Abstract

A novel Lactobacillus panis PM1 isolate was found to be capable of converting glycerol to 1,3-propanediol (1,3-PDO), an increasingly valuable commodity chemical. In this study the effects of various process parameters, including glucose and glycerol concentrations, inoculum size, temperature, aeration, pH, and carbon source were examined to determine the optimal conditions for the production of 1,3-PDO using a culture method simulating late log to early stationary phases. Inoculum size did not influence the production of 1,3-PDO, and temperature variance showed similar 1,3-PDO production between 25 and 37 °C under the examined conditions. Glycerol concentration and pH played a primary role in the final concentration of 1,3-PDO. The highest production occurred at 150–250 mM glycerol when 50 mM glucose was available. Alkaline initial conditions (pH 9–10) stimulated the production of 1,3-PDO which concurrently occurred with increased acetic acid production. Under these conditions, 213.6 mM of 1,3-PDO were produced from 300 mM glycerol (conversion efficiency was 71 %). These observations indicated that the production of 1,3-PDO was associated with the shift of the metabolic end-product ethanol to acetic acid, and that this shift resulted in an excess concentration of NADH available for the processing of glycerol to 1,3-PDO.

Similar content being viewed by others

References

Ahrens K, Menzel K, Zeng AP, Deckwer WD (1998) Kinetic, dynamic, and pathway studies of glycerol metabolism by Klebsiella pneumoniae in anaerobic continuous culture: III. Enzymes and fluxes of glycerol dissimilation and 1,3-propanediol formation. Biotech Bioeng 59:544–552

Baeza-Jimenez R, Lopez-Martinez LX, De la Cruz-Medina J, Espinosa-de-los-Monteros JJ, Garcia-Galindo HS (2011) Effect of glucose on 1,3-propanediol production by Lactobacillus reuteri. Rev Mex Ing Quim 10:39–46

Barbirato F, Soucaille P, Bories A (1996) Physiologic mechanisms involved in accumulation of 3-hydroxypropionaldehyde during fermentation of glycerol by Enterobacter agglomerans. Appl Environ Microbiol 62:4405–4409

Bauer R, du Toit M, Kossmann J (2010) Influence of environmental parameters on production of the acrolein precursor 3-hydroxypropionaldehyde by Lactobacillus reuteri DSMZ 20016 and its accumulation by wine Lactobacilli. Int J Food Microbiol 137:28–31

Biebl H, Menzel K, Zeng AP, Deckwer WD (1999) Microbial production of 1,3-propanediol. Appl Microbiol Biotechnol 52:289–297

Chen X, Xiu Z, Wang J, Zhang D, Xu P (2003) Stoichiometric analysis and experimental investigation of glycerol bioconversion to 1,3-propanediol by Klebsiella pneumoniae under microaerobic conditions. Enzyme Microbiol Technol 33:386–394

Deutscher J (2008) The mechanisms of carbon catabolite repression in bacteria. Curr Opin Microbiol 11:87–93

Doleyres Y, Beck P, Vollenweider S, Lacroix C (2005) Production of 3-hydroxypropionaldehyde using a two-step process with Lactobacillus reuteri. Appl Microbiol Biotechnol 68:467–474

Durnin G, Clomburg J, Yeates Z, Alvarez PJJ, Zygourakis K, Campbell P, Gonzalez R (2009) Understanding and harnessing the microaerobic metabolism of glycerol in Escherichia coli. Biotechnol Bioeng 103:148–161

Gonzalez R, Murarka A, Dharmadi Y, Yazdani SS (2008) A new model for the anaerobic fermentation of glycerol in enteric bacteria: Trunk and auxiliary pathways in Escherichia coli. Metabol Eng 10:234–245

Görke B, Stülke J (2008) Carbon catabolite repression in bacteria: many ways to make the most out of nutrients. Nat Rev Microbiol 6:613–624

Johnson EA, Lin EC (1987) Klebsiella pneumoniae 1,3-propanediol:NAD+ oxidoreductase. J Bacteriol 169:2050–2054

