Abstract

For the first time, a mechanistic study of methane oxy-steam reforming and LNG (OSR-LNG) processes is presented using Fourier transform infrared (FTIR) spectroscopy. The FTIR measurements were carried out in the temperature range of 200–600 °C in the tested processes. The reaction mechanisms of oxy-steam reforming of CH4 or LNG were proposed from the results obtained. It was found that the dissociation of methane into carbon-containing molecules and/or into carbon molecules adsorbed on the catalyst surface is a crucial step in determining the reaction rate. The results can be used to design catalytic systems for natural gas reforming.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Natural gas steam reforming is one of the main industrial methods of producing hydrogen. It is a cheap and energy-efficient process but generates significant amounts of carbon dioxide into the atmosphere. For this reason, methane oxy-steam reforming process is widely investigated by many scientists as a potential alternative [1,2,3,4,5,6,7]. However, there is still controversy about the mechanism of this process. As a catalyst for hydrogen production via steam reforming of methane (SRM), Ni has also been extensively studied [8,9,10]. The mechanism underpinning this reaction can be explained by the adsorption of the reactants. Adsorption mechanisms involve the dissociative adsorption of methane on the nickel surface as well as a dissociative adsorption of steam also on the nickel or the support surfaces. The adsorbed steam can be easily spillover from the support onto the surface of the active nickel centers. Therefore, the activity of the nickel catalyst applied for the reforming processes should be characterized by high nickel dispersion. This means that the promotion of active phase and carriers by various modifiers improves the nickel catalyst activity and selectivity.

Kinetics studies of steam reforming of methane over Ni systems also confirmed that the contribution of various adsorption mechanism [11,12,13]. These reports claim that the dehydrogenation of the hydrocarbon, which take place on active nickel centers, is the rate-determining stage of the steam reforming reaction. It is also reported that high dispersion of Ni on the carrier surface is required to achieve high activity in steam reforming process [12] and that stepped nickel atoms are responsible for catalysing the cleavage of the C–H bond present in the hydrocarbon molecule [14]. The authors of ref. [12] also confirmed that the stabilization of methyl group and hydrogen atoms formed from the dissociative adsorbtion of methane is an important factor determining the catalytic activity of a nickel based catalyst in the SRM reaction [15, 16]. Therefore, catalytic systems which adsorb larger amount of methane exhibited higher activity in SRM process [17]. It is generally accepted that in the process of producing H2 from methane, three stages of the reaction mechanism take place, namely the complete oxidation of CH4 to CO2, the partial oxidation of CH4 to CO and H2, and the decomposition of methane towards the formation of carbon deposit. All of these three stages are postulated to run through an oxygen vacancy via a Mars–van Krevelen type mechanism [18]. According to this mechanism, methane is first adsorbed to the surface oxygen vacancy of the support. Next, it reacts with surface oxygen species. This results in high conversion of methane during the first few minutes of the process. Thereafter, the methane conversion decreases because of the consumption of surface oxygen. Such a situation occurs when the migration of network oxygen from the bulk to the surface does not keep up with the methane activation rate. When the network oxygen is not released from the carrier fast enough to compensate for the deficiency. Oxygen vacancies are formed on the surface of the carrier and the migration of lattice oxygen from the bulk to the surface is promoted. Mihai et al. [19] also reported that vacancy sites are generated as a result of the removal of lattice oxygen, which increases the rate of the SRM process. In addition, the availability of the surface oxygen vacancies increases the energy barrier for total oxidation of methane, thus, increasing the selectivity toward CO. The authors stated that catalytic systems which exhibited larger amount of mobile oxygen and adsorbed higher quantity of oxygen species on their surface also showed higher activity in the studied reaction. This means that the partial oxidation of the catalyst system depends on the mobile oxygen and lattice oxygen migration rate. Therefore, addition of carrier oxides improves carbon deposition resistant and promotes methane oxidation rate. During the running reaction, when the network oxygen is not replenished synchronously with the rate of methane activation, methane dissociation on active centers causes the formation of carbon deposits, which leads to blocking of active sites and lowering the speed of the process. Shafiefarhood et al. [20] proposed a modified Mars–van Krevelen mechanism, according to which oxygen evolution and the conductivity of oxygen anions, and/or their evolution to electrophilic surface oxygen species are termed the rate limiting step of steam reforming of methane. Xiao et al. [21] studied iron-based oxygen carriers modified by CeO2 in chemical looping hydrogen generation and found that the modified carriers effectively inhibit carbon deposit or Fe3C formation and showed excellent recycle ability. Xiang et al. [22] also tested iron modified oxygen carriers in chemical looping hydrogen generation, and showed that CeO2 addition improves the reduction of Fe2O3, promote of the oxygen vacancies formation and the splitting of steam. CeO2 has recently attracted wide interest as a catalytic support due to its oxygen storage capacity and special crystal structure. During the chemical reaction, oxygen network on the CeO2 surface creates oxygen vacancies through conversion between Ce4+ and Ce3+. The migration of oxygen vacancy on the CeO2 surface is a key factor for oxygen transfer efficiency [23, 24]. The migration of oxygen vacancy on the CeO2 surface is a key factor in oxygen transfer. Based on this suggestion, a two-stage exchange mechanism can be proposed, based on the assumption that when oxygen vacancy occurs at the CeO2 surface, oxygen from the subsurface moves and fills the oxygen vacancy at the surface. In addition, oxygen next to the subsurface vacant fills it, creating a new oxygen vacancy [25]. The authors of references [25, 26] showed that the reactive oxygen present on the CeO2 surface easily reacts with CO. Furthermore, Baron et al. [27] found that the addition of CeO2 to the support improves its plasticity, dispersion and stability of the metal oxide. Zarur and Ying [28] investigated the CeO2-BHA catalyst in the CH4 combustion reaction and found that addition of CeO2 improves the reactivity and thermal stability of the tested catalyst.

