Abstract

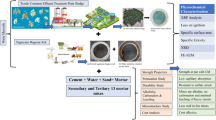

Minimization , utilization and disposal of industrial waste are very important from the environmental esthetic point of view. Sludge generated during the treatment of distillery spent wash by electrocoagulation process is highly complex in nature and requires proper disposal. In this context, the present study was conducted to employ the electrocoagulation-generated sludge as a partial replacement of cement while manufacturing the non-constructional building blocks. Various physiochemical and thermo-gravimetric characterization studies have been carried out on electrocoagulation-generated sludge and cement. Mortar specimens with different proportions of sludge ranging from 0 to 15 % by weight of cement were tested for density, compressive strength and leachability of heavy metals by standard method. Results from the analysis showed that the cement-based solidification of EC sludge reduces the heavy metal concentration in the leachate from cement–sludge mortars compared to the EC sludge alone. Reduction in the compressive strength of mortar with 7.5 % substitution of cement by EC sludge was <5 % against the control mortar (without sludge), thereafter the reduction was substantial. The optimum percentage of sludge that can replace the cement with marginal change in the physiochemical properties is found to be 7.5. This can be used in the manufacturing of the non-constructional building material within the industry for their different types of usages such as paving, pot making and fencing of garden without affecting the environment.

Similar content being viewed by others

References

Adyel TM, Rahman SH, Islam SMN, Khan M (2012a) Analysis of heavy metal in electrocoagulated metal hydroxide sludge (EMHS) from textile industry by energy dispersive X-ray fluorescence (EDXRF). Metals 2(4):478–487

Adyel TM, Rahman SH, Islam SMN, Sayem HM, Khan M, Zaman MM (2012b) Geo-engineering potentiality of electrocoagulated metal hydroxide sludge (EMHS) from textile industry and EMHS amended soil for using as building material. Int J Curr Res 4(2):21–25

Alam JB, Awal ASMA, Alam MJB, Rahman MS, Banik BK, Islam S (2006) Study of utilization of fly ash generated from Barapukeria power plant as admixture in manufacturing of cement. Asian J Civil Eng 7(3):225

Alleman JE, Bryan EH, Stumm TA, Marlow WW, Hocevar RC (1990) Sludge-amended brick production: applicability formetal-laden residues. Water Sci Technol 22(12):309–317

American Society for Testing and Materials (1992) Standard test method for compressive strength of hydraulic cement mortars (using 2-in. or 50-mm cube specimens). ASTM C109-92, Philadelphia

APHA, Awwa, WEF (1998) Standards methods for examination of water and wastewater, 20th edn. American Public Health Association, Washington

Awashthi SK (2000) Prevention of food adulteration act no 37 (1954) Central and State rules as amended for 1999, 3rd edn. Ashoka Law House, New Delhi

Balasubramania J, Sabumon PC, Lazar JU, Ilangovan R (2006) Reuse of textile effluent treatment plant sludge in building materials. Waste Manag 26(1):22–28

Baskar R, Begum KMMS, Sundaram S (2006) Characterization and reuse of textile effluent treatment plant waste sludge in clay bricks. J Univ Chem Technol Metall 41(4):473–478

Begum BSS, Gandhimathi R, Ramesh ST, Nidheesh PV (2013) Utilization of textile effluent wastewater treatment plant sludge as brick material. J Mater Cycles Waste Manag 15:564–570

Benson RE, Chandler HW, Chacey KA (1986) Hazardous waste disposal as concrete admixture. J Environ Eng 111(4):441–447

Boyle WC, Ham RK, Pastene J, Stanforth F (1983) Leach testing of foundry process waste. In: Conway RA, Gulledge WP (eds) Proceedings hazardous and industrial solid waste testing: second symposium, ASTM STP 805, American Society for Testing and Materials, Philadelphia p 67

Bureau of Indian Standard (1982) Recommended guidelines for concrete mix design. IS: 10262. BIS, New Delhi

Bureau of Indian Standards (1989) Specifications for 43-grade portland cement. IS: 8112. BIS, New Delhi

Central Pollution Control Board (2002) Management of distillery waste water. Resource recycling series: RERES/4/2001–2002, CPCB: New Delhi, India. http://cpcbenvis.nic.in/scanned%20reports/RERES%204%20Management%20of%20distillery%20wastewater.pdf

Chen L, Lin DF (2009) Applications of sewage sludge ash and nano-SiO2 to manufacture tile as construction material. Constr Build Mater 23(11):3312–3320

Environment protection agency (1986) Environment protection rules. http://cpcb.nic.in/GeneralStandards.pdf

Golder AK, Samanta AN, Ray S (2006) Anionic reactive dye removal from aqueous solution using a new adsorbent-sludge generated in removal of heavy metal by electrocoagulation. Chem Eng J 122:107–115

Ha NT, Yem T, Mai VT (2008) Study on reuse of heavy metal rich sludge in ceramic pigment and construction material production. VNU J Sci Nat Sci Technol 24:280–286

Islam MM, Halim MA, Safiullah S, Hoque SAMW, Islam MS (2009) Heavy metal (Pb, Cd, Zn, Cu, Cr and Mn) content in textile sludge in Gazipur, Bangladesh. Res J Environ Sci 3:311–315

