

In this study, the traditional method, which is recommended to be used for the prediction of internal friction angle (ϕ) when triaxial test data is not available, was briefly assessed with its some limitations and an alternative method using theoretical tensile strength (To) and UCS to predict ϕ was proposed. The prediction performances of traditional and proposed methods were compared using a very large data collected from published literature. The main conclusions drawn from the study are given below.

The estimates for ϕ from the traditional method based on UCS and tensile strength yield very high absolute errors and standard deviations. Particularly, the values of internal friction angle predicted from the traditional method based on direct tensile strength data can reach approximately 1.9 times the experimental values for a few rock types. So it can be inferred that traditional method based on direct tensile strength data for the prediction of ϕ is generally inappropriate.

The prediction equations derived to estimate theoretical tensile strength needed for proposed method have very high correlation coefficient. The statistical reliability of the derived equations was assessed using F- and t-tests and according to the test results the prediction equations were found to be statistically reliable.

The average ratios between ϕ values predicted from the proposed method and the values of experimentally determined ϕ values were found to be 1.03 and 1.04 for direct tensile strength data and Brazilian tensile strength data, respectively. Therefore, the method proposed in this study using the theoretical tensile strength yields best predictions of ϕ when compared to those estimated from the traditional methods based on direct and Brazilian tensile strength values.

Appendix 1

The parameters calculated using C0 and σt (Direct) data pairs [All ϕexp values in this table, Except the data from Bell and Jermmy (2000), all data was derived from the triaxial test data in Sheorey (1997)].

References | Rock type | ϕindr | cindr | ϕexp | T0 | T0(pre) | ϕpre | Error (this method) | Absolute error (this method) | Error (indirect method) | Absolute error (indirect method) |

|---|---|---|---|---|---|---|---|---|---|---|---|

Barat (1995) | Schist | 56.45 | 14 | 54.15 | 8.81 | 13.46 | 45.27 | 8.88 | 8.88 | − 4.49 | 4.49 |

Bell and Jermmy (2000) | Dolerite | 60.76 | 18.4 | 55.5 | 12.43 | 18.21 | 47.92 | 7.58 | 7.58 | − 5.26 | 5.26 |

Betourney et al. (1991) | Quartzite | 58.13 | 23.99 | 43.34 | 26.39 | 21.54 | 48.07 | − 4.73 | 4.73 | − 29.61 | 29.61 |

Betourney et al. (1991) | Andesite | 66.55 | 23.37 | 35.14 | 47.82 | 25.41 | 50.77 | − 15.63 | 15.63 | − 40.12 | 40.12 |

Betourney et al. (1991) | Diorite | 56.98 | 21.43 | 43.45 | 22.60 | 19.25 | 47.22 | − 3.77 | 3.77 | − 35.42 | 35.42 |

Betourney et al. (1991) | Basalt | 53.44 | 16.35 | 36 | 20.42 | 14.63 | 44.81 | − 8.81 | 8.81 | − 42.83 | 42.83 |

Betourney et al. (1991) | Rhyolite | 53.05 | 18.71 | 35.76 | 23.29 | 16.25 | 45.24 | − 9.48 | 9.48 | − 24.47 | 24.47 |

Betourney et al. (1991) | Quartzdiorite | 58.54 | 21.83 | 58.56 | 11.41 | 20.09 | 47.84 | 10.72 | 10.72 | 1.03 | 1.03 |

Betourney et al. (1991) | Granite | 62.96 | 26.91 | 56.93 | 18.17 | 26.07 | 50.12 | 6.81 | 6.81 | − 9.74 | 9.74 |

Betourney et al. (1991) | Sandstone | 65.63 | 15.74 | 54.84 | 13.32 | 17.93 | 48.97 | 5.87 | 5.87 | − 14.74 | 14.74 |

Betourney et al. (1991) | Limestone | 55.61 | 8.73 | 44.65 | 8.39 | 9.02 | 42.88 | 1.77 | 1.77 | − 13.12 | 13.12 |

Betourney et al. (1991) | Gneiss | 65.12 | 36.04 | 58.94 | 23.47 | 34.90 | 51.88 | 7.06 | 7.06 | − 16.61 | 16.61 |

Betourney et al. (1991) | Granodiorite | 48.27 | 15.87 | 48.33 | 10.55 | 13.46 | 42.62 | 5.71 | 5.71 | − 2.14 | 2.14 |

Betourney et al. (1991) | Limestone | 59.69 | 17.35 | 47.68 | 16.71 | 16.99 | 47.31 | 0.37 | 0.37 | − 16.54 | 16.54 |

Betourney et al. (1991) | Quartzdiorite | 58.27 | 26.22 | 51.4 | 20.18 | 23.22 | 48.47 | 2.93 | 2.93 | − 13.59 | 13.59 |

Betourney et al. (1991) | Granite breccia | 65.03 | 40.19 | 58.19 | 27.31 | 38.07 | 52.24 | 5.95 | 5.95 | − 22.61 | 22.61 |

Betourney et al. (1991) | Gneiss | 27.28 | 13.62 | 36.86 | 8.95 | 11.39 | 29.39 | 7.47 | 7.47 | 10.89 | 10.89 |

Betourney et al. (1991) | Diorite | 39.98 | 13.72 | 37.8 | 11.39 | 11.29 | 38.04 | − 0.24 | 0.24 | − 4.54 | 4.54 |

Betourney et al. (1991) | Lamprophyre | 56.77 | 20.95 | 45.04 | 20.55 | 18.83 | 47.06 | − 2.02 | 2.02 | − 22.35 | 22.35 |

