Abstract

Fluid blobs in an immiscible Newtonian fluid flowing in a capillary tube with varying radius show highly nonlinear behavior. We consider here a generalization of previously obtained results to blobs of non-Newtonian fluids. We compute here the yield pressure drop and the mean flow rate in two cases: (i) When a single blob is injected, (ii) When many blobs are randomly injected into the tube. We find that the capillary effects emerge from the non-uniformity of the tube radius and contribute to the threshold pressure for flow to occur. Furthermore, in the presence of many blobs the threshold value depends on the number of blobs and their relative distances which are randomly distributed. For a capillary fiber bundle of identical parallel tubes, we calculate the probability distribution of the threshold pressure and the mean flow rate. We consider two geometries: tubes of sinusoidal shape, for which we derive explicit expressions, and triangular-shaped tubes, for which we find that essential singularities are developed. We perform numerical simulations confirming our analytical results.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

In many industrial, geophysical or biological applications related to porous media, non-Newtonian fluids are frequently encountered. Indeed many complex fluids present a nonlinear rheology as, for example, slurries, heavy oils, suspensions (Barnes et al. 1989; Coussot 2005) or some biological fluids like blood (Popel and Johnson 2005; Bessonov et al. 2016). Here, we are interested in yield stress fluids, which require a minimal applied stress to flow. These fluids are involved in many practical applications, such as drilling for oil extraction, where proppant fluids are injected in the soil for the fracking process (Barbati et al. 2016), stabilization of bone fractures in biomedical engineering (Widmer Soyka et al. 2013) or ground reinforcement by cement injection. Yield stress fluid in porous media is a challenging and interesting problem which has been the subject of many studies in the last decades (Entov 1967; Park et al. 1973; Al-Fariss and Pinder 1987; Chen et al. 2005; Sochi and Blunt 2008; Talon and Bauer 2013; Rodríguez de Castro and Radilla 2017; Liu et al. 2019). Because of the presence of a yield stress, the fluid is able to flow only if a certain amount of pressure is imposed (Roux and Herrmann 1987; Chen et al. 2005; Liu et al. 2019; Fraggedakis et al. 2021). There is then a strong coupling between the rheology of the fluid and the disorder of the porous structure, implying that some regions are easier to yield than others. Above this pressure threshold, as demonstrated by several studies (Roux and Herrmann 1987; Talon and Bauer 2013; Chevalier and Talon 2015; Waisbord et al. 2019; Liu et al. 2019), a progressive increase of flowing paths occurs. As a consequence, the flow rate Q increases with the applied pressure drop \(\Delta P\) according to a power-law:

where \(\Delta P_c\) is a pressure drop threshold and \(\beta\) a characteristic exponent to be determined. The origin of this flowing regime is an effect of the disorder, but remarkably the value of the exponent \(\beta =2\) found in a recent work by Liu et al. (2019) for 2D porous media is independent from the type of disorder.

This is, however, not the case in 1D, if one describes the porous media by a series of uniform bundle of capillaries. The flow curve above the threshold depends then on the details of the opening distribution (Nash and Rees 2016).

If the flow of yield stress fluids in porous media is already a challenging problem, in many situations the complexity is increased by the presence of different immiscible fluids. Multi-phase flow in porous media is a very old and rich subject, and is still the topic of many ongoing researches. One of the main difficulties lies in the presence of numerous interfaces exerting capillary forces on the fluids present, which makes the dynamic very nonlinear. It is then surprising that, during many decades, the models predicting the mean flow rate as function of the mean applied pressure have assumed linear relations (Bear 1988; Dullien 1991).

In the last decade, however, a series of experiments and simulations (Tallakstad et al. 2009; Rassi et al. 2011; Sinha and Hansen 2012; Yiotis et al. 2013; Chevalier et al. 2015; Zhang et al. 2021) have shown the existence of a nonlinear flowing regime at low flow rate. Similarly to the yield stress fluid case, the physical reason behind this observation lies in the presence of the heterogeneity. In fact, due to capillary forces the interfaces can only move if a certain pressure is applied. In a disordered media, certain regions allow the movement of interfaces more easily than others. At very low applied pressure, the displacement of the interfaces occurs only in few pathways whose number rises with the applied pressure (Yiotis et al. 2019). This increase is then responsible for a nonlinear flow rate–pressure relationship similar to Eq. (1), where the exponent \(\beta\) has been reported to vary in the range \(\beta \in [1.5,2]\) depending on the flow condition (Tallakstad et al. 2009; Yiotis et al. 2013; Rassi et al. 2011; Sinha and Hansen 2012; Sinha et al. 2017; Yiotis et al. 2019; Zhang et al. 2021). An argument based on comparing length scales associated with the viscous forces with those set by the capillary forces gave \(\beta =2\) (Tallakstad et al. 2009). This value was also found using a mean field theory-based calculation (Sinha and Hansen 2012), whereas a calculation based on the capillary fiber bundle model gives either \(\beta =3/2\) or \(\beta =2\) depending on the statistical distribution of the flow thresholds (Roy et al. 2019). These approaches are all based on the mobilization of interfaces and can be understood for instance by considering many blobs in a single 1D pore with spatial varying opening. In this case, there exists a minimal pressure threshold to initiate the flow. Above, the flow rate increases with a power-law as Eq. (1), similarly to a Herschel–Bulkley yield stress fluid with index \(n=1/\beta\). Aursjø et al. (2014) found the values \(\beta = 1.49\) and 1.35 for a two-dimensional porous model where transport of one of the fluids occurs entirely through film flow, depending on the fractional flow rate.

In this work, we aim to investigate two-phase flows, but in the case where one of the two fluids presents a yield threshold. The situation is then more complex as both the rheology and the surface tension lead to a threshold pressure to initiate the flow. For simplification, we propose to model a porous medium by a set of identical capillaries with varying opening (i.e., the capillary fiber bundle model, see Scheidegger (1953, 1974)). The first question we want to address is the determination of the pressure threshold depending on the rheology, the surface tension and the disorder of the capillaries. The second question is then to determine the flow curve just above this threshold. We will show that the flow rate follows a power law, and we will determine the exponent depending the structure disorder.

For a Newtonian fluid in a cylindrical capillary tube, neglecting inertia, the volumetric flow rate, q, is expected to grow linearly with the pressure gradient \(\Delta P/ l\). Here, \(\Delta P = P_\mathrm{{in}} - P_\mathrm{{out}}\) is the pressure difference applied to the edges of a tube of length l (in the following we assume \(\Delta P>0\) for simplicity). This behavior is given by the celebrated Poiseuille law \(q=\pi r_0^4 \Delta P/ (8 \mu l)\), where \(\mu\) is the fluid viscosity and \(r_0\) the tube radius. However, non-Newtonian yield stress fluids display a nonlinear response. Their rheology can be modeled by the Herschel–Bulkley constitutive equation (Bird 1976), that gives a relation between the shear stress \(\tau\) applied to the fluid and the shear rate \({\dot{\gamma }}\)

The constant k is the consistency, the exponent \(n>0\) is the flow index, and \(\tau _y\) is the yield stress. In this case, the flow in the tube occurs only above a yield pressure drop \(\Delta P_c\), and the flow rate grows with pressure in a nonlinear way. For example, for a perfect cylindrical tube filled with a non-Newtonian yield stress fluid, the yield pressure is \(\Delta P_c = 2\tau _y l/r_0\) and the flow law (Bird et al. 1987):

here \(C_0 =n \pi /( (n+1)2^{1+1/n} k^{1/n}\tau _y)\), \(C_{\infty } = n \pi / ((3n +1)(2k)^{1/n})\) and \(\Delta {\widetilde{P}}_c = ((3n+1)/(2n+1)) \Delta P_c\) is a pseudo critical pressure (see Talon et al. (2014); Bauer et al. (2019)).

