Abstract

This article describes a fundamental study using the fluorescence measurement method to understand the rheologic properties (such as viscosity and solidification) of elasto-hydrodynamic lubrication (EHL) film. The measurement principle is based upon the excimer emission of a pyrene fluorescence agent, which depends on the viscosity. To investigate the relationship between the excimer emission and viscosity, the measurements were taken under low temperature, with the results showing that the excimer emission decreased with decreasing temperature because of increasing of viscosity. No remarkable peak was observed below the temperature at which the state changed from liquid into a viscoelastic or elastic–plastic solid. The fluorescence was clearly observed in EHL film, and its spectrum revealed that the intensity of excimer emission decreases along the flow direction, with a contact area having the same behavior as that of the elastic–plastic solid at 243 K. These results suggest that the viscosity increased at the inlet of contact because of increasing hydrodynamic pressure under the wedge action and that the state in the contact region changes to solid because of high contact pressure. This study also proposes that this measurement method can be used to understand the viscosity change and solidification in the lubrication film.

Similar content being viewed by others

References

Dowson, D., Higginson, G.R.: Elasto-hydrodynamic Lubrication, The Fundamentals of Roller and Gear Lubrication. Pergamon Press, London (1966)

Cameron, A., Gohar, R.: Theoretical and experimental studies of the oil film in lubricated point contact. Proc. R. Soc. Lond. A 291, 520–536 (1966)

Foord, C.A., Wedeven, L.D., Westlake, F.J., Cameron, A.: Optical elastohydrodynamics. Proc. IMechE 184(1), 487–505 (1969–1970)

Johnston, G.J., Wayte, R., Spikes, H.A.: The measurement and study of very thin lubricant films in concentrated contacts. Tribol. Trans. 34(2), 187–194 (1991)

Gustafsson, L., Höglund, E., Marklund, O.: Measuring lubricant film thickness with image analysis. Proc. IMechE Part J J. Eng. Tribol. 208, 199–205 (1994)

Cann, P.M., Spikes, H.A., Hutchinson, J.: The development of a spacer layer imaging method (SLIM) for mapping elastohydrodynamic contacts. Tribol. Trans. 39(4), 915–921 (1996)

Hamrock, B.J., Dowson, D.: Ball Bearing Lubrication. Wiley, New York (1981)

Venner, C.H., Lubrecht, A.A.: Multilevel Methods in Lubrication, Tribology Series 37. Elsevier, Amsterdam (2000)

Spikes, H.A.: The behavior of lubricants in contacts: current understanding and future possibilities. Proc. IMechE Part J J. Eng. Tribol. 208, 3–15 (1994)

Alsaad, M., Bair, S., Sanborn, D.M., Winer, W.O.: Glass transitions in lubricants: its relation to elastohydrodynamic lubrication (EHD). Trans. ASME J. Lubr. Technol. 100, 404–417 (1978)

Ponjavic, A., di Mare, L., Wong, J.S.S.: The effect of pressure on the flow behavior of polybutene. J. Polym. Sci. Part B Polym. Phys. 52, 708–715 (2014)

ASME: A Report of the ASME Research Committee on Lubrication, Pressure Viscosity Report, vols. 1&2. ASME, New York (1953)

Alsaad, M.A., Winer, W.O., Medina, F.D., O’Shea, D.C.: Light scattering study of the glass transition in lubricants. Trans. ASME J. Lubr. Technol. 100, 418–422 (1978)

Ohno, N.: High-pressure behavior of toroidal CVT fluid for automobile. Tribol. Int. 40, 233–238 (2007)

Yasutomi, S., Bair, S., Winer, W.O.: An application of a free volume model to lubricant rheology I—dependence of viscosity on temperature and pressure. Trans. ASME J. Tribol. 106, 291–303 (1984)

Yasutomi, S., Bair, S., Winer, W.O.: An application of a free volume model to lubricant rheology 2—variation in viscosity of binary blended lubricants. Trans. ASME J. Tribol. 106, 304–312 (1984)

Ohno, N., Hattori, N., Kuwano, N., Hirano, F.: Some observations on the relationship between rheological properties of lubricants at high pressure and regimes of traction (part 1) –The rheological properties of lubricants at high pressure. J. Jpn. Soc. Lubr. Eng. 33(12), 922–928 (1988). (in Japanese)

