Abstract

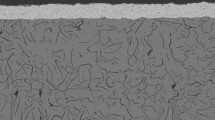

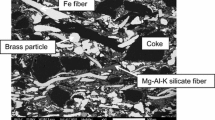

Pin-on-disc tribotesting is widely used to investigate the sliding behaviour of materials, including friction materials used in braking systems. The evaluation of the average contact temperature is paramount to understand the acting friction and wear mechanisms, and to determine the role of the materials. In the present work, the tribological behaviour of a commercial low-metallic friction material during dry sliding against a pearlitic cast iron has been investigated and the evolution of pin and disc temperature was recorded. The temperature distributions in the pin and the disc were modelled using a finite element analysis with three different approaches, i.e. considering a perfect contact, the separated bodies concept, and the presence of a third body between the sliding surfaces. The results were then discussed by considering the damaging phenomena occurring at the sliding contact. Wear was found to be nearly mild in nature in agreement with the contact temperatures that were determined to be lower than 100 °C. During sliding, a limited third body was formed, made of a partially covering friction layer on the pin surface, and a thin and irregular oxide layer on the cast iron wear track. The approach based on the perfect contact with thermal continuity at the interface was found to better fit the experimental temperature records and to be in substantial agreement with the observed wear phenomena occurring at the pin–disc interface.

Similar content being viewed by others

References

Chan, D., Stachowiak, G.W.: Review of automotive brake friction materials. Proc. Inst. Mech. Eng. D J. Automob. Eng. 218(9), 953–966 (2004)

Eriksson, M., Bergman, F., Jacobson, S.: On the nature of tribological contact in automotive brakes. Wear 252, 26–36 (2002)

Bode, K., Ostermayer, G.-P.: A comprehensive approach for the simulation of heat and heat-induced phenomena in friction materials. Wear 311, 47–56 (2014)

Sanders, P., Xu, N., Dalka, T.M., Maricq, M.M.: Airborne brake wear debris: size distributions, composition, and a comparison of dynamometer and vehicle tests. Environ. Sci. Technol. 37, 4060–4069 (2003)

Kukutschova, J., Roubicek, V., Malachova, K., Pavlickova, Z., Holusa, R., Kubackova, J., Micka, V., MacCrimmon, D., Filip, P.: Wear mechanism in automotive brake materials, wear debris and its potential environmental impact. Wear 267, 807–817 (2009)

Thorpe, A., Harrison, R.M.: Sources and properties of non-exhaust particulate matter from road traffic: a review. Sci. Total Environ. 400, 270–282 (2008)

Wahsltröm, J., Gventsadze, D., Olander, L., Kutelia, E., Gventsadze, L., Tsurtsumia, O., Olofsson, U.: A pin-on-disc investigation of novel nanoporous composite-based and conventional brake pad materials focusing on airborne wear particles. Tribol. Int. 42, 1838–1843 (2011)

Ciudin, R., Verma P.C., Gialanella, S., Straffelini, G.: Wear debris materials from brake systems: environmental and health issues. In: Proceedings of 9th International Conference on Urban Regeneration and Sustainability (The Sustainable City IX), Wit Press, Southampton, pp. 1423–1434. (2014)

Straffelini, G.: Friction and Wear, Methodologies for Design and Control. Springer, Berlin (2015)

Kennedy, F.E.: Thermal and thermomechanical effects in dry sliding. Wear 100, 453–476 (1984)

Kennedy, F.E., Lu, Y., Baker, I.: Contact temperatures and their influence on wear during pin-on-disk tribotesting. Tribol. Int. 82, 534–542 (2015)

Laraqui, N., Alilat, N., Garcia de Maria, J.M., Bairi, A.: Temperature and division of heat in a pin-on-disc frictional device-Exact analytical solution. Wear 266, 765–770 (2009)

Blok, H.: Theoretical field study of temperature rise at surfaces of actual contact under oiliness lubricating conditions. Proc. Inst. Mech. Eng. Lond. 45, 222–235 (1937)

Jaeger, J.C.: Moving surfaces of heat and the temperature at sliding surfaces. Proc. R. Soc. N.S.W. 76, 203–224 (1942)

Grzes, P.: Partition of heat in 2D finite element model of a disc brake. Acta Mech. Autom. 5, 35–41 (2011)

Nosko, O.: Partition of friction heat between sliding semispaces due to adhesion-deformational heat generation. Int. J. Heat Mass Transf. 64, 1189–1195 (2013)