2 Model for a Single Blob

2.1 Uniform Tube

We now consider the case of a cylindrical tube with constant radius filled with a Newtonian liquid, in which one small blob of yield stress fluid (YSF) is injected, as pictured in Fig. 1.

We assume the fluids to be immiscible and incompressible. The blob, of size \(\Delta x_b \ll l\) and position \(x_b\), is at the origin of a critical yield pressure \(\Delta P_c= P_y^0 = 2\tau _y \Delta x_b/r_0\). The total pressure drop \(\Delta P\) needed to sustain a flow rate q can be expressed as the sum of the pressure drops across every portion of fluid. We call \(P_{x_b}^-\) and \(P_{x_b}^+\), respectively, the pressure value just before and just after the left surface separating the Newtonian fluid from the blob (positioned at \(x_b\)), while \(P_{x_b + \Delta x_b}^-\) and \(P_{x_b + \Delta x_b}^+\) will be, respectively, the pressure just before and just after the right surface (positioned at \(x_b + \Delta x_b\)). The pressure drops across both portions of Newtonian fluid, in the intervals \(0< x < x_b\) and \(x_b+\Delta x_b< x < l\), are given by the Poiseuille law

The pressure drop across the blob is instead given by Eq. (3) and writes

Moreover, when two immiscible fluids are in contact, at the interface emerges a discontinuity in pressure, called capillary pressure, whose sign depends on the curvature of the interface (Bear 1988). Hence, in a perfect cylindrical tube, the total capillary pressure across the two interfaces of a blob cancels out since at each interface the capillary pressure discontinuity is \(2\sigma /r_0\) (\(\sigma\) being the surface tension between the two fluids)Footnote 1, but the signs of the two contributions are opposite as the two interfaces have opposite curvature.

The sum of the three pressure drops given in Eqs. (4) and (5) in the limit \(\Delta P \gtrsim \Delta P_{c}\) is then

In this limit, the flow vanishes to 0, so we can neglect the linear term in Eq. (6) as \(n/(n+1) < 1\ \forall \ n > 0\).

In the opposite limit \(\Delta P\gg \Delta P_c\), we have

Since now \(q\rightarrow \infty\), we should distinguish between a shear-thinning fluid and a shear-thickening fluid, for which \(n<1\) and \(n>1\), respectively. In the first case, the leading term is the one proportional to \(q^n\), while in the other case the leading term is the linear one. Finally, we can write the volumetric flow rate in the two different limits:

2.2 Non-Uniform Tube

We consider now a tube still of length l, but with varying radius r(x) (see Fig. 2) described by the following equation

where \(f(x/r_0)\) is a bounded function with zero average in the interval \(x/r_0\in [0,l/r_0]\), \(a \ll 1\) a dimensionless constant and \(r_0\) a characteristic radius.

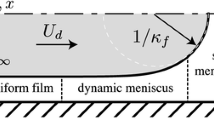

Two-dimensional sketch of a blob of yield stress fluid in a non-uniform tube. On the x-axis, the one-dimensional model relative to the problem is pictured, where the thick line is the projection along x of the yield stress blob, while the thin line represents the part occupied by the Newtonian fluid

In this work, we will assume that the radius varies slowly enough that the radial component of the fluid velocity can be neglected compared to the axial component \(f' \ll 1\). The size of the blob \(\Delta x_b\) can also be considered constant along the tube. This hypothesis, also named lubrication approximation, is usually used in heterogeneous tube or fracture (Brown 1987) as it allows to determine the flow rate as function of the local gradient of pressure (Happel and Brenner 1983).

For Newtonian fluids, this approximation holds for a sufficiently slow variation of the radius (Happel and Brenner 1983; Malevich et al. 2006). For yield stress fluid, a mathematical criterion of application remains an open question. This approximation has, however, been successfully applied in many pore network models for Newtonian and non-Newtonian fluids (for example: Lopez et al. (2003); Balhoff and Thompson (2004); Sochi and Blunt (2008)).

Indeed, this approximation allows to determine a general relationship between pressure drop and flow rate. Even when the condition of applicability is not full-filled, the deviation to the lubrication prediction can then be circumvented by introducing an effective hydraulic radius ( Dullien (1991)). For yield stress fluids, the lubrication approximation is more complicated (see Frigaard and Ryan (2004)). For example, Roustaei et al. (2016) study the flow-pressure relationship for Bingham fluid in different heterogeneous fractures. The flow-pressure relationship is affected by two other mechanisms. First, the lubrication approximation predicts an unyielded plug in the center that breaks when the variation in opening is too large. More important is the presence of a unyielded “fouling” layer at the wall. Interestingly, this layer tends to smooth out the effect of the heterogeneity of the opening. As in the Newtonian case, it follows that even if the lubrication approximation does not hold, the flow-pressure relationship can be approximated by an equation like Eq. (3) providing the introduction of an equivalent radius distribution.

2.2.1 Analytic Radius Variability

Let us assume \(f(x/r_0)\) to be analytic in \(x\in [0,l]\). Two modifications should be included with respect to the uniform case. First, the capillary pressure across the blob interfaces does not cancel anymore (Sinha et al. 2013). Since \(P_{x_b}^- - P_{x_b}^+ = 2 \sigma /r(x_b)\) and \(P_{x_b + \Delta x_b}^{+} - P_{x_b + \Delta x_b}^{-} = 2 \sigma /r(x_b + \Delta x_b)\), their difference is in general nonzero and approximately equal to

with \(P_\sigma = 2 \sigma /r_0\) and \(f'(x_b /r_0)\) the derivative of f at \(x_b\). Secondly, as r(x) is non-constant, both Poiseuille law and Eq. (3) can be considered valid only along infinitesimal intervals of length dx. For both reasons, the flow rate varies in time as a function of the blob location \(x_b\). The Poiseuille equation becomes \(q(x_b) =-\pi r(x)^4 (dP/dx)/(8\mu )\) from which, integrating along both portions of Newtonian fluids, at the first order of a we get:

Considering the limit \(\Delta P \rightarrow \Delta P_c^+\), Eq. (3) becomes instead \(q(x_b) = C_0\, r(x)^{4+\frac{1}{n}}\left( dP/dx - 2\tau _y/r(x) \right) ^{\frac{1}{n} + 1}\), which, integrated along the blob interval, gives:

where \(P_y^0= 2 \tau _y \Delta x_b / r_0\). Note that we approximated the integral:

because the correction only affects the prefactor of the flow curve, and not the exponent or the threshold. Since in this limit \(q(x_b) \ll 1\), the leading behavior of the flow curve can be written as:

where we have defined the function:

From Eq. (14), we note that in a deformed tube the critical pressure drop \(\Delta P_y\) above which flow is possible has increased with respect to the cylindrical tube, and is equal to the maximum of \(\gamma (x_b)\):

we denote \(x_m\) the position of such maximum along the tube. Three terms contribute to the critical pressure. The first constant one is due to the yield threshold. The second is also due to the yield stress, but depends on the tube shape. The last one, related to the capillary force, is based on the derivative of f. The competition between the last two terms is then governed by the ratio between the relative derivative \(f/f'\) and the dimensionless number \(\frac{P_\sigma \Delta x_b}{P_y^0 r_0} = \frac{\sigma }{r_0 \tau _y}\).