In the present paper we present for the first time the,,in situ’’ FTIR measurements during the OSRM and OSR-LNG processes in the temperature range 200–600 °C. To the best of our knowledge, up to now there was a gap in knowledge concerning the FTIR studies performed on Ni catalysts tested in reforming of natural gas and LNG components processes at high temperature range. This work presents detailed unexplored FTIR studies of a 5%Ni/CeO2 catalyst tested in reforming of natural gas and LNG processes, which will help to explain the mechanisms of these processes. FTIR studies were carried out on this catalytic system because of its high methane conversion and high selectivity towards CO and H2 formation at high temperature in OSRM and OSR-LNG. In addition, the influence of the reaction mixture (the presence of H2O or/and O2) on the methane or LNG reforming processes at 600 °C was investigated.

Materials and methods

Catalytic material preparation

The support oxide CeO2 was synthesized by a precipitation method using aqueous ammonia as a precipitation agent. To prepare of CeO2 support cerium precursor, Ce(NO3)3·6H2O was used. The obtained precipitate was washed in deionized water, filtered, and dried at 120 °C for 12 h. In the next step, the obtained support was calcined in an air atmosphere at 400 °C for 4 h. Next, a monometallic nickel catalyst was prepared using a wet impregnation method [29,30,31]. In order to achieve 5%Ni/CeO2 catalyst appreciate amount of a Ni(NO3)2·6H2O solution was used as a metal precursor. The impregnation process lasted 12 h. Then the solution was evaporated using a rotary evaporator and then dried at 80 °C for 2 h and finally calcined in an air atmosphere at 400 °C for 4 h.

Characterization techniques

The mechanism of the oxy-steam reforming of methane and LNG process was studied using Nicolet iS50 FT-IR spectrometer (Thermo Scientific, Waltham, MA, USA) equipped with a liquid-nitrogen-cooled MCT detector. A resolution of 4.0 cm−1 was used throughout the investigation. 64 scans were taken to achieve a satisfactory signal-to-noise ratio. The background spectrum was collected before measurements in the selected temperature. The FTIR spectrometer was equipped with a special reaction chamber (Harrick -Praying Mantis™) which allowed to carry out the selected processes in the temperature range of 200–600 °C under atmospheric pressure using about 0.2 g of catalyst sample. Each spectrum was acquired after 15 min of stabilization at the selected temperature and atmosphere. During the FTIR measurements following mixtures were used: 5%CH4-Ar, 5%O2-Ar and a model gas mixture of LNG (5% CH4, 0.4% C2H6, 0.2% C3H8, 0.05% C4H10 and 94.35%Ar) were used. The molar ratio between reagents in the reaction mixture using in oxy-steam reforming of methane was CH4:H2O:O2 = 1:2.7:0.35 or during the oxy-steam reforming of LNG (OSR-LNG) C:H2O:O2 = 1:2.75:0.35. During all investigated processes the total flow of the reaction mixture was 51 cm3/min.

