Abstract

Background

Digital Volume correlation (DVC) consists in identifying the displacement fields that allow for the best possible registration of volume images of a sample captured at various loading stages. With cellular materials, the use of DVC faces an intrinsic limit: in the absence of an exploitable texture on (or in) the struts or cell walls, the available speckle pattern will unavoidably be formed by the material architecture itself. This leads to the inability of classical DVC techniques to measure kinematics below the cellular scale, i.e. at the sub-cellular or micro scales.

Objectives

Here, we extend a newly developed architecture-driven DIC technique [1] for the measurement of 3D displacement fields in real cellular materials at the scale of the architecture.

Methods

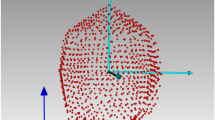

The proposed solution consists in assisting DVC by a weak elastic regularization using, as support, an automatic finite-element image-based mechanical model.

Results

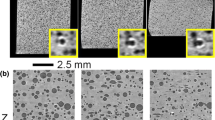

Complex (locally buckling) kinematics of a polyurethane foam under compression are accurately measured during an in-situ test. The method is essential to evidence the class of dominance (stretching versus bending) of the foam.

Conclusion

The proposed method allows to confirm that the foam used is bending-dominated, which is not possible with a classical mesoscopic DVC approach. This method is a good candidate for the analysis of complex local deformation mechanisms at the architecture scale.

Similar content being viewed by others

References

Rouwane A, Bouclier R, Passieux JC, Périé JN (2022) Architecture-driven digital image correlation technique (ADDICT) for the measurement of sub-cellular kinematic fields in speckle-free cellular materials. Int J Solids Struct 234–235

Ashby M (2013) Designing architectured materials. Scripta Mater 68(1):4–7

Brechet Y, Embury JD (2013) Architectured materials: Expanding materials space. Scripta Mater 68(1):1–3

Greer JR, Deshpande VS (2019) Three-dimensional architected materials and structures: Design, fabrication, and mechanical behavior. MRS Bull 44(10):750–757

Dallago M, Winiarski B, Zanini F, Carmignato S, Benedetti M (2019) On the effect of geometrical imperfections and defects on the fatigue strength of cellular lattice structures additively manufactured via selective laser melting. Int J Fatigue 124:348–360

Hernández-Nava E, Smith C, Derguti F, Tammas-Williams S, Leonard F, Withers P, Todd I, Goodall R (2016) The effect of defects on the mechanical response of ti-6al-4v cubic lattice structures fabricated by electron beam melting. Acta Materialia 108:279–292

Maire E, Fazekas A, Salvo L, Dendievel R, Youssef S, Cloetens P, Letang JM (2003) X-ray tomography applied to the characterization of cellular materials. related finite element modeling problems. Compos Sci Technol 63(16):2431–2443 Porous Materials

van Rietbergen B, Weinans H, Huiskes R, Odgaard A (1995) A new method to determine trabecular bone elastic properties and loading using micromechanical finite-element models. J Biomech 28(1):69–81

Frey P, Sarter B, Gautherie M (1994) Fully automatic mesh generation for 3-d domains based upon voxel sets. Int J Numer Meth Eng 37(16):2735–2753

Hollister S, Brennan J, Kikuchi N (1994) A homogenization sampling procedure for calculating trabecular bone effective stiffness and tissue level stress. J Biomech 27(4):433–444

Ulrich D, van Rietbergen B, Weinans H, Rüegsegger P (1998) Finite element analysis of trabecular bone structure: a comparison of image-based meshing techniques. J Biomech 31(12):1187–1192

Lozanovski B, Leary M, Tran P, Shidid D, Qian M, Choong P, Brandt M (2019) Computational modelling of strut defects in slm manufactured lattice structures. Materials & Design 171

Müller R, Rüegsegger P (1995) Three-dimensional finite element modelling of non-invasively assessed trabecular bone structures. Med Eng Phys 17(2):126–133

