Abstract

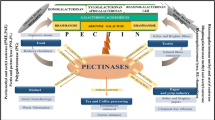

The wide utility and catalytic efficiency of microbial pectinase in various industries has greatly increased its global demand. Among the natural sources of pectinases, microbial pectinases are used frequently for its ease of production and unique physicochemical properties. Yet similar to other industrial enzymes, pectinases also face the constraint of thermo-tolerance and low yield in its economised production. The current review addresses the various strategies adopted to meet the high yield and thermo-tolerance of pectinases as well as the various attempts made in the field of pectinases to its improved production and better catalytic efficiency. The utilisation of natural as well as recombinant microbial sources, metagenomic approaches, metabolic engineering, site directed mutagenesis and media engineering techniques adopted in the field of pectinases have been discussed. The significance of pectinases in various industries is depicted by enlisting its applications. To the best our knowledge the current review is unique being the first attempt to compile the recent advancements in the field of pectinases.

Similar content being viewed by others

References

Abbott DW, Boraston AB (2007) The structural basis for exopolygalacturonase activity in a family 28 glycoside hydrolase. J Mol Biol 368(5):1215–1222

Abdulrachman D et al (2017) Heterologous expression of Aspergillus aculeatus endo-polygalacturonase in Pichia pastoris by high cell density fermentation and its application in textile scouring. BMC Biotechnol 17:15. doi:10.1186/s12896-017-0334-9

Ahlawat S, Mandhan RP, Dhiman SS, Kumar R, Sharma J (2008) Potential application of alkaline pectinase from Bacillus subtilis SS in pulp and paper industry. Appl Biochem Biotechnol 149:287–293

Akhter N, Morshed MA, Uddin A, Begum F, Sultan T, Azad AK (2011) Production of pectinase by Aspergillus niger cultured in solid state media. Int J Biosci 1:33–42

Aliaa ARN, Mazlina MKS, Taip FS (2010) Impact of commercial pectolytic enzymes on selected properties of white dragon fruit juice. J Inst Eng Malays 71:25–31

Almeida C, Brainyik TA, Moradas-Ferreira P, Teixeira J (2003) Continuous production of pectinase by immobilized yeast cells on spent grains. J Biosci Bioeng 96(6):513–518

Amin F, Bhatti HN, Bhatti IA, Asgher M (2013) Utilization of wheat bran for enhanced production of exopolygalacturonase by Penicillium notatum using response surface methodology. Pak J Agric Sci 50:469–477

Amin F, Bhatti HN, Bilal M, Asgher M (2017a) Multiple parameter optimizations for enhanced biosynthesis of exo-polygalacturonase enzyme and its application in fruit juice clarification. Int J Food Eng 13(2). doi:10.1515/ijfe-2016-0256

Amin F, Bhatti HN, Bilal M, Asgher M (2017b) Purification, kinetic, and thermodynamic characteristics of an exo-polygalacturonase from Penicillium notatum with industrial perspective. Appl Biochem Biotechnol. doi:10.1007/s12010-017-2455-y

Azzaz HH, Murad HA, Khalif AM, Morsy TA, Mansour AM (2013) Pectinase production optimization and its application in banana fibre degradation Egypt. J Nutr Foods 16:117–125

Banafshe R, Hamid RKH (2014) Isolation and partial characterization of a bacterial thermostable polymethyl galacturonase from a newly isolated Bacillus sp. strain BR1390. Iran. J Biotechnol 12(4):e1133

Benen JAE, van Alebeek GJWM, Voragen AGJ, Visser J (2003) Mode of action analysis and structure-function relationships of Aspergillus niger pectinolytic enzymes. In: Voragen F, Schols H, Visser R (eds) Advances in pectin and pectinase research. Springer, Netherlands, pp 235–256. doi:10.1007/978-94-017-0331-4_18

Bennamoun L et al (2016) Production and properties of a thermostable, pH-stable exo-polygalacturonase using Aureobasidium pullulans isolated from Saharan soil of Algeria grown on tomato pomace. Foods 5:72

Bezerra T, Montibra R, Hansen EB, Contiero J (2017) Microbial glycosidases for nondigestible oligosaccharides production. In: Senturk M (ed) Enzyme inhibitors and activators. InTech Open Access Publishers, pp 181–206. doi:10.5772/65935

