The technological process of natural water treatment before being supplied to the water supply network is accompanied by the formation of water treatment sludge. The chemical composition of water treatment precipitation is characterized by the presence of aluminum and iron hydroxides, manganese oxide, and an undissolved residue of chemical reagents used in water treatment. The strategy of sustainable development presupposes proper management of man-made waste, capable of ensuring their reuse and reducing the associated environmental burden on the environment. There are known options for using water treatment sludge in the production of bricks, expanded clay, and cement. The use of water treatment sediments in the production of burnt ceramic materials is effective. A promising direction for the utilization of water treatment sludge is the possibility of its use in a mixture with peat as a potential raw material for the production of construction and ceramic materials. An installation is developed for the collection of milled peat, its mixing with water treatment sludge, and subsequent drying of the resultant mixture.

Similar content being viewed by others

References

E. Petrov, “A glass of water gets closer,” Rossiyskaya Gazeta. National projects., No. 8960, 6 (25.01.2023).

“The acid will be converted into fertilizer,” Rossiyskaya Gazeta. The economy of the Ural District, No. 8968, 16 (02.02.2023).

I. U. Aubakirova, “Use of sludge from water treatment plants in the production of building materials,” Water and Ecology: Problems and Solutions, No. 4 (84) (2020). URL: https://cyberleninka.ru/article/n/ispolzovanie-osadka-vodoochistnyhsooruzheniypri-proizvodstve-stroitelnyh-materialov.

GOST 530–2012. Ceramic brick and stone. General Technical Specifications [In Russian], Standartinform, Moscow (2013).

K.-Y. Chiang, P.-H. Chou, C.-R. Hua, et al., “Light weight bricks manufactured from WTS and rice husks,” J. Hazard. Mater., 171, 76 – 82 (2009). https://doi.org/10.1016/j.jhazmat.2009.05.144.

C.-H. Huang and S.-Y. Wang, “Application of WTS in the manufacturing of light weight aggregate,” Constr. Build. Mater., 43, 174 – 183 (2013). https://doi.org/10.1016/j.conbuildmat.2013.02.016.

H. El-Didamony, K. A. Khalil, and M. Heikal, “Physicochemical and surface characteristics of some granulate slagfired drinking water sludge composite cement pastes,” HBRC J., No. 10, 73 – 81 (2014). https://doi.org/10.1016/j.hbrcj.2013.09.004.

A. Benlalla, M. Elmoussaouiti, M. Dahhou, and M. Assafi, “Utilization of water treatment plant sludge in structural ceramics bricks,” Appl. Clay Sci., 118, 171 – 177 (2015). https://doi.org/10.1016/j.clay.2015.09.012.

E. M. Silva, D. M. Morita, A. C. M. Lima, and L. G. Teixeira, “Manufacturing ceramic bricks with polyaluminum chloride (PAC) sludge from a water treatment plant,” Water Sci. Technol., 71 (11), 1638 – 1645 (2015). https://doi.org/10.2166/wst.2015.132.

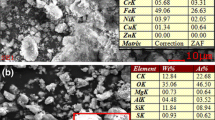

R. A. Apakashev, O. M. Guman, and N. G. Valiev, “Results of spectral semi-quantitative analysis of water treatment sludge,” Sustainable Development of Mountain Territories. Vladikavkaz, 12, No. 2(44), 229 – 236 (2020).

N. V. Grevtsev, S. Ya. Davydov, I. A. Tyabotov, and L. N. Oleinikova, “Production of porousized ceramic materials with the use of depleted peat-based admixtures,” Refract. Ind. Ceram., 58(4), 364 – 367 (2017).

N. P. Kosarev, N. V. Grevtsev, I. A. Tyabotov, et al., “Method of production of porous building bricks,” [in Russian] patent No. 105094, Russian Federation, appl. No. 2010101916; appl. on 21/01/2010, publ. 04/27/2011, Bul. No. 18.

R. A. Apakashev, S. Ya. Davydov, A. M. Bakaleyshchik, M. S. Lebzin, and A. N. Malyshev, “Method of disposal of sludge of water treatment facilities,” [in Russian] Appl. No. 105094, Russian Federation, applicant Ural State Mining University, appl. on 24.01.2022.

S. Ya. Davydov and R. A. Apakashev, “Collection and preparation of raw materials for the refractory industry”, Novye Orgneupory, No. 1, 8 – 12 (2023).

S. Ya. Davydov, L. N. Oleynikova, A. V. Gorbunov, et al., “Vehicle for loose material collection”, [in Russian] patent 2772001, Russian Federation, appl. No. 2022101451, appl. on 24/01/2022, publ. 08/12/2022, Bul. No. 14.

GOST R52067–2003. Peat for the production of nutrient soils. [in Russian] Specifications. Moscow, State Standard of Russia., p. 7 (2003).

S. Ya. Davydov, Energy-Saving Equipment for the Transportation of Bulk Materials. Research, Development, Production, GOU VPO USTU-UPI, Yekaterinburg, Russia (2007).

S. Y. Davydov and A. N. Semin, Energy-Saving Equipment of Pneumatic Transport: Yesterday, Today, Tomorrow. Theory, Calculation, Research, Production, Cadastral Reserve, Moscow (2016).

The study was supported by a grant of the Russian Science Foundation No. 22-24-20102, https://rscf.ru/project/22-24-20102/ with the financial support of the Government of the Sverdlovsk region.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Novye Ogneupory, No. 4, pp. 3 – 8, April, 2023.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Davydov, S.Y., Apakashev, R.A. & Oleynikova, L.N. Use of Water Treatment Sludge in the Production of Building and Ceramic Materials. Refract Ind Ceram 64, 109–114 (2023). https://doi.org/10.1007/s11148-023-00811-3

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11148-023-00811-3