Abstract

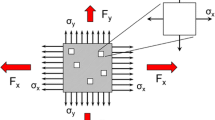

A testing apparatus has been developed to study the behavior of sheet metals and composite materials under monotonic and cyclic biaxial loading conditions. This test facility employs cruciform specimens that are loaded in their plane. Problems encountered while developing the test system are discussed.

We also discuss the difficulties common to test methods employing cruciform specimens. These relate to the design of a suitable specimen geometry and to the determination of the stresses throughout the specimen. A method for designing an optimal geometry for these specimens is presented. This method is based on the statistical tools of factorial and response surface designs. The statistical method, coupled with a finite-element analysis of the specimen, was successfully applied to optimize the geometry of a cruciform specimen with a circular reduced central region.

Similar content being viewed by others

References

Lefebvre, D., Chebl, C., Thibodeau, L. andKhazzari, E., “A High-Strain Biaxial-Testing Rig for Thin-Walled Tubes Under Axial Load and Pressure,”Experimental Mechanics,23,384–392 (1983).

Found, M.S., Fernando, U.S. and Miller, K.J., “Requirements of a New Multiaxial Fatigue Testing Facility,” Multiaxial Fatigue, ASTM STP 853, ed. K.J. Miller and M.W. Brown, 11–23 (1985).

Pascoe, K.J. andde Villiers, J.W.R., “Low-Cycle Fatigue of Steels Under Biaxial Straining,”J. Strain Anal.,2,117–126 (1967).

Parsons, M.W. andPascoe, K.J., “Development of a Biaxial Fatigue Testing Rig,”J. Strain Anal.,10,1–9 (1975).

Shiratori, E. andIkegami, K., “A New Biaxial Tensile Testing Machine With Flat Specimen,”Bul. Tokyo Inst. Tech.,82,105–118 (1967).

Shimada, H., Shimizu, K., Obata, M., Chikugo, K. andChiba, M., “A New Biaxial Testing Machine for the Flat Specimen and a Fundamental Study on the Shape of Specimen,”Tech. Rep., Tohoku Univ.,41,351–369 (1976).

Hopper, C.D. andMiller, K.J., “Fatigue Crack Propagation in Biaxial Stress Fields,”J. Strain Anal.,12,23–28 (1977).

Daniel, I.M., “Behavior of Graphite/Epoxy Plates With Holes Under Biaxial Loading,”Experimental Mechanics,20,1–8 (1980).

Charvat, I.M.H. andGarrett, G.G., “The Development of a Closed-Loop, Servo-Hydraulic Test System for Direct Stress Monotonic and Cyclic Crack Propagation Studies Under Biaxial Loading,”J. Test. Eval.,8,9–17 (1980).

Liu, A.F. andYamane, J.R., “Crack Growth Under Equibiaxial Tension,”Res. Mech.,5,1–11 (1982).

Jones, D.L., Poulose, P.K. andLiebowitz, H., “The Effects of Biaxial Loading on the Fracture Characteristics of Several Engineering Materials,”Eng. Fract. Mech.,24,187–205 (1986).

Bert, C.W., Mayberry, B.L. andRay, J.D., “Behavior of Fiber-Reinforced Plastic Laminates Under Biaxial Loading,”ASTM STP 460, 362–380 (1969).

Ferron, G. andMakinde, A., “Design and Development of a Biaxial Strength Testing Device,”J. Test. Eval.,16,253–256 (1988).

Johnson, A.E. andKhan, B., “A Biaxial-Stressing Creep Machine and Extensometer,”Proc. Inst. Mech. Eng.,180A,318–323 (1965–1966).

Hayhurst, D.R., “A Biaxial-Tension Creep-Rupture Testing Machine,”J. Strain Anal.,8,119–123 (1973).

Kelly, D.A., “Problems in Creep Testing Under Biaxial Stress Systems,”J. Strain Anal.,11,1–6 (1976).

Fessler, H. andMusson, J.K., “A 30-Ton Biaxial Testing Machine,”J. Strain Anal.,4,22–26 (1969).

Chaudonneret, M., Gilles, P., Labourdette, R. andPolicella, H., “Machine d'essais de traction biaxiale pour essais statiques et dynamiques,”La Recherche Aérospatiale,5,299–305 (1977).

Makinde, A., Thibodeau, L., Lefebvre, D., Neale, K.W. and Lahoud, A.E., “Development of a Servohydraulic Machine for Testing Cruciform Specimens,” Proc. 1989 SEM Spring Corf. on Exp. Mech., 112–116 (1989).

MTS Systems Corporation, Minneapolis, Minnesota, Technical service manuals.

Makinde, A., Thibodeau, L., Neale, K.W. and Lefebvre, D., “Design of a Biaxial Extensometer for Measuring Strains in Cruciform Specimens,” Experimental Mechanics,22 (2), (1992).

Smith, E.W. andPascoe, K.J., “The Behaviour of Fatigue Cracks Subject to Applied Biaxial Stress: A Review of Experimental Evidence,”Fatigue Eng. Mat. Struct.,6,201–224 (1983).

Monch, E. andGalster, D., “A Method for Producing a Defined Uniform Biaxial Tensile Stress Field,”Brit. J. Appl. Phys.,14,810–812 (1963).

Liu, A.F., Allison, J.E., Dittmer, D.F. and Yamane, J.R., “Effect of Biaxial Stresses on Crack Growth,” ASTM STP 677, ed. C.W. Smith, 5–22 (1979).

Parsons, M.W. andPascoe, K.J., “Low-Cycle Fatigue Under Biaxial Stress,”Proc. Inst. Mech. Eng.,188,657–675 (1975).

Makinde, A., “Mise au point d'un dispositif original de traction biaxiale: Application à l'étude expérimentale de l'écrouissage des metaux sous différents chemins de déformation,”PhD Thesis, Université de Poitiers, Poitiers, France (1986).

Kreissig, R. andSchindler, J., “Some Experimental Results on Yield Condition in Plane Stress State,”Acta Mech.,65,169–179 (1986).

Bremand, F. andLagarde, A., “Optical Method of Strain Measurements: Biaxial Tension Specimen for Birefringent Elastomer,”Arch. Mech.,40,515–527 (1988).

Box, G.E.P., Hunter, W.G. andHunter, J.S., Statistics for Experimenters, John Wiley & Sons, New York (1978).

Wilson, I.H. andWhite, D.J., “Cruciform Specimens for Biaxial Fatigue Tests: An Investigation Using Finite Element Analysis and Photoelastic-Coating Techniques,”J. Strain Anal.,6,27–37 (1971).

Hill, R., “A General Theory of Uniqueness and Stability in Elastic-Plastic Solids,”J. Mech. Phys. Solids,6,236–249 (1958).

Hutchinson, J.W., “Finite Strain Analysis of Elastic-Plastic Solids and Structures,” Numerical Solution of Non-Linear Structural Problems, ed. R.F. Hartung, ASME, 17–29 (1973).

Neglo, K., Chater, E. andNeale, K.W., “Effects of the Shape of a Geometric Defect and of Interactions Between Defects on Limit Strains for Biaxially Stretched Sheets,”Int. J. Mech. Sci.,29,807–820 (1987).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Makinde, A., Thibodeau, L. & Neale, K.W. Development of an apparatus for biaxial testing using cruciform specimens. Experimental Mechanics 32, 138–144 (1992). https://doi.org/10.1007/BF02324725

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF02324725