Abstract

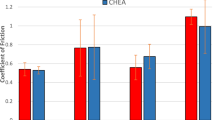

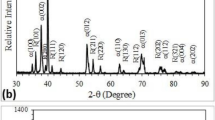

The mild sliding wear of Fe–0.2%C, Ti–6%Al–4%V and Al-7072 was investigated by means of pin-on-disc sliding tests. The applied pressure was 1 MPa and the sliding velocity was varied between 0.2 and 1 m/s. The sliding behaviour was followed by continuous measurements of the friction coefficient, pin wear and pin temperature. For the Fe alloy, wear was mixed (delamination and oxidation), and friction and wear coefficients were found to decrease with sliding velocity. The Al and Ti alloys displayed a different behaviour, characterised by the occurrence of sliding distance transitions at 0.8 and 1 m/s for the Al alloy, and at 0.4 up to 1 m/s for the Ti alloy. Before the transition, the wear coefficient of the Al alloy was very low, because of the presence of a compacted tribolayer on the sliding surface. After the transition wear was by delamination: the wear rate increased but the friction coefficient decreased. For the Ti alloy, wear occurred by oxidation and was quite high before the transition. After the transition, both the wear rate and the friction coefficient decreased, although the wear process became unstable with repeated oscillations in the friction coefficient. The results allowed us to highlight the role of flash temperature in determining the wear mechanisms of the alloys under study and the necessity of properly considering the sliding distance transitions to make reliable comparisons and obtain guidelines for safe operations.

Similar content being viewed by others

References

Archard, J.F.: Contact and rubbing of flat surfaces. J. Appl. Phys. 24, 981–988 (1953)

Hutchings, I.M.: Tribology: Friction and Wear of Engineering Materials. Edward Arnold, London (1992)

Rabinowicz, E.: Friction and Wear of Materials. Wiley, New York (1965)

Lim, S.C.: The relevance of wear-mechanism maps to mild-oxidational wear. Tribol. Int. 35, 717–723 (2002)

Quinn, T.F.J.: Oxidational wear. Wear 18, 413–419 (1971)

Quinn, T.F.J., Sullivan, J.L., Rowson, D.M.: Origins an development of oxidational wear at low ambient temperatures. Wear 94, 175–191 (1984)

Batchelor, A.W., Stachowiak, G.W., Cameron, A.: The relationship between oxide films and the wear of steels. Wear 118, 203–223 (1986)

Wilson, J.E., Stott, F.H., Wood, G.C.: The development of wear protective oxides and their influence on sliding friction. Proc. R. Soc. Lond. A. 369, 557–574 (1980)

Stott, F.H.: The role of oxidation in the wear of metals. Tribol. Int. 31, 61–71 (1998)

Sullivan, J.L., Hodgson, S.G.: A study of mild oxidational wear for conditions of low load and sliding speed. Wear 121, 95–106 (1988)

Sullivan, J.L., Atwhwal, S.S.: Mild wear of low alloy steel at temperatures up to 500°C. Tribol. Int. 16, 123–131 (1983)

Straffelini, G., Trabucco, D., Molinari, A.: Sliding wear of austenitic and austenitic–ferritic stainless steel. Metall. Mater. Trans. A 33, 613–624 (2002)

Lim, S.C., Ashby, M.F.: Wear mechanism maps. Acta Mater. 35, 1–24 (1987)

Zhang, J., Alpas, A.T.: Transition between mild and severe wear in aluminium alloys. Acta Mater. 45, 513–528 (1997)

Somi Reddy, A., Pramila Bai, B.N., Murty, K.S.S., Biswas, S.K.: Wear and seizure of binary Al–Si alloys. Wear 171, 115–127 (1994)

Razavizadeh, K., Eyre, T.S.: Oxidative wear of aluminium alloys: part II. Wear 87, 261–271 (1983)

Budinski, K.G.: Tribological properties of titanium alloys. Wear 151, 203–217 (1991)

Molinari, A., Straffelini, G., Tesi, B., Bacci, T.: Dry sliding wear mechanisms of the Ti6Al4V alloy. Wear 208, 105–112 (1997)

Shell, J., Heilmann, P., Rignay, D.A.: Friction and wear of Cu–Ni alloys. Wear 75, 205–220 (1983)

Scardi, P., Leoni, M., Straffelini, G., De Giudici, G.: Microstructure of Cu–Be alloy triboxidative wear debris. Acta Mater. 55, 2531–2538 (2007)

Chen, H., Alpas, A.T.: Sliding wear map for the magnesium alloy Mg–9Al–0.9Zn (AZ91). Wear 246, 106–116 (2000)