Activity tests

The catalytic activity tests in OSRM on 5%Ni CeO2 catalyst were carried out. The reactivity measurements were performed in a quartz micro-reactor in the temperature range of 400–700 °C under atmospheric pressure. The mass of the catalytic material was 0.3 g. The reaction mixture flow rate was 51 cm3/min and argon was used as a balance gas. The composition of the reaction mixture was following CH4:H2O:O2 = 1:2.7:0.35. The detailed description of the product analysis and the determination of the methane conversion were described in detail in our previous work[5].

Results and discussion

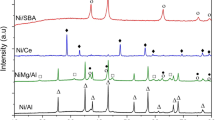

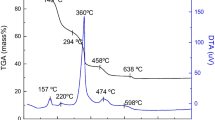

FTIR measurements were carried out to understand the mechanisms of the OSRM and OSR-LNG processes over a 5%Ni/CeO2 system. First, methane decomposition and its reactions with H2O and O2 were studied. Fig. 1 presents the FTIR spectra recorded during the decomposition of methane and its reaction at 600 °C with different reactants. Next, the OSRM process was studied in the temperature range 200–600 °C and the results are shown in Fig. 2. All FTIR measurements were carried out over the 5%Ni/CeO2 catalyst. The IR spectra’s of the adsorbed species formed on the catalyst surface during methane decomposition and reaction with various reactants (H2O or/and O2) were collected at 600 °C (see Fig. 1). The IR spectra recorded during the performed reactions showed several characteristic bands located at the wavenumber ranges of 2800–3800 cm−1 and 800–1700 cm−1. The visible bands located in the range 2800–3200 cm−1 and at about 1305 cm−1 are attributed to adsorbed methane. The intensity of the specific bands assigned to the adsorbed methane decreased when steam and/or oxygen were added to the gaseous methane. This means that the methane is converted into the reaction products at 600 °C. These measurements are in good agreement with our earlier results [32]. The IR bands located at the wavenumbers in the range 1200–1620 cm−1 (\({\mathrm{CO}}_{3}^{2-}\): 1620, 1570–1440, 1220 cm−1) are attributed to carbonate species formed during the investigated conversion of methane process from the CO2. In this case, the carbon dioxide produced is generated from the CO via the Boudouard reaction [33] or from the interaction of carbonaceous species with hydroxyl groups present on the catalyst surface.

The band at 851 cm−1 is assigned to the out-of-plane vibration of carbonate species adsorbed on the support [34]. Azancot et al. [35] reported that the IR bands positioned at 1654, 1428 and 1223 cm−1 are ascribed to bicarbonate species, while the specific bands located at 1595, 1560, 1545, 1394, 1370 and 1360 cm−1 correspond to the typical values of ν(OCO) symmetric and asymmetric stretching vibrations attributed to carbonate-like species with different coordination geometry. In other work [36], the authors also observed IR bands located at 2012 and 1850 cm−1, which were attributed to linear CO and bridges adsorbed on Ni centers. In our spectra, only the specific band located at about 2020 cm−1 is visible for the process carried out during the reaction between CH4 with H2O and/or O2. These bands have been assigned to CO linearly adsorbed on Ni. Fig. 1 also presents the specific bands at 2305, 2350 cm−1 which are attributed to the CO2 product. At the same time, the formation of the main reaction product, CO, was confirmed by the bands visible at 2118 and 2171 cm−1. It can be easily seen from the FTIR spectra in Fig. 1 that when only methane is flowing through the reaction chamber at 600 °C, only CO and hydroxyl groups can be distinguished in the IR spectrum, which means that the decomposition process of the methane has taken place. The FTIR spectrum recorded for this system showed additional IR bands assigned to carbonate species. Addition of O2 to the mixture of 5%CH4-Ar results in appearance of additional specific bands attributed to CO2. This means that partial oxidation of methane runs at this temperature. These results agree well with the literature data [1, 37, 38]. In the next step of the IR studies, oxygen was removed from the reaction mixture which resulted in a dramatic decrease in the intensity of the IR bands assigned to the products of the process (see Fig. 1—third spectrum from the top). These results agree well with the studies of Chen et al. [38]. Further, the influence of water vapor on methane conversion was investigated. The FTIR results showed that the reaction between water vapor and methane (SRM) proceeds, which is confirmed by the appearance of the specific IR bands assigned to the products (CO and CO2) of the process studied. It should also be noted that the intensity of the IR bands of these products was lower compared to the partial oxidation of methane. This means that the SRM process is limited at this temperature and confirms that the oxidation of methane by oxygen is favored. This conclusion also agrees well with published literature data which reports that partial oxidation of methane is much a quicker process that steam reforming of methane. Next, the introduction of oxygen into the reaction mixture containing methane and water vapor was also evaluated and the FTIR spectrum collected during the OSRM showed that the introduction of oxygen into a mixture of CH4 and H2O improved the methane conversion. This result was confirmed by the decrease of the intensity of the IR bands assigned to adsorbed methane (see Fig. 1—fifth spectrum from the top). The obtained results mean that firstly oxygen is consumed to oxidize formed CO or carbon atoms coming from the dissociation of methane species through the breaking the C-H bonds. Next, the oxygen coming from the dissociation of H2O or from the hydroxyl groups may oxidize carbon atoms or CO formed from the decomposition of the CH4 species. These results demonstrate that the generated CO can also be oxidized to carbon dioxide by oxygen surface species such as oxygen vacancies of the support or surface oxygen. Fig. 2 presents IR spectra collected during the OSRM process realized on 5%Ni/CeO2 catalyst in the temperature range 200–600 °C.

