Abstract

Background

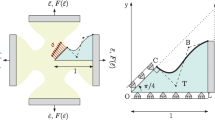

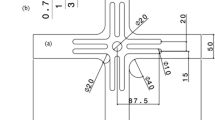

Evaluation of material properties under biaxial loading is a cumbersome process. Biaxial mechanical properties using the planar biaxial testing technique is a very accurate method compared to other out-of-plane biaxial testing techniques. Though the planar biaxial tests predict the deformation behavior of the material precisely, their applicability is limited to the design of the cruciform specimens. Improper cruciform specimen design induces inhomogeneous strain distribution, which leads to failure at a very low strain level or out of the gauge region.

Objective

The present study aims to design a novel cruciform specimen to achieve homogenous and maximum strain distribution at the gauge region.

Methods

Initially, an optimized cruciform biaxial specimen was designed using a commercial finite element method. 1050 Aluminum alloy sheet with 2.5 mm thickness was used for the experimental validation. Strain evolution during planar biaxial testing was captured with the help of the Digital Image Correlation method.

Results

It was found that a cruciform sample with 60% thickness reduction at the gauge region is capable of achieving 87.5% of the fracture strain achieved during uniaxial tensile testing before breaking. It was observed that the optimized cruciform specimen was deformed uniformly with a fracture at the gauge region.

Conclusions

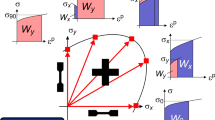

The optimized design was used for the measurement of yield locus up to higher plastic strain values. The experimental yield loci were compared to the yield criteria of von Mises, Hill’48, Hill’93, and Barlat. The Barlat yield criteria is the most accurate for AA1050 yield loci evaluation.

Similar content being viewed by others

Data Availability

The data is available at the reader’s request.

References

Hannon A, Tiernan P (2008) A review of planar biaxial tensile test systems for sheet metal. J Mater Process Technol 198:1–13. https://doi.org/10.1016/j.jmatprotec.2007.10.015

Pereira AB, Fernandes FAO, de Morais AB, Maio J (2020) Biaxial testing machine: Development and evaluation. Machines 8:1–15. https://doi.org/10.3390/MACHINES8030040

Shiratori E, Ikegami K (1968) Experimental study of the subsequent yield surface by using cross-shaped specimens. J Mech Phys Solids 16:373–394. https://doi.org/10.1016/0022-5096(68)90002-1

Kuwabara T, Ikeda S, Kuroda K (1998) Measurement and analysis of differential work hardening in cold-rolled steel sheet under biaxial tension. J Mater Process Technol 80–81:517–523. https://doi.org/10.1016/S0924-0136(98)00155-1

Lin J, Bao X, Hou Y et al (2020) Investigation on yield behavior of 7075-T6 aluminum alloy at elevated temperatures. Chin J Mech Eng 33:1-12. https://doi.org/10.1186/s10033-020-00494-8

Raj A, Singh PK, Verma RK, Narasimhan K (2020) Cruciform specimen machining using EDM and a new design verification for biaxial testing. J Mater Eng Perform 29:4716–4724. https://doi.org/10.1007/s11665-020-04921-8

Creuziger A, Iadicola MA, Foecke T et al (2017) Insights into cruciform sample design. Jom 69:902–906. https://doi.org/10.1007/s11837-017-2261-6

Xiao R, Li XX, Lang LH et al (2017) Forming limit in thermal cruciform biaxial tensile testing of titanium alloy. J Mater Process Technol 240:354–361. https://doi.org/10.1016/j.jmatprotec.2016.10.016

Zidane I, Guines D, Léotoing L, Ragneau E (2010) Development of an in-plane biaxial test for forming limit curve (FLC) characterization of metallic sheets. Meas Sci Technol 21:055701. https://doi.org/10.1088/0957-0233/21/5/055701

Seymen Y, Güler B, Efe M (2016) Large strain and small-scale biaxial testing of sheet metals. Exp Mech 56:1519–1530. https://doi.org/10.1007/s11340-016-0185-7