Blanco P, Thow G, Simpson CG, Villa TG, Williamson B (2002) Mutagenesis of key amino acids alters activity of a Saccharomyces cerevisiae endo-polygalacturonase expressed in Pichia pastoris. FEMS Microbiol Lett 210:187–191

Bonivento D et al (2008) Crystal structure of the endopolygalacturonase from the phytopathogenic fungus Colletotrichum lupini and its interaction with polygalacturonase inhibiting proteins. Proteins Struct Funct Bioinf 70(1):294–299

Bussink HJD, Buxton FP, Fraaye BA, Graaff LHd, Visser J (1992) The polygalacturonases of Aspergillus niger are encoded by a family of diverged genes. Eur J Biochem 208:83–90

Butot S, Putallaz T, Sanchez G (2007) Procedure for rapid concentration and detection of enteric viruses from berries and vegetables. Appl Environ Microbiol 73(1):186–192

Byrne CE, Cavalitto SF, Voget CE (2017) Purification and characterization of two inducible exopolygalacturonases from Aspergillus kawachii. Biocatal Agric Biotechnol 10:38–45. doi:10.1016/j.bcab.2017.02.005

Cao J, Zheng L, Chen S (1992) Screening of pectinase producer from alkalophilic bacteria and study on its potential application in degumming of ramie. Enzyme Microb Technol 14:1013–1016

Caprari C et al (1993) Fusarium moniliforme secretes four endopolygalacturonases derived from a single gene product. Physiol Mol Plant Path 43:453–462

Carroll SB, Grenier JK, Weatherbee SD (2005) From DNA to diversity. Molecular genetics and the evolution of animal design, 2nd edn. Blackwell Scientific, Malden

Celestino SMC et al (2006) Purification and characterization of a novel pectinase from Acrophialophora nainiana with emphasis on its physicochemical properties. J Biotechnol 123:33–42. doi:10.1016/j.jbiotec.2005.10.024

Charoenrat T et al (2013) Improvement of recombinant endoglucanase produced in Pichia pastoris KM71 through the use of synthetic medium for inoculum and pH control of proteolysis. J Biosci Bioeng 116:193–198. doi:10.1016/j.jbiosc.2013.02.020

Chen Q, Jin Y, Zhang G, Fang Y, Xiao Y, Zhao H (2012) Improving production of bioethanol from duckweed (Landoltia punctata) by pectinase pretreatment. Energies 5:3019–3032

Cheng Z et al (2017) Identification of an acidic endo-polygalacturonase from Penicillium oxalicum CZ1028 and its broad use in major tropical and subtropical fruit juices production. J Biosci Bioeng 23(6):665–672. doi:10.1016/j.jbiosc.2017.01.013

Colla E, Santos LO, Deamici K, Magagnin GN, Vendruscolo M, Costa JAV (2016) Simultaneous production of amyloglucosidase and exo-polygalacturonase by Aspergillus niger in a rotating drum reactor. Appl Biochem Biotechnol 181(2):627–637

Comtet-Marre S et al (2017) Metatranscriptomics reveals the active bacterial and eukaryotic fibrolytic communities in the rumen of dairy cow fed a mixed diet. Front Microbiol 8:67. doi:10.3389/fmicb.2017.00067

Cuesta UI (2016) A Review of natural and engineered enzymes involved in bioethanol production. University of Montana, Montana

Damak N, Hadj-Taieb N, Bonnin E, Ben Bacha A, Gargouri A (2011) Purification and biochemical characterization of a novel thermoactive fungal pectate lyase from Penicillium occitanis. Process Biochem 46:888–893. doi:10.1016/j.procbio.2010.12.014

Demir H, Tari C (2017) Bioconversion of wheat bran for polygalacturonase production by Aspergillus sojae in tray type solid-state fermentation. Int Biodeterior Biodegrad 106:60–66

Finkler ATJ et al (2017) Intermittent agitation contributes to uniformity across the bed during pectinase production by Aspergillus niger grown in solid-state fermentation in a pilot-scale packed-bed bioreactor. Biochem Eng J 121:1–12. doi:10.1016/j.bej.2017.01.011

Giacobbe S, Pepe O, Ventorino V, Birolo L, Vinciguerra R, Faraco V (2014) Identification and characterisation of a pectinolytic enzyme from Paenibacillus xylanolyticus. BioResources 9:4873–4887