The presented IR spectra show analogical adsorbed species observed in previous studies [32]. The obtained results clearly showed that at the initial step of the OSRM process at low temperature range only CO2 and H2O (3300–3900 cm−1) was formed via the oxidation process of the intermediate products during the dissociation of the CH4 and its fragments. Increasing of the reaction temperature to 600 °C led to the formation of CO via the oxidation process of carbon containing species formed on the catalyst surface. This result was also confirmed by the catalytic activity tests performed for Ni/CeO2 catalyst in OSR-LNG in our previous work [32]. It was also confirmed that at higher temperature steam reforming and partial oxidation of methane proceeds easier. CO2 was formed via oxidation of the CO species or via the water gas shift reaction (WGS). These results confirm that at a low temperature the CO formed is afterwards transformed to CO2 via the WGS process which is thermodynamically favored compared to processes of steam reforming or partial oxidation of methane. Chen et al. [38] carried out calculation using density functional theory (DFT) in order to understand the reaction mechanism of the autothermal reforming of methane reaction over a Pt (111) surface. Based on the calculation, the authors proposed a mechanism of the process. According to this mechanism, methane adsorbs dissociatively on the Pt (111) surface and generates methyl, which undergoes oxidative dehydration to carbon oxide species (CO, CO2) by oxygen radicals. The authors also reported that the oxidation reactions of carbon containing species to CH3O, CHxO or even methanol are possible, but these processes are limited due to the low coverage of the Pt (111) surface by hydroxyl radicals. The authors also reported that the dissociative chemisorption of methane is the rate-determining step in the autothermal reforming process. In our previous work [32], we proposed a mechanism based on published literature. According to our mechanism, the OSRM process consists of two stages. In the first stage, the oxidation process proceeds using oxygen radicals coming from the reaction mixture and lead to formations of CO2. At this stage, the conversion of methane remains low. CO2 is formed via the water gas shift reaction or as a result of the oxidation process of CHx species chemisorbed on the surface. In the next step, the steam reforming or partial oxidation of methane reactions take place. In this second steps the equilibrium between WGS and RWGS process controls the selectivity of the process. The main products of the realized process are CO and H2.

Decomposition of LNG was also studied using FTIR spectroscopy. The reaction was carried out over the same catalytic system in the temperature range 200–600 °C. The spectra collected during the FTIR measurements, are presented in Fig. 3. The recorded spectra showed the presence of an analogical bands visible during decomposition process of methane. The specific bands located in the range 2800–3200 cm−1 are attributed to adsorbed LNG components (methane, propane, ethane and butane). Characteristic bands located between 800 and 1100 cm−1 can be assigned to the other carbon compound, containing a C–C bond in the molecule. Detailed analysis of the FTIR spectra showed that above 450 °C decomposition product of LNG components are formed, as evidenced by the characteristic bands attributed to CO.