Betourney et al. (1991) | Quartzdiorite | 50.31 | 13.72 | 49.38 | 9.17 | 12.19 | 42.81 | 6.57 | 6.57 | − 2.34 | 2.34 |

Betourney et al. (1991) | Agglomera tuff | 45.39 | 14.85 | 43.51 | 15.61 | 17.16 | 41.11 | 2.40 | 2.40 | − 12.19 | 12.19 |

Borecki et al. (1982) | Sandstone | 57.15 | 18.49 | 35.96 | 25.90 | 17.10 | 46.68 | − 10.72 | 10.72 | − 26.43 | 26.43 |

Borecki et al. (1982) | Sandstone | 54.73 | 18.34 | 36.64 | 23.28 | 16.37 | 45.78 | − 9.14 | 9.14 | − 22.96 | 22.96 |

Chan et al (1972) | Quartzite | 60.35 | 29.66 | 53.99 | 21.44 | 26.71 | 49.64 | 4.35 | 4.35 | − 10.93 | 10.93 |

Dayre and Giraud (1986) | Granodiorite | 59.58 | 31.27 | 49.03 | 28.20 | 27.48 | 49.58 | − 0.55 | 0.55 | − 13.45 | 13.45 |

Dlugosz et al. (1981) | Sandstone | 62.97 | 12.5 | 41.28 | 17.71 | 13.90 | 47.14 | − 5.86 | 5.86 | − 25.47 | 25.47 |

Everling (1960) | Sandstone | 61.81 | 16.01 | 37.04 | 25.37 | 16.60 | 47.73 | − 10.69 | 10.69 | − 29.25 | 29.25 |

Glushko and Kirnichanskiy (1974) | Sandstone | 60.07 | 5.61 | 54.23 | 3.97 | 6.78 | 42.63 | 11.60 | 11.60 | − 12.36 | 12.36 |

Gnirk and Cheatham (1963) | Limestone | 66.38 | 19.47 | 35.26 | 39.38 | 21.77 | 50.03 | − 14.77 | 14.77 | − 41.57 | 41.57 |

Gnirk and Cheatham (1965) | Marble | 59.87 | 13.84 | 35.52 | 21.55 | 14.16 | 46.46 | − 10.94 | 10.94 | − 29.24 | 29.24 |

Hobbs (1964) | Coal | 67.66 | 1.57 | 38.01 | 3.06 | 2.87 | 39.78 | − 1.77 | 1.77 | − 34.03 | 34.03 |

Hobbs (1964) | Coal | 57.39 | 1.52 | 37.08 | 2.07 | 2.22 | 35.05 | 2.03 | 2.03 | − 22.80 | 22.80 |

Hobbs (1964) | Coal | 68.42 | 2.89 | 36.23 | 6.20 | 4.83 | 42.94 | − 6.71 | 6.71 | − 35.87 | 35.87 |

Hobbs (1964) | Coal | 58.14 | 1.93 | 39.31 | 2.48 | 2.72 | 36.65 | 2.66 | 2.66 | − 21.36 | 21.36 |

Hobbs (1964) | Coal | 66.49 | 2.64 | 37.51 | 4.97 | 4.25 | 41.74 | − 4.23 | 4.23 | − 32.38 | 32.38 |

Hobbs (1964) | Coal | 64.7 | 1.54 | 39.89 | 2.46 | 2.60 | 38.39 | 1.50 | 1.50 | − 28.43 | 28.43 |

Hobbs (1964) | Coal | 66.84 | 1.34 | 38.45 | 2.48 | 2.46 | 38.65 | − 0.20 | 0.20 | − 31.12 | 31.12 |

Hobbs (1964) | Coal | 68.7 | 2.02 | 38.61 | 4.04 | 3.64 | 41.43 | − 2.82 | 2.82 | − 34.57 | 34.57 |

Hobbs (1964) | Coal | 66.31 | 2.62 | 37.72 | 4.86 | 4.20 | 41.63 | − 3.91 | 3.91 | − 32.40 | 32.40 |

Hobbs (1964) | Coal | 66 | 2.09 | 41.93 | 3.27 | 3.46 | 40.44 | 1.49 | 1.49 | − 27.24 | 27.24 |

Hobbs (1964) | Coal | 51.74 | 1.2 | 39.58 | 1.25 | 1.68 | 30.95 | 8.63 | 8.63 | − 13.99 | 13.99 |

Hobbs (1964) | Coal | 63.01 | 1.58 | 36.3 | 2.69 | 2.56 | 37.78 | − 1.48 | 1.48 | − 28.96 | 28.96 |

Hobbs (1964) | Coal | 61.11 | 6.62 | 32.27 | 11.98 | 7.93 | 43.77 | − 11.50 | 11.50 | − 34.13 | 34.13 |

Hobbs (1964) | Coal | 57.2 | 3.52 | 37.76 | 4.64 | 4.39 | 39.27 | − 1.51 | 1.51 | − 22.76 | 22.76 |

Hobbs (1964) | Coal | 58.02 | 3.12 | 36.62 | 4.40 | 4.04 | 39.02 | − 2.40 | 2.40 | − 24.13 | 24.13 |

Hobbs (1964) | Coal | 52.85 | 3.65 | 40.17 | 3.85 | 4.24 | 37.55 | 2.62 | 2.62 | − 15.64 | 15.64 |

Hobbs (1964) | Coal | 45.03 | 3.24 | 39.22 | 2.89 | 3.57 | 33.07 | 6.15 | 6.15 | − 7.90 | 7.90 |

Hobbs (1964) | Coal | 69.65 | 2.12 | 38.63 | 4.44 | 3.90 | 42.05 | − 3.42 | 3.42 | − 35.60 | 35.60 |