Gummadi SN, Panda T (2003) Purification and biochemical properties of microbial pectinases—a review. Process Biochem 38:987–996

Gummadi SN, Manoj N, Kumar DS (2007) Structural and biochemical properties of pectinases. In: Polaina J, MacCabe AP (eds) Industrial enzymes structure, function and applications. Springer, Netherlands, pp 99–115. doi:10.1007/1-4020-5377-0_7

Hoondal G, Tiwari R, Tewari R, Dahiya NB, Beg Q (2002) Microbial alkaline pectinases and their industrial applications: a review. Appl Microbiol Biotechnol 59(4):409–418

Jurnak F et al (1996) Functional implications of the three-dimensional structures of pectate lyases. In: Visser J, Voragen AGJ (eds) Progress in biotechnology, vol 14. Elsevier, Netherlands, pp 295–308. doi:10.1016/S0921-0423(96)80263-2

Kashyap DR, Vohra PK, Chopra S, Tewari R (2001) Applications of pectinases in the commercial sector: a review. Bioresour Technol 77:215–227. doi:10.1016/s0960-8524(00)00118-8

Kaur A, Mahajan R, Singh A, Garg G, Sharma J (2010) Application of cellulase-free xylano-pectinolytic enzymes from the same bacterial isolate in biobleaching of kraft pulp. Bioresour Technol 101:9150–9155. doi:10.1016/j.biortech.2010.07.020

Khan M, Nakkeeran E, Umesh-Kumar S (2013) Potential application of pectinase in developing functional foods. Annu Rev Food Sci Technol 4:21–34

Khatri BP, Bhattarai T, Shrestha S, Maharjan J (2015) Alkaline thermo-stable pectinase enzyme from Aspergillus niger strain MCAS2 isolated from Manaslu Conservation Area, Gorkha Nepal. SpringerPlus 4:1–8. doi:10.1186/s40064-015-1286-y

Kluskens LD et al (2005) Characterization and mode of action of an exopolygalacturonase from the hyperthermophilic bacterium Thermotoga maritime. FEBS J 272:5464–5473

Ko CH, Tsai CH, Tu J, Tang SH, Liu CC (2011) Expression and thermostability of Paenibacillus campinasensis BL11 pectate lyase and its applications in bast fibre processing. Ann Appl Biol 158:218–225. doi:10.1111/j.1744-7348.2010.00456.x

Kuhad RC, Singh A (2013) Biotechnology for environmental management and resource recovery. Springer, Berlin

Kulkarni NG, Kar JR, Singhal RS (2017) Extraction of flaxseed oil: a comparative study of three-phase partitioning and supercritical carbon dioxide using response surface methodology. Food Bioprocess Technol 10(5):940–948

Kusuma MP, Sri RRD (2014) Thermoalkaline polygalacturonases—a review. Int J Pharm Sci Rev Res 28:162–165

Li X, Wang H, Zhou C, Ma Y, Li J, Song J (2014) Cloning, expression and characterization of a pectate lyase from Paenibacillus sp. 0602 in recombinant Escherichia coli. BMC Biotechnol 14:18. doi:10.1186/1472-6750-14-18

Liao CH (1989) Analysis of pectate lyases produced by soft rot bacteria associated with spoilage of vegetables. Appl Environ Microbiol 55(7):1677–1683

Lima JO, Pereira JF, Araujo EFd, Queiroz MVd (2017) Pectin lyase overproduction by Penicillium griseoroseum mutants resistant to catabolite repression. Braz J Microbiol . doi:10.1016/j.bjm.2016.12.009

Ma X et al (2017) Characteristics of pectinase treated with ultrasound both during and after the immobilization process. Ultrason Sonochem 36:1–10. doi:10.1016/j.ultsonch.2016.10.026

Maisuria VB, Nerurkar AS (2012) Biochemical properties and thermal behaviour of pectate lyase produced by Pectobacterium carotovorum subsp. carotovorum BR1 with industrial potentials. Biochem Eng J 63:22–30. doi:10.1016/j.bej.2012.01.007

Maldonado MC, Saad AM (1998) Production of pectinesterase and polygalacturonase by Aspergillus niger in submerged and solid state systems. J Ind Microbiol Biotechnol 20:34–38

