Abstract

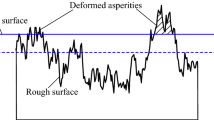

This work attempts to investigate contact between two self-affine fractal surfaces with one being of a rigid solid and other of a FCC deformable body. A normal contact model between two self-affine fractal surfaces at the nanoscale is established. Effects of surface morphology on contact force, atomic structure, dislocation with normal displacement are investigated by simulating the contact process of self-affine surfaces. Results show that the normal force for rougher surfaces at initial contact yields the larger negative extremum due to effects of surface morphology on interatomic repulsion and attraction. Furthermore, the atomic structure change proportion varies monotonically with normal displacement whereas effects of surface morphology can be approximately ignored. However, the phase transition generated by too large atomic slip leads to a non-monotonic variation between total dislocation lines length and normal displacement. Differences in contact ratio-separation dependence between the classical micro-asperity model and the established model are compared.

Graphical Abstract

Similar content being viewed by others

References

Gu, B., Shen, S., Li, H.: Mechanism of microweld formation and breakage during Cu–Cu wire bonding investigated by molecular dynamics simulation. Chin. Phys. B 31(1), 0160101 (2022). https://doi.org/10.1088/1674-1056/ac0e24

Schneider, F., Das, J., Kirsch, B., Linke, B., Aurich, J.C.: Sustainability in ultra precision and micro machining: a review. Int J Precis Eng Manuf-Green Technol 6, 601–610 (2019). https://doi.org/10.1007/s40684-019-00035-2

Zhang, Y., Li, C., Jia, D., Zhang, D., Zhang, X.: Experimental evaluation of the lubrication performance of MoS2/CNT nanofluid for minimal quantity lubrication in Ni-based alloy grinding. Int. J. Mach. Tools Manuf. 99, 19–33 (2015). https://doi.org/10.1016/j.ijmachtools.2015.09.003

Lautenschlaeger, M.P., Stephan, S., Horsch, M.T., Kirsch, B., Aurich, J.C., Hasse, H.: Effects of lubrication on friction and heat transfer in machining processes on the nanoscale: a molecular dynamics approach. Procedia CIRP 67, 296–301 (2018). https://doi.org/10.1016/j.procir.2017.12.216

Stephan, S., Lautenschlaeger, M.P., Alhafez, I.A., Horsch, M.T., Urbassek, H.M., Hasse, H.: Molecular dynamics simulation study of mechanical effects of lubrication on a nanoscale contact process. Tribol. Lett. 66, 126 (2018). https://doi.org/10.1007/s11249-018-1076-0

Yu, X., Sun, Y., Zhao, D., Wu, S.: A revised contact stiffness model of rough curved surfaces based on the length scale. Tribol. Int. 164, 107206 (2021). https://doi.org/10.1016/j.triboint.2021.107206

Liu, Z., Jiang, K., Zhang, C., Zhao, Y., Tian, Y.: A stiffness model of a joint surface with inclination based on fractal theory. Precis. Eng. 62, 47–61 (2020). https://doi.org/10.1016/j.precisioneng.2019.10.012

Hinkle, A.R., Nöhring, W.G., Leute, R., Junge, T., Pastewka, L.: The emergence of small-scale self-affine surface roughness from deformation. Science Advances. 6(7), eaax0847 (2020). https://doi.org/10.1126/sciadv.aax0847

Gu, B., Wang, W., Shen, S., Chen, Z., Ma, H.: Investigation of formation and breakage mechanism of microweld of typical wire bonding materials via molecular dynamics simulation. MRS Commun. 12, 864–872 (2022). https://doi.org/10.1557/s43579-022-00259-5

Long, Y., He, B., Cui, W., Ji, Y., Zhuang, X., Twiefel, J.: Investigations on the mechanism of microweld changes during ultrasonic wire bonding by molecular dynamics simulation. Mate. Design 192, 108718 (2020). https://doi.org/10.1016/j.matdes.2020.108718

Zhao, P., Zhao, B., Pan, J., Wu, J.: Nano-grinding process of single-crystal silicon using molecular dynamics simulation: nano-grinding parameters effect. Mater. Sci. Semicond. Process. 143, 106531 (2022). https://doi.org/10.1016/j.mssp.2022.106531

Yan, W., Komvopoulos, K.: Contact analysis of elastic-plastic fractal surfaces. J. Appl. Phys. 84(7), 3617–3624 (1998). https://doi.org/10.1063/1.368536

Komvopoulos, K., Ye, N.: Three-dimensional contact analysis of elastic-plastic layered media with fractal surface topographies. J. Tribol. 123(3), 632–640 (2001). https://doi.org/10.1115/1.1327583

Liu, M., Proudhon, H.: Finite element analysis of frictionless contact between a sinusoidal asperity and a rigid plane: elastic and initially plastic deformations. Mech. Mater. 77, 125–141 (2014). https://doi.org/10.1016/j.mechmat.2014.06.009