Hossaini and Vutukuri (1993) | Sandstone | 58.38 | 6.8 | 34.48 | 10.42 | 7.69 | 42.84 | − 8.36 | 8.36 | − 27.45 | 27.45 |

Ilnitskaya (1969) | Sandstone | 54.9 | 22.17 | 43.51 | 21.86 | 19.17 | 46.62 | − 3.11 | 3.11 | − 15.66 | 15.66 |

Kuntysh (1964) | Sandstone | 57.92 | 16.56 | 39.94 | 20.64 | 15.83 | 46.50 | − 6.56 | 6.56 | − 20.45 | 20.45 |

Kwasnievski (1983) | Sandstone | 57.2 | 11.89 | 40.76 | 14.03 | 11.92 | 44.85 | − 4.09 | 4.09 | − 19.72 | 19.72 |

Kwasnievski (1983) | Sandstone | 56.5 | 12.63 | 38.77 | 15.69 | 12.38 | 44.85 | − 6.08 | 6.08 | − 21.91 | 21.91 |

Kwasnievski (1983) | Sandstone | 52.63 | 15.52 | 36.21 | 18.80 | 13.87 | 44.27 | − 8.06 | 8.06 | − 20.62 | 20.62 |

Misra (1972) | Sandstone | 61.66 | 5.23 | 35.96 | 8.55 | 6.61 | 42.93 | − 6.97 | 6.97 | − 28.07 | 28.07 |

Misra (1972) | Sandstone | 65.62 | 6.18 | 37.13 | 11.34 | 8.32 | 45.17 | − 8.04 | 8.04 | − 31.93 | 31.93 |

Misra (1972) | Sandstone | 61.49 | 5.63 | 41.91 | 7.36 | 6.99 | 43.19 | − 1.28 | 1.28 | − 22.38 | 22.38 |

Misra (1972) | Sandstone | 61.17 | 12.27 | 42.93 | 15.24 | 13.17 | 46.42 | − 3.49 | 3.49 | − 21.55 | 21.55 |

Misra (1972) | Sandstone | 62.09 | 22.25 | 45.5 | 25.70 | 21.88 | 49.11 | − 3.61 | 3.61 | − 25.89 | 25.89 |

Misra (1972) | Sandstone | 63.47 | 11.43 | 45.76 | 13.77 | 13.07 | 46.95 | − 1.19 | 1.19 | − 20.85 | 20.85 |

Misra (1972) | Sandstone | 59.86 | 12.39 | 44.97 | 13.50 | 12.93 | 45.99 | − 1.02 | 1.02 | − 17.38 | 17.38 |

Murrel (1965) | Sandstone | 67.63 | 7.84 | 35.9 | 16.41 | 10.70 | 46.91 | − 11.01 | 11.01 | − 33.02 | 33.02 |

Ramamurthy (1989) | Sandstone | 49.6 | 4.47 | 38 | 4.67 | 4.82 | 37.10 | 0.90 | 0.90 | − 16.89 | 16.89 |

Rao et al. (1983) | Sandstone | 53.73 | 13.31 | 56.66 | 6.70 | 12.41 | 44.03 | 12.63 | 12.63 | 3.40 | 3.40 |

Rao et al. (1983) | Sandstone | 48.91 | 11.77 | 55.21 | 5.62 | 10.59 | 41.52 | 13.69 | 13.69 | 7.40 | 7.40 |

Rao et al. (1983) | Sandstone | 49.19 | 12.89 | 55.39 | 6.14 | 11.45 | 42.06 | 13.33 | 13.33 | 6.60 | 6.60 |

Schwartz (1964) | Marble | 47.02 | 5.69 | 37.11 | 5.74 | 5.74 | 37.11 | 0.00 | 0.00 | − 12.39 | 12.39 |

Schwartz (1964) | Granite | 57.48 | 11.9 | 54.02 | 7.80 | 11.98 | 44.96 | 9.06 | 9.06 | − 4.24 | 4.24 |

Singh et al. (1992) | Quartzite | 55.5 | 16.05 | 53.4 | 10.21 | 14.84 | 45.50 | 7.90 | 7.90 | − 4.34 | 4.34 |

Singh et al. (1992) | Sandstone | 60.2 | 9 | 50.85 | 7.61 | 10.02 | 44.76 | 6.09 | 6.09 | − 16.47 | 16.47 |

Stowe (1969) | Limestone | 51.06 | 12.02 | 45.06 | 9.94 | 11.03 | 42.51 | 2.55 | 2.55 | − 10.45 | 10.45 |

Appendix 2

The results obtained using C0 and σt (Brazilian) data pairs compiled from literature.

References | Rock type | ϕindr | cindr | ϕexp | T0 | T0(pre) | ϕpre | Error (this method) | Absolute error (this method) | Error (indirect method) | Absolute error (indirect method) |

|---|---|---|---|---|---|---|---|---|---|---|---|

Arzua and Alejano (2003) | Granite | 54.65 | 13.61 | 57.59 | 6.67 | 11.79 | 46.41 | 11.18 | 11.18 | − 2.94 | 2.94 |

Arzua and Alejano (2003) | Granite | 64.51 | 15.6 | 59.52 | 9.55 | 16.16 | 50.00 | 9.52 | 9.52 | 4.99 | 4.99 |

Arzua and Alejano (2003) | Granite | 60.76 | 16 | 54.91 | 11.16 | 15.12 | 48.92 | 5.99 | 5.99 | 5.85 | 5.85 |

Choi et al 2022 | Igneous | 52.56 | 23.41 | 54.56 | 12.82 | 18.24 | 47.41 | 7.15 | 7.15 | − 2 | 2 |