Martens-Uzunova ES, Schaap PJ (2009) Assessment of the pectin degrading enzyme network of Aspergillus niger by functional genomics. Fungal Genet Biol 46:S170–S179

Martin N, Guez MAU, Sette LD, Da Silva R, Gomes E (2010) Pectinase production by a Brazilian thermophilic fungus Thermomucor indicae-seudaticae N31 in solid-state and submerged fermentation. Microbiology 79:306–313. doi:10.1134/s0026261710030057

Martins ES, Silva D, Da Silva R, Gomes E (2002) Solid state production of thermostable pectinases from thermophilic Thermoascus aurantiacus. Process Biochem 37:949–954. doi:10.1016/S0032-9592(01)00300-4

Mehanni AE, El-Reffaei WH, Melo A, Casal S, Ferreira IM (2017) Enzymatic extraction of oil from Balanites Aegyptiaca (desert date) kernel and comparison with solvent extracted oil. J Food Biochem 41(2):e12270. doi:10.1111/jfbc.12270

Mei Y, Chen Y, Zhai R, Liu Y (2013) Cloning, purification and biochemical properties of a thermostable pectinase from Bacillus halodurans M29. J Mol Catal B: Enzym 94:77–81. doi:10.1016/j.molcatb.2013.05.00

Mostafa FA, Ahmed SA, Helmy WA (2013) Enzymatic saccharification of pretreated lemon peels for fermentable sugar production. J Appl Sci Res 9:2301–2310

Nathan VK, Rani ME, Rathinasamy G, Dhiraviam KN (2017) Low molecular weight xylanase from Trichoderma viride VKF3 for bio-bleaching of newspaper pulp. BioResource 12(3):5264–5278

Ortega N et al (2004) Kinetic behaviour and thermal inactivation of pectinlyase used in food processing. Int J Food Sci Technol 39:631–639. doi:10.1111/j.1365-2621.2004.00822.x

Ortiz GE et al (2017) Pectinase production by Aspergillus giganteus in solid-state fermentation: optimization, scale-up, biochemical characterization and its application in olive-oil extraction. J Indus Microbiol Biotechnol 44(2):197–211

Parani K, Eyini M (2011) Mycelial protoplasts release from Pleurotus eous and P.flabellatus. J Biosci Res 2:130–135

Pasha KM, Anuradha P, Subbarao D (2013) Applications of pectinases in industrial sector. Int J Pure Appl Sci Technol 16:89–95

Pedrolli DB, Carmona EC (2010) Purification and characterization of the exopolygalacturonase produced by Aspergillus giganteus in submerged cultures. J Ind Microbiol Biotechnol 37:567–573. doi:10.1007/s10295-010-0702-0

Pedrolli DB, Monteiro AC, Gomes E, Carmona EC (2009) Pectin and pectinases: production, characterization and industrial application of microbial pectinolytic enzymes. Open Biotechnol J 3:9–18

Phutela U, Dhuna V, Sandhu S, Chadha BS (2005) Pectinase and polygalacturonase production by a thermophilic Aspergillus fumigatus isolated from decomposting orange peels. Braz J Microbiol 36:63–69

Pijning T et al (2009) The crystal structure of a hyperthermoactive exopolygalacturonase from Thermotoga maritima reveals a unique tetramer. FEBS Lett 583(22):3665–3670

Pitol LO, Biz A, Mallmann E, Krieger N, Mitchell DA (2016) Production of pectinases by solid-state fermentation in a pilot-scale packed-bed bioreactor. Chem Eng J 283:1009–1018

Poletto P, TsA Polidoro, Mr Zeni, da Silveira MM (2017) Evaluation of the operating conditions for the solid-state production of pectinases by Aspergillus niger in a bench-scale, intermittently agitated rotating drum bioreactor.LWT-Food. Sci Technol 79:92–101. doi:10.1016/j.lwt.2017.01.018

Prathyusha K, Suneetha V (2011) Bacterial pectinases and their potent biotechnological application in fruit processing/juice production industry: a review. J Phytol 3:16–19

Priya V, Sashi V (2014) Pectinase producing microorganisms. Int J Sci Res Pub 4:1–4

Rebello S, Jose L, Sindhu R, Aneesh EM (2017) Molecular advancements in the development of thermostable phytases. Appl Microbiol Biotechnol 101:2677–2689