Buffiere JY, Maire E, Adrien J, Masse JP, Boller E (2010) In situ experiments with x ray tomography: an attractive tool for experimental mechanics. Exp Mech 50(3):289–305

Bay BK, Smith TS, Fyhrie DP, Saad M (1999) Digital volume correlation: three-dimensional strain mapping using x-ray tomography. Exp Mech 39(3):217–226

Chen Y, DallÁra E, Sales E, Manda K, Wallace R, Pankaj P, Viceconti M (2017) Micro-ct based finite element models of cancellous bone predict accurately displacement once the boundary condition is well replicated: A validation study. J Mech Behav Biomed Mater 65:644–651

Rannou J, Limodin N, Réthoré J, Gravouil A, Ludwig W, Baïetto-Dubourg MC, Buffiëre JY, Combescure A, Hild F, Roux S (2010) Three dimensional experimental and numerical multiscale analysis of a fatigue crack. Comput Meth Appl Mech Eng 199(21):1307–1325, multiscale Models and Mathematical Aspects in Solid and Fluid Mechanics

Zauel R, Yeni Y, Bay B, Dong X, Fyhrie DP (2006) Comparison of the linear finite element prediction of deformation and strain of human cancellous bone to 3d digital volume correlation measurements. J Biomech Eng 128(1):1–6

Buljac A, Trejo Navas VM, Shakoor M, Bouterf A, Neggers J, Bernacki M, Bouchard PO, Morgeneyer TF, Hild F (2018) On the calibration of elastoplastic parameters at the microscale via x-ray microtomography and digital volume correlation for the simulation of ductile damage. Eur J Mech A Solids 72:287–297

Marter AD, Dickinson AS, Pierron F, Browne M (2018) A practical procedure for measuring the stiffness of foam like materials. Exp Tech 42(4):439–452

Salvo L, Belestin P, Maire E, Jacquesson M, Vecchionacci C, Boller E, Bornert M, Doumalin P (2004) Structure and mechanical properties of afs sandwiches studied by in-situ compression tests in x-ray microtomography. Adv Eng Mater 6(6):411–415

Bastawros AF, Bart-Smith H, Evans A (2000) Experimental analysis of deformation mechanisms in a closed-cell aluminum alloy foam. J Mech Phys Solids 48(2):301–322

Hu Z, Du Y, Luo H, Zhong B, Lu H (2014) Internal deformation measurement and force chain characterization of mason sand under confined compression using incremental digital volume correlation. Exp Mech 54(9):1575–1586

Verhulp E, Rietbergen B, Huiskes R (2004) A three-dimensional digital image correlation technique for strain measurements in microstructures. J Biomech 37(9):1313–1320

Roux S, Hild F, Viot P, Bernard D (2008) Three-dimensional image correlation from x-ray computed tomography of solid foam. Compos Part A: Appl Sci Manufac 39(8):1253–1265

DallÁra E, Peña-Fernández M, Palanca M, Giorgi M, Cristofolini L, Tozzi G (2017) Precision of digital volume correlation approaches for strain analysis in bone imaged with micro-computed tomography at different dimensional levels. Frontiers in Materials 4:31

Leclerc H, Périé JN, Roux S, Hild F (2011) Voxel-scale digital volume correlation. Exp Mech 51(4):479–490

Réthoré J, Roux S, Hild F (2009) An extended and integrated digital image correlation technique applied to the analysis of fractured samples. European Journal of Computational Mechanics 18(3–4):285–306

Fischer B, Modersitzki J (2004) A unified approach to fast image registration and a new curvature based registration technique. Linear Algebra Appl 380:107–124

Sotiras A (2011) Discrete image registration: a hybrid paradigm. PhD thesis, Ecole Centrale Paris

Claire D, Hild F, Roux S (2004) A finite element formulation to identify damage fields: the equilibrium gap method. Int J Numer Meth Eng 61(2):189–208

Mendoza A, Neggers J, Hild F, Roux S (2019) Complete mechanical regularization applied to digital image and volume correlation. Comput Methods Appl Mech Eng 355:27–43