Wang, S.Q., Yang, Z.R., Zhao, Y.T., Wei, M.X.: Sliding wear characteristics of AZ91D alloy at ambient temperatures of 25–200°C. Tribol. Lett. 38, 39–45 (2010)

Wilson, S., Alpas, A.T.: Thermal effects on mild wear transitions in dry sliding of an aluminium alloy. Wear 225–229, 440–449 (1999)

Li, X.Y., Tandon, K.N.: Mechanical mixing induced by sliding wear of an Al–Si alloy against M2 steel. Wear 225–229, 640–648 (1999)

Rainforth, W.M., Leonard, A.J., Perrin, C., Bedolla-Jacuinde, A., Wang, Y., Jones, H., Luo, Q.: High resolution observations of friction-induced oxide and its interaction with the worn surface. Tribol. Int. 35, 731–748 (2002)

Straffelini, G., Molinari, A.: Dry sliding wear of Ti–6Al–4V alloy as influenced by the counterface and sliding conditions. Wear 236, 328–338 (1999)

Chelliah, N., Kailas, S.V.: Synergy between tribo-oxidation and stain rate response on governing the dry sliding wear behavior of titanium. Wear 266, 704–712 (2009)

Qu, J., Blau, P.J., Watkins, T.R., Cavin, O.B., Kulkarni, N.S.: Friction and wear of titanium alloys sliding against metal, polymer, and ceramic counterfaces. Wear 258, 1348–1356 (2005)

Alam, M.O., Haseeb, A.S.M.: Response of Ti–6Al–4V and Ti–24Al–11Nb alloys to dry sliding wear against hardened steel. Tribol. Int. 35, 357–362 (2002)

Amiri, M., Khonsari, M.M., Brahmeshwarkar, S.: On the relationship between wear and thermal response in sliding systems. Tribol. Lett. 38, 147–154 (2010)

Liu, Y., Asthana, R., Rohatgi, P.: A map for wear mechanisms in aluminium alloys. J. Mater. Sci. 26, 99–102 (1991)

The elaboration of the XRD-spectra by the Rietveld method has been carried out using the program ‘Maud’ developed by L. Lutterotti, http://www.ing.unitn.it/luttero/maud

So, H.: The mechanism of oxidational wear. Wear 184, 161–167 (1995)

Stachowiak, G.W., Batchelor, A.W.: Engineering Tribology, 3rd edn. Elsevier, Amsterdam (2005)

Cui, H.X., Wang, S.Q., Wang, F., Chen, K.M.: Research on oxidation wear mechanism of the cast steels. Wear 265, 468–476 (2008)

Barrau, O., Boher, C., Gras, R., Rezai-Aria, F.: Analysis of the friction and wear behaviour of hot work tool steel for forging. Wear 255, 1444–1454 (2003)

Straffelini, G., Trabucco, D., Molinari, A.: Oxidative wear of heat-treated steels. Wear 250, 485–491 (2001)

Straffelini, G.: A simplified approach to the adhesive theory of friction. Wear 249, 79–85 (2001)

Ashby, M.F., Abulawi, J., Kong, H.S.: On surface temperatures at dry sliding surfaces. Cambridge University Press, Cambridge (1990)

Asbhy, M.F.: Materials selection in mechanical design. Pergamon Press, Oxford (1993)

Coddet, C., Chaze, A.M., Beranger, G.: Measurement of the adhesion of thermal oxide films: application to the oxidation of titanium. J. Mater. Sci. 22, 2969–2974 (1987)

Gularyuz, H., Cimenoglu, H.: Oxidation of Ti–6Al–4V alloy. J. Alloys Compd. 472, 241–246 (2009)

Abdel-Aal, H.A.: On the interdependence between kinetics of friction-released thermal energy and the transition in wear mechanisms during sliding of metallic pairs. Wear 254, 884–900 (2003)

Griffiths, B.J.: Mechanisms of white layer generation with reference to machining and deformation processes. J. Tribol. 109, 525–530 (1987)

Baumann, G., Fecht, H.J., Liebelt, S.: Formation of white-etching layers on rail treads. Wear 191, 133–140 (1996)

Acknowledgement

The authors acknowledge the contribution of Eddy Sandri for the experimental testing.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Straffelini, G., Molinari, A. Mild Sliding Wear of Fe–0.2%C, Ti–6%Al–4%V and Al-7072: A Comparative Study. Tribol Lett 41, 227–238 (2011). https://doi.org/10.1007/s11249-010-9705-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11249-010-9705-2