The results of force, thermal, and combined stress analysis of the surface layer of Al2O3–TiC-ceramics with AlN and TiN coatings are analyzed and systematized. The established relationships are used to create a new generation of ceramic cutting tools with an expanded field of application

Similar content being viewed by others

References

Valery V. Kuzin, Sergey N. Grigor’ev, David R. Burton, and Andrey D. Batako, “A new generation of ceramic tools,” in: Proceedings of the 10th International Conference on Manufacturing Research ICMR 2012, (2012), pp. 523 – 528.

Q. F. Zan, C. A. Wang, L. M. Dong, and Y. Huang, “Temperature mechanical properties of Al2O3/Ti3SiC2 multilayer ceramics,” Key Eng. Mater., 280 – 283, 1877 – 1880 (2007).

G. Nie, Y. Li, P. Sheng, and Z. Tian, “Fabrication of Al2O3/AlN composite ceramics with enhanced performance via a heterogeneous precipitation coating process,” Ceram. Int., 46(13), 21156 – 21165 (2020).

W. Xue, Y. Huang, Z. Xie, and W. Liu, “Al2O3 ceramics with well-oriented and hexagonally ordered pores: The formation of microstructures and the control of properties,” J. Eur. Ceram. Soc., 32(12), 3151 – 3159 (2012).

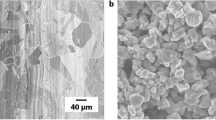

V. V. Kuzin, S. N. Grigor’ev, and S. Yu. Fedorov, “Correlation of Al2O3-ceramic structure with the mechanism of surface layer formation for workpieces during diamond grinding,” Refract. Ind. Ceram., 60(1), 82 – 85 (2019).

V. Kuzin, S. Grigoriev, M. Fedorov, and M. Portnoy, “Surface modification of zirconia (Y-TZP) ceramics induced by pulsed laser machining,” Appl. Mech. Mater., 752 – 753, 481 – 484 (2015).

V. V. Kuzin and S. Yu. Fedorov, “Correlation of diamond grinding regimes with Al2O3–TiC-ceramic surface condition,” Refract. Ind. Ceram., 57(5), 520 – 525 (2017).

V. V. Kuzin, S. Yu. Fedorov, and S. N. Grigor’ev, “Features of Al2O3–TiC ceramic specimen edge morphology formation during diamond grinding,” Refract. Ind. Ceram., 58(3), 319 – 323 (2017).

V. V. Kuzin, M. Yu. Fedorov, and M. A. Volosova, “Estimation of the sensitivity of a complex of characteristics of the stressed state of ceramics–coating boundary to the changes in the properties of structural elements of this system,” Refract. Ind. Ceram., 58(6), 697 – 703 (2018).

V. Kuzin, “A model of forming the surface layer of ceramic parts based on silicon nitride in the grinding process,” Key Eng. Mater., 496, 127 – 131 (2012).

J. Nemecek, K. Kolarik, J. Capek, N. Ganev, K. Trojan, and V. V. Kuzin, “x-ray diffraction study of macroscopic residual stresses of Al2O3 + TiC oxide cutting ceramics after surface machining,” Experimental Stress Analysis — 56th International Scientific Conference, EAN 2018, Conference Proceedings, 2018, pp. 296 – 302.

V. V. Kuzin, “Oxide ceramic surface layer modification using continuous laser radiation,” Refract. Ind. Ceram., 57(1), 53 – 57 (2016).

S. Grigoriev, V. Kuzin, D. Burton, and A. D. Batako, “The stress-strained state of ceramic tools with coating,” Proceedings of the 37th International MATADOR Conference, 2013, pp. 181 – 184.

Z. Yin, C. Huang, J. Yuan, and B. Zou, “Cutting performance and life prediction of an Al2O3/TiC micro–nano–composite ceramic tool when machining austenitic stainless steel,” Ceram. Int., 41(5) (B). 7059 – 7065 (2015).

T. Kivak, M. Sarikaya, C. V. Yildirim, and S. Şirin, “Study on turning performance of PVD TiN coated Al2O3 + TiCN ceramic tool under cutting fluid reinforced by nano-sized solid particles,” J. Manuf. Processes, 56, Part A, 522 – 539 (2020).

T. Erbacher, M. Ott, T. Beck, and O. Vohringer, “Determination of residual stress gradients in Al2O3 ceramics after thermal and mechanical loading,” Mater. Sci. Forum, 490 – 491, 485 – 490 (2005).