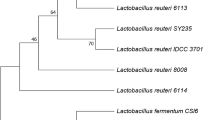

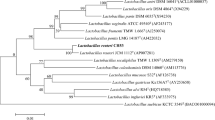

Khan NH, Kang TS, Grahame DA, Haakensen MC, Ratanapariyanuch K, Korber DR, Tanaka T (2013) Isolation and microbial characterization of novel 1,3-propanediol producing Lactobacillus panis PM1 from bioethanol thin stillage. Appl Microbiol Biotechnol 97:417–428

Kraus GA (2008) Synthetic methods for the preparation of 1,3-propanediol. Clean-Soil Air Water 36:648–651

Liu S, Skinner-Nemec KA, Leathers TD (2008) Lactobacillus buchneri strain NRRL B-30929 converts a concentrated mixture of xylose and glucose into ethanol and other products. J Ind Microbiol Biotechnol 35:75–81

Lüthi-Peng Q, Dileme FB, Puhan Z (2002) Effect of glucose on glycerol bioconversion by Lactobacillus reuteri. Appl Microbiol Biotechnol 59:289–296

Mu Y, Teng H, Zhang DJ, Wang W, Xiu ZL (2006) Microbial production of 1,3-propanediol by Klebsiella pneumoniae using crude glycerol from biodiesel preparations. Biotechnol Lett 28:1755–1759

Ratanapariyanuch K, Tyler RT, Jia Y, Shen J, Shim YY, Reaney MJT (2011) Rapid NMR method for the quantification of organic compounds in thin stillage. J Agric Food Chem 59:10454–10460

Saxena RK, Anand P, Saran S, Isar J (2009) Microbial production of 1,3-propanediol: recent developments and emerging opportunities. Biotechnol Adv 27:895–913

Snell KD, Peoples OP (2009) PHA bioplastic: a value-added coproduct for biomass biorefineries. Biofuels Bioproducts Biorefining-Biofpr 3:456–467

Talarico TL, Axelsson LT, Novotny J, Fiuzat M, Dobrogosz WJ (1990) Utilization of glycerol as a hydrogen acceptor by Lactobacillus reuteri: purification of 1,3-Propanediol-NAD+ oxidoreductase. Appl Environ Microbiol 56:943–948

Tobajas M, Mohedano AF, Casas JA, Rodriguez JJ (2009) Unstructured kinetic model for reuterin and 1,3-propanediol production by Lactobacillus reuteri from glycerol/glucose cofermentation. J Chem Technol Biotechnol 84:675–680

Vanajakshi J, Annapurna J (2011) Isolation and Identification of 1,3-propanediol producing strain of K. pneumoniae 141B from soil and optimization of process parameters. Res J Biotechnol 6:29–36

Veiga Da Cunha M, Foster MA (1992a) 1,3-Propanediol-NAD+ oxidoreductases of Lactobacillus-brevis and Lactobacillus-buchneri. Appl Environ Microbiol 58:2005–2010

Veiga Da Cunha M, Foster MA (1992b) Sugar glycerol cofermentations in lactobacilli the fate of lactate. J Bacteriol 174:1013–1019

Vollenweider S, Lacroix C (2004) 3-Hydroxypropionaldehyde: applications and perspectives of biotechnological production. Appl Microbiol Biotechnol 64:16–27

Yazdani SS, Gonzalez R (2008) Engineering Escherichia coli for the efficient conversion of glycerol to ethanol and co-products. Metabol Eng 10:340–351

Zhang J (2004) Study of poly(trimethylene terephthalate) as an engineering thermoplastics material. J Appl Polym Sci 91:1657–1666

Acknowledgments

We acknowledge the Saskatchewan Agriculture Development Fund and Agricultural Bioproducts Innovation Program of Agriculture and Agri-Food Canada for supporting this research. We thank Pound-Maker Agventures Ltd. for thin stillage samples. We are obliged to Jori Harrison for her assistance in the laboratory experiments. Ms. Sylvia Yada is also acknowledged for her careful editorial advice.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Grahame, D.A.S., Kang, T.S., Khan, N.H. et al. Alkaline conditions stimulate the production of 1,3-propanediol in Lactobacillus panis PM1 through shifting metabolic pathways. World J Microbiol Biotechnol 29, 1207–1215 (2013). https://doi.org/10.1007/s11274-013-1283-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11274-013-1283-7