Choi et al 2022 | Metamorphic | 48.99 | 21.52 | 51.29 | 12.66 | 16.26 | 45.87 | 5.42 | 5.42 | − 2.3 | 2.3 |

Choi et al 2022 | Sedimantary | 49.06 | 25.93 | 51.28 | 15.29 | 19.10 | 46.50 | 4.78 | 4.78 | − 2.22 | 2.22 |

Dintwe et al (2019) | Tuff | 41.24 | 2.40 | 30 | 2.15 | 1.83 | 35.14 | − 5.14 | 5.14 | 11.24 | 11.24 |

Ergüler (2007) | Siltstone | 37.79 | 11.27 | 40 | 8.22 | 8.67 | 38.57 | 1.43 | 1.43 | − 2.21 | 2.21 |

Ergüler (2007) | Mudstone | 48.85 | 7.77 | 42.5 | 6.72 | 6.76 | 42.36 | 0.14 | 0.14 | 6.35 | 6.35 |

Ergüler (2007) | Mudstone | 50.27 | 8.05 | 45 | 6.53 | 7.08 | 43.05 | 1.95 | 1.95 | 5.27 | 5.27 |

Ergüler (2007) | Siltstone | 28.54 | 18.16 | 37.5 | 11.96 | 13.24 | 34.53 | 2.97 | 2.97 | − 8.96 | 8.96 |

Ergüler (2007) | Siltstone | 41.57 | 18.63 | 48.5 | 10.41 | 13.55 | 42.32 | 6.18 | 6.18 | − 6.93 | 6.93 |

Ergüler (2007) | Siltstone | 41.34 | 20.23 | 31 | 21.71 | 14.52 | 42.51 | − 11.51 | 11.51 | 10.34 | 10.34 |

Ergüler (2007) | Mudstone | 53.09 | 19.99 | 49.5 | 14.37 | 16.03 | 47.10 | 2.40 | 2.40 | 3.59 | 3.59 |

Ergüler (2007) | Marl | 52.63 | 14.28 | 33 | 19.23 | 11.93 | 45.86 | − 12.86 | 12.86 | 19.63 | 19.63 |

Ergüler (2007) | Ignimbrite | 50.98 | 1.17 | 38.5 | 1.24 | 1.35 | 36.08 | 2.42 | 2.42 | 12.48 | 12.48 |

Ergüler (2007) | Siltstone | 36.74 | 3.9 | 44 | 2.38 | 3.47 | 33.64 | 10.36 | 10.36 | − 7.26 | 7.26 |

Ergüler (2007) | Marl | 51.99 | 14.25 | 43 | 13.17 | 11.81 | 45.62 | − 2.62 | 2.62 | 8.99 | 8.99 |

Ergüler (2007) | Mudstone | 21.67 | 5.12 | 33 | 3.44 | 4.78 | 21.51 | 11.49 | 11.49 | − 11.3 | 11.33 |

Ergüler (2007) | Marl | 37.64 | 2.95 | 36.5 | 2.43 | 2.73 | 32.99 | 3.51 | 3.51 | 1.14 | 1.14 |

Ergüler (2007) | Ignimbrite | 38.17 | 3.13 | 43.5 | 2.01 | 2.88 | 33.57 | 9.93 | 9.93 | − 5.33 | 5.33 |

Ergüler (2007) | Ignimbrite | 41.42 | 2.18 | 47 | 1.30 | 2.14 | 33.89 | 13.11 | 13.11 | − 5.58 | 5.58 |

Ergüler (2007) | Marl | 59.55 | 3.23 | 41 | 4.09 | 3.73 | 43.35 | − 2.35 | 2.35 | 18.55 | 18.55 |

Ergüler (2007) | Mudstone | 42.96 | 2.25 | 31 | 2.51 | 2.22 | 34.85 | − 3.85 | 3.85 | 11.96 | 11.96 |

Eum (2002) | Basaltic intact rock | 54.42 | 6.46 | 43.24 | 6.35 | 6.19 | 43.86 | − 0.62 | 0.62 | 11.18 | 11.18 |

Eum (2002) | Basaltic intact rock | 58.17 | 12.72 | 45.71 | 12.69 | 11.80 | 47.38 | − 1.67 | 1.67 | 12.46 | 12.46 |

Heidarzadeh et al. (2021) | Carbonatite | 54.04 | 18.35 | 47.32 | 14.99 | 15.10 | 47.16 | 0.16 | 0.16 | 6.72 | 6.72 |

Heidarzadeh et al. (2021) | Syenite | 53.23 | 15.08 | 49.41 | 10.93 | 12.61 | 46.25 | 3.16 | 3.16 | 3.82 | 3.82 |

Heidarzadeh et al. (2021) | Carbonatite and Siyenite | 54.25 | 17.8 | 47.65 | 14.42 | 14.75 | 47.13 | 0.52 | 0.52 | 6.6 | 6.6 |

Heng et al. (2020) | Shale | 47.23 | 27 | 36.22 | 24.15 | 16.38 | 46.27 | − 10.05 | 10.05 | 11.01 | 11.01 |

Hosseini and Khodayari (2019) | Sandstone | 58.84 | 10.15 | 47.94 | 9.39 | 9.84 | 46.89 | 1.05 | 1.05 | 10.9 | 10.9 |

Kahraman et al. (2004) | Dol. Limestone | 55.55 | 21.19 | 53 | 13.78 | 17.49 | 48.11 | 4.89 | 4.89 | 2.55 | 2.55 |

Kahraman et al. (2004) | Limestone | 65.18 | 19.26 | 47.5 | 23.01 | 19.71 | 50.81 | − 3.31 | 3.31 | 17.68 | 17.68 |

