Abstract

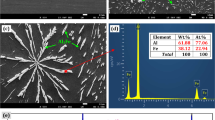

Copper–graphite composite is a tribological composite that can be used in sliding electrical contact applications requiring low friction and wear in addition to high electrical conductivity. The graphite powder (5 wt%) was mixed with the copper powder, and then composite was fabricated through powder metallurgy (P/M) route. P/M product generally requires secondary operations such as rolling, extrusion, etc. to improve their mechanical properties. Post-heat-treatment technique is also applicable to improve the properties of P/M components. Microwave-post-heat-treatment research studies are gaining momentum nowadays due to the improved quality of products with reduced time, energy, and associated cost. Microwave post-heat treatment of copper–graphite composites for different heat treating duration was carried out in a hybrid microwave heating setup. Microstructural studies were carried out using SEM with EDAX. Microwave-heat-treated samples exhibited reduced porosity, improved density, and hardness. In order to understand the friction and wear properties of microwave-heat-treated copper–graphite composites, pin-on-disk wear experiments were conducted. For comparison, untreated copper–graphite composites were also subjected to similar studies. Microwave-heat-treated samples exhibited reduced coefficient of friction and specific wear rate when compared to the untreated ones. The wear mechanism of untreated composites was observed to be plastic deformation characterized by large wear fragments, whereas the mechanism of heat-treated composite was delamination observed through peel off tribolayer.

Similar content being viewed by others

References

He, D.H., Manory, R.R.: A novel electrical contact material with improved self-lubrication for railway current collectors. Wear 249, 626–636 (2001)

Kato, H., Takama, M., Iwai, Y., Washida, K., Sasaki, Y.: Wear and mechanical properties of sintered copper-tin composites containing graphite. Wear 255, 573–578 (2003)

Cho, K.H., Hong, U.S., Lee, K.S., Jang, H.: Tribological properties and electrical signal transmission of Copper–graphite composites. Tribol. Lett. 27, 301–306 (2007)

Kestursatya, M., Kim, J.K., Rohatgi, P.K.: Wear performance of copper–graphite composite and a leaded copper alloy. Mater. Sci. Eng. A 339, 150–158 (2003)

Moustafa, S.F., El-Badry, S.A., Sanad, A.M., Kieback, B.: Friction and wear of copper–graphite composite made with Cu-coated and uncoated graphite powders. Wear 253, 699–710 (2002)

Myshkin, N.K., Konchits, V.V.: Fiction and wear of metal-graphite composite electrical contacts. Wear 158, 119–140 (1992)

Savitskiil, A.P., Zhdanoval, V.N., Girya, E.N.: The effect of sintering temperature on the strength of powder copper subjected to repeated pressing. J. Powder Metall. Metal Ceram. 3, 311–315 (1964)

Ott, R.D., Blue, C.A., Santella, M.L., Blau, P.J.: Wear of iron–aluminide intermetallic-based alloys and composites by hard particles. Wear 251, 875–884 (2001)

Thostenson, E.T., Chou, T.W.: Microwave processing: fundamentals and applications in composites. Appl. Sci. Manuf. 30, 1055–1071 (1999)

Saitou, K.: Microwave sintering of iron, cobalt, nickel, copper and stainless steel powders. Scr. Mater. 54, 875–879 (2006)

Ankelekar, R.M., Agrwal, D.K., Roy, R.: Microwave sintering and mechanical properties of PM copper steel. Powder Metall. 44, 355–362 (2001)

Gupta, M., Wong, W.L.E.: Enhancing overall mechanical performance of metallic materials using two-directional microwave assisted rapid sintering. Scr. Mater. 52, 479–483 (2005)

Ripley, E.B., Douhlas, D.M., Hallman, R.L Jr., Morrell, J.S., Oberhaus, J.A., Seals, R.D., Warren, B.C.: Current advances in microwave processing of metals and related emerging technologies: In Microwave and Radio Frequency Applications, Proceedings of the Fourth World Congress on Microwave and Radio frequency Applications, Arnold, MD, pp 302–310, 2004

Ripley, E.B., Oberhaus, J.A.: Melting and heat treating metals using microwave heating. Ind. Heat. 72, 65–69 (2005)

Holcombe, C.E., Dykes, N.L., Tiegs, T.N.: Method of nittriding,carburizing, or oxidizing refractory metal articles using microwaves. US Patent 5154779, 13 Oct 1992

Ramkumar, J., Aravindan, S., Malhotra, S.K., Krishnamurthy, R.: Enhancing the metallurgical properties of WC insert (K-20). Mater. Lett. 53, 200–204 (2002)

Aravindan, S., Krishnamurthy, R.: Joining of ceramic composites by microwave heating. Mater. Lett. 38, 245–249 (1999)

Sharma, A.K., Aravindhan, S., Krishnamurthy, R.: Microwave glazing of alumina–titania ceramic composite coatings. Mater. Lett. 50, 295–301 (2001)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rajkumar, K., Aravindan, S. Tribological Performance of Microwave-Heat-Treated Copper–Graphite Composites. Tribol Lett 37, 131–139 (2010). https://doi.org/10.1007/s11249-009-9499-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11249-009-9499-2