Ohno, N., Sunahara, K., Kumamoto, T., Hirano, F.: Predictions of liquid lubricant viscosity at high pressure from the density measurements. J. Jpn. Soc. Tribol. 44(7), 560–566 (1999). (in Japanese)

Ausherman, V.K., Nagaraj, N.S., Sanborn, D.M., Winer, W.O.: Infrared temperature mapping in elastohydrodynamic lubrication. Trans. ASME J. Lubr. Technol. 98, 236–243 (1976)

Lauer, J.L., Peterkin, M.E.: Infrared emission spectra of elastohydrodynamic contacts. Trans. ASME J. Lubr. Technol. 98, 230–235 (1976)

Nagaraj, H.S., Sanborn, D.M., Winer, W.O.: Effects of load, speed, and surface roughness on sliding EHD contact temperatures. Trans. ASME J. Lubr. Technol. 99, 254–263 (1977)

Imado, K., Kido, Y., Miyagawa, H., Hirano, F.: A study of temperature rise in oil due to compression. Proc. IMechE Part J J. Eng. Tribol. 212(4), 291–299 (1998)

Yagi, K., Kyogoku, K., Nakahara, T.: Relationship between temperature distribution in EHL film and dimple formation. Trans. ASME J. Tribol. 127, 658–665 (2005)

Reddyhoff, T., Spikes, H.A., Olver, A.V.: Compression heating and cooling in elastohydrodynamic contacts. Tribol. Lett. 36, 69–80 (2009)

Cann, P.M., Spikes, H.A.: In lubro studies of lubricants in EHD contacts using FTIR absorption spectroscopy. Tribol. Trans. 34(2), 248–256 (1991)

Hoshi, Y., Shimotomai, N., Sato, M., Mori, S.: Change of concentration of additives under EHL condition—observation by micro-FTIR. J. Jpn. Soc. Tribol. 44(9), 736–743 (1999). (in Japanese)

Yagi, K., Vergne, P., Nakahara, T.: In situ pressure measurements in dimpled elastohydrodynamic sliding contacts by Raman microspectroscopy. Tribol. Int. 42, 724–730 (2009)

Kaneta, M., Nishikawa, H., Kanda, T., Matsuda, K.: Abnormal phenomena appearing in EHL contacts. Trans. ASME J. Tribol. 118, 886–892 (1996)

Cann, P.M., Spikes, H.A.: Determination of the shear stresses of lubricants in elastohydrodynamic contacts. Tribol. Trans. 32(3), 414–422 (1989)

Glovnea, R.P., Spikes, H.A.: Mapping shear stress in elastohydrodynamic contacts. Tribol. Trans. 38(4), 932–940 (1995)

Spikes, H.A., Anghel, V., Glovnea, R.: Measurement of the rheology of lubricant films within elastohydrodynamic contacts. Tribol. Lett. 17(3), 593–605 (2004)

Smart, A.E., Ford, R.A.J.: Measurement of thin liquid films by a fluorescence technique. Wear 29, 41–47 (1974)

Ford, R.A.J., Foord, C.A.: Laser based fluorescence techniques for measuring thin liquid films. Wear 51, 289–297 (1978)

Ting, L.L.: Development of a laser fluorescence technique for measuring piston ring oil film thickness. Trans. ASME J. Lubr. Technol. 102, 165–171 (1980)

Sato, Y., Toda, A., Nakamura, K., Yamamoto, Y.: Measurement of the lubricant film thickness of radial shaft seals using laser induced fluorescent method. In: Proceedings of International Tribology Conference Nagasaki 2000 (ITC Nagasaki 2000), pp. 1897–1902 (2000)

Tokunaga, Y., Hosoe, T., Inoue, H., Okada, K., Yamamoto, Y.: Measurement of film distribution by two-dimensional dynamic measuring system for mechanical seals. In: Proceedings of 19th International Conference on Fluid Sealing, pp. 221–234 (2017)