Kahraman et al. (2004) | Travertine | 56.95 | 12.36 | 49.4 | 10.04 | 11.26 | 46.89 | 2.51 | 2.51 | 7.55 | 7.55 |

Kahraman et al. (2004) | Limestone | 64.4 | 15.25 | 52.8 | 13.67 | 15.80 | 49.90 | 2.90 | 2.90 | 11.6 | 11.6 |

Kahraman et al. (2004) | Travertine (Limra) | 61.01 | 6.5 | 41.7 | 8.43 | 7.01 | 46.19 | − 4.49 | 4.49 | 19.31 | 19.31 |

Kahraman et al. (2004) | Limestone | 57.08 | 11.74 | 53.9 | 7.64 | 10.80 | 46.77 | 7.13 | 7.13 | 3.18 | 3.18 |

Kahraman et al. (2004) | Travertine | 53.13 | 9.60 | 41.8 | 9.61 | 8.54 | 44.73 | − 2.93 | 2.93 | 11.33 | 11.33 |

Kahraman et al. (2004) | Travertine | 48.23 | 8.66 | 43.6 | 7.05 | 7.37 | 42.49 | 1.11 | 1.11 | 4.63 | 4.63 |

Kahraman et al. (2004) | Limestone | 64.79 | 14.4 | 46.9 | 17.40 | 15.20 | 49.85 | − 2.95 | 2.95 | 17.89 | 17.89 |

Kahraman et al. (2004) | Travertine | 53.63 | 8.26 | 45.9 | 7.10 | 7.56 | 44.41 | 1.49 | 1.49 | 7.73 | 7.73 |

Kahraman et al. (2004) | Travertine | 67.05 | 6.09 | 41.2 | 10.25 | 7.72 | 47.97 | − 6.77 | 6.77 | 25.85 | 25.85 |

Kainthola et al (2015) | Quartzite | 41.71 | 44.5 | 35.95 | 41.01 | 28.66 | 45.36 | − 9.41 | 9.41 | 5.76 | 5.76 |

Kainthola et al (2015) | Slate | 41.5 | 31.87 | 31.53 | 33.78 | 21.49 | 44.15 | − 12.62 | 12.62 | 9.97 | 9.97 |

Kainthola et al (2015) | Quartz mica schist | 42.22 | 12.88 | 35.88 | 12.04 | 9.89 | 41.30 | − 5.42 | 5.42 | 6.34 | 6.34 |

Kainthola et al (2015) | Limestone | 41.88 | 24.84 | 33.47 | 24.96 | 17.38 | 43.47 | − 10.00 | 10.00 | 8.41 | 8.41 |

Kazerani and Zhao (2008) | Granite | 55.89 | 20.5 | 53 | 12.31 | 15.58 | 48.17 | 4.83 | 4.83 | 2.89 | 2.89 |

Kazerani and Zhao (2008) | Granite | 56.29 | 18.51 | 53 | 12.31 | 15.75 | 47.93 | 5.07 | 5.07 | 3.29 | 3.29 |

Min et al (2019) | Granite gneiss | 62.88 | 30 | 59.2 | 16.37 | 25.39 | 51.36 | 7.84 | 7.84 | 3.68 | 3.68 |

Min et al (2019) | Gneiss A | 56.93 | 24.6 | 53.1 | 15.27 | 18.66 | 49.04 | 4.06 | 4.06 | 3.83 | 3.83 |

Min et al (2019) | Gneiss B | 54.89 | 25.9 | 49.12 | 18.73 | 19.23 | 48.54 | 0.58 | 0.58 | 5.77 | 5.77 |

Moon and Yang (2020) | Basalt | 53.88 | 6.71 | 41.43 | 6.97 | 6.35 | 43.79 | − 2.36 | 2.36 | 12.45 | 12.45 |

Moon and Yang (2020) | Basalt | 60.79 | 23.86 | 51.76 | 19.67 | 21.33 | 50.11 | 1.65 | 1.65 | 9.03 | 9.03 |

Moon and Yang (2020) | Scoria | 44.8 | 4.33 | 26.49 | 5.76 | 3.94 | 38.42 | − 11.93 | 11.93 | 18.31 | 18.31 |

Paşamehmetoğlu et al. (1981) | Andesite | 54.81 | 20.31 | 50 | 14.99 | 16.66 | 47.73 | 2.27 | 2.27 | 4.81 | 4.81 |

Paşamehmetoğlu et al. (1981) | Andesite | 50.61 | 12.18 | 48 | 8.74 | 10.14 | 44.60 | 3.40 | 3.40 | 2.61 | 2.61 |

Paşamehmetoğlu et al. (1981) | Andesite | 49.13 | 9.88 | 46 | 7.44 | 8.33 | 43.31 | 2.69 | 2.69 | 3.13 | 3.13 |

Paşamehmetoğlu et al. (1981) | Andesite | 51.81 | 2.94 | 32 | 4.00 | 3.03 | 40.04 | − 8.04 | 8.04 | 19.81 | 19.81 |

Paşamehmetoğlu et al. (1981) | Andesite | 53.52 | 24.73 | 32 | 35.27 | 19.36 | 47.91 | − 15.91 | 15.91 | 21.52 | 21.52 |

Paşamehmetoğlu et al. (1981) | Andesite | 48.62 | 18.90 | 33 | 22.78 | 14.47 | 45.30 | − 12.30 | 12.30 | 15.62 | 15.62 |

Paşamehmetoğlu et al. (1981) | Andesite | 50.82 | 6.59 | 34 | 8.16 | 5.99 | 42.56 | − 8.56 | 8.56 | 16.82 | 16.82 |