The blob position moves as \(dx_b/dt = q/(\pi r_0^2)\); hence from Eq. (14), we get the equation of motion

The time T needed for the blob to move from one end of the tube to the other can be computed from (18):

In general, \(\gamma (x_b/r_0)\) relies on the specific form of \(f(x_b/r_0)\). However, supposing that \(f(x_b/r_0)\) is analytical, we can expand \(\gamma (x_b/r_0)\) around \(x_m\): \(\gamma (x_b/r_0) = \Delta P_c - \alpha (x_b-x_m)^2 + \dots\)

For \(\Delta P \rightarrow \Delta P_c^+\), the dominant contribution to the integral of Eq. (19) is around \(x_m\), so we can write

The flux averaged over the time T, \(\langle q \rangle _T\) is then

Note that close to the yield threshold \(\Delta P_c\), the power-law exponent \(1/n+1/2\) of the flow rate turns out to be different from \(1+1/n\) in Eq. (8) for the uniform tube.

On the other hand, in the opposite limit \(\Delta P\gg \Delta P_c\), since the fluctuations along the critical pressure are negligible, we expect the same behavior of the cylindrical tube.

2.2.2 Non-Analytic Radius Variability

As a final remark, we discuss the case where \(f(x_b/r_0)\) is not analytic. In the framework of the fiber bundle model, capillary tubes presenting non-analytic points allow to model porous materials presenting a rough and angular micro-structure, e.g., matrices of randomly packed grains of quartz sand (Xiong et al. 2019). The nonlinear prediction of Eq. (21) hold only if \(\gamma (x_b/r_0)\) is derivable at least twice. Otherwise, its expansion around \(x_m\) is of the form: \(\gamma (x_b) = \Delta P_c + \alpha |x_b-x_m|^\delta + \dots\), with \(\delta > 0\). In this case, the behavior of the integral in Eq. (20) is modified and the flux averaged over T is then

To provide a concrete example, we consider a sawtooth triangular geometry:

A sketch of such geometry is shown in Fig. 3.

In this case, we have

Its maximum is located at the discontinuity point \(x_m=l\) and writes

Integrating Eq. (19) yields to \(\delta =1\) if the blob fluid presents yield stress, while \(\langle q \rangle _T \propto ( \Delta P - \Delta P_c)^{\frac{1}{n}+1}\) in the absence of yield stress (\(P_y^0 = 0\)).

3 Model for Many Blobs

In a uniform tube, the flow curve obtained when a single shot of non-Newtonian fluid is injected is identical to the one obtained when the same amount of fluid is split in N small blobs. This is not the case for a non-uniform tube. To be concrete, we address the case of several identical blobs of non-Newtonian fluid (see Fig. 4).

Two-dimensional sketch of several blobs of yield stress fluid in a non-uniform tube of length l. On the x-axis, the one-dimensional model relative to the problem is pictured, where the thick line is the projection along x of the yield stress blobs, while the thin line represents the part occupied by the Newtonian fluid

It comes out that the critical pressure obtained with N blobs of length \(\Delta x_b\) is larger than \(N P_y^0= 2 N \Delta x_b \, \tau _y /r_0\), the value expected for a single shot of length equal to \(N \Delta x_b\). The difference depends on the total number of blobs and on the specific blob configuration.

During the flow, the relative distances between different blobs remain constant as the fluids are incompressible. Moreover, periodic boundary conditions are set, namely \(f(x/r_0)=f\left( \frac{x+l}{r_0}\right)\). This assumption can describe two different situations: (i) a tube of length l with periodic boundary conditions (ii) a tube of length \(L\gg l\) presenting a periodic deformation of spatial period l. In the latter case, the blobs are in general located on different periods, but it is convenient to shift their position in the first period: more precisely, if a blob is located at a certain position in the k-th period, the dynamics of the system does not change if we subtract the quantity \((k-1)l\) from that position. We then denote with \(x_b\) the position of the most left blob and with \(x_i\) the distance from its i-th blob neighbor. Thus \(i=1,\ldots , N-1\), and the i-th right neighbor is located at \(x_b + x_i\). When \(x_b\) moves from 0 to l all the other blobs move exactly one period.

In the limit of small flow rate \(q \rightarrow 0\), the pressure drop at the edges of the i-th blob is

At this, one must add the capillary pressure drop \(a P_{\sigma } \frac{\Delta x_b}{r_0} f'(\frac{x_b+x_i}{r_0})\). Summing the contributions of all the N blobs and neglecting the pressure drop induced by the Newtonian fluid, we obtain the following flow rate equation, that depends not only on the variable \(x_b\), but also on the set of constant values \(\{x_i\}\):

with

where the function

and \(F'(y;\{ \frac{x_i}{r_0}\})\) is the first derivative of \(F(y;\{ \frac{x_i}{r_0}\})\) with respect to y. The critical pressure \(\Delta P_c\) needed for the system to flow is then given by the maximum of \(\gamma ( \frac{x_b}{r_0},\{ \frac{x_i}{r_0}\})\) in the interval \(0<x_b<l\):

From Eq. (29), we can see that the value of the critical pressure relies thus not only on the number of blobs, but also on the specific configuration of the blobs position along the tube, namely on their distances \(\{x_i\}\).

Since there is no preferred position of the blobs along the tube, the most important configuration is the one where the positions of the blobs are uniformly (evenly) distributed. In the diluted limit where \(N \Delta x_b\) is very small compared to the tube length, the position of every blob shifted in the first period is uniformly distributed in the interval (0, l). Our first goal is to compute the probability distribution function of the critical pressure, \(\Pi (\Delta P_c)\), associated to such ensemble.

The second goal is to characterize the flow rate. Again the flow of a given tube averaged over a period, \(\langle q \rangle _T = \langle q(\{x_i\}) \rangle _T\), depends on its specific blobs configuration, and thus on its pressure threshold value \(\Delta P_c = \Delta P_c(\{x_i\})\). For \(\Delta P \rightarrow \Delta P_c^+\):

and thus \(\langle q\rangle _T \propto (\Delta P - \Delta P_c)^{1/n + 1/2}\) if the tube modulation is analytical, or, more generally, \(\langle q \rangle _T \propto (\Delta P - \Delta P_c)^{1/n + 1 - 1/\delta }\).