Ismail M, Ismail MA, Lau SK, Muhammad B, Majid Z (2010) Fabrication of bricks from paper sludge and palm oil fuel ash. Concr Res Lett 1(2):13–18

Kaur G, Siddique R, Rajor A (2010) Influence of fungus on properties of concrete made with waste foundry sand. J Mater Civil Eng 25:484–490

Kohno K, Komatsu H (1986) Use of ground bottom ash and silica fume in mortar and concrete. In: Proceedings of the second international conference on silica fume, slag, and natural pozzolanas in concrete. Madrid, Special Publication 91, American Concr Inst, Michigan, pp 1279–1292

Liew AG, Idris A, Samad AA, Wong CHK, Jaafar MS, Baki AM (2004) Reusability of sewage sludge in clay bricks. J Mat Cycles Waste Manag 6(1):41–47

Lin DF, Weng CH (2001) Use of sewage sludge ash as brick material. J Environ Eng 127(10):922–927

Mahzuz HMA, Alam R, Alam MN, Basak R, Islam MS (2009) Use of arsenic contaminated sludge in making ornamental bricks. Int J Environ Sci Technol 6(2):291–298

Manahan SE (2005) Environmental chemistry, 8th edn. Lewis Publisher, Boca Raton

Montgomery DM, Sollars CJ, Perry R (1988) Cement based solidification for the safe disposal of hazardous waste. Waste Manag Res 6:217–226

Muchuweti M, Birkett JW, Chinyanga E, Zvauya R, Scrimshaw MD, Lester JN (2006) Heavy metal content of vegetables irrigated with mixture of wastewater and sewage sludge in Zimbabwe: implications for human health. Agric Ecosyst Enviorn 112:41–48

Puri BR, Walker PL (1966) Chemistry and physics of carbon. Marcel Dekker 161, New York

Rahman SH, Khanam D, Adyel TM, Islam MS, Ahsan MA, Akbor MA (2012) Assessment of heavy metal contamination of agricultural soil around Dhaka export processing zone (DEPZ), Bangladesh: implication of seasonal variation and indices. Appl Sci 2(3):584–601

Rouf MA, Hossain MD (2003) Effect of using arsenic-iron sludge in brick making. The international symposium on fate of arsenic in the environment organized by Bangladesh University of Engineering and Technology (BUET), Dhaka, Bangladesh and The United Nations University, Tokyo, Japan with assistance from ITN Centre, Bangladesh

Saha NK, Balakrishnan M, Batra VS (2005) Improving industrial water use: case study for an Indian distillery. Resour Conserv Recycl 43:163–174

Sarode DB, Jadhav RN, Khatik VA, Ingle ST, Attarde SB (2010) Extraction and leaching of heavy metals from thermal power plant fly ash and its admixtures. Pol J Environ Stud 19(6):1325–1330

Sharma KM, Laxmi S (2002) Utilization of building materials from industrial wastes. Civil Eng Constr Rev 15(2):55–58

Sharma P, Joshi H, Srivastava VC (2015) Two-stage electrochemical treatment of bio-digested distillery spent wash using stainless steel and aluminum electrodes. J Environ Sci Health Part A. doi:10.1080/10934529.2015.994968

Shin HS, Bae BU, Lee JJ, Paik BC (1992) Anaerobic digestion of distillery wastewater in a two-phase UASB reactor system. Water Sci Technol 25(7):361–371

Siddique R (2003) Effect of fine aggregate replacement with class F fly ash on the mechanical properties of concrete. Cem Concr Res 33:539–547

Sogancioglu M, Yel E, Yilmaz-Keskin US (2013) Utilization of andesite processing wastewater treatment sludge as admixture in concrete mix. Constr Build Mat 46:150–155

Tay JH (1987) Bricks manufactured from sludge. J Environ Eng 113(2):278–283

Thomson JC, Azariah J, Viji AGR (2009) Impact of textile industries on river Noyyal and riverine ground water quality in Tirupur, India. J Pollut Res 18(4):359–368

Trauner EJ (1993) Sludge ash bricks fired to above and below ash vitrifying temperature. J Environ Eng 119(3):506–519

USEPA (1990) Toxicity characteristic leaching procedure. Fed Regist 55(61):11798

Webster MT, Loehr RC (1996) Long term leaching of metals from concrete product. J Environ Eng 122(8):714–721

Weng CH, Lin DF, Chiang PC (2003) Utilization of sludge as brick materials. Adv Environ Res 7(3):679–685

Wilson B, Pyatt FB (2007) Heavy metal dispersion, persistence, and bioaccumulation around an ancient copper mine situated in Anglesey, UK. Ecotoxicol Environ Saf 66:224–231

Zain MFM, Islam MN, Radin SS, Yap SG (2004) Cement-based solidification for the safe disposal of blasted copper slag. Cem Concr Compos 26:845–851

Acknowledgments

Authors thankfully acknowledge DST for supporting this research under the Project Grant DST-675-HYD and Central Building Research Institute (CBRI), Roorkee, for technical support and providing the facilities to conduct this research work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sharma, P., Joshi, H. Utilization of electrocoagulation-treated spent wash sludge in making building blocks. Int. J. Environ. Sci. Technol. 13, 349–358 (2016). https://doi.org/10.1007/s13762-015-0845-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13762-015-0845-7