Rehman HU et al (2015) Morphological and molecular based identification of pectinase producing Bacillus licheniformis from rotten vegetable. J Genet Eng Biotechnol 13:139–144

Ruiz HA, Rodriguez-Jasso RM, Rodriguez R, Contreras-Esquivel JC, Aguilar CN (2012) Pectinase production from lemon peel pomace as support and carbon source in solid-state fermentation column-tray bioreactor. Biochem Eng J 65:90–95

Saadoun I, Dawagreh A, Jaradat Z, Ababneh Q (2013) Influence of culture conditions on pectinase production by Streptomyces sp (strain J9). Int J Life Sci Med Res 3:148

Saleem Z, Rennebaum H, Pudel F, Grimm E (2008) Treating bast fibres with pectinase improves mechanical characteristics of reinforced thermoplastic composites. Compos Sci Technol 68(2):471–476

Sapunova LI, Lobanok AG, Mikhailova RV (1997) Conditions of synthesis of pectinases and proteases by Aspergillus alliaceus and production of a complex macerating preparation. Appl Biochem Microbiol 33:257–260

Schnitzhofer W et al (2007) Purification and mechanistic characterisation of two polygalacturonases from Sclerotium rolfsii. Enzyme Microb Technol 40:1739–1747. doi:10.1016/j.enzmictec.2006.11.005

Sharma DC, Satyanarayana T (2012) Biotechnological potential of agro residues for economical production of thermoalkali-stable pectinase by Bacillus pumilus dcsr1 by solid-state fermentation and its efficacy in the treatment of ramie fibres. Enzyme Res 2012:1–7

Sharma N, Rathore M, Sharma M (2013) Microbial pectinase: sources, characterization and applications. Rev Environ Sci Biotechnol 12:45–60

Sharma D, Agrawal S, Yadav RD, Mahajan R (2017) Improved efficacy of ultrafiltered xylanase -pectinase concoction in biobleaching of plywood waste soda pulp. 3. Biotech 7(1):2

Sieiro C, da Silva AF, Garcia-Fraga B, Lopez-Seijas J, Villa TG (2012) Microbial pectic enzymes in the food and wine industry. INTECH Open Access Publisher, Rijeka

Singh SA, Ramakrishna M, Rao AGA (1999) Optimization of downstream processing parameters for the recovery of pectinase from the fermented broth of Aspergillus carbonarious. Process Biochem 35:411–417

Singh A, Yadav RD, Kaur A, Mahajan R (2012a) An ecofriendly cost effective enzymatic methodology for deinking of school waste paper. Bioresour Technol 120:322–327. doi:10.1016/j.biortech.2012.06.050

Singh R, Dhawan S, Singh K, Kaur J (2012b) Cloning, expression and characterization of a metagenome derived thermoactive/thermostable pectinase. Mol Biol Rep 39:8353–8361

Solbak AI et al (2005) Discovery of pectin-degrading enzymes and directed evolution of a novel pectate lyase for processing cotton fabric. J Biol Chem 280:9431–9438

Tapre AR, Jain RK (2014) Pectinases: enzymes for fruit processing industry Int Food Res J 21:447–453

Teixeira JA, Gonçalves DB, de Queiroz MV, de Araujo EF (2011) Improved pectinase production in Penicillium griseoroseum recombinant strains. J Appl Microbiol 111:818–825. doi:10.1111/j.1365-2672.2011.05099.x

Thakur J, Gupta R (2012) Improvement of tea leaves fermentation through pectinases. Acta Microbiol Immunol Hung 59:321–334

Tu T et al (2016) Probing the role of cation-π interaction in the thermotolerance and catalytic performance of endo-polygalacturonases. Sci Rep 6:38413

Varavallo MA et al (2007) Isolation of recombinant strains with enhanced pectinase production by protoplast fusion between Penicillium expansum and Penicillium griseoroseum. Braz J Microbiol 38:52–57

Versari A, Biesenbruch S, Barbanti D, Farnell PJ, Galassi S (1998) Effects of pectolytic enzymes on selected phenolic compounds in strawberry and raspberry juices. Food Res Int 30:811–817. doi:10.1016/S0963-9969(98)00050-7