Once these two quantities are obtained, we can calculate the flow rate in a fiber bundle model (Roy et al. 2019), in which the same pressure drop \(\Delta P\) is applied to many tubes which are identically shaped. Each tube is assumed to be filled with a Newtonian liquid together with N blobs injected at random positions along the tube, as pictured in Fig. 5. In the limit of many tubes, the mean flow rate averaged over a period is obtained by averaging over all possible configurations of the blobs positions (Fig. 6). We will call it \(\overline{\langle q \rangle _T}\), where the overline denotes the average over the blob configurations.

For \(\Delta P\) slightly greater than \(N P_y^0\), we expect that the flow rate of every tube of the fiber bundle follows the small flow power-law exponent \(1/n + 1 - 1/\delta\) if the pressure drop applied is greater than the pressure threshold of that tube, namely \(\Delta P > \Delta P_c\), or is null if on the contrary \(\Delta P \le \Delta P_c\). Instead, we have tubes in the large flow limit, whose flow rate is described by the second case of Eq. (8), only if \(\Delta P\) is sufficiently greater than \({{\widetilde{\Delta }}} P_c = ((3n+1)/(2n+1))N P_y^0\). Since \(N P_y^0< \Delta {\widetilde{P}}_c < (3/2) N P_y^0\) for all \(n>0\), there is always a finite range of values of \(\Delta P\) for which all tubes in the bundle presenting non-null flow obey to the small flow regime. Moreover, \(\Delta P_c \ge NP_y^0\) but is typically much lower than \(\Delta {\widetilde{P}}_c\), because the fluctuations on the value of \(\Delta P_c\) are smaller than the difference between \(NP_y^0\) and \(\Delta {\widetilde{P}}_c\). The effects on the mean flow rate caused by the non-uniformity of the tubes can then be seen only if \(\Delta P\) is sufficiently close to \(N P_y^0\). In this limit, we can compute the mean flow rate per tube as

3.1 Sinusoidal Geometry

In this section, we study the case

It is useful to introduce the angle variables \(\theta _b = 2\pi \frac{ x_b}{l}\) and \(\theta _i = 2\pi \frac{ x_i}{l}\). Using the trigonometric relations, we can write

where the amplitude is

and the phase shift \(\phi = \arcsin \left( \sqrt{N} \sum _{i=1}^{N-1} \sin \theta _i/A \right)\). Similarly, we obtain \(F'(\theta _b) = - (2\pi /l)\sqrt{N} A\sin (\theta _b + \phi )\). So \(\gamma (\theta _b,\{\theta _i\})\) can be written as a cosine function

where

and \(\varphi = -\arccos \left( P_0^y/P_{\gamma }\right)\), from which it’s easy to see that the pressure threshold is

We now discuss three different possible cases related to different configurations of the blobs positions:

-

Each blob is separated from its nearest neighbors by a distance equal to the spatial period l, namely \(\theta _i = 0\ \forall \ i\). This implies that \(A = \sqrt{N}\), and \(\Delta P_c\) reaches the highest possible value

$$\begin{aligned} \Delta P_c = N\left( P_y^0 + P_{\gamma }\right) \end{aligned}$$(40) -

Each blob is separated from its nearest neighbors by half of the spatial period l/2, so \(\theta _i = \pi\) for i odd and \(\theta _i = 2 \pi\) for i even. It follows that \(A = 0\) if N is even, or \(A = 1\) if N is odd, and \(\Delta P_c\) takes the lowest possible value

$$\begin{aligned} \Delta P_c = {\left\{ \begin{array}{ll} NP^0_{y}&\quad \text {if}\; N\;\text{even}\\ NP^0_{y} + P_{\gamma}&\quad \text{if}\; N\;\text{odd} \end{array}\right. } \end{aligned}$$(41) -

The position of every blob is uniformly distributed along the tube. This is equivalent to suppose that all the \(N-1\) angular differences \(\theta _i\) are uniformly distributed in the interval \([0,2\pi ]\). In the limit of N sufficiently large, A follows, in the interval \([0,+\infty [\), the probability distribution

$$\begin{aligned} \Pi (A) = 2A\,e^{-A^2}. \end{aligned}$$(42)

Probability distribution of the amplitude A defined in Eq. (34). Blue dots represent the histogram of \(10^6\) numerical samplings of A, each obtained generating \(N = 1000\) values of \(\theta _i\) uniformly distributed in \((0,2\pi )\); the samplings are collected in 50 bins of equal size in the domain [0, 4]. The solid line is the analytical prediction given by Eq. (42)

In order to prove Eq. (42), we first calculate the probability distribution of the variable \(B = N A^2\):

To solve (43), it is convenient to perform a Laplace transform:

We define \(m_x = \sum _{i=1}^{N-1} \cos \theta _i\) and \(m_y = \sum _{i=1}^{N-1} \sin \theta _i\). Note that the average and the variance of both \(\cos \theta _i\) and \(\sin \theta _i\) in the interval \([0,2\pi ]\), are, respectively, 0 and 1/2. Moreover, their crossed integral (the covariance) in the same interval is zero, meaning that \(m_x\) and \(m_y\) are statistical independent. According to the central limit theorem, when \(N-1\simeq N\) is sufficiently large, the distribution of both \(m_x\) and \(m_y\) is Gaussian with mean zero and variance N/2. Equation (44) can be rewritten as

The inverse Laplace transform leads to \(g(B) = \exp {(-B/N)}/N\), from which Eq. (42) follows directly.

From \(\Pi (A)\), we get the distribution of \(\Delta P_c\) in the interval \([NP^0_y,+\infty [\):

The mean flow rate per tube is finally obtained from (31) and using \(\Delta P \rightarrow (NP_y^0)^+\) in Eq. (46)

3.2 Beyond the Sinusoidal Geometry: The Triangular Saw Tooth Shape

In the previous section, we computed explicitly the distribution of critical threshold (see Eq. (46)) for a tube tube with a sinusoidal deformation and random located identical blobs. In particular it comes out that the distribution vanishes linearly at \(N P_y^0\). How general is this result?

We can prove that the result is still robust if the N blobs have slightly different sizes (see Appendix 1). However, in this section we show that the shape of the distribution is very sensitive to the analytical properties of f(x). As an important example, we discuss in detail the triangular saw tooth shape introduced in Eq. (23), and we first focus on the fully Newtonian case (for which \(\tau _y=0\)), and then on the non-Newtonian blobs case but where capillarity effects can be neglected (for which \(\sigma =0\)).

