Abstract

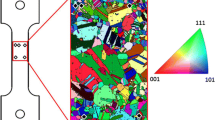

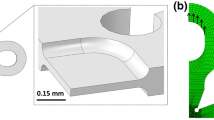

Plastic deformation and fracture of two grades of fully martensitic steel are investigated with a miniature tensile stage, a custom image acquisition algorithm and digital image correlation. The image acquisition algorithm controls the camera framing rate according to user defined load, displacement and timing thresholds. This provides a greater number of images captured during periods of rapid load change over small displacements. True stress–true strain curves reveal substantial differences in material ductility and failure behavior. Fracture surfaces are examined using scanning electron microscopy and energy dispersive spectroscopy to provide insight into differences in the tensile behaviors observed for these steels.

Similar content being viewed by others

References

Horvath CD, Fekete JR (2004) Opportunities and challenges for increased usage of advanced high strength steels in automotive applications. International Conference on Advanced High Strength Sheet Steels for Automotive Applications Proceedings, Association for Iron & Steel Technology, June, pp 3–10

Cornette D, Hourman T, Hudin O, Laurent JP, Reynaert A (2001) High strength steels for automotive safety parts. Society of Automotive Engineers 2001-01-0078, Warrendale.

Zrník J, Manuzíc I, Dobatkin SV (2006) Recent progress in high strength low carbon steels. Metallurgija 45:323–331.

Pérez R, Benito JA, Prado JM (2005) Study of the inelastic response of TRIP steels after plastic deformation. ISIJ Int 45:1925–1933. doi:10.2355/isijinternational.45.1925.

Jacques PJ, Girault E, Mertens A, Verlinden B, van Humbeek J, Delannay F (2001) The development of cold rolled TRIP-assisted multiphase steels. ISIJ Int 41:1068–1074. doi:10.2355/isijinternational.41.1068.

Chen L, Kim HS, Kim SK, De Cooman BC (2007) Localized deformation due to Portevin LeChatelier effect in 18Mn–0.6C TWIP austenitic steel. ISIJ Int 47:1804–1812. doi:10.2355/isijinternational.47.1804.

Frommeyer G, Brux U, Neumann P (2003) Supra-ductile and high strength manganese-TRIP/TWIP steels development. ISIJ Int 43:438–446. doi:10.2355/isijinternational.43.438.

Grässel O, Krüger L, Frommeyer G, Meyer LW (2000) High strength Fe–Mn–(Al,Si) TRIP/TWIP steels development—properties-application. Int J Plast 16:1391–1409. doi:10.1016/S0749-6419(00)00015-2.

Jiang Z, Guan Z, Lian J (1995) Effects of microstructural variables on the deformation behaviour of dual-phase steel. Mater Sci Eng A 190:55–64. doi:10.1016/0921-5093(94)09594-M.

Jeong BY, Gauvin R, Yue S (2002) EBSD study of martensite in a dual phase steel. Microsc Microanal 8:700–701.

Sarwar M, Priestner R (1996) Influence of ferrite-martensite microstructural morphology on tensile properties of dual-phase steel. J Mater Sci 31:2091–2095. doi:10.1007/BF00356631.

Tong W, Tao H, Jiang X, Zhang N, Marya M, Hector LG Jr, Gayden XQ (2005) Deformation and fracture of miniature tensile bars with resistance spot weld microstructures: an application of digital image correlation to dual-phase steels. Met Mat Trans A 36:2651–2669. doi:10.1007/s11661-005-0263-4.

Marya M, Wang K, Hector LG Jr, Gayden XQ (2006) Tensile-shear forces and fracture modes in single and multiple weld specimens in dual-phase steels. ASME J Manuf Sci Eng 128:287–298. doi:10.1115/1.2137751.

Long X, Khanna SK (2007) Fatigue properties and failure characterization of spot welded high strength steel sheet. Int J Fatigue 29:879–886. doi:10.1016/j.ijfatigue.2006.08.003.

Leslie WC (1981) The physical metallurgy of steels. Tech Books, Marietta.

Krauss G (2005) Steels: processing, structure and performance. ASM International, Materials Park.

Alexander WO, Davies GJ, Reynolds KA, Bradbury EJ (1985) Essential metallurgy for engineers. Van Nostrand Reinhold, United Kingdom.

Cafolla J, Hall RW, Norman DP, McGregor IJ (2003) Forming to crash simulation in full vehicle models. Proc. 4th European LS-DYNA Users Conference DYNAmore GmbH pp. E-11-17–E-11-26

Cornette D, Hourman T, Hudin O, Laurent JP, Reynaert A (2001) High strength steels for automotive safety parts. Society of Automotive Engineers 2001-01-0078, Warrendale.