Güler B, Efe M (2018) Forming and fracture limits of sheet metals deforming without a local neck. J Mater Process Technol 252:477–484. https://doi.org/10.1016/j.jmatprotec.2017.10.004

Hayhurst DR (1973) A biaxial-tension creep-rupture testing machine. J Strain Anal 8:119–123. https://doi.org/10.1243/03093247v082119

Kelly DA (1976) Biaxial stress systems. J Strain Anal 11:1–6

Makinde A, Thibodeau L, Neale KW (1992) Development of an apparatus for biaxial testing using cruciform specimens. Exp Mech 32:138–144. https://doi.org/10.1007/BF02324725

Terriault P, Settouane K, Brailovski V (2003) Biaxial testing at different temperatures of cruciform Ti-Ni samples. In: Proceedings of the International Conference on Shape Memory and Superelastic Technologies. SMST, California, pp 247–257

Geiger M, Hußnätter W, Merklein M (2005) Specimen for a novel concept of the biaxial tension test. J Mater Process Technol 167:177–183. https://doi.org/10.1016/j.jmatprotec.2005.05.028

Merklein M, Biasutti M (2013) Development of a biaxial tensile machine for characterization of sheet metals. J Mater Process Technol 213:939–946. https://doi.org/10.1016/j.jmatprotec.2012.12.005

Green DE, Neale KW, MacEwen SR et al (2004) Experimental investigation of the biaxial behaviour of an aluminum sheet. Int J Plast 20:1677–1706. https://doi.org/10.1016/j.ijplas.2003.11.012

Deng N, Kuwabara T, Korkolis YP (2015) Cruciform specimen design and verification for constitutive identification of anisotropic sheets. Exp Mech 55:1005–1022. https://doi.org/10.1007/s11340-015-9999-y

Nasdala L, Husni AH (2020) Determination of yield surfaces in accordance with ISO 16842 using an optimized cruciform test specimen. Exp Mech 60:815–832. https://doi.org/10.1007/s11340-020-00601-9

Vic-3D® (2009) Correlated Solutions Inc. http://www.correlatedsolutions.com/

Jones EMC, Iadicola MA, Bigger R et al (2018) A good practices guide for digital image correlation. Int Digit Image Correl Soc 1–94. https://doi.org/10.32720/idics/gpg.ed1

Pan B, Wang B (2016) Digital image correlation with enhanced accuracy and efficiency: A comparison of two subpixel registration algorithms. Exp Mech 56:1395–1409. https://doi.org/10.1007/s11340-016-0180-z

Siebert T, Becker T, Spiltthof K et al (2007) Error estimations in digital image correlation technique. Appl Mech Mater 7–8:265–270. https://doi.org/10.4028/www.scientific.net/AMM.7-8.265

Wang D, Diazdelao FA, Wang W et al (2016) Uncertainty quantification in DIC with Kriging regression. Opt Lasers Eng 78:182–195. https://doi.org/10.1016/j.optlaseng.2015.09.006

Producers BR, Bureau N (1948) A theory of the yielding and plastic flow of anisotropic metals. Proc R Soc London Ser A Math Phys Sci 193:281–297. https://doi.org/10.1098/rspa.1948.0045

Xiao R (2019) A review of cruciform biaxial tensile testing of sheet metals. Exp Tech 43:501–520. https://doi.org/10.1007/s40799-018-00297-6

Ellis JR, Sandlass GS, Bayyari M (2001) Specimens and reusable fixturing for testing advanced aeropropulsion materials under in-plane biaxial loading. Natl Aeronaut Sp Adm 1:1–46. https://doi.org/10.1520/stp13516s

Ferron G, Makinde A (1988) Design and development of a biaxial strength testing device. J Test Eval 16:253–256. https://doi.org/10.1520/jte10375j

Zhang W, Zhu Z, Zhou C, He X (2021) Biaxial tensile behavior of commercially pure titanium under various in-plane load ratios and strain rates. Metals (Basel) 11:1–18. https://doi.org/10.3390/met11010155