3.2.1 Blobs of Newtonian Fluid

If the tube is non-uniform, even Newtonian blobs lead to a critical pressure \(\Delta P_c\), due to the capillary pressure drop at the interface. The value of \(\Delta P_c\) corresponds to the global maximum, in the interval \(0\le x_b<l\), of the function \(\gamma (x_b/r_0)\), expressed by Eq. (27), with \(P_y^0 = 0\), namely

where

and \(P_{\gamma } = (4 r_0/l) a P_{\sigma }\Delta x_b\). We remind that \(F'(y;\{ \frac{x_i}{r_0}\})\) is the first derivative of Eq. (28) with respect to y, and can be seen as the sum of N contributions. For the triangular saw tooth shape, there is a contribution \(-4 r_0/l\) for every blob located in the semi-period interval [0, l/2] and \(+4 r_0/l\) for every blob in the other semi-period [l/2, l]. When \(x_b\) moves from 0 to l, all the blobs are shifted of the same quantity. The function \(\gamma (\frac{x_b}{r_0};\{ \frac{x_i}{r_0}\})\) remains constant until one of the two facts occurs: either the most right blob belonging to the first semi-period enters the second, so that the function \(\gamma\) increases by \(2P_{\gamma }\), or the last blob belonging to the second semi-period enters the first, so that \(\gamma\) decreases by \(-2P_{\gamma }\). A sketch of this procedure is shown in Fig. 7.

Sketch of several blobs in a tube presenting the triangular modulation given by Eq. (23)

Increasing \(x_b\) further, other jumps occur for every blob entering in a new semi-period. \(\gamma\) corresponds then to a 1-dimensional simple random walk (Weiss 1996), a process in which, for each of the N steps corresponding to the N blobs, \(\gamma\) will perform a stepwise increment of \(\pm 2P_{\gamma }\). Since the probability for a blob to be in the first or second semi-period is the same, \(\gamma\) can increase by \(2P_{\gamma }\) or \(-2P_{\gamma }\) with equal probability, so this random walk is symmetric with a diffusion coefficient of \(D = 2 P^2_{\gamma }\). Moreover, due to the periodicity of the system, this random walk is periodical of period l. A typical trajectory is shown in Fig. 8.

The random walk displays the symmetry \(\gamma \left( \frac{x_b}{r_0};\{ \frac{x_i}{x_0}\}\right) =-\gamma \left( \frac{l/2+x_b}{r_0};\left\{ \frac{x_i}{x_0}\right\} \right)\) and can be decomposed into two Brownian bridges with mirror symmetry, namely two Brownian processes constraint to both start and end at 0 and with opposite sign (Fig. 9). If we denote the two processes \(z_1(i)\) and \(z_2(i)\), they evolve from \(i=0\), in which \(z_1(0)=z_2(0)=0\), to \(i=N\), in which \(z_1(N)=z_2(N)=0\); the two bridges are identical but opposite in sign, namely \(z_1(i)=-z_2(i)\). As a consequence, Eq. (49) can be written as

The exact calculation of the distribution of A can be done using the methods discussed in Mori et al. (2020) for Brownian bridges. However, the statistical behavior of \(\max _{0<i\le N}\left| z_1(i)\right|\) should be similar to the one of the span S of the process, defined as \(S =\max _{0<i\le N}(z_1) -\min _{0<i\le N} (z_1)\). For the span, rigorous results are proven not only for the Brownian motion but for Gaussian processes with generic Hurst exponent H (the Brownian motion corresponds to \(H=1/2\)). In particular, the probability to have a small span \(\varepsilon\) is known to vanish singularly as

where k is a numerical prefactor of order one (Dean et al. 2014). From Eq. (51), we can infer that the probability distribution of A vanishes as

The presence of an essential singularity at the origin indicates that the tubes with small critical pressure are extremely rare. From (52), it follows that the probability distribution of \(\Delta P_c\) goes as

From Eq. (31), we then find that, in the limit of small \(\Delta P\), the mean flow rate per tube vanishes exponentially as

Distribution of A for a train of blobs of Newtonian fluid in a triangular tube. Blue dots represent the histogram of \(10^7\) numerical samplings of A, each obtained generating \(N = 1000\) values of blob positions and calculating (49); the samplings are collected in 100 bins of equal size in the domain \(\left[ 0, 200/\sqrt{N}\right]\). The dashed curve is the probability distribution (42) valid for a sinusoidal tube. In the inset, the numerical data \((A^{-2}, \Pi (A))\) are compared to the asymptotic trend of Eq. (52) setting \(k\simeq 3.2\)

3.2.2 Blobs of Yield Stress Fluid Without Capillary Effects

The same approach allows to solve the case of blobs of non-Newtonian fluid for which we neglect capillary effects. The value of \(\Delta P_c\) corresponds to the maximum, in the interval \(0<x_b<l\), of (27) with \(P_\sigma = 0\), namely

where

and \(P_{\gamma } = a P_{y}^0\). Here, \(F\left( \frac{x_b}{r_0},\left\{ \frac{x_i}{r_0}\right\} \right)\) is the integral of the random walk discussed in the Newtonian case. A typical trajectory is shown in Fig. 10 and corresponds to the trajectory of a random acceleration process (RAP) (Burkhardt 2007), a piecewise linear function where the slope performs a Random walk; in particular, this Gaussian process represents the integral of a Brownian bridge, and is characterized by \(H=3/2\).

The methods discussed in Majumdar et al. (2010) may be a starting point for deriving an exact form for the distribution of the maximum of a RAP. However, following the lines of the previous discussion, we expect that the distribution of A vanishes at 0 as

\(k^*\) is a numerical prefactor different from k. It follows that the distribution of the critical pressure vanishes at \(N P_y^0\) as

For \(\Delta P \gtrsim NP_y^0\), the mean flow rate per tube scales now as

As a final remark we note that, as \(H \rightarrow +\infty\) the function \(\gamma \left( \frac{x_b}{r_0}, \left\{ \frac{x_i}{r_0}\right\} \right)\) becomes smoother in \(x_b\) and the critical pressure distribution remains singular, but at a higher order of derivative (Fig. 11). The linear behavior in the limit \(\Delta P_c \rightarrow 0\) found for the sinusoidal case represents then the most regular behavior we can expect.

Distribution of A for a train of blobs of yield stress fluid in a triangular tube neglecting capillary effects. Blue dots represent the histogram of \(10^7\) numerical samplings of A, each obtained generating \(N = 1000\) values of blob positions and calculating (56); the samplings are collected in 100 bins of equal size in the domain \(\left[ 0, 100/\sqrt{N}\right]\). The dashed curve is the probability distribution (42) valid for a sinusoidal tube. In the inset, the numerical data \((A^{-2}, \Pi (A))\) are compared to the asymptotic trend of Eq. (57) setting \(k^*\simeq 1.2\)

4 Conclusion

In this paper, we studied the flow rate curve in tubes filled with a Newtonian fluid and where blobs of non-Newtonian (or Newtonian) fluid are injected.