Deshpande V, Ashby M, Fleck N (2001) Foam topology: bending versus stretching dominated architectures. Acta Mater 49(6):1035–1040. https://doi.org/10.1016/S1359-6454(00)00379-7

Somera A, Poncelet M, Auffray N, Réthoré J (2022) Quasi-periodic lattices: Pattern matters too. Scripta Materialia 209:114378 https://doi.org/10.1016/j.scriptamat.2021.114378

Ahrens J, Geveci B, Law C (2005) Paraview: An end-user tool for large data visualization. The visualization handbook 717(8)

Ayachit U (2015) The paraview guide: a parallel visualization application

Réthoré J (2010) A fully integrated noise robust strategy for the identification of constitutive laws from digital images. Int J Numer Meth Eng 84(6):631–660

Leclerc H, Périé JN, Hild F, Roux S (2012) Digital volume correlation: what are the limits to the spatial resolution ? Mechanics & Industry 13(6):361–371

Horn BKP, Schunck BG (1981) Determining optical flow. Artif Intell 17(1–3):185–203

Leclerc H, Roux S, Hild F (2015) Projection savings in ct-based digital volume correlation. Exp Mech 55(1):275–287

Gomes Perini L, Passieux JC, Périé JN (2014) A multigrid pgd-based algorithm for volumetric displacement fields measurements. Strain 50(4):355–367

Neggers J, Blaysat B, Hoefnagels JPM, Geers MGD (2016) On image gradients in digital image correlation. Int J Numer Meth Eng 105(4):243–260

Passieux JC, Bouclier R (2019) Classic and inverse compositional gauss-newton in global DIC. Int J Numer Meth Eng 119(6):453–468

Fedele R, Galantucci L, Ciani A (2013) Global 2d digital image correlation for motion estimation in a finite element framework: a variational formulation and a regularized, pyramidal, multi-grid implementation. Int J Numer Meth Eng 96(12):739–762

Pan B, Xie H, Wang Z, Qian K, Wang Z (2008) Study on subset size selection in digital image correlation for speckle patterns. Opt Express 16(10):7037–7048

Bomarito G, Hochhalter J, Ruggles T, Cannon A (2017) Increasing accuracy and precision of digital image correlation through pattern optimization. Opt Lasers Eng 91:73–85

Fouque R, Bouclier R, Passieux JC, Périé JN (2021) Fractal pattern for multiscale digital image correlation. Exp Mech 61(3):483–497

Passieux JC, Périé JN, Marguerès P, Douchin B, Gomes Perini L (2013) On the joint use of an opacifier and digital volume correlation to measure micro-scale volumetric displacement fields in a composite. In: ICTMS2013 - The 1st International Conference on Tomography of Materials and Structures, Ghent, Belgium

Brault R, Germaneau A, Dupré JC, Doumalin P, Mistou S, Fazzini M (2013) In-situ analysis of laminated composite materials by X-ray micro-computed tomography and digital volume correlation. Exp Mech 53(7):1143–1151

Xu F (2018) Quantitative characterization of deformation and damage process by digital volume correlation: A review. Theor Appl Mech Lett 8(2):83–96

Dufour JE, Beaubier B, Hild F, Roux S (2015) Cad-based displacement measurements with stereo-dic. Exp Mech 55(9):1657–1668

Colantonio G, Chapelier M, Bouclier R, Passieux JC, Marenić E (2020) Noninvasive multilevel geometric regularization of mesh-based three-dimensional shape measurement. Int J Numer Meth Eng 121(9):1877–1897

Chapelier M, Bouclier R, Passieux JC (2021) Free-form deformation digital image correlation (ffd-dic): A non-invasive spline regularization for arbitrary finite element measurements. Comput Methods Appl Mech Eng 384

Bouclier R, Passieux JC (2017) A domain coupling method for finite element digital image correlation with mechanical regularization: Application to multiscale measurements and parallel computing. Int J Numer Meth Eng 111(2):123–143

