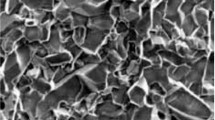

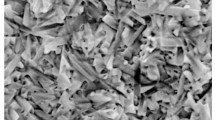

Results are provided for a study of the effect of planar grinding regimes with diamond wheels on Al2O3–TiC-ceramic surface condition. A correlation is established for grinding depth, and longitudinal and transverse feed with roughness, waviness, and morphology of a machined surface. The correlations revealed are planned for application in creating methodology for standardizing the precision of ceramic components and its production provision.

Similar content being viewed by others

References

N. N. Markov, V. V. Osipova, M. B. Shabalina, and Yu. M. Solomentsev, Standardization of Strength in Engineering, 2nd. Ed. [in Russian], Vysshaya Shkola, Akademiya, Moscow (2001).

A. G. Suslov, Component Surface Engineering [in Russian], Mashinostroenie, Moscow (2008).

V. M. Yaroslavtsev, “Development of methodology for finding new treatment methods and practical implementation,” Vestn. MGTU. Mashinostroenie, No. 2(67), 56 – 70 (2007).

Y. Jin and H. Lin, “Study on high precision control scheme of ceramic ferrule concentricity grinder,” Appl. Mechan. Mater., 635 – 637, 1266 – 1270 (2014).

V. V. Kuzin, “Technology for machining high refractory ceramic parts based on silicon nitride,” Refract. Indust. Ceram., 47(4), 204 – 208 (2006).

Z. L. Li,W. B. Lee, B. C. F. Cheung, et al., “A study of computer controlled ultra-precision polishing of silicon carbide reflecting lenses for enhancing surface roughness,” Key Eng. Mater., 625, 437 – 445 (2015).

V. V. Kuzin, “Technological aspects of diamond grinding of the nitride ceramics,” Russ. Eng. Res., 24(1), 23 – 28 (2004).

V. Kuzin, S. Grigoriev, S. Fedorov, M. Fedorov, “Surface defects formation in grinding of silicon nitride ceramics,” Applied Mechan. Mater., 752/753, 402 – 406 (2015).

V. Kuzin, “A model of forming the surface layer of ceramic parts based on silicon nitride in the grinding Process,” Key Engineering Materials, Precision Machining, 496, 127 – 131 (2012).

S. H. Li, M. H. Feng, and Y. H. Wu, “Research on optimal design and processing of high-speed ceramic ball bearings without inner rings,” Appl. Mechan. Mater, 446/447, 513 – 517 (2014).

Y. Yamamoto, H. Yasui, Y. Tanaka, et al., “Investigation on high depth of cut of ultra-smoothness grinding of Al2O3–TiC ceramic,” Proc. ASPE 2007 Annual Meeting (2007).

Y. Ling, H. Huang, K. Ramesh, and T. Huang, “High speed versus conventional grinding in high removal rate machining of alumina and alumina–titania,” Internat. J. Machine Tools and Manufacture, 45, 897 – 907 (2005).

Y. Ohbuchi, T. Matsuo, and N. Ueda, “Warp in high precision cut-off grinding of Al2O3–TiC ceramic thin plate,” CIRP Annals — Manufacturing Technology, 48, 285 – 288 (1999).

Zhu Rupeng, He Ning, Fu Yucan, and Yang Changyong, “Experimental research on grinding surface waviness of engineer ceramics,” Materials Science Forum Advances in Materials Manufacturing Science and Technology XV, 770, 175 – 178 (2014).

B. Zhang, B. X. L. Zheng, H. Tokura, and M. Yoshikawa, “Grinding induced damage in ceramics,” J. Mater. Process. Technol., 132, 353 – 364 (2003).

T. Matsuo, M. Touge, and H. Yamada, “High-precision surface grinding of ceramics with superfine grain diamond cup wheels,” CIRP Annals — Manufact. Technol., 46, 249 – 252 (1997).

L. Tanovic, P. Bojanic, and M. Popovic, “Mechanisms in oxide-carbide ceramic BOK60 grinding,” Internat. J. Advanced Manufact. Technol., 58, 9 – 12 (2011).

V. V. Kuzin and S. Yu. Fedorov, “Interaction of diamond grinding regimes with Al2O3-ceramic surface condition,” Novye Ogneupory, No. 7, 65 – 70 (2016).

Work was carried out with financial support of the RF Ministry of Education and Science within the scope of fulfilling a state assignment in the sphere of scientific activity (assignment No. 2014/105, project No. 1908).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Novye Ogneupory, No. 9, pp. 63 – 68, September, 2016.

Rights and permissions

About this article

Cite this article

Kuzin, V.V., Fedorov, S.Y. Correlation of Diamond Grinding Regimes with Al2O3–TiC-Ceramic Surface Condition. Refract Ind Ceram 57, 520–525 (2017). https://doi.org/10.1007/s11148-017-0016-0

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11148-017-0016-0