One blob. When a single blob is injected, we found a yield pressure threshold \(\Delta P_c\) below which there is no flow. Above this threshold, the flow Q is strongly nonlinear and grows with a characteristic exponent:

The value of the threshold for the uniform tube of radius \(r_0\) is: \(\Delta P_c = P_{y}^0 = 2\tau _y \Delta x_b /r_0\), where \(\tau _y\) is the yield stress of the non-Newtonian blob of size \(\Delta x_b\). For a non-uniform tube of radius \(r(x) = r_0/\!\left( 1 + a f(x/r_0)\right)\), the value of the threshold is modified:

where the value of \(P_\gamma\) depends on the geometry of the tube. The exponent \(\beta\) depends on both the rheology and the geometry of the tube. Its value has been summarized in Table 1.

Concerning \(P_{\gamma }\), we show that in general:

where \(P_{\sigma }\) is the contribution of the surface tension, and l is the length of the tube. Two special cases have been studied.

-

Sinusoidal deformation, \(f(x/r_0) = \cos {(2 \pi x/l)}\):

$$\begin{aligned} \begin{aligned} P_{\gamma }&= a\sqrt{\left( P_y^0\right) ^2 + \left( 2 \pi P_{\sigma }\Delta x_b/l\right) ^2}\\&= a P_y^0 \sqrt{1 + \left( \frac{2 \pi \sigma }{\tau _y l} \right) ^2} \end{aligned} \end{aligned}$$(63)In this case, the function \(\gamma (x/r_0)\) is regular around the maximum, so that \(\beta = 1/2\) for the Newtonian case and \(\beta = 1/2 + 1/n\) for the non-Newtonian one.

-

Triangular deformation, \(f(x/r_0) = \frac{4 r_0}{l}\left| \frac{x}{r_0} - \frac{l}{2 r_0}\right| - 1\):

$$\begin{aligned} \begin{aligned} P_{\gamma }&= a \left( 2 P_y^0 + \frac{4 \Delta x_b}{l} P_{\sigma } \right) \\&= 2 a P_y^0 \left( 1 + \frac{2 \sigma }{ \tau _y l} \right) \end{aligned} \end{aligned}$$(64)In this case, the function \(\gamma (x/r_0)\) is singular around the maximum (\(\delta =1\)), so that \(\beta = 0\) for the Newtonian case and \(\beta = 1/n\) for the non-Newtonian one.

N blobs. In the case of the uniform tube, the flow curve is identical as for the single blob. The value of the threshold coincides with the one of a single blob with the same amount of fluid. The case of a non-uniform tube is instead more interesting. The value of the pressure threshold \(\Delta P_c\) depends explicitly on the number of blobs and their relative distance. Assuming that the blobs are identical and evenly distributed, we show that \(\Delta P_c\) can be written as

where A is a non-dimensional positive random variable of order 1. The probability distribution of A depends on the tube shape.

We studied the following particular cases:

-

Sinusoidal deformation, \(f(x) = \cos {\frac{2 \pi }{x}{l}}\). We found an explicit formula for \(\Pi (A)\), valid in the limit of many blobs

$$\begin{aligned} \Pi (A) = 2 A e^{-A^2}. \end{aligned}$$(66) -

Triangular deformation, \(f(x/r_0) = \frac{4 r_0}{l}\left| \frac{x}{r_0} - \frac{l}{2 r_0}\right| - 1\). We do not have an explicit formula for \(\Pi (A)\), but we show how \(\Pi (A)\) vanishes when \(A\rightarrow 0\), in two limiting cases:

-

1.

Newtonian fluid:

$$\begin{aligned} \Pi (A\rightarrow 0) \propto \frac{1}{A^3} e^{- \frac{k}{A^2}}, \end{aligned}$$(67)where k is a numerical constant.

-

2.

Non-Newtonian fluid neglecting capillary effects:

$$\begin{aligned} \Pi (A\rightarrow 0) \propto \frac{1}{A^{5/3}} e^{- \frac{k^*}{A^{2/3}}}, \end{aligned}$$(68)where \(k^*\) is another numerical constant.

-

1.

Concerning the flow, for a fiber bundle model and in the limit of many tubes, the total flow curve results from averaging all the blobs position configurations. It can be written in the form:

where the overline stands for an average over all blobs configurations. The values obtained for the exponent \(\beta\) are given in Table 2.

It is important to remark that within the fiber bundle model, the value of \(\beta\) depends explicitly on the regularity of the function \(\gamma (x)\). For example, in the triangular case, \(\beta =0\) and the flow displays an essential singularity:

the Hurst exponent H characterizes the self-affine behavior of the function \(\gamma (x)\). For example, we showed that in the triangular geometry \(H=1/2\) for a Newtonian fluid and \(H=3/2\) for a non-Newtonian fluid with negligible capillarity. One can wonder if this dependence holds also for a realistic porous media. Indeed, the fiber bundle model is a crude approximation as all tubes are independent. A challenge for future works is then to solve the flow in frameworks of interacting tubes.

Notes

Here, we implicitly assume the contact angle between the meniscus and the tube to be small such that the radius of the spherical interface is approximately equal to the radius of the tube.

References

Al-Fariss, T., Pinder, K.L.: Flow through porous media of a shear-thinning liquid with yield stress. Can. J. Chem. Eng. 65(3), 391–405 (1987). https://doi.org/10.1002/cjce.5450650306

Aursjø, O., Erpelding, M., Tallakstand, K.T., et al.: Film flow dominated simultaneous flow of two viscous incompressible fluids through a porous medium. Front Physics 2, 63 (2014). https://doi.org/10.3389/fphy.2014.00063

Balhoff, M.T., Thompson, K.E.: Modeling the steady flow of yield-stress fluids in packed beds. AIChE J. 50(12), 3034–3048 (2004). https://doi.org/10.1002/aic.10234

Barbati, A.C., Desroches, J., Robisson, A., et al.: Complex fluids and hydraulic fracturing. Annu. Rev. Chem. Biomol. Eng. 7(1), 415–453 (2016). https://doi.org/10.1146/annurev-chembioeng-080615-033630

Barnes, H., Hutton, J., Walters, K.: An introduction to rheology, vol. 3. Elsevier Science Limited, New York, NY (1989)

Bauer, D., Talon, L., Peysson, Y., et al.: Experimental and numerical determination of Darcy’s law for yield stress fluids in porous media. Phys. Rev. Fluids. 4(063), 301 (2019). https://doi.org/10.1103/PhysRevFluids.4.063301

Bear, J.: Dynamics of Fluids in Porous Media. Elsevier, New York, NY (1988)

Bessonov, N., Sequeira, A., Simakov, S., et al.: Methods of blood flow modelling. Math. Modell. Nat. Phenom. 11(1), 1–25 (2016). https://doi.org/10.1051/mmnp/201611101

Bird, R., Armstrong, R., Hassager, O.: Dynamics of polymeric liquids. Fluid mechanics. John Wiley and Sons Inc, New York, NY (1987)

Bird, R.B.: Useful non-Newtonian models. Annu. Rev. Fluid Mech. 8(1), 13–34 (1976). https://doi.org/10.1146/annurev.fl.08.010176.000305

Brown, S.R.: Fluid flow through rock joints: The effect of surface roughness. J. Geophys. Res.: Solid Earth 92(B2), 1337–1347 (1987). https://doi.org/10.1029/JB092iB02p01337