Passieux JC, Périé JN (2012) High resolution digital image correlation using proper generalized decomposition: Pgd-dic. Int J Numer Methods Eng 92(6):531–550

van Dijk NP, Wu D, Persson C, Isaksson P (2019) A global digital volume correlation algorithm based on higher-order finite elements: Implementation and evaluation. Int J Solids Struct 168:211–227

Tsitova A, Bernachy-Barbe F, Bary B, Dandachli S, Bourcier C, Smaniotto B, Hild F (2021) Damage quantification via digital volume correlation with heterogeneous mechanical regularization: Application to an in situ meso-flexural test on mortar. Exp Mech pp. 1–17

Unser M (1999) Splines: a perfect fit for signal and image processing. IEEE Signal Process Mag 16(6):22–38

Unser M, Aldroubi A, Eden M et al (1991) Fast b-spline transforms for continuous image representation and interpolation. IEEE Trans Pattern Anal Mach Intell 13(3):277–285

Jones EM, Iadicola MA etal (2018) A good practices guide for digital image correlation. International Digital Image Correlation Society 10

Bajcsy R, Kovačič S (1989) Multiresolution elastic matching. Computer vision, graphics, and image processing 46(1):1–21

Rueckert D, Sonoda LI, Hayes C, Hill DL, Leach MO, Hawkes DJ (1999) Nonrigid registration using free-form deformations: application to breast mr images. IEEE Trans Med Imaging 18(8):712–721

Haber E, Modersitzki J (2006) A multilevel method for image registration. SIAM J Sci Comput 27(5):1594–1607

Réthoré J, Hild F, Roux S (2007) Shear-band capturing using a multiscale extended digital image correlation technique. Comput Methods Appl Mech Eng 196(49–52):5016–5030

Fedele R, Ciani A, Galantucci L, Bettuzzi M, Andena L (2013) A regularized, pyramidal multi-grid approach to global 3d-volume digital image correlation based on x-ray micro-tomography. Fund Inform 125(3–4):361–376

Valmalle M, Vintache A, Smaniotto B, Gutmann F, Spagnuolo M, Ciallella A, Hild F (2022) Local-global dvc analyses confirm theoretical predictions for deformation and damage onset in torsion of pantographic metamaterial. Mech Mater p. 104379

Lorensen WE, Cline HE (1987) Marching cubes: A high resolution 3d surface construction algorithm. Computer Graphics 21(4):163–169

van der Walt S, Schünberger JL, Nunez-Iglesias J, Boulogne F, Warner JD, Yager N, Gouillart E, Yu T (2014) scikit-image: image processing in Python. PeerJ 2

The CGAL Project (2021) CGAL user and reference manual. https://doc.cgal.org/5.3.1/Manual/packages.html

Szeliski R, Lavallée S (1996) Matching 3-d anatomical surfaces with non-rigid deformations using octree-splines. Int J Comput Vis 18(2):171–186

Ferrant M, Warfield SK, Guttmann CR, Mulkern RV, Jolesz FA, Kikinis R (1999) 3d image matching using a finite element based elastic deformation model. In: International Conference on Medical Image Computing and Computer-Assisted Intervention, Springer, pp 202–209

Chen Y, Davis TA, Hager WW, Rajamanickam S (2008) Algorithm 887: Cholmod, supernodal sparse cholesky factorization and update/downdate. ACM Transactions on Mathematical Software (TOMS) 35(3):1–14

Réthoré J, Muhibullah Elguedj T, Coret M, Chaudet P, Combescure A (2013) Robust identification of elasto-plastic constitutive law parameters from digital images using 3d kinematics. Int J Solids Struct 50(1):73–85

Tournier PH, Aliferis I, Bonazzoli M, De Buhan M, Darbas M, Dolean V, Hecht F, Jolivet P, El Kanfoud I, Migliaccio C et al (2019) Microwave tomographic imaging of cerebrovascular accidents by using high-performance computing. Parallel Comput 85:88–97

MacNeil JML, Morozov D, Panerai F, Parkinson D, Barnard H, Ushizima D (2019) Distributed global digital volume correlation by optimal transport. In: 2019 IEEE/ACM 1st Annual Workshop on Large-scale Experiment-in-the-Loop Computing (XLOOP), IEEE, pp 14–19