I. S. Konovalenko, E. M. Vodopjyanov, and E. V. Shilko, “Numerical study of deformation and fracture of ceramics nanocomposite with different structural parameters under mechanical loading,” Key Eng. Mater., 683, 601 – 608 (2016).

T. Sadowski and L. Marsavina, “Theoretical meso–model of Al2O3/ZrO2 ceramic response under compression,” Key Eng. Mater., 601, 92 – 95 (2014).

O. Sevecek, M. Kotoul, D. Leguillon, and E. Martin, “Assessment of crack-related problems in layered ceramics using the finite fracture mechanics and coupled stress-energy criterion,” Procedia Struct. Integr., 2, 2014 – 2021 (2016).

E. Medvedovski, “Influence of corrosion and mechanical loads on advanced ceramic components,” Ceram. Int., 39, No. 3, 2723 – 2741 (2013).

C. Liu, J. Sun, C. Wang, and F. Li, “Fracture behaviour, microstructure, and performance of various layered-structured Al2O3–TiC–WC–Co composites,” Ceram. Int., 47(14), 19766 – 19773 (2021).

Z. Yin, C. Huang, B. Zou, and H. Liu, “Dynamic fatigue behavior of Al2O3/TiC micro–nano–composite ceramic tool materials at ambient and high temperatures,” Mater. Sci. Eng., A, 593, 64 – 69 (2014).

J. L. Sullivan, B. Shi, and S. O. Saied, “Microtribological studies of two-phase Al2O3–TiC ceramic at low contact pressure,” Tribol. Int., 38(11/12), 987 – 994 (2006).

J. Ruiz-Hervias, G. Bruno, J. Gurauskis, A. J. Sanchez-Herencia, and C. Baudin, “Residual stresses in Al2O3/Y–TZP ceramic laminates fabricated by tape and slip casting,” Mater. Sci. Forum, 571 – 572, 327 – 332 (2008).

R. Del Valle, D. Leveque, and M. Parlier, “Optimizing substrate and intermediate layers geometry to reduce internal thermal stresses and prevent surface crack formation in 2D-multilayered ceramic coatings,” J. Eur. Ceram. Soc., 28(4), 711 – 716 (2008).

G. Zhang, G. Wu, Y. Zeng, and G. Xie, “Discrete element simulation of the ultrasonic–assisted scratching process of Al2O3 ceramic under compressive pre-stress,” Ceram. Int., 46(18) (A), 29090 – 29100 (2020).

M. Zhang, X. Sun, and X. Hu, “A study on the failure behavior of Al2O3–Ni micro-layered beams under three point bending,” Theor. Appl. Fract. Mech., 110, 102773 (2020).

T. Sakuma, Y. Ikuhara, and T. Yamamoto, “A modern approach to control grain boundaries in ceramics,” Mater. Sci. Forum, 467 – 470, 557 – 566 (2004).

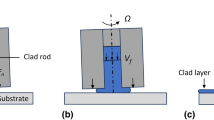

V. V. Kuzin, M. A. Volosova, and M. Yu. Fedorov, “Force analysis of the stress-strain state of the surface layer of Al2O3–TiC-ceramics with AlN and TiN coatings,” Refract. Ind. Ceram., 62(3), 355 – 360 (2021).

V. V. Kuzin, M. A. Volosova, and M. Yu. Fedorov, “Thermal analysis of the stress–strain state of Al2O3–TiC-ceramics surface layer with AlN and TiN coatings,” Refract. Ind. Ceram., 62(4), 433 – 438 (2021).

V. V. Kuzin, M. A. Volosova, and M. Yu. Fedorov, “Combined analysis of the stress-strain state of Al2O3–TiC-ceramics surface layer with AlN and TiN coatings,” Refract. Ind. Ceram., 62(4), 439 – 443 (2021).

V. V. Kuzin, S. N. Grigor’ev, and M. A. Volosova, “Systematic analysis of the stress-strain state of the surface layer of ground Si3N4–TiC ceramics,” Refract. Ind. Ceram., 62(2), 189 – 195 (2021).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Novye Ogneupory, No. 10, pp. 63 – 69, October, 2021.

Rights and permissions

About this article

Cite this article

Kuzin, V.V., Grigor’ev, S.N., Volosova, M.A. et al. Analysis of the Influence of the Loading Scheme on the Stress State of the Surface Layer of Al2O3–TiC-Ceramics with AlN and TiN Coatings. Refract Ind Ceram 62, 604–609 (2022). https://doi.org/10.1007/s11148-022-00649-1

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11148-022-00649-1