Burkhardt, T.W.: The random acceleration process in bounded geometries. J. Stat. Mech.: Theory Exp. 07, P07004 (2007). https://doi.org/10.1088/1742-5468/2007/07/p07004

Chen, M., Rossen, W., Yortsos, Y.C.: The flow and displacement in porous media of fluids with yield stress. Chem. Eng. Sci. 60(15), 4183–4202 (2005). https://doi.org/10.1016/j.ces.2005.02.054

Chevalier, T., Talon, L.: Generalization of Darcy’s law for Bingham fluids in porous media: From flow-field statistics to the flow-rate regimes. Phys. Rev. E 91(023), 011 (2015). https://doi.org/10.1103/PhysRevE.91.023011

Chevalier, T., Salin, D., Talon, L., et al.: History effects on nonwetting fluid residuals during desaturation flow through disordered porous media. Phys. Rev. E 91(043), 015 (2015). https://doi.org/10.1103/PhysRevE.91.043015

Coussot, P.: Rheometry of pastes, suspensions, and granular materials: applications in industry and environment. John Wiley and Sons, New York, NY (2005)

Dean, D.S., Gupta, S., Oshanin, G., et al.: Diffusion in periodic, correlated random forcing landscapes. J. Phys. A: Math. Theorl. 47(37), 372001 (2014). https://doi.org/10.1088/1751-8113/47/37/372001

Dullien, F.A.: Porous media: fluid transport and pore structure. Academic press, Cambridge, MA (1991)

Entov, V.: On some two-dimensional problems of the theory of filtration with a limiting gradient. Prikl Mat Mekh 31, 820–833 (1967). https://doi.org/10.1016/0021-8928(67)90120-7

Fraggedakis, D., Chaparian, E., Tammisola, O.: The first open channel for yield-stress fluids in porous media. J. Fluid Mech. 911, A58 (2021). https://doi.org/10.1017/jfm.2020.1105

Frigaard, I., Ryan, D.: Flow of a visco-plastic fluid in a channel of slowly varying width. J. Non-Newton Fluid. Mech. 123(1), 67–83 (2004). https://doi.org/10.1016/j.jnnfm.2004.06.011

Happel, J., Brenner, H.: Low Reynolds number hydrodynamics. D. Reidel Publishing Co., Hingham, MA (1983)

Liu, C., De Luca, A., Rosso, A., et al.: Darcy’s law for yield stress fluids. Phys. Rev. Lett. 122(245), 502 (2019). https://doi.org/10.1103/PhysRevLett.122.245502

Lopez, X., Valvatne, P.H., Blunt, M.J.: Predictive network modeling of single-phase non-Newtonian flow in porous media. J. Colloid. Interface. Sci. 264(1), 256–265 (2003). https://doi.org/10.1016/S0021-9797(03)00310-2

Majumdar, S.N., Rosso, A., Zoia, A.: Time at which the maximum of a random acceleration process is reached. J. Phys. A: Math. Theor. 43(11), 115001 (2010). https://doi.org/10.1088/1751-8113/43/11/115001

Malevich, A., Mityushev, V., Adler, P.: Stokes flow through a channel with wavy walls. Acta Mech. 182(3–4), 151–182 (2006)

Mori, F., Majumdar, S.N., Schehr, G.: Distribution of the time between maximum and minimum of random walks. Phys. Rev. E 101(5), 052111 (2020). https://doi.org/10.1103/physreve.101.052111

Nash, S., Rees, D.S.: The effect of microstructure on models for the flow of a Bingham fluid in porous media. Transp. Porous. Media. (2016). https://doi.org/10.1007/s11242-016-0813-9

Park, H., Hawley, M., Blanks, R.: The flow of non-Newtonian solutions through packed beds. SPE 15(11), 4722 (1973). https://doi.org/10.1002/pen.760151102

Popel, A.S., Johnson, P.C.: Microcirculation and hemorheology. Annu. Rev. Fluid Mech. 37(1), 43–69 (2005). https://doi.org/10.1146/annurev.fluid.37.042604.133933

Rassi, E.M., Codd, S.L., Seymour, J.D.: Nuclear magnetic resonance characterization of the stationary dynamics of partially saturated media during steady-state infiltration flow. New. J. Phys. 13(1), 015007 (2011). https://doi.org/10.1088/1367-2630/13/1/015007

Rodríguez de Castro, A., Radilla, G.: Non-Darcian flow of shear-thinning fluids through packed beads: Experiments and predictions using forchheimer’s law and ergun’s equation. Adv. Water Resour. 100, 35–47 (2017). https://doi.org/10.1016/j.advwatres.2016.12.009

Roustaei, A., Chevalier, T., Talon, L., et al.: Non-Darcy effects in fracture flows of a yield stress fluid. J. Fluid Mech. 805, 222–261 (2016). https://doi.org/10.1017/jfm.2016.491

Roux, S., Herrmann, H.J.: Disorder-induced nonlinear conductivity. Europhys. Lett. 4(11), 1227 (1987). https://doi.org/10.1209/0295-5075/4/11/003

Roy, S., Hansen, A., Sinha, S.: Effective rheology of two-phase flow in a capillary fiber bundle model. Front. Phys. 7, 92 (2019). https://doi.org/10.3389/fphy.2019.00092

Scheidegger, A.: Theoretical models of porous matter. Producers Monthly 17, 17–23 (1953)

Scheidegger, A.: The physics of flow through porous media. University of Toronto Press, UK (1974)

Sinha, S., Hansen, A.: Effective rheology of immiscible two-phase flow in porous media. Europhys Lett. 99(4), 44004 (2012). https://doi.org/10.1209/0295-5075/99/44004

Sinha, S., Hansen, A., Bedeaux, D., et al.: Effective rheology of bubbles moving in a capillary tube. Phys. Rev. E 87(025), 001 (2013). https://doi.org/10.1103/PhysRevE.87.025001

Sinha, S., Bender, A.T., Danczyk, M., et al.: Effective rheology of two-phase flow in three-dimensional porous media: Experiment and simulation. Transp. Porous Media 119(1), 77–94 (2017). https://doi.org/10.1007/s11242-017-0874-4

Sochi, T., Blunt, M.: Pore-scale network modeling of Ellis and Herschel-Bulkley fluids. J. Pet. Sci. Eng. 60(2), 105–124 (2008). https://doi.org/10.1016/j.petrol.2007.05.009

Tallakstad, K.T., Løvoll, G., Knudsen, H.A., et al.: Steady-state, simultaneous two-phase flow in porous media: An experimental study. Phys. Rev. E 80(036), 308 (2009). https://doi.org/10.1103/PhysRevE.80.036308

Talon, L., Bauer, D.: On the determination of a generalized Darcy equation for yield-stress fluid in porous media using a lattice-Boltzmann trt scheme. Eur. Phys. J. E 36(12), 139 (2013). https://doi.org/10.1140/epje/i2013-13139-3

Talon, L., Auradou, H., Hansen, A.: Effective rheology of Bingham fluids in a rough channel. Front Physics 2(24), 24 (2014). https://doi.org/10.3389/fphy.2014.00024