In the next step, partial oxidation of LNG was carried out and the results of this process are given in Fig. 4. The presented results showed that products of LNG oxidation are generated above 400 °C. This means that the oxidation of the carbon containing species using oxygen proceeds quicker than the decomposition process and may explain the observed products of the investigated process. The main product in the investigated temperature range of 400–600 °C was also CO2. However, CO was also formed above 550 °C in parallel with an increase in the reaction temperature to 600 °C. This result can be explained by the thermodynamic limitations of the studied processes. The high yield of CO2 formation may be explained by the WGS process or/and by oxidation of carbon or carbon containing molecule by hydroxide radicals, oxygen vacancies or by oxygen atoms adsorbed on the surface of the support. In the next investigations, FTIR measurements during steam reforming of LNG were done and the results are presented in Fig. 5. The obtained results confirmed the same tendency which was observed during partial oxidation of LNG.

These results clearly confirm that at low temperature, the oxidation process of carbon or carbon containing molecule is prevailing and that thermodynamic limitations are responsibility for the direction of the reaction. Moreover, in the first step of the process, oxygen from the oxygen vacancies or from the surface are consumed during the oxidation of carbon containing species to CO and then to CO2. Carbon containing molecule may be transformed to CO only in the case of oxygen deficiency on the catalyst surface. These results confirmed the postulated Mars-van Krevelen mechanism of reforming of methane or LNG. During this process CO is formed starts from 600 °C.

Fig. 6 presents the FTIR measurements performed during the OSR-LNG process in the temperature range of 200–600 °C over a 5%Ni/CeO2 system. The visible specific IR bands shows the same bands which were observed during steam and partial oxidation of LNG. In this case, we can easily distinguish on the collected spectra that products of the OSR-LNG process can be observed above 400 °C. At 600 °C, the collected IR spectrum shows visible conversion of LNG components and the specific bands assigned to the products of the process. Introduction of the oxidizing reactants may explain the observed products in the outgas of the reaction. Increasing of the reaction temperature to 600 °C leads to the formation of CO. At lower temperature, the thermodynamic limitation and oxidizing reactants lead to the formation of CO2, which was a main product of the process.

Fig. 7 presents the FTIR measurements carried out for the same catalytic systems during LNG decomposition and reaction with various reactants at 600 °C. The FTIR spectra collected for the 5%Ni/CeO2 system during LNG decomposition showed the specific bands assigned to LNG components (2800–3200 cm−1 and at 1300 cm−1). In addition, in Fig. 7 the characteristic bands assigned to the CO can be distinguished. Addition of oxygen into LNG mixture result in increase of the IR bands intensity assigned to CO2 and CO (second spectrum from the bottom). These results agree well with our previous studies [32]. Subsequent removal of O2 from the reaction mixture leads to decreasing the intensity of the specific bands assigned to CO2 and increasing of the IR bands assigned to CO (third spectra named LNG collected after 15 min in a LNG mixture). Further addition of water vapor leads to reappear increase of the CO2 bands intensity. Then, introduction of oxygen to a mixture of LNG + H2O result in further increase the intensity of the specific bands assigned to CO2 and leads to decrease of the intensity of the CO bands what is connected with the oxidation of the CO to CO2 [32]. These results agree well with the FTIR measurements obtained during the OSRM performed for the same catalytic system.

In order to further confirm the FTIR results we carried out the activity results in OSRM reaction and the reactivity results are given in Table 1. The activity measurements performed in the studied process showed that at low temperature of the reaction process (500–550 °C) only a low of the methane conversion values can be observed. In addition, also the main product of the process at the low temperature range was CO2. The formation of H2 and CO were not observed in the temperature range (500–550 °C). The catalytic activity results showed that starts from 600 °C the hydrogen formation was observed. This result confirm the FTIR measurements performed in the studied reaction. The increase of the OSRM reaction to 600 °C and 700 °C result in increase of the methane conversion and the appearance of CO and H2 in the reaction product. An increase of the reaction temperature from 600 to 700 °C leads to the formation higher amount of CO and hydrogen in the final product and increase of the CH4 conversion.