Ashby, M.F., Abulawi, J., Kong, H.S.: Temperature maps for frictional heating in dry sliding. Tribol. Trans. 34, 577–587 (1991)

Day, A.: Braking of Road Vehicles. Elsevier, Amsterdam (2014)

Majcherczak, D., Dufrenoy, P., Nait-Abdelaziz, M.: Third body influence on thermal friction contact problems: application to braking. ASME J. Tribol. 127, 89–95 (2005)

Loizou, A., Qui, H.S., Day, A.J.: A fundamental study on the heat partition ratio of vehicle disk brakes. J. Heat Transf. 135, 121302-1–121302-8 (2013)

Talati, F., Jalalifar, S.: Analysis of heat conduction in a disk brake system. Heat Mass Transf. 45, 1047–1059 (2009)

Verma, P.C., Alemani, M., Gialanella S., Lutterotti, L., Olofsson, U., Straffelini, G.: Wear debris from brake system materials: a multi-analytical characterization approach. Tribol. Int. 94, 249–259 (2016)

Straffelini, G., Maines, L.: The relationship between wear of semimetallic friction materials and pearlitic cast iron in dry sliding. Wear 307, 75–80 (2013)

Mkhitarian, S.M., Shekyan, L.A., Verlinski, S.V., Aidun, D., Marzocca, P.: Stationary theory of heat-conductivity for an axi-symmetrical piece homogeneous space with circular inclusion. J. Therm. Stress. 35, 424–447 (2012)

Majcherczak, D., Dufrenoy, P., Berthier, Y., Nait-Abdelaziz, M.: Experimental thermal study of contact with third body. Wear 261, 467–478 (2006)

Lutterotti, L.: Total pattern fitting for the combined size-strain-stress-texture determination in thin film diffraction. Nucl. Instrum. Methods Phys. Res. B268, 334–340 (2010)

Lutterotti, L., Matthies, S., Wenk, H.-R.: MAUD: a friendly Java program for material analysis using diffraction. IUCr Newsl. CPD 21, 14–15 (1999)

ANSYS v. 16.0: Ansys User Manual. ANSYS, Inc., Houston (1996)

Belhocine, A., Bouchetara, M.: Thermal analysis of a solid brake disc. Appl. Therm. Eng. 32, 59–67 (2012)

Zhang, J., Xia, C.G.: Research of the transient temperature field and friction properties on disc brakes. Adv. Mater. Res. 756–759, 4331–4335 (2013)

Handbook, A.S.M.: Properties and Selection: Iron, Steels, and High-Performance Alloys, vol. 1, 10th edn. ASM Handbook, Metals Park (1990)

Valota, G., De Luca, S., Soderberg, A.: Use of FEA to clarify pin-on-disc tribometer tests of disc brake materials. In: Proceedings of Eurobrake, Dresden, Germany, 4–6 May 2015

Osterle, W., Griepentrog, M., Gross, Th, Urban, I.: Chemical and microstructural changes induced by friction and wear of brakes. Wear 251, 1469–1476 (2001)

Verma, P.C., Menapace, L., Bonfanti, A., Ciudin, R., Gialanella, S., Straffelini, G.: Braking pad–disc system: wear mechanisms and formation of wear fragments. Wear 322–323, 251–258 (2015)

Straffelini, G., Trabucco, D., Molinari, A.: Oxidative wear of heat-treated steels. Wear 250, 485–491 (2001)

Straffelini, G., Molinari, A.: Mild sliding wear of Fe-0.2%C, Ti-5%Al-4%V and Al-7072: a comparative study. Tribol. Lett. 41, 227–238 (2011)

Cho, M.H., Kim, S.J., Kim, D., Jang, H.: Effects of ingredients on tribological characteristics of a brake lining: an experimental case study. Wear 258, 1682–1687 (2005)

Acknowledgments

The research leading to these results has received funding from the European Union Seventh Framework Programme (FP-PEOPLE-2012-IAPP) under the Rebrake Project, Grant Agreement No. 324385 (www.rebrake-project.eu). The authors wish to thank Guido Perricone (Brembo S.p.A.) and Rodica Ciudin for useful discussions; Gloria Ischia and Lorena Maines for wear testing and characterization support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Straffelini, G., Verlinski, S., Verma, P.C. et al. Wear and Contact Temperature Evolution in Pin-on-Disc Tribotesting of Low-Metallic Friction Material Sliding Against Pearlitic Cast Iron. Tribol Lett 62, 36 (2016). https://doi.org/10.1007/s11249-016-0684-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11249-016-0684-9