Paşamehmetoğlu et al. (1981) | Andesite | 50.70 | 4.64 | 33 | 5.92 | 4.43 | 41.27 | − 8.27 | 8.27 | 17.70 | 17.70 |

Paşamehmetoğlu et al. (1981) | Andesite | 44.87 | 13.51 | 48 | 8.36 | 10.49 | 42.65 | 5.35 | 5.35 | − 3.13 | 3.13 |

Paşamehmetoğlu et al. (1981) | Andesite | 43.84 | 10.87 | 46 | 7.16 | 8.64 | 41.42 | 4.58 | 4.58 | − 2.16 | 2.16 |

Paşamehmetoğlu et al. (1981) | Andesite | 46.30 | 7.02 | 45 | 5.13 | 6.04 | 40.92 | 4.08 | 4.08 | 1.30 | 1.30 |

Paşamehmetoğlu et al. (1981) | Andesite | 46.53 | 2.59 | 42 | 2.15 | 2.57 | 37.22 | 4.78 | 4.78 | 4.53 | 4.53 |

Paşamehmetoğlu et al. (1981) | Andesite | 53.53 | 20.11 | 52 | 12.95 | 16.21 | 47.27 | 4.73 | 4.73 | 1.53 | 1.53 |

Paşamehmetoğlu et al. (1981) | Andesite | 52.74 | 16.70 | 45 | 14.51 | 13.66 | 46.41 | − 1.41 | 1.41 | 7.74 | 7.74 |

Paşamehmetoğlu et al. (1981) | Andesite | 50.42 | 10.80 | 38 | 11.54 | 9.12 | 44.12 | − 6.12 | 6.12 | 12.42 | 12.42 |

Sriapai et al. (2012) | Salt | 22.42 | 12.68 | 28.85 | 9.81 | 10.31 | 27.14 | 1.71 | 1.71 | − 6.43 | 6.43 |

Stoxreiter et al. (2020) | Granite | 57.73 | 20.97 | 56.8 | 11.85 | 17.99 | 48.78 | 8.02 | 8.02 | 0.93 | 0.93 |

Stoxreiter et al. (2020) | Sandstone | 55.78 | 22.32 | 52.4 | 15.08 | 18.35 | 48.34 | 4.06 | 4.06 | 3.38 | 3.38 |

Stoxreiter et al. (2020) | Marble | 38.87 | 22.39 | 26.88 | 25.65 | 15.68 | 41.69 | − 14.81 | 14.81 | 11.99 | 11.99 |

Wang and He (2023) | Sandstone | 22.67 | 12.06 | 17.79 | 12.57 | 9.84 | 27.18 | − 9.39 | 9.39 | 4.88 | 4.88 |

Wang and He (2023) | Shale | 36.39 | 16.44 | 31.31 | 15.64 | 11.96 | 39.25 | − 7.94 | 7.94 | 5.08 | 5.08 |

Wang and He (2023) | Diorite | 24.79 | 32.91 | 32.87 | 23.54 | 22.75 | 33.92 | − 1.05 | 1.05 | − 8.08 | 8.08 |

Wang et al (2015) | Carbonate Rock | 39.54 | 2.5 | 35.51 | 2.06 | 2.18 | 33.75 | 1.76 | 1.76 | 4.03 | 4.03 |

Wang et al (2015) | Carbonate Rock | 41.63 | 3.2 | 35.84 | 2.67 | 2.65 | 35.99 | − 0.15 | 0.15 | 5.79 | 5.79 |

Wang et al (2015) | Carbonate Rock | 59.19 | 2.5 | 35.73 | 3.30 | 2.59 | 42.35 | − 6.62 | 6.62 | 23.46 | 23.46 |

Wei et al (2020) | Gypsum | 49.58 | 7.36 | 27 | 10.91 | 6.50 | 42.46 | − 15.46 | 15.46 | 22.58 | 22.58 |

Yasar (2021) | Tuff | 46 | 15.08 | 40.2 | 13.25 | 11.64 | 43.51 | − 3.31 | 3.31 | 5.80 | 5.80 |

Yasar (2021) | Tuff | 49.04 | 13.84 | 41.36 | 12.58 | 11.13 | 44.43 | − 3.07 | 3.07 | 7.68 | 7.68 |

References

AlAwad MNJ (2022) Modification of the Brazilian indirect tensile strength formula for better estimation of the tensile strength of rocks and rock-like geomaterials. J King Saud Univ Eng Sci 34(2):147–154. https://doi.org/10.1016/j.jksues.2020.08.003

Armaghani DJ, Hajihassani M, Bejarbaneh BY et al (2014) Indirect measure of shale shear strength parameters by means of rock index tests through an optimized artificial neural network. Measurement 55:487–498. https://doi.org/10.1016/j.measurement.2014.06.001

Arzua J, Alejano LR (2003) Dilation in granite during servo-controlled triaxial strength tests. Int J Rock Mech Min Sci 61:43–56

ASTM (2023) Standard test methods for compressive strength and elastic moduli of intact rock core specimens under varying states of stress and temperatures. American Society for Testing and Materials Test Designated D7012-23

Barat D (1995) Personal communication by Shorey (1997) from CMRI, Dhanbat

Bell FG, Jermy CA (2000) The geotechnical character of some South African dolerites especially their strength and durability. Q J Eng Geol Hydrogeol 33:59–76

Betourney MC, Gorski B, Labrie D, Jackson R, Gyenge M (1991) New considerations in the determination of Hoek and Brown material constants. In: Wittke W (ed) 7th Int Cong ISRM Rock Mech, Aachen, Germany, Vol 1, pp 195–200