In our previous work [32] we studied OSR-LNG process on Ni/CeO2 system and we obtain analogical results as in the case of the OSRM process. The catalytic activity results showed that up to 600 °C the main product of the reaction was CO2. The reactivity results obtained at 600 °C and above showed that conversion of LNG components increase and CO was detected as the main product of the reaction. Further increasing of the reaction temperature result in increase of the CO and hydrogen in the gaseous product. These results confirmed the observed FTIR measurements performed in the studied catalytic process.

All results obtained during the oxy-steam reforming of methane or LNG components confirmed that the oxy-steam reforming processes proceeds through the following reaction stages presented in Fig. 8. Firstly, methane or other hydrocarbons (ethane propane, butane) are adsorbed on the surface of the catalyst. At the same time, other reaction reactants such like O2 and H2O, also adsorb on the catalyst surface. Then, methane or its fragment can further be oxidized or dehydrogenated to a methyl group, then to a methylene group and finally to a CH group. The CH group may be further oxidized or dehydrogenated to carbon species. Carbon formed on the catalyst surface can undergo oxidation by the oxygen surface, oxygen vacancy of the support or by oxygen species present on the catalyst surface to CO or CO2. Carbon dioxide formed from the CO may be hydrogenated to COOH group which may by hydrogenated to bicarbonates and further to methoxy and finally to methanol. However, this hydrogenation step is unlikely. Carbon species formed on the catalyst surface can be hydrogenated or interact with hydroxy species and form CH group on the surface. This group may further undergo similar processes and crate even methane or higher hydrocarbons. Hydrogen formed during the investigated processes may be also formed via decomposition of methane or water vapor.

Conclusions

Monometallic Ni/CeO2 catalyst was prepared by wet impregnation method and studied in OSRM and OSR-LNG processes under atmospheric pressure in the temperature range of 200–600 °C using special FTIR reaction chamber. The FTIR measurements carried out on synthesized catalyst allowed to propose the mechanism of OSRM and OSR-LNG reactions. The FTIR measurements carried out in the OSRM, and OSR-LNG processes showed that the mechanisms of these processes consist of several steps. At the beginning of the reaction, methane or higher hydrocarbons (ethane, propane, butane) dissociates into carbon-containing molecules, and then the resulting molecules are adsorbed on the surface. This is a key step that determines the rate of the reaction. In the next step, the carbon containing species are oxidized to CO or CO2. CO2 is readily formed at low temperatures as a result of the WGS reaction or the oxidation of carbon-containing compounds formed from the dissociation of methane or higher hydrocarbons (ethane, propane, butane). At higher temperature range, carbon monoxide is visible on the recorded IR spectra. This result confirmed that methane or LNG reforming processes (SRM and partial methane oxidation or methane or LNG decomposition) proceeds at higher temperature. The FTIR measurements confirmed that carbonates were oxidized intermediates formed during methane/LNG reforming processes. The obtained FTIR results may be useful in the design of catalysts for reforming processes.

References

Mosinska M, Szynkowska MI, Mierczynski P (2020) Catalysts 10:1–26

Takeguchi T, Furukawa S-N, Inoue M, Eguchi K (2003) Appl Catal A 240:223–233

Sun L, Tan Y, Zhang Q, Xie H, Song F, Han Y (2013) Int J Hydrogen Energy 38:1892–1900

Souza AEAM, Maciel LJL, Cavalcanti-Filho VO, Filho NML, Abreu CAM (2011) Ind Eng Chem Res 50:2585–2599

Mierczynski P, Mosinska M, Stepinska N, Chalupka K, Nowosielska M, Maniukiewicz W, Rogowski J, Goswami N, Vasilev K, Szynkowska MI (2021) Catal Today 364:46–60

Ayabe S, Omoto H, Utaka T, Kikuchi R, Sasaki K, Teraoka Y, Eguchi K (2003) Appl Catal A 241:261–269

Mierczynski P, Stępińska N, Mosinska M, Chalupka K, Albinska J, Maniukiewicz W, Rogowski J, Nowosielska M, Szynkowska MI (2020) Catalysts 10:346

Matsumura Y, Nakamori T (2004) Appl Catal A 258:107–114

Ertl G, Knözinger H, Weitkamp J (1997) Handbook of heterogeneous catalysis. VCH Weinheim, Hoboken

Seo JG, Youn MH, Park S, Park DR, Jung JC, Chung JS, Song IK (2009) Catal Today 146:44–49