PyMesh DT (2020) Pymesh: geometry processing library for python. https://github.com/PyMesh/PyMesh

Akenine-Mller T, Haines E, Hoffman N (2018) Real-time Rendering, Fourth Edition, 4th edn. A. K, Peters Ltd, USA

Funding

This work was supported by Région Occitanie and Université Fédérale Toulouse-Midi-Pyrénées.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix: FE interrogation for arbitrary points

Appendix: FE interrogation for arbitrary points

We present in this appendix a procedure that allows to perform automatically the displacement exchange between two arbitrary finite-element meshes. We consider the following steps for solving this geometric problem:

Step 1: Location of the Nearest Face of the FE Mesh to the Point

Efficient data structures (very common in collision detection algorithms) can be efficiently used to speed up point queries with respect to complex geometric objects represented by faces. In this work, we mainly use a rootine from the CGAL library [69] and PyMesh [76]. Efficient point queries such as intersections, distance computation, ray shooting can be performed using Axis Aligned Bounding Boxes (AABB) trees [77]. This allows to detect the nearest face to an arbitrary point.

Step 2: Location of the Tetrahedral Element Containing the Point

After determining the nearest face, the location test is performed on the tetrahedrons that share this same face (they are at most two). To do so, one can consider two methods:

-

Method 1: Computation of the barycentric coordinates by resolution of the linear system:

$$\begin{aligned} \left\{ \begin{array}{l} x = \displaystyle \sum _{i=1}^m \lambda _i t_i \\ \displaystyle \sum _{i=1}^m\lambda _i = 1 \end{array} \right. \end{aligned}$$(12)If \(\lambda _i>0, \quad \forall i\in \left\{ 1,...,m\right\}\) then the point x belongs to the tetrahedron bounded by the nodes \((t_i)_{i\in \left\{ 1,...,m\right\} }\). m is the number of nodes per convex set (4 in our case).

-

Method 2: A faster method which does not consist in solving a linear system can be considered. We only evaluate the signed distance of the point to each of the tetrahedron faces. First, the orientation of the faces must be determined so that all the face normal vectors point towards the same direction. This is given by an orientation matrix denoted \(\textbf{O}\in \mathbb {R}^{3\times 4}\) that depends of the used mesh. Each column of \(\textbf{O}\) represents the indices of the nodes of the tetrahedron faces. The point x belongs to the tetrahedron if the distances to all the faces have the same sign. This is written as follows:

$$\begin{aligned} (x- t_{\textbf{O}_{2,i}})^T n_i(t_{\textbf{O}_{2,i}}) < 0, \quad \forall i \in \left\{ 1,..,4 \right\} \end{aligned}$$(13)where \(n_i(t_{\textbf{O}_{2,i}})\) is the normal vector at node \(t_{\textbf{O}_{2,i}}\) (which is the second node of the face i). It is defined by \(n_i(t_2)=(t_{\textbf{O}_{2,i}}-t_{\textbf{O}_{1,i}}) \times (t_{\textbf{O}_{3,i}}-t_{\textbf{O}_{2,i}})\).

Step 3: Evaluation of the Displacement Field at the Point

Once the tetrahedron containing the point is determined, the isoparametric transformation \((x=\sum _{i}N_i(\xi )t_i)\) is inverted in order to find the isoparametric coordinate \(\xi\) of the point x. The finite element interpolation formula can afterwards be applied to evaluate the desired displacement field \((u^{fine}(x)=\sum _{i}N_i(\xi )u^{coarse}(t_i))\), where \(t_i\) are again the nodes of the tetrahedron.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Rouwane, A., Doumalin, P., Bouclier, R. et al. Architecture-Driven Digital Volume Correlation: Application to the Analysis of In-Situ Crushing of a Polyurethane Foam. Exp Mech 63, 897–913 (2023). https://doi.org/10.1007/s11340-023-00957-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-023-00957-8