Liu, M., Proudhon, H.: Finite element analysis of contact deformation regimes of an elastic-power plastic hardening sinusoidal asperity. Mech. Mater. 103, 78–86 (2016). https://doi.org/10.1016/j.mechmat.2016.08.015

Jackson, R.L., Ghaednia, H., Pope, S.: A solution of rigid-perfectly plastic deep spherical indentation based on slip-line theory. Tribol. Lett. 58, 47 (2015). https://doi.org/10.1007/s11249-015-0524-3

An, B., Wang, X., Xu, Y., Jackson, R.L.: Deterministic elastic-plastic modelling of rough surface contact including spectral interpolation and comparison to theoretical models. Tribol. Int. 135, 246–258 (2019). https://doi.org/10.1016/j.triboint.2019.02.039

Megalingam, A., Mayuram, M.M.: Effect of surface parameters on finite element method based deterministic Gaussian rough surface contact model. J. Eng. Tribol. 228(12), 1358–1373 (2014). https://doi.org/10.1177/1350650114539300

Jana, T., Mitra, A., Sahoo, P.: Dynamic contact interactions of fractal surfaces. Appl. Surf. Sci. 392, 872–882 (2017). https://doi.org/10.1016/j.apsusc.2016.09.025

You, S., Tang, J., Wen, Y.: Three-dimensional elastoplastic contact analysis of rough surface considering a micro-scale effect. J. Tribol. 144(1), 011503 (2022). https://doi.org/10.1115/1.4050737

Luan, B., Robbins, M.O.: The breakdown of continuum models for mechanical contacts. Nature 435(7044), 929–932 (2005). https://doi.org/10.1038/nature03700

Luan, B., Robbins, M.O.: Contact of single asperities with varying adhesion: comparing continuum mechanics to atomistic simulations. Phys. Rev. E 74(2), 026111 (2006). https://doi.org/10.1103/PhysRevE.74.026111

Solhjoo, S., Vakis, A.I.: Single asperity nanocontacts: comparison between molecular dynamics simulations and continuum mechanics models. Comput. Mater. Sci. 99, 209–220 (2015). https://doi.org/10.1016/j.commatsci.2014.12.010

He, Y., She, D., Liu, Z., Wang, X., Zhong, L., Wang, C., Wang, G., Mao, S.X.: Atomistic observation on diffusion-mediated friction between single-asperity contacts. Nat. Mater. 21, 173–180 (2022). https://doi.org/10.1038/s41563-021-01091-3

Xie, W., Liu, C., Jiang, D., Jin, J.: Inelastic contact behaviors of nanosized single-asperity and multi-asperity on α-Fe surface: molecular dynamic simulations. Int J. Mech. Sci. 204, 106569 (2021). https://doi.org/10.1016/j.ijmecsci.2021.106569

Liu, X., Zhang, B., Wei, Y.: Interference effect on friction behavior of asperities on single crystal copper. Tribol. Int. 81, 169–178 (2015). https://doi.org/10.1016/j.triboint.2014.08.007

Spijker, P., Anciaux, G., Molinari, J.F.: Dry sliding contact between rough surfaces at the atomistic scale. Tribol. Lett. 44(2), 279–285 (2011). https://doi.org/10.1007/s11249-011-9846-y

Spijker, P., Anciaux, G., Molinari, J.F.: The effect of loading on surface roughness at the atomistic level. Comput. Mech. 50(3), 273–283 (2012). https://doi.org/10.1007/s00466-011-0574-9

Dai, Y., Lin, J., Huang, J.: Fractal contact behavior of single crystal copper substrate and rigid plane. J. Dispersion Sci. Technol. 41(10), 1504–1512 (2020). https://doi.org/10.1080/01932691.2019.1627881

Papanikolaou, M., Salonitis, K.: Fractal roughness effects on nanoscale grinding. Appl. Surf. Sci. 467–468, 309–319 (2019). https://doi.org/10.1016/j.apsusc.2018.10.144

Papanikolaou, M., Salonitis, K.: Contact stiffness effects on nanoscale high-speed grinding: a molecular dynamics approach. Appl. Surf. Sci. 493, 212–224 (2019). https://doi.org/10.1016/j.apsusc.2019.07.022

Yang, J., Komvopoulos, K.: A stress analysis method for molecular dynamics systems. Int. J. Solids Struct. 193–194, 98–105 (2020). https://doi.org/10.1016/j.ijsolstr.2020.02.003

Daw, M.S., Baskes, M.I.: Embedded-atom method: derivation and application to impurities, surfaces, and other defects in metals. Phys. Rev. B 29(12), 6443–6453 (1984). https://doi.org/10.1103/PhysRevB.29.6443