Simunovic S, Shaw J, Aramayo G (2001) Steel processing effects on impact deformation of ultralight steel autobody. Society of Automotive Engineers 2001-01-1056, Warrendale.

Zeng D, Liu SD, Makam V, Shetty S, Zhang L, Zweng F (2002) Specifying steel properties and incorporating forming effects in full vehicle impact simulation. Society of Automotive Engineers 2002-01-0639, Warrendale.

Sriram S, Yan B, Huang M (2004) Characterization of press formability of advanced high-strength steels using laboratory tests. Society of Automotive Engineers 2004-01-0506, Warrendale.

Yan B, Kantner C, Zhu H, Nadkarni G, Horvath C (2005) Evaluation of crush performance of a hat section component using dual-phase and martensitic steels. Society of Automotive Engineers 2005-01-0837, Warrendale.

Savic V, Hector L Jr (2007) Tensile deformation and fracture of press hardened boron steel using digital image correlation. Society of Automotive Engineers 2007-01-0790, Warrendale, PA.

Tarigopula V, Hopperstand OS, Langseth M, Clausen AH, Hild F, Lademo OG, Eriksson M (2008) A study of large plastic deformations in dual phase steel using digital image correlation and FE analysis. Exp Mech 48:181–196. doi:10.1007/s11340-007-9066-4.

Mohr D, Oswald M (2008) A new experimental technique for the multi-axial testing of advanced high strength steel sheets. Exp Mechanics 48:65–77. doi:10.1007/s11340-007-9053-9.

Kang J, Ososkov Y, Embury JD, Wilkinson DS (2007) Digital image correlation studies for microscopic strain distribution and damage in dual phase steels. Scr Mater 56:999–1002. doi:10.1016/j.scriptamat.2007.01.031.

Hodge JM, Orehoski MA (1946) Relationship between hardenability and percentage of martensite in some low-alloy steels. Trans AIME 167:627–642.

Chait R (1972) Factors influencing the strength differential of high strength steels. Metall Mater Trans B 3:369–375.

Tong W (2004) A user’s guide to the Yale surface deformation mapping program (SDMAP), Technical Report. Department of Mechanical Engineering, Yale University, New Haven.

Smith BW, Li X, Tong W (1998) Error assessment for strain mapping by digital image correlation. Exp Tech 22:19–21. doi:10.1111/j.1747-1567.1998.tb02332.x.

Tong W, Li X (1999) Evaluation of two plastic strain mapping methods. Proc. of SEM Annual Conference on Theoretical, Experimental and Computational Mechanics, June, pp 23–26

Tong W (2005) An evaluation of digital image correlation criteria for strain mapping applications. Strain 41:167–175. doi:10.1111/j.1475-1305.2005.00227.x.

Sutton MA, McNeill SR, Jang J, Babai M (1988) Effect of subpixel image restoration on digital correlation error estimates. Opt Eng 27:870–877.

Bruck HA, McNeill SR, Sutton MA, Peters WH (1989) Digital image correlation using Newton–Raphson method of partial differential corrections. Exp Mech 29:261–267. doi:10.1007/BF02321405.

Vendroux G, Knauss WG (1998) Submicron deformation field measurements, Part 2. Improved digital image correlation. Exp Mech 38:86–91. doi:10.1007/BF02321649.

Hong T, Tong W, Zhang N, Hector LG (2005) Time-resolved strain measurements of Portevin–LeChatelier bands in aluminum using a high speed digital camera. Scr Mater 53:87–92. doi:10.1016/j.scriptamat.2005.03.020.

Hector LG Jr, Lai YH, Tong W, Lukitsch M (2007) Strain accumulation in hydrogen fuel cell membranes during a single hydration/dehydration cycle. ASME J Fuel Cell Sci Technol 4:19–28. doi:10.1115/1.2393302.

Tong W, Zhang N (2001) An experimental investigation of necking in thin sheets. Proceedings of the ASME manufacturing Engineering Division MED, 12:231–238

Acknowledgements

The authors wish to thank J. Shotts for invaluable help with DASYLab programming, W Tong for many illuminating discussions on DIC analysis, and Y. Myasnikova for expert assistance with the SEM and EDS analyses.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Savic, V., Hector Jr, L.G. & Fekete, J.R. Digital Image Correlation Study of Plastic Deformation and Fracture in Fully Martensitic Steels. Exp Mech 50, 99–110 (2010). https://doi.org/10.1007/s11340-008-9185-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-008-9185-6