Borecki M, Kwasnewski M, Pacha J, Oleksy S, Berszakiewicz Z, Guzik J (1982) Triaxial compressive strength of two mineralogic/diagenetic varieties of coal-measure, fine-medium grained Pniowek and Anna sandstones tested under confining pressure up to 60 MPa. In: Proc. Instiytutu PBKiOP PolitechnikiSlaskiej, 119/2, Gliwice

Chan SSM, Crocker TJ, Wardell GG (1972) Engineering properties of rocks and rock masses in the deep mines of the Coeur d’Alene Mining District, Idaho. Trans Soc Min Eng AIME 252:353–361

Choi S, Jeong H, Cheon DS (2022) Prediction of Mohr-Coulomb constants of selected Korean rocks based on extreme gradient boosting method and its evaluation. KSCE J Civ Eng 26:2468–2477. https://doi.org/10.1007/s12205-022-1388-3

Dayre M, Giraud A (1986) Mechanical properties of granodiorite from laboratory tests. Eng Geol 23:109–124

Dintwe TKM, Seiki T, Aydan Ö, Tokashiki N, Shimada H (2019) Experimental study on the effects of large single-joints on oya tuff pillar strength. Paper presented at the 14th ISRM Congress, Foz do Iguaçu, Brazil, Paper Number: ISRM-14CONGRESS-2019-240

Dlugosaz M, Gustkiewicz J, Wysocki A (1981) Apparatus for investigation of rocks in a triaxial state of stress: part II, some investigation results concerning certain rocks. Arcjhiwum Gornictwa 26:29–41

Erguler ZA (2007) Investigation of the effect of water content on engineering behavior of the clay-bearing rocks. Dept. of Geological Engineering, Hacettepe University, Ankara, Turkey PhD Thesis (in Turkish)

Esterhuizen GS, Bajpayee TS, Ellenberger JL, Murphy MM (2013) Practical estimation of rock properties for modeling bedded coal mine strata using the coal mine roof rating. Paper presented at the 47th US Rock Mechanics/Geomechanics Symposium, San Francisco, California, Paper Number: ARMA-2013-154

Eum KY (2002) Study on the mechanical properties of volcanic rocks in Chejudo, Master thesis, Yonsei University, p 63 (in Korean)

Everling G (1960) Rock mechanical investigations and basis for determination of rock pressure according to deformation of drill holes. Gluckauf 96:390–409

Glushko VT, Kirnichanskiy GT (1974) Engineering-geological prognosticating of stability of the opening in deep coal mines. Nedra, Moscow

Gnirk PF, Cheatham JB (1963) Identation experiments on dry rocks under pressure. Trans Soc Petr Eng AIME 228:1031–1039

Gnirk PF, Cheatham JB (1965) An experimental study of single bit tooth penetration into dry rock at confining pressures of 0–5000 psi. J Soc Pet Eng 5:117–130

Gong F, Zhang L, Wang S (2019) Loading rate effect of rock material with the direct tensile and three brazilian disc tests. Adv Civ Eng 2019:6260351. https://doi.org/10.1155/2019/6260351

Goodman RE (1989) Introduction to rock mechanics, 2nd edn. Wiley, New York

Heidarzadeh S, Saeidi A, Lavoie C, Rouleau A (2021) Geomechanical characterization of a heterogenous rock mass using geological and laboratory test results: a case study of the Niobec Mine, Quebec (Canada). SN Appl Sci 3:640. https://doi.org/10.1007/s42452-021-04617-1

Heng S, Li X, Liu X, Chen Y (2020) Experimental study on the mechanical properties of bedding planes in shale. J Nat Gas Sci Eng 76:103161

Hobbs DW (1964) The strength and the stress strain characteristics of coal in triaxial compression. J Geol 72:214–223

Hossaini SME, Vutukuri VS (1993) On the accuracy of multifailure triaxial test for the determination of peak and residual strength of rocks. In: Szwedzicki (ed) Aust. Conf. Geotech. Instrumentation and Monitoring in Open Pit and underground Mining, Kalgoorlie, pp 223–228

Hosseini M, Khodayari AR (2019) Effect of freeze-thaw cycle on strength and rock strength parameters (A Lushan sandstone case study). J Min Environ 10(1):257–270

Ilnitskaya EI, Teder RI, Vatolin ES, Kuntysh MF (1969) Properties of rocks and methods of their determination. Nedra, Moscow

ISRM (International Society for Rock Mechanics and Rock Engineering) (2007) The Complete ISRM Suggested Methods for Rock Characterization, Testing and Monitoring: 1974–2006. In: Ulusay R, Hudson JA (eds) Suggested methods prepared by the commission on testing methods, international society for rock mechanics, compilation arranged by the ISRM Turkish National Group, Ankara, Turkey, Kozan Publishing

ISRM (International Society for Rock Mechanics and Rock Engineering) (1981) In: Brown ET (ed) Rock Characterization Testing and Monitoring: ISRM Suggested Methods. Pergamon, p. 211

Jeager JE, Cook NGW (1979) Fundamentals of rock mechanics. Chapman and Hall, London, p 585

Kahraman S, Fener M, Gunaydin O (2004) Predicting the sawability of carbonate rocks using multiple curvilinear regression analysis. Int J Rock Mech Min Sci 41(7):1123–1131

Kainthola A, Singh PK, Verma D, Singh R, Sarkar K, Singh TN (2015) Prediction of strength parameters of himalayan rocks: a statistical and anfıs approach. Geotech Geol Eng 33:1255–1278. https://doi.org/10.1007/s10706-015-9899-z