Visser J, Bussink HJ, Witteveen C (2004) Gene expression in filamentous fungi. In: Smith A (ed) Gene expression in recombinant microorganisms. Marcel Dekker Inc., New York, pp 241–308

Wang H, Li X, Ma Y, Song J (2014) Characterization and high-level expression of a metagenome-derived alkaline pectate lyase in recombinant Escherichia coli. Process Biochem 49:69–76. doi:10.1016/j.procbio.2013.10.001

Wang C et al (2016) Metagenomic analysis of microbial consortia enriched from compost: new insights into the role of Actinobacteria in lignocellulose decomposition. Biotechnol Biofuels 9:22. doi:10.1186/s13068-016-0440-2

Wolf-Marquez VE et al (2015) Batch and pulsed fed-batch cultures of Aspergillus flavipes FP-500 growing on lemon peel at stirred tank reactor. Appl Biochem Biotechnol 177(6):1201–1215

Wolf-Marquez VE et al (2017) Scaling-up and ionic liquid-based extraction of pectinases from Aspergillus flavipes cultures. Bioresour Technol 225:326–335. doi:10.1016/j.biortech.2016.11.067

Wong LY, Saad WZ, Mohamad R, Tahir PM (2017) Optimization of cultural conditions for polygalacturonase production by a newly isolated Aspergillus fumigatus R6 capable of retting kenaf. Ind Crops Prod 97:175–183. doi:10.1016/j.indcrop.2016.12.019

Xiao Z et al (2008) Improvement of the Thermostability and activity of a pectate lyase by single amino acid substitutions, using a strategy based on melting-temperature-guided sequence alignment. Appl Environ Microbiol 74:1183–1189. doi:10.1128/aem.02220-07

Yang J, Luo H, Li J, Wang K, Cheng H, Bai Y (2011) Cloning, expression and characterization of an acidic endo-polygalacturonase from Bispora sp. MEY-1 and its potential application in juice clarification. Process Biochem 46:272–277. doi:10.1016/j.procbio.2010.08.022

You C, Huang Q, Xue H, Xu Y, Lu H (2010) Potential hydrophobic interaction between two cysteines in interior hydrophobic region improve thermostability of a family 11 xylanase from Neocallimastix patriciarum. Biotechnol Bioeng 105:861–870

Yu P, Zhang Y, Gu D (2017) Production optimization of a heat-tolerant alkaline pectinase from Bacillus subtilis ZGL14 and its purification and characterization. Bioengineered 16:1–11. doi:10.1080/21655979.2017.1292188

Yuan P, Meng K, Huang H, Shi P, Luo H, Yang P (2011) A novel acidic and low-temperature-active endo-polygalacturonase from Penicillium sp. CGMCC 1669 with potential for application in apple juice clarification. Food Chem 129:1369–1375. doi:10.1016/j.foodchem.2011.05.065

Yuan P et al (2012) Abundance and genetic diversity of microbial polygalacturonase and pectate lyase in the sheep rumen ecosystem. PLoS ONE 7:e40940

Zhang J et al (2013) High-level extracellular production of alkaline polygalacturonate lyase in Bacillus subtilis with optimized regulatory elements. Bioresour Technol 146:543–548. doi:10.1016/j.biortech.2013.07.129

Zhang F, Tian M, Du M, Fang T (2017) Enhancing the activity of pectinase using pulsed electric field (PEF) treatment. J Food Eng 205:56–63. doi:10.1016/j.jfoodeng.2017.02.023

Zhou C, Xue Y, Ma Y (2017) Cloning, evaluation, and high-level expression of a thermo-alkaline pectate lyase from alkaliphilic Bacillus clausii with potential in ramie degumming. Appl Microbiol Biotechnol 9:1–14

Acknowledgements

Sharrel Rebello acknowledges SERB for National Post Doctoral Fellowship (File no PDF/2015/000472). One of the authors Raveendran Sindhu acknowledges Department of Biotechnology for sanctioning a project under DBT Bio-CARe scheme (File no BT/Bio-CARe/06/890/2011-2012).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rebello, S., Anju, M., Aneesh, E.M. et al. Recent advancements in the production and application of microbial pectinases: an overview. Rev Environ Sci Biotechnol 16, 381–394 (2017). https://doi.org/10.1007/s11157-017-9437-y

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11157-017-9437-y