Wei J, Iglesia E (2004) J Catal 224:370–383

Trimm DL (1988). In: Bibby DM, Chang CD, Howe RF, Yurchak S (eds) Studies in surface science and catalysis, vol 36. Elsevier, Amsterdam

Seo JG, Youn MH, Jung JC, Song IK (2010) Int J Hydrogen Energy 35:6738–6746

Bang Y, Seo JG, Song IK (2011) Int J Hydrogen Energy 36:8307–8315

Bang Y, Han SJ, Yoo J, Choi JH, Lee JK, Song JH, Lee J, Song IK (2014) Appl Catal B 148–149:269–280

Bang Y, Han SJ, Yoo J, Park S, Choi JH, Lee YJ, Song JH, Song IK (2014) Int J Hydrogen Energy 39:4909–4916

Bang Y, Park S, Han SJ, Yoo J, Song JH, Choi JH, Kang KH, Song IK (2016) Appl Catal B 180:179–188

Zhao K, Zhang R, Gao Y, Lin Y, Liu A, Wang X, Zheng A, Huang Z, Zhao Z (2022) Fuel Process Technol 236:107398

Mihai O, Chen D, Holmen A (2011) Ind Eng Chem Res 50:2613–2621

Shafiefarhood A, Hamill JC, Neal LM, Li F (2015) Phys Chem Chem Phys 17:31297–31307

Sun S, Zhao M, Cai L, Zhang S, Zeng D, Xiao R (2015) Energy Fuels 29:7612–7621

Demirbas A (2007) Energy Convers Manag 48:937–941

Trovarelli A, de Leitenburg C, Boaro M, Dolcetti G (1999) Catal Today 50:353–367

Lee Y, He G, Akey AJ, Si R, Flytzani-Stephanopoulos M, Herman IP (2011) J Am Chem Soc 133:12952–12955

Wang ZL, Feng X (2003) J Phys Chem B 107:13563–13566

Li J, Lu G, Li H, Wang Y, Guo Y, Guo Y (2011) J Colloid Interface Sci 360:93–99

Baron M, Abbott H, Bondarchuk O, Stacchiola D, Uhl A, Shaikhutdinov S, Freund H-J, Popa C, Ganduglia-Pirovano MV, Sauer J (2009) Angew Chem Int Ed 48:8006–8009

Zarur AJ, Ying JY (2000) Nature 403:65–67

Munnik P, de Jongh PE, de Jong KP (2015) Chem Rev 115:6687–6718

Zhang S, Lee J, Kim DH, Kim T (2020) Catal Sci Technol 10:2359–2368

Mierczynski P, Ciesielski R, Kedziora A, Nowosielska M, Kubicki J, Maniukiewicz W, Czylkowska A, Maniecki T (2015) Reac Kinet Mech Cat 117:1–17

Mosinska M, Maniukiewicz W, Szynkowska-Jozwik MI, Mierczynski P (2021) Int J Mol Sci 22:9076

Khani Y, Shariatinia Z, Bahadoran F (2016) Chem Eng J 299:353–366

Tibiletti D, Goguet A, Meunier FC, Breen JP, Burch R (2004) Chem Commun 14:1636–1637

Azancot L, Bobadilla LF, Centeno MA, Odriozola JA (2021) Appl Catal B 285:119822

Vogt C, Kranenborg J, Monai M, Weckhuysen BM (2020) ACS Catal 10:1428–1438

Jiménez-González C, Boukha Z, De Rivas B, Delgado JJ, Cauqui MÁ, González-Velasco JR, Gutiérrez-Ortiz JI, López-Fonseca R (2013) Appl Catal A 466:9–20

Chen J, Li L (2021) Appl Surf Sci 539:148288

Funding

The authors gratefully acknowledge that this work was financially supported by the National Science Centre (NCN) in Poland within the “OPUS” Programme (Grant no. 2018/29/B/ST8/01317).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Mierczynski, P., Mierczynska-Vasilev, A., Vasilev, K. et al. Fourier transform infrared spectroscopic studies of methane and liquefied natural gas reforming processes on Ni/CeO2 catalyst. Reac Kinet Mech Cat 136, 603–620 (2023). https://doi.org/10.1007/s11144-023-02362-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11144-023-02362-7