Sugimura, J., Hashimoto, M., Yamamoto, Y.: Study of elastohydrodynamic contacts with fluorescence microscope, thinning films and tribological interfaces. In: Proceedings of 26th Leeds-Lyon Symposium Tribology. Elsevier, Amsterdam, pp. 609–617 (2000)

Necas, D., Sperka, P., Vrbka, M., Krupka, I., Hartl, M.: Film thickness mapping in lubricated contacts using fluorescence. MM Sci. J. 4, 1–16 (2015). https://doi.org/10.17973/MMSJ.2015_12_201524

Reddyhoff, T., Choo, J.H., Spikes, H.A., Glovnea, R.P.: Lubricant flow in an elastohydrodynamic contact using fluorescence. Tribol. Lett. 38, 207–215 (2010)

Myant, C., Reddyhoff, T., Spikes, H.A.: Laser-induced fluorescence for film thickness mapping in pure sliding lubricated, compliant, contacts. Tribol. Int. 43, 1960–1969 (2010)

Ponjavic, A., Dench, J., Morgan, N., Wong, J.S.S.: In situ viscosity measurements of confined liquids. RSC Adv. 5, 99585–99593 (2015)

Dench, J., Morgan, N., Wong, J.S.S.: Quantitative viscosity mapping using fluorescence lifetime measurements. Tribol. Lett. 65, 25 (2017)

Seidel, H.-P., Selinger, B.K.: The effect of pressure on excimer formation. Aust. J. Chem. 18, 977–984 (1965)

Birks, J.B.: Photophysics of Aromatic Molecules, pp. 301–316. Wiley, London (1970)

Johnson, P.C., Offen, H.W.: Effect of pressure on pyrene excimer fluorescence in toluene. J. Chem. Phys. 56(4), 1638–1642 (1972)

Atkins, P., de Paula, J.: Atkins’ Physical Chemistry, 10th edn, pp. 890–891. Oxford University Press, Oxford (2014)

Cameron, A.: Principles of Lubrication, vol. 23. Wiley, New York, pp. 194 & 203–208 (1966)

Nakamura, Y., Tsunoda, M., Matsui, T., Fujishiro, I.: Laser light scattering measurement of lubricants at high pressure and evaluation of mechanical properties (4th report, evaluation of high viscosity of solidified lubricants by Rayleigh scattering and photon correlation technique). Trans. Jpn. Soc. Mech. Eng. Ser. C 65(635), 2866–2891 (1997). (in Japanese)

Acknowledgements

The authors acknowledge the financial support provided by the Mitutoyo Association for Science and Technology (MAST). The authors are grateful to Atsuyoshi Miura and Ryo Ikeda for the technical support.

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

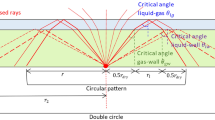

In this study, a one-dimensional Ertel-Grubin calculation is used as a simple simulation model. The calculation model is shown in Fig. 13. The calculated part is the region from the start of the lubricated zone x1 to the inlet position of the contact x2. A value of 5 mm is assumed for x1 based on the location of the outlet meniscus.

In Ertel-Grubin’s equation [47], a one-dimensional modified Reynolds equation is described by following Eq. (5), which uses a reduced pressure, p0, defined in Eq. (6). In Eq. (5), h m is an integration constant.

where

where α and U are the pressure-viscosity coefficient and rolling speed, respectively.

The film shape, h(x), is assumed to be described by Eq. (7) [47].

where RB is the equivalent radius of the ball and a is the radius of Hertzian contact under the test condition. The value measured using optical interferometry was used as h0.

The reduced pressure p0 distribution can be obtained by integrating Eq.(5), in which the boundary conditions p0 at x1 and x2 are assumed to be zero and 1/α, respectively.

where

The value of the viscosity (2.5 Pa s at 295 K [48]) and pressure-viscosity coefficient (54 GPa−1 at 295.5 K [14]) are the same as those under experimental conditions.

Finally, the pressure p and viscosity ratio, η/η0, are given by Eqs. (10) and (11).

Rights and permissions

About this article

Cite this article

Otsu, T., Imado, K. Study on Changes in the Rheologic Properties of EHL Film Using Fluorescence Measurements. Tribol Lett 66, 40 (2018). https://doi.org/10.1007/s11249-018-0983-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11249-018-0983-4