Mechanik MUND (1928) Zeitschrift for Angewandte. Differ Equations 1:

Hill R (1993) A user-friendly theory of orthotropic plasticity in sheet metals. Int J Mech Sci 35:19–25. https://doi.org/10.1016/0020-7403(93)90061-X

Barlat F, Lian K (1989) Plastic behavior and stretchability of sheet metals. Part I: A yield function for orthotropic sheets under plane stress conditions. Int J Plast 5:51–66. https://doi.org/10.1016/0749-6419(89)90019-3

Woodthorpe J, Pearce R (1970) The anomalous behaviour of aluminium sheet under balanced biaxial tension. Int J Mech Sci 12:341–347. https://doi.org/10.1016/0020-7403(70)90087-1

Acknowledgements

The authors are grateful for the experimental resources provided by the Advanced Mechanical Testing Facility (AMTF) at IIT Bombay. The authors would like to acknowledge the Indian Space Research Organisation (ISRO) for providing materials for this project.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

Von Mises Yield Criteria [31]

The von Mises yield criteria is one of the most widely used plasticity models. Assuming the sheet material behaves isotopically, the 3D yield function is represented by all 6 components of the stress tensor as follows:

For plane stress condition von Mises yield criteria can be written as (\({\upsigma }_{\mathrm{zz}}={\upsigma }_{\mathrm{zx}}={\upsigma }_{\mathrm{yz}}\)=0)

where \(\overline{\upsigma }\) is effective stress

Hill'48 Yield Criteria [26]

One of the most commonly used yield criteria for anisotropic materials is the Hill48 yield criteria. The yield criteria is written as a quadratic function of the following form:

where \(\tilde{\sigma }\) is effective stress and F, G, H, L, M and N are material parameters. Here x, y, and z represent rolling, transverse and thickness direction of sheet.

For plane stress conditions, the Hill'48 quadratic yield criteria is given by (\({\upsigma }_{\mathrm{zz}}={\upsigma }_{\mathrm{zx}}={\upsigma }_{\mathrm{yz}}\)=0)

where

Hill'93 Yield Criteria [32]

In 1993 Hill proposed an improved yield criteria for plastic behaviour of sheet metals given by following quadratic equation:

where \({\upsigma }_{1}\) and \({\upsigma }_{2}\) are the principal stresses, \(\mathrm{c},\mathrm{p}\) and \(\mathrm{q}\) are material parameters which can be determined by using the following expressions:

where \({\upsigma }_{0}{,\upsigma }_{90}\) are \({\mathrm{R}}_{0}, {\mathrm{R}}_{90}\) are the yield strength and R-values along 0 and 90 to the rolling direction respectively and \({\upsigma }_{\mathrm{b}}\) is biaxial yield strength.

Barlet Yield Criteria [33]

All the above mentioned yield criteria are the quadratic yield criteria, whereas in 1989 Barlat proposed a non-quadratic yield criteria of the following form:

where \({\mathrm{K}}_{1}=\frac{{\upsigma }_{\mathrm{xx}}+\mathrm{h}{\upsigma }_{\mathrm{yy}}}{2},{\mathrm{K}}_{2}=\sqrt{{\left(\frac{{\upsigma }_{\mathrm{xx}}-\mathrm{h}{\upsigma }_{\mathrm{yy}}}{2}\right)}^{2}+{\left(\mathrm{p}{\upsigma }_{\mathrm{xy}}\right)}^{2}},\mathrm{M},\mathrm{a},\mathrm{c},\mathrm{p}\) and \(\mathrm{h}\) are material parameters which can be calculated by using the following expressions:

where \({\upsigma }_{0}\) tensile yield strength and \(\uptau\) is the yield strength in shear.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Siddiqui, A.H., Patil, J.P. & Mishra, S. Design of a Biaxial Cruciform Specimen with a High Degree of Plastic Deformation and Yield Locus Evolution. Exp Mech 63, 853–869 (2023). https://doi.org/10.1007/s11340-023-00958-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-023-00958-7