Zhou, X.W., Wadley, H.N.G., Johnson, R.A., Larson, D.J., Tabat, N., Cerezo, A., Petford-Long, A.K., Smith, G.D.W., Clifton, P.H., Martens, R.L., Kelly, T.F.: Atomic scale structure of sputtered metal multilayers. Acta Mater. 49(19), 4005–4015 (2001). https://doi.org/10.1016/S1359-6454(01)00287-7

Jones, J.E.: On the determination of molecular fields II from the equation of state of a gas. Proc. Royal Soc. A: Math., Phys. Eng. Sci. 106, 463–477 (1924). https://doi.org/10.1098/rspa.1924.0082

Rappe, A.K., Casewit, C.J., Colwell, K.S., Goddard, W.A., Skiff, W.M.: UFF, a full periodic table force field for molecular mechanics and molecular dynamics simulations. J. Am. Chem. Soc. 25(114), 10024–10035 (1992). https://doi.org/10.1021/ja00051a040

Filippova, V.P., Kunavin, S.A., Pugachev, M.: Calculation of the parameters of the Lennard-Jones potential for pairs of identical atoms based on the properties of solid substances. Inorg. Mater. Appl. Res. 6(1), 1–4 (2015). https://doi.org/10.1134/S2075113315010062

Zu, H., Dai, W., de Waele A.T.A.M.: Development of dilution refrigerators-a review. Cryogenics 121, 103390 (2022). https://doi.org/10.1016/j.cryogenics.2021.103390

Wang, J.Z., Bian, X., Li, Q., Wu, J.H.: Numerical investigation on low-temperature superconducting negative spring in magnetic levitation. J. Supercond. Novel Magn. 34, 347–355 (2021). https://doi.org/10.1007/s10948-020-05679-9

Safaeifar, H., Farshidianfar, A.: A new model of the contact force for the collision between two solid bodies. Multibody Sys.Dyn. 50, 233–257 (2020). https://doi.org/10.1007/s11044-020-09732-2

Goodman, F.O., Garcia, N.: Roles of the attractive and repulsive forces in atomic-force microscopy. Phys. Rev. B. 43(6), 4728–4731 (1991). https://doi.org/10.1103/PhysRevB.43.4728

Si, L., Wang, X.: Nano-adhesion influenced by atomic-scale asperities: a molecular dynamics simulation study. Appl. Surf. Sci. 317, 710–717 (2014). https://doi.org/10.1016/j.apsusc.2014.07.192

Stukowski, A.: Visualization and analysis of atomistic simulation data with OVITO-the open visualization tool. Model. Simul. Mater. Sci. Eng. 18, 015012 (2010). https://doi.org/10.1088/0965-0393/18/1/015012

Chen, B., Wu, W.: Molecular dynamics simulations of dynamics mechanical behavior and interfacial microstructure evolution of Ni-based single crystal superalloys under shock loading. J. Market. Res. 15, 6786–6796 (2021). https://doi.org/10.1016/j.jmrt.2021.11.116

Zheng, X., Zhu, H., Tieu, A.K., Kosasih, B.: Roughness and lubricant effect on 3D atomic asperity contact. Tribol. Lett. 53, 215–223 (2014). https://doi.org/10.1007/s11249-013-0259-y

Funding

This work was supported by the National Natural Science Foundation of China [Grant number 52105270].

Author information

Authors and Affiliations

Contributions

B.W. and Y.S. devised the study. B.W. carried out and analyzed contact mechanics calculations. Y.S. wrote the main manuscript text. All authors contributed to editing and finalizing the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

There is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix A

Appendix A

A system of two contacting rough surfaces can be considered as an equivalent system of a flat deformable surface with an effective elastic modulus E*. The effective elastic modulus E* can be written as,

where v1, v2, and E1, E2 are the Poisson’s ratios and elastic modulus of the two interacting surfaces, respectively.

In the contact analysis of fractal surfaces, the real contact area Ar depends on the contact state, which is judged according to the relationship between the critical micro contact area ac' and the largest truncated micro contact area aL'. When aL' ≤ ac', all microcontacts are in the fully plastic contact state, thus,

when aL' > ac', both elastic and fully plastic microcontacts exist at the interface, and the real contact area Ar is given by,

The critical micro contact area ac' is expressed as follows,

The largest truncated micro contact area aL' at a given mean surface separation distance d can be determined from the total truncated area S' of the equivalent rough surface, by

The total truncated area S' can be determined from numerical integration of the truncated areas of the rough surface. The material properties are listed in Table 2.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wu, B., Sun, Y. Normal Contact Analysis Between Two Self-affine Fractal Surfaces at the Nanoscale by Molecular Dynamics Simulations. Tribol Lett 71, 30 (2023). https://doi.org/10.1007/s11249-023-01705-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11249-023-01705-8