Kazerani T, Zhao J (2008) A bonded particle modelling for rock material. Paper presented at the ISRM International Symposium—5th Asian Rock Mechanics Symposium, Tehran, Iran, Vol. 2, pp 1077–1084

Kuntysh MF (1964) Investigation of methods of determining the basic physico-mechanical characteristics of rocks, used while solving the problem of rock pressure. Cand Tech Sci Thesis, Moscow

Kwasniewski MA (1983) Deformational and strength properties of the three structural varieties of carboniferous sandstones. In: 5th Int. Cong. Rock Mech. (ISRM), 1, Balkema, Rotterdam, pp. A105–A115

Labuz JF, Zang A (2012) Mohr–Coulomb failure criterion. Rock Mech Rock Eng 45:975–979. https://doi.org/10.1007/s00603-012-0281-7

Li D, Wong LNY (2013) The Brazilian disc test for rock mechanics applications: review and new insights. Rock Mech Rock Eng 46:269–287. https://doi.org/10.1007/s00603-012-0257-7

Min G, Oh S, Park S, Cho S, You Y, Park L (2019) Evaluation of the dynamic shear strength of rocks under confining pressure. In: ISRM Rock Dynamics Summit, Okinawa, Japan, Paper Number: ISRM-RDS-2019-018

Misra B (1972) Correlation of rock properties with machine performance. Leeds University PhD thesis (unpublished)

Moon K, Yang SB (2020) Cohesion and ınternal friction angle estimated from brazilian tensile strength and unconfined compressive strength of volcanic rocks in jeju ısland. J Korean Geotech Soc 36(2):17–28. https://doi.org/10.7843/kgs.2020.36.2.17

Murrel SAF (1965) The effect of triaxial stress systems on the strength of rock at atmospheric temperature. Geophys J 10:231–281

Pasamehmetoglu AG, Karpuz C, Irfan TY (1981) The weathering characteristics of ankara andesites from the rock mechanics point of view. ISRM International Symposium, Tokyo, Japan, Paper Number: ISRM-IS-1981-031.

Piratheepan J, Gnanendran CT, Arulrajah A (2012) Determination of c and ϕ from an IDT and unconfined compression testing and numerical analysis. J Mater Civ Eng 24:1153–1163

Ramamurthy T (1989) Personal communication from IIT, Delhi (after Sheorey, 1997)

Rao KS, Rao GV, Ramamurthy T (1983) Strength anisotropy of a Vindhyan sandstone. Indian Geotech Conf Madras 1:141–148

Schwartz AE (1964) Failure of rock in triaxial shear test. 6th Symp. Rock Mech. Rolla, pp 109–135

Serati M, Alehossein H, William DJ (2014) 3D elastic solutions for laterally loaded discs: generalised brazilian and point load tests. Rock Mech Rock Eng 47:1087–1101. https://doi.org/10.1007/s00603-013-0449-9

Sheorey PR (1997) Empirical rock failure criteria. A.A Balkema, Rotterdam

Singh M, Sahu AK, Srivastava RK, Tiwari RP (1992) Evaluation and applicability of strength for rocks: sandstones and quartzites of Mirzapur region. In: Asian Regional Symposium, Rock Slopes, Oxford and IBH, New Delhi, India, pp 117–124

Sivakugan N, Das BM, Lovisa J, Patra CR (2014) Determination of c and ϕ of rocks from indirect tensile strength and uniaxial compression tests. Int J Geotech Eng 8(1):59–65

Sriapai T, Walsri C, Fuenkajorn K (2012) Effect of temperature on compressive and tensile strengths of salt. ScienceAsia 38(2):166–174

Stowe RL (1969) Strength and deformation properties of granite, basalt, limestone and tuff at various loading rates. US Army Corps Eng., Waterways Exp. Stn., Vicksburg Miss., Misc. Paper C-69-1

Stoxreiter T, Gehwolf P, Galler R (2020) Alternative approaches for the determination of unconfined rock deformation and strength properties. Rock Mech Rock Eng 53:411–433. https://doi.org/10.1007/s00603-019-01908-3

Turk N, Dearman WR (1986) Estimation of friction properties of rocks from deformation measurements. Paper presented at the The 27th US Symposium on Rock Mechanics (USRMS), Tuscaloosa, Alabama, Paper Number: ARMA-86-0093

Wang D, Nawrocki PA, Jebbouri A, Hozayen M, Radwan ES, Zhang X (2015) Geomechanical study of fractured carbonate reservoir—part I rock testing data. In: 13th ISRM International Congress of Rock Mechanics, Montreal, Canada, Paper Number: ISRM-13CONGRESS-2015-013

Wang H, He M (2023) Determining method of tensile strength of rock based on friction characteristics in the drilling process. Rock Mech Rock Eng 56:4211–4227. https://doi.org/10.1007/s00603-023-03276-5

Wei S, Wang C, Yang Y, Wang M (2020) Physical and mechanical properties of gypsum-like rock materials. Adv Civ Eng 2020:3703706. https://doi.org/10.1155/2020/3703706

Yasar S (2021) An experimental study to determine the Hoek-Brown constant (mi) for tuffs. Bull Earth Sci 42(1):52–69

Funding

Open access funding provided by the Scientific and Technological Research Council of Türkiye (TÜBİTAK). The authors did not receive support from any organization for the submitted work.

Author information

Authors and Affiliations

Contributions

H.K. and R.U. wrote the main manuscript text and H.K. prepared all figures. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The author declares that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Karakul, H., Ulusay, R. An alternative method for predicting internal friction angle of rock materials. Environ Earth Sci 83, 306 (2024). https://doi.org/10.1007/s12665-024-11606-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12665-024-11606-1