Waisbord, N., Stoop, N., Walkama, D.M., et al.: Anomalous percolation flow transition of yield stress fluids in porous media. Phys. Rev. Fluids. 4(063), 303 (2019). https://doi.org/10.1103/PhysRevFluids.4.063303

Weiss, G.H.: Random walks and random environments, volume 1: Random walks. J. Stat. Phys. 82(5), 1675–1677 (1996). https://doi.org/10.1007/BF02183400

Widmer Soyka, R.P., López, A., Cecilia Persson, C., et al.: Numerical description and experimental validation of a rheology model for non-Newtonian fluid flow in cancellous bone. J. Mech. Behav. Biomed. Mater. 27, 43–53 (2013). https://doi.org/10.1016/j.jmbbm.2013.06.007

Xiong, Y., Long, X., Huang, G., et al.: Impact of pore structure and morphology on flow and transport characteristics in randomly repacked grains with different angularities. Soils Foundations 59(6), 1992–2006 (2019). https://doi.org/10.1016/j.sandf.2019.10.002

Yiotis, A.G., Talon, L., Salin, D.: Blob population dynamics during immiscible two-phase flows in reconstructed porous media. Phys. Rev. E 87(033), 001 (2013). https://doi.org/10.1103/PhysRevE.87.033001

Yiotis, A.G., Dollari, A., Kainourgiakis, M.E., et al.: Nonlinear Darcy flow dynamics during ganglia stranding and mobilization in heterogeneous porous domains. Phys. Rev. Fluids 4(114), 302 (2019). https://doi.org/10.1103/PhysRevFluids.4.114302

Zhang, Y., Bijeljic, B., Gao, Y., et al.: Quantification of nonlinear multiphase flow in porous media. Geophys. Res. Lett. (2021). https://doi.org/10.1029/2020GL090477

Funding

Open access funding provided by NTNU Norwegian University of Science and Technology (incl St. Olavs Hospital - Trondheim University Hospital). This work was partly supported by the Research Council of Norway through its Center of Excellence funding scheme, project number 262644. Further support, also from the Research Council of Norway, was provided through its INTPART program, project number 309139. This work was also supported by “Investissements d’Avenir du LabEx” PALM (ANR-10-LABX-0039-PALM).

Author information

Authors and Affiliations

Contributions

FL developed the theory and performed the analytical and numerical calculations. AR and LT helped in performing the analytical calculations. AH suggested the problem. All the authors contributed in writing the manuscript to its final form.

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix 1: Blobs of different sizes in a tube with sinusoidal geometry

Appendix 1: Blobs of different sizes in a tube with sinusoidal geometry

We generalize the study of the flow in a tube considering N blobs of different lengths. We call \(\Delta x_0\) the size of the blob positioned at \(x_b\) and \(\Delta x_i\) the size of the blob at \(x_b + x_i\), and for all i we take \(\Delta x_i \ll l\). We also consider a radius variation small enough so that we can take every \(\Delta x_i\) constant. In the limit of small flow rate \(q \rightarrow 0\), the pressure drop at the edges of the i-th blob is

where \(P_{y,i}^0 = 2\tau _y\Delta x_i/r_0\). To this, one must add the capillary pressure drop \(a P_{\sigma }\Delta x_i f'((x_b+x_i)/r_0)\). Summing the contributions of all the N blobs and neglecting the pressure drop induced by the Newtonian fluid, we obtain the following flow rate equation:

where

and the function

We now focus on the case of a tube presenting the sinusoidal modulation given by Eq. (32). Defining \(\theta _b = 2\pi x_b/l\) and \(\theta _i = 2\pi x_i/l\), Eq. (74) can be written as a single sine function

with the amplitude

and the phase shift \(\phi = \arcsin \left( A^{-1} \sum _{i=1}^{N-1}\Delta x_i \sin \theta _i \right)\). Similarly, we obtain \(G'(x_b;\{x_i\},\{\Delta x_i\}) = - \sqrt{N} A (2\pi /l) \sin (\theta _b + \phi )\). So \(\gamma (\theta _b;\{\theta _i\},\{\Delta x_i\})\) can be written as:

where \(P'_{\gamma } = a\sqrt{ (2\tau _y/r_0)^2 + (2\pi P_{\sigma }/l)^2 }\) and \(\varphi = -\arccos \left( 2\tau _y/(r_0 P'_{\gamma })\right)\).The maximum of Eq. (76) gives the pressure threshold

We now suppose that every blob size is distributed uniformly between two extreme values \(\Delta x_\mathrm{{m}}\) and \(\Delta x_\mathrm{{M}}\), with \(\Delta x_\mathrm{{m}}<\Delta x_\mathrm{{M}}\ll l\). Then, for N sufficiently large, \(\sum _{i=0}^{N-1} P^0_{y,i} = N \left\langle P^0_{y} \right\rangle\) with \(\left\langle P^0_{y} \right\rangle = \tau _y\left( \Delta x_\mathrm{{M}} + \Delta x_\mathrm{{m}}\right) /r_0\). Moreover, we assume the angular position \(\theta _i\) to be distributed uniformly in the interval \([0,2\pi ]\). It follows that the probability distribution \(\Pi (A)\), in the domain \([0, +\infty [\), has the following expression:

here we define \(q = (\Delta x^2_\mathrm{{M}} + \Delta x ^2_\mathrm{{m}} + \Delta x_\mathrm{{m}}\Delta x_\mathrm{{M}})/3\). In particular, \(\Pi (A)\) vanishes linearly as \(A \rightarrow 0\). To prove (78), we calculate the probability distribution of the variable \(B=N A^2\)

The Laplace transform of Eq. (43) is

We now define the statistical variables \(m_x=\sum _{i=1}^{N-1}\Delta x_i\cos \theta _i\) and \(m_y=\sum _{i=1}^{N-1}\Delta x_i\sin \theta _i\). The mean and variance of both \(\Delta x_i \cos \theta _i\) and \(\Delta x_i \sin \theta _i\) in the interval \([0,2\pi ]\! \times \![\Delta x_\mathrm{{m}}, \Delta x_\mathrm{{M}}]\) are, respectively, 0 and q/2. \(m_x\) and \(m_y\) are statistical independent since their covariance is zero. When \(N-1\simeq N\) is sufficiently large, the distribution of both \(m_x\) and \(m_y\) is Gaussian with mean zero and variance Nq/2. Equation (80) becomes:

The Laplace inversion gives \(g(B)=\exp (-B/(Nq))/(Nq)\), from which Eq. (82) follows. From \(\Pi (A)\), we get the distribution of \(\Delta P_c\) in the interval \(\left[ N\left\langle P^0_y\right\rangle , +\infty \right]\):

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Lanza, F., Rosso, A., Talon, L. et al. Non-Newtonian Rheology in a Capillary Tube with Varying Radius. Transp Porous Med 145, 245–269 (2022). https://doi.org/10.1007/s11242-022